Abstract

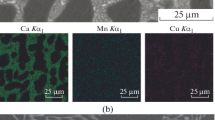

This study is focused on the design of new Al–Cu–Mn alloys with enhanced strength and heat resistance achieved without high-temperature exposure. There are seven alloys considered with permanent Mn content of 2% and variable Cu content of 0–4%. It is found that ~2% Mn is almost completely dissolved in the solid solution after casting, while the copper is distributed between the solid solution and Al2Cu eutectic constituents. It is experimentally established that, when the copper content is 2 and 3%, the solid solution of aluminum contains approximately the same amount of copper, up to 1.5%. The deformation plasticity of experimental alloys in the cold rolling mode with the reduction rate of 80 and 95% is investigated. It is shown that no preliminary treatment is required for alloys containing up to 3% Cu, as they exhibit high processability at rolling. The effect of heat treatment in the annealing temperature range of 200–600°C on the structural and phase parameters of the alloys is studied. Alloy hardening in the process of multistage annealing by means of hardness measurement is estimated. The resulting data allow us to determine the influence of copper and analyze the thermal stability of the model alloys. Tensile tests of cold-rolled sheets with a thickness of 0.5 mm and a reduction level of 95% of alloys containing 2 and 3% copper show high values. In particular, the alloy containing 3% Cu has a strength performance compatible with that of 1201 alloy in T6 condition.

Similar content being viewed by others

REFERENCES

Polmear, I., StJohn, D., Nie, J.F., and Qian, M., Physical metallurgy of aluminium alloys, in Light Alloys, London: Elsevier, 2017.

Aluminum: Properties and Physical Metallurgy, Hatch, J.E., Ed., Metals Park, OH: ASM Int., 1984.

Mondol, S., Kashyap, S., Kumar, S., and Chattopadhyay, K., Improvement of high temperature strength of 2219 alloy by Sc and Zr addition through a novel three-stage heat treatment route, Mater. Sci. Eng., A, 2018, vol. 732, pp. 157–166. https://doi.org/10.1016/j.msea.2018.07.003

Mondol, S., Alam, T., Banerjee, R., Kumar, S., and Chattopadhyay, K., Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy, Mater. Sci. Eng., A, 2017, vol. 687, pp. 221–231. https://doi.org/10.1016/J.MSEA.2017.01.037

GOST (State Standard) no. 4784–2019: Aluminium and wrought aluminium alloys. Grades, Moscow: Standartinform, 2019.

Mansurov, Yu.N., Buravlev, I.Yu., Belov, N.A., and Sannikov, A.V., Optimization of composition and properties of heat-resistant complex-alloyed aluminum alloy castings, Non-Ferrous Met. (Moscow, Russ. Fed.), 2015, vol. 39, no. 2, pp. 48–55. https://doi.org/10.17580/nfm.2015.02.09

Dar, S.M. and Liao, H., Creep behavior of heat resistant Al–Cu–Mn alloys strengthened by fine (θ′) and coarse (Al20Cu2Mn3) second phase particles, Mater. Sci. Eng., A, 2019, vol. 763, p. 138062. https://doi.org/10.1016/j.msea.2019.138062

Belov, N.A., Alabin, A.N., and Matveeva, I.A., Optimization of phase composition of Al–Cu–Mn–Zr–Sc alloys for rolled products without requirement for solution treatment and quenching, J. Alloys Compd., 2014, vol. 583, pp. 206–213. https://doi.org/10.1016/j.jallcom.2013.08.202

Belov, N.A. and Alabin, A.N., Energy efficient technology for Al–Cu–Mn–Zr sheet alloys, Mater. Sci. Forum, 2013, vol. 765, pp. 13–17. https://doi.org/10.4028/www.scientific.net/MSF.765.13

Belov, N.A. and Alabin, A.N., RF Patent 2534170, 2014.

Belov, N.A. and Alabin, A.N., Microstructure and mechanical properties of Al–Cu–Mn cold rolled sheet alloys, in Aluminium Alloys: Their Physical and Mechanical Properties [Proc. 11th Int. Conference on Aluminium Alloys, Aachen, September 22–26, 2008], Hirsch, J., Scrotzki, B., Gottstein, G., Eds., Weinheim: Wiley-VCH, 2008, pp. 1653–1659.

Toleuova, A.R., Belov, N.A., Smagulov, D.U., and Alabin, A.N., Quantitative analysis of the Al–Cu–Mn–Zr phase diagram as a base for deformable refractory aluminum alloys, Met. Sci. Heat Treat., 2012, vol. 54, nos. 7/8, pp. 402–406. https://doi.org/10.1007/s11041-012-9521-4

Belov, N.A., Fazovyi sostav promyshlennykh i perspektivnykh alyuminievykh splavov (Phase Composition of Industrial and Promising Aluminum Alloys), Moscow: National Univ. of Science and Technology MISiS, 2010.

Belov, N.A., Korotkova, N.O., Akopyan, T.K., and Pesin, A.M., Phase composition and mechanical properties of Al–1.5% Cu–1.5% Mn–0.35% Zr(Fe,Si) wire alloy, J. Alloys Compd., 2019, vol. 782, pp. 735–746. https://doi.org/10.1016/j.jallcom.2018.12.240

Zupanič, F., Wang, D., Gspan, C., and Bončin, T., Precipitates in a quasicrystal-strengthened Al–Mn–Be–Cu alloy, Mater. Charact., 2015, vol. 106, pp. 93–99. https://doi.org/10.1016/j.matchar.2015.05.013

Chena, J., Liao, H., Wu, Y., and Li, H., Contributions to high temperature strengthening from three types of heat-resistant phases formed during solidification, solution treatment and ageing treatment of Al–Cu–Mn–Ni alloys respectively, Mater. Sci. Eng., A, 2020, vol. 772, p. 138819. https://doi.org/10.1016/j.msea.2019.138819

Feng, Z.Q., Yang, Y.Q., Huang, B., Li, M.H., Chen, Y.X., and Ru, J.G., Crystal substructures of the rotation-twinned T (Al20Cu2Mn3) phase in 2024 aluminum alloy, J. Alloys Compd., 2014, vol. 583, pp. 445−451. https://doi.org/10.1016/j.jallcom.2013.08.200

Belov, N.A., Alabin, A.N., and Yakovlev, A.A., Influence of copper on formation of cast microstructure of aluminium alloys, containing 1% (wt) of Mn, Tsvetn. Met. (Moscow, Russ. Fed.), 2014, no. 7, pp. 66–72.

Chen, Zh., Pei, Ch., and Ma, C., Microstructures and mechanical properties of Al–Cu–Mn alloy with La and Sm addition, Rare Met., 2012, vol. 31, no. 4, pp. 332–335. https://doi.org/10.1007/s12598-012-0515-6

Chen, Z., Chen, P.P., and Li, S., Effect of Ce addition on microstructure of Al20Cu2Mn3 twin phase in an Al–Cu–Mn casting alloy, Mater. Sci. Eng., A, 2012, vol. 532, pp. 606–609. https://doi.org/10.1016/j.msea.2011.11.025

Mondol, S., Kumar, S., and Chattopadhyay, K., Effect of thermo-mechanical treatment on microstructure and tensile properties of 2219 ScMg alloy, Mater. Sci. Eng., A, 2019, vol. 759, pp. 583–593. https://doi.org/10.1016/j.msea.2019.05.084

Ber, L.B., Heat Treatment of Aluminum Alloys, London: Taylor & Francis, 2020.

Flattum Muggerud, A.M., Li, Ya., and Holmestad, R., Orientation studies of a-Al(Fe,Mn)Si dispersoids in 3xxx Al alloys, Mater. Sci. Forum, 2014, vols. 794–796, pp. 39–44. https://doi.org/10.4028/www.scientific.net/MSF.794-796.39

Robson, J.D., Hill, T., and Kamp, N., The effect of hot deformation on dispersoid evolution in a model 3xxx alloy, Mater. Sci. Forum, 2014, vols. 794–796, pp. 697–703. https://doi.org/10.4028/www.scientific.net/MSF.794-796.697

Belov, N.A., Korotkova, N.O., Cherkasov, S.O., and Aksenov, A.A., Electrical conductivity and hardness of Al–1.5% Mn and Al–1.5% Mn–1.5% Cu (wt %) cold-rolled sheets: comparative analysis, Tsvetn. Met. (Moscow, Russ. Fed.), 2020, no. 4, pp. 70–76. https://doi.org/10.17580/tsm.2020.04.08

Funding

This study was supported by the Russian Science Foundation, grant no. 20-19-00249.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Chubarova

About this article

Cite this article

Korotkova, N.O., Shurkin, P.K., Cherkasov, S.O. et al. Effect of Copper Concentration and Annealing Temperature on the Structure and Mechanical Properties of Ingots and Cold-Rolled Sheets of Al–2% Mn Alloy. Russ. J. Non-ferrous Metals 63, 190–200 (2022). https://doi.org/10.3103/S1067821222020080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222020080