Abstract

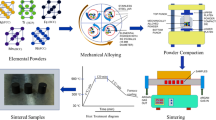

In this study, A356 powder was alloyed with elemental Nickel (Ni) powder in different ratios using a mechanochemical alloying method. Alloyed A356/XNi powders were cold pressed along one axis under a load of 350 MPa and sintered at 600°C. To determine the effect of intermetallic phases formed on the microstructure in proportion to the amount of Ni, the A356/XNi alloys were characterized by X-ray diffraction (XRD) analysis, density, and microhardness values. As a result, after mechanical alloying, the spherical microstructure of the A356 alloy turned into a spongy form due to the sponge-like Ni elemental powders. After sintering, it was determined by optical microscopy and scanning electron microscopy (SEM) examinations that the grain size of A356/XNi alloys increased with an increasing amount of Ni. In addition, it was determined that the relative density and amount of porosity increased with an increasing amount of Ni. According to the XRD analysis results, it was determined that AlNi, Al3Ni2, Al3Ni and AlFeNi intermetallic phases formed in the microstructure due to the mechanochemical and sintering process.

Similar content being viewed by others

REFERENCES

Samal, P.K. and Newkirk, J.W., Powder Metallurgy, Materials Park, OH: ASM Int., 2015, vol. 7.

Sherif El-Eskandarany, M., Mechanical Alloying: Nanotechnology, Materials Science and Powder Metallurgy, New York: William Andrew, 2015.

Benjamin, J.S. and Volin, T.E., The mechanism of mechanical alloying, Metall. Trans., 1974, vol. 5, no. 8, pp. 1929–1934.

Suryanarayana, C., Mechanical alloying and milling, Prog. Mater. Sci., 2001, vol. 46, pp. 1–84.

Sopicka-Lizer, M., High-Energy Ball Milling: Mechanochemical Processing of Nanopowders, Elsevier, 2010.

Murty, B.S. and Ranganathan, S., Novel materials synthesis by mechanical alloying/milling, Int. Mater. Rev., 1998, vol. 43, no. 3, pp. 101–141.

Liu, X.Q., Li, C.J., You, X., Xu, Z.Y., Li, X., Bao, R., Tao, J.M., and Yi, J.H., Size-dependent effects of Ti powders in the pure aluminum matrix composites reinforced by carbon nanotubes, J. Alloys Compd., 2020, vol. 823, no. 153824, pp. 1–9.

Tan, L., Li, Y., Deng, W., Liu, Y., Liu, F., Nie, Y., and Jiang, L., Tensile properties of three newly developed Ni-base powder metallurgy superalloys, J. Alloys Compd., 2019, vol. 804, pp. 322–330.

Dileep, B.P., Ravikumar, V., and Vital, H.R., Mechanical and corrosion behavior of Al-Ni-Sic metal matrix composites by powder metallurgy, Mater. Today: Proc., 2018, vol. 5, no. 5, pp. 12257–12264.

Hou, L., Li, B., Wu, R., Cui, L., Ji, P., Long, R., Zhang, J., Li, X., Dong, A., and Sun, B., Microstructure and mechanical properties at elevated temperature of Mg–Al–Ni alloys prepared through powder metallurgy, J. Mater. Sci. Technol., 2017, vol. 33, no. 9, pp. 947–953.

Jiang, H., Ye, S., Ma, R., and Yu, P., Influences of sintering parameters on shape-retention ability of porous Ni3Al intermetallic fabricated by powder metallurgy, Intermetallics, 2019, vol. 105, pp. 48–55.

Shevtsova, L., Mali, V., Bataev, A., Anisimov, A., and Dudina, D., Microstructure and mechanical properties of materials obtained by spark plasma sintering of Ni3Al–Ni powder mixtures, Mater. Sci. Eng., A, 2020, vol. 773, no. 138882, pp. 1–8.

Mahday, A.A., Sherif El-Eskandarany, M., Ahmed, H.A., and Amer, A.A., Mechanically induced solid state carburization for fabrication of nanocrystalline ZrC refractory material powders, J. Alloys Compd., 2020, vol. 299, nos. 1–2, pp. 244–253.

Semel, F.J. and Lados, D.A., Porosity analysis of PM materials by helium pycnometry, Powder Metall., 2006, vol. 49, no. 2, pp. 173–182.

Khorsand, H., Yoozbashizade, H., Habibi, S.M., Janghorban, K., Nangir, A., and Reihani, S.M.S., Carbon, porosity and fatigue in sintered steel, Met. Powder Rep., 2002, vol. 57, no. 4, pp. 32–36.

Danninger, H., de Oro Calderon, R., and Gierl-Mayer, C., Powder metallurgy and sintered materials, in Ullmann’s Encyclopedia of Industrial Chemistry, Wiley-VCH, 2017, pp. 1–57.

Jiang, H., Ye, S., Ma, R., and Yu, P., Influences of sintering parameters on shape-retention ability of porous Ni3Al intermetallic fabricated by powder metallurgy, Intermetallics, 2019, vol. 105, pp. 48–55.

Abuthakir, J., Subramanian, R., Kavitha, M., Venkatesh, G., Krishna kumar, K., and Manikandan, P., Corrosion studies of Alx–Ni insitu intermetallics reinforced Al metal matrix composites, Mater. Today: Proc., 2020, vol. 28, no. 2, pp. 1158–1163.

Kwiecien, I., Bobrowski, P., Wierzbicka-Miernik, A., Litynska-Dobrzynska, L., and Wojewoda-Budka, J., Growth kinetics of the selected intermetallic phases in Ni/Al/Ni system with various nickel substrate microstructure, Nanomaterials, 2019, vol. 9, no. 2, pp. 1–18.

Rzyman, K. and Moser, Z., Calorimetric studies of the enthalpies of formation of Al3Ni2, AlNi, and AlNi3, Prog. Mater. Sci., 2004, vol. 49, nos. 3–4, pp. 581–606.

Elkady, O.A., Abolkassem, S.A., Elsayed, A.H., Hussein, W.A, and Hussein, K.F.A., Microwave absorbing efficiency of Al matrix composite reinforced with nano-Ni/SiC particles, Results Phys., 2019, vol. 12, pp. 687–700.

Bao, C.M., Dahlborg, U., Adkins, N., and Calvo-Dahlborg, M., Structural characterisation of Al–Ni powders produced by gas atomisation, J. Alloys Compd., 2009, vol. 481, nos. 1–2, pp. 199–206.

Deng, Z., Yin, H., Zhang, C., Zhang, G., Li, W., Zhang, T., Zhang, R., Jiang, X., and Qu, X., Microstructure and mechanical properties of Cu–12Al–xNi alloy prepared using powder metallurgy, Mater. Sci. Eng., A, 2019, vol. 759, pp. 241–251.

German, R.M., Suri, P., and Park, S.J., Review: Liquid phase sintering, J. Mater. Sci., 2009, vol. 44, pp. 1–39.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Tunçay, T. Microstructural and Mechanical Properties of A356/Ni Alloys Produced by the Mechanochemical Method. Russ. J. Non-ferrous Metals 63, 201–211 (2022). https://doi.org/10.3103/S1067821222020110

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222020110