Abstract

The main operating characteristics of cylinder liner include the liner deformation and coolant flow. The insufficient coolant flow can lead to greater deformation of cylinder liner and hence worse engine performance and emissions performance. However, previous works have been done focusing on the characteristics of liner bore deformation and comprehensive coolant flow and the importance of the characteristics of different loads on liner deformation has not been recognized when analyzing cylinder liner. Therefore, the aim of this study is to reveal the characteristics of the coolant flow around cylinder liners and the effect of different loads on liner deformation. A simulation model of a diesel engine was developed to analyze coolant flow characteristics, deformation, and temperature distribution of cylinder liners in steady-state conditions. The effects of thermal stress, bolt preload, firing pressure, and piston side thrust on deformations of cylinder liners were analyzed in various designed conditions based on simulation results. It is found from the analysis results that the temperature of the cylinder liners gradually decreases from the top to the bottom. Meanwhile, the temperature gradient of the upper portion of the cylinder liner is greater than that of the middle portion or the bottom portion due to uneven distributions of the coolant flow in the cooling water jackets of different cylinder liners. In addition, the coolant flow velocity in the valve bridge area is lower than the target value. The expansion and compression deformations of the liner 1 and liner 4 are greater than those of other two liners, and the comprehensive deformation trends of different cylinder liners are similar in various loading conditions. The thermal load has the greatest impact on liner deformation because the total liner deformation contributed by the impacts of different types of loads looks similar to the liner deformation caused by only the thermal load.

Similar content being viewed by others

Abbreviations

- a:

-

Thermal stress

- b:

-

Bolt preload

- c:

-

Firing pressure

- d:

-

Piston side thrust

- BP:

-

Pressure measurement location in the water jacket of the cylinder liner

- BT:

-

Temperature measurement location in the water jacket of the cylinder liner

- CP:

-

Pressure measurement location in the water jacket of the cylinder head

- CT:

-

Temperature measurement location in the water jacket of the cylinder head

- CFD:

-

Computational fluid dynamics

- Comb.:

-

Combination

- Comp.:

-

Computational results

- Exp.:

-

Experimental results

- TDC:

-

Top dead center

References

Rahmani R, Rahnejat H, Fitzsimons B and Dowson D 2017 The effect of cylinder liner operating temperature on frictional loss and engine emissions in piston ring conjunction. Appl. Energy 191: 568–581

Joachim D, Cecile F, Dirk B, Frank B, Joachim S and Andreas K 2019 Diesel Vehicle with Ultra-Low NOx Emissions on the Road. SAE Technical Paper, No. 2019-24-0145

Wang H, Sun J, Zhao X Y and Gui C L 2011 Simulation study on influencing factors to the roundness of cylinder liner in diesel engines. Trans. CSICE 29: 370–377

Marathe A V, Venkatachalam G and Marathe N V 2020 Cylinder head bolt tightening strategies in case of multi-cylinder engines and its effect on gasket sealing performance, bore deformation and piston ring conformability. Aust. J. Mech. Eng. 18: 303–321

Maassen F, Koch F, Schwaderlapp M, Ortjohann T and Dohmen J 2001 Analytical and Empirical Methods for Optimization of Cylinder Liner Bore Distortion. SAE Technical Paper, No. 2001-01-0569

Loenne K and Ziemba R 1988 The GOETZE Cylinder Distortion Measurement System and the Possibilities of Reducing Cylinder Distortions. SAE Technical Paper, No. 880142

Fujimoto H and Yoshihara Y 1991 Measurement of Cylinder Bore Deformation During Actual Operating Engines. SAE Technical Paper, No. 910042

Koch F, Fahl E and Haas A 1995 A New Technique for Measuring the Deformation of Cylinder Bores During Engine Operation. SAE Technical Paper, No. 950540

Tian T 2002 Dynamic behaviours of piston rings and their practical impact-part I Ring flutter and ring collapse and their effects on gas flow and oil transport. P. I. Mech. Eng. J-J Eng. 216: 209–227

Johnson J H 1994 A Review of Diesel Particulate Control Technology and Emissions Effects. SAE Technical Paper, No. 940233

Ito A, Shirakawa H, Nakamura M, Yoshida K and Akiyama H 2005 A Study on the Mechanism of Lubricating Oil Consumption of Diesel Engines -1st report: The Effect of the Design of Piston Skirt on Lubricating Oil Consumption. SAE Technical Paper, No. 2005-05-11

Tomanik E 1996 Piston Ring Conformability in a Distorted Bore. SAE Technical Paper, No. 960356

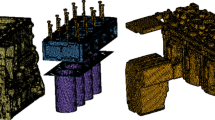

Ghasemi A 2012 CAE Simulations for Engine Block Bore Distortion. SAE Technical Paper, No. 2012-01-1320

Patwardhan M, Paranjpe J, Ramdasi S, Karanth N, Marathe N and Bhat P 2015 Use of Non Linear Analysis in Powertrain Design for Prediction of Cylinder Bore Distortion, Design Changes for Reduction along with Experimental Validation. SAE Technical Paper, No. 2015-26-0202

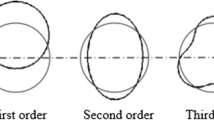

Liang X Y, Wang Y S, Huang S H, Yang G C, Tang L and Cui G Q 2017 Investigation on Cylinder Bore Deformation under Static Condition Based on Fourier Decomposition. SAE Technical Paper, No. 2017-01-0366

Wang X Y, Zhang Z, Chen Y and Li Y L 2020 Study on the coolant pressure of internal combustion engines through vibro-acoustical analysis of a real cylinder block structure. J. Braz. Soc. Mech. Sci. Eng. 42: 1–10

Chandekar G, Hercamp and Hudgens D 2012 Numerical Model of Effect of Coolant Physical Properties on the Diesel Engine Liner Cavitation, SAE Technical Paper, No. 2012-01-1682

Selim M Y E and Helali A H B 2001 Effect of coolant additives on thermal loading of a diesel engine. P. I. Mech. Eng. D-J Aut. 215: 1131–1142

Liang X Y 2007 CFD Analysis on the Flow Field in the Water Jacket of a Turbocharged Intercooled Diesel Engine. Master's thesis, Kunming University of Science and Technology, Kunming

Bi Y H, Xiang R, Lei J L, Shen L Z, Zhang P Y and Song G F 2014 Study on cylinder liner hot deformation of turbocharged inter-cooled diesel engine. Trans. Chin. Soc. Agric. Eng. 30: 34–41

Koch F and Decker P 1998 Cylinder Liner Deformation Analysis-Measurements and Calculations. SAE Technical Paper, No. 980567

Zu B F, Xu Y L, Liu J, Jin S H, Qian D D, Yang L Q and Su C 2009 Simulation on cylinder bore deformation of automotive diesel engines using integral contact multi-field indirect coupling method. J. Tianjin Univ. 11: 1011–1016

Chen Q 2003 Computational Fluid Dynamics Analysis on Water Jacket of Vehicle Diesel Engine. Doctoral dissertation, Jilin University, Changchun

Chen Y 2010 Numerical Simulation of Diesel Engine Cooling System. Master's thesis, Jiangsu University, Zhenjiang

Bi Y H, Shen L Z, Lei J L, Xu Y Z and Jia D W 2013 Study on cylinder liner pretightening deformation and influence of structure factors on it. Chin. Intern. Combust. Engine Eng. 34: 62–68

Kessler M, Kruger M, Ataídes R, Siqueira C, Argachoy C and Mendes A 2007 Numerical Analysis of Flow at Water Jacket of an Internal Combustion Engine. SAE Technical Paper, No. 2007-01-2711

Ma Q Z, Jiang S L, Guo C H, Yao X L, Gu Q, Dong B and Ye Q 2008 Analysis of deformation of cylinder liner of YZ4DE diesel engine based on finite element method. Chin. Intern. Combust. Engine Eng. 4: 59–62

Acknowledgement

This work was supported by the National Natural Science Foundation of China [Grant Number: 51765025]. The authors are grateful for the support given by the foundation and the Yunnan Province Innovation Team.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bi, Y., Wang, P., Xiang, R. et al. Numerical investigation on the operating characteristics of the cylinder liners of a turbocharged diesel engine. Sādhanā 46, 150 (2021). https://doi.org/10.1007/s12046-021-01679-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01679-0