Abstract

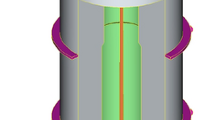

Cold flow simulation of Pobeda furnace bubbled bath hydro-gas dynamics was performed using a bottom gas-protected lance. It was shown that gas infusion into liquid at Archimedes criterion Ar = 5–60 is carried out in the pulse-coupled regime. The area of gas and liquid interaction was investigated at Ar = idem for separated and united air egress through ring and round nozzles. At all considered values of Ar, a two-phase zone was formed in liquid that was composed of “leg” with different geometrical shape, cavity, and gas-liquid layer over the bath surface. Characteristic features of blowing zone formation, flame configuration, and its structure in relation to the blow injection configuration and Ar values were found. It was detected that, at intense blowing through the lance center and ring gap, an ejected liquid prevailed in the cavity structure, the content of which increased upon increase in gas consumption in shell, but near the nozzle face, the “leg” is composed of the gas phase. A hypothesis was formulated that the presence of an additional amount of sulfide melt in oxidative streamline provides more complete magnetite destruction in the bath volume and at close proximity of the nozzle provides formation of a protective coating. The sizes of the most indicative geometrical areas of flame were quantified, which gave evidence about periodic and extreme behavior of jet spread in liquid. Empirical equations of the relation between maximum linear and across “leg” sizes at dynamical conditions of blow injection in shell (Arshell) and central tube (Arc) are obtained for two values Arshell ≥ Arcand Arshell ≤ Arc. It was estimated that blow injection in shell increases extension velocity of the “leg” on the nozzle face to 137 mm/s. The dependence of average height (Havg, m) of splash lift over calm bath surface was defined, which at 25 ≥ Arshell ≥ 5 and 60 ≥ Arc ≥ 12 has the form Havg = 0.027(Arshell + Arc)0.27. Using Schlichting’s equation, a value of maximum offset from the nozzle surface where cooperative axial movement in liquid of ring and round flow with isovelocity is preserved is calculated. It is proposed that a protective effect of bottom lance with shell appears in the lance belt area over a distance of 7–10 cm from the nozzle surface. The cavity after separation from the nozzle moves down vertically, but countercurrent liquid flow bounding on the cavity front moves in the opposite direction, flowing around the phase interface with comparable velocity. On the basis of more intense change in the transverse size of the interaction zone in the nozzle area and noticeable sideways liquid movement, it was recommended to take corrective action for decreasing the action of melt erosion in the lance belt of the Pobeda furnace on the entrance region of flow development.

Similar content being viewed by others

REFERENCES

Bulatov, K.V., Zhukov, V.P., Bratygin, E.V., Tomilov, N.A., and Menshikov, V.A., Investigation of Pobeda furnace bubbling zone physics using cold modeling method. Message 1. Investigation of fluid and gas dynamics of bubbling using a side-blowing gas-protected lance, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2021, no. 3, pp. 15–23.

El’darkhanov, A.S., Nuradinov, A.S., and Nakhaev, M.R., Physical modeling of the movement of liquid steel in the intermediate bucket under the bottom blowing of an inert gas, Stal’, 2018, no. 3, pp. 14–17.

Pis’menov, S.A., Povolotskii, D.Ya., and Ustyugov, A.A., Bath hydrodynamics with gas injection in a ladle–furnace unit: physical modeling, Steel Transl., 2007, vol. 37, no. 3, pp. 189–190.

Timofeeva, A.S., Kozhukhov, A.A., Nikitchenko, T.V., and Kamenev A.A., Cold modeling of liquid steel purging with an inert gas through the submersible lance and the bottom blowing unit, Trudy Mezhdunarodnoi nauchnoi konferntsii, posvyashchennoi 115-letiyu so dnya rozhdeniya akademika A.M. Samarina (Moskva, 14–15 noyabrya 2017 g.) (Proc. Int. Scientific Conference, Dedicated to the 15th Anniversary of the Birth of Academician A.M. Samarin (Moscow, November 14–15, 2017), Moscow: OOO Interkontact Nauka, 2017, pp. 16–18.

Yushkevich, P.O. and Molchanov, L.S., Cold modeling of circulating streams in a converter bath with a combined purge, Metalozn. Term. Obrob. Met., 2017, no. 3 (78), pp. 44–50.

Rogotovskii, A.N., Shipelnikov, A.A., Skakov, S.V., Bobyleva, N.A., Tyulenev, E.N., Kononykhin, G.N., and Glebov, V.P., Simulation of steel hydrodynamics in bucket under argon flow through bottom porous unit, Trudy 3-ei Vserossiiskoi nauchno-prakticheskoi konferentsii s mezhdunarodnym uchastiem (Lipetsk, 20–22 maya 2020 g.) (Proc. 3rd All-Russian Scientific and Practical Conference with International Participation (Lipetsk, May 20–22, 2020). Lipetsk: Lipetsk State Technical Univ., 2020, pp. 105–111.

Gizatulin, R.A. The patterns of the distribution of the gas phase in the liquid under purging from the bottom, Vestn. Yuzhno-Ural. Gos. Univ. Ser.: Metall., 2006, no. 10 (65), pp. 63–69.

Mazumdar, D. and Guthrie, R., Modeling energy dissipation in slag-covered steel baths in steelmaking ladles, Metall. Mater. Trans. B, 2010, vol. 41, pp. 976–989.

Nakanishi, K., Fujii, T., and Szekely, J., Possible relationship between energy dissipation and agitation in steel-processing operations, Ironmaking Steelmaking, 1975, vol. 2, no. 3, pp. 193–197.

Bulatov, K.V., Yakornov, S.A., Ibragimov, A.F., and Iskhakov, I.I., Industrial tests of sulphide copper concentrate melting in smelter “Pobeda” on oxygen blow using bottom tuyeres, Metallurg, 2020, no. 8, pp. 36–40.

Bulatov, K.V., Yakornov, S.A., Ibragimov, A.F., Iskhakov, I.I., and Zhukov, V.P., RF Patent 2734613, 2020.

Chen, L., Hao, Z.D., Yang, T.Z., Liu, W.F., Zhang, D.C., Zhang, L., Bin, S., and Bin, W.D., A comparison study of the oxygen-rich side blow furnace and the oxygen-rich bottom blow furnace for liquid high lead slag reduction, JOM, 2015, vol. 67, pp. 1123–1129.

Zhao, B., Cui, Z., and Wang, Z.A., New copper smelting technology bottom blown oxygen furnace developed at dongying fangyuan nonferrous metals, Proc. 4th Int. Symposium on High Temperature, San Antonio, TX, Hoboken, NJ: John Wiley and Sons, 2013, pp. 1–10.

Cui, Z., Shen, D., and Wang, Z., New process of copper smelting with oxygen enriched bottom blowing technology, Youse Jinshu, 2010.

Jiang, X., Cui, Z., Chen, M., and Zhao, B., Study of plume eye in the copper bottom-blown smelting furnace, Metall. Mater. Trans. B, 2019, vol. 50, pp. 765–778.

Shui, L., Cui, Z.X., Ma, X.D., Rhamdhani, M.A., Nguyen, A.V., and Zhao, B.J., Mixing phenomena in a bottom blown copper smelter: A water model study, Metall. Mater. Trans. B, 2015, vol. 46, pp. 1218–1225.

Wang, Q.M., Guo, X.Y., Wang, S.S., Liao, L.L., and Tian, Q.H., Multiphase equilibrium modeling of oxygen bottom-blown copper smelting process, Trans. Nonferrous Met. Soc. China, 2017, vol. 27, pp. 2503–2511.

Shao, P. and Jiang, L., Flow and mixing behavior in a new bottom blown copper smelting furnace, Int. J. Mol. Sci., 2019, vol. 20, no. 22, article no. 5757. https://doi.org/10.3390/ijms20225757

Shui, L., Cui, Z., Ma, X., Jiang, X., Chen, M., Xiang, Y., and Zhao, B., A water model study on mixing behavior of the two-layered bath in bottom-blown copper smelting furnace, JOM, 2018, vol. 70, no. 10, pp. 2065–2070.

Zhang, Z.Y., Chen, Z., Yan, H.J., Liu, F.K., Liu, L., Cui, Z.X., and Shen, D.B., Numerical simulation of gas–liquid multi-phase flows in oxygen enriched bottom-blown furnace, Chin. J. Nonferrous Met., 2012, vol. 22, pp. 1826–1834.

Cheremisin, D.D., Development of mathematical models of the process of copper fire refining in the aggregates with bottom blowing, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Yekaterinburg: Ural Federal Univ. Named after the First President of Russia B.N. Yeltsin, 2019.

Surin, V.A. and Nazarov, Yu.N., Masso- i teploobmen, gidrogazodinamika metallurgicheskoi vanny (Mass and Heat Transfer, Hydro-Gas Dynamics of a Metallurgical Bath), Moscow: Metallurgiya, 1993.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Bulatov, K.V., Zhukov, V.P., Bratygin, E.V. et al. Investigation of Pobeda Furnace Bubbling Zone Physics Using Cold Modeling Method. Part 2. Hydro-Gas Dynamics of Liquid Blowing by Gas Using Bottom Gas-Protected Lance. Russ. J. Non-ferrous Metals 63, 113–120 (2022). https://doi.org/10.3103/S1067821222020031

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222020031