Abstract

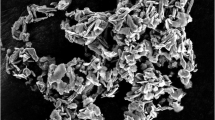

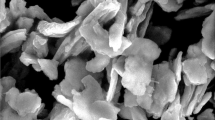

Magnetorheological (MR) fluid properties are essential in analyzing the performance of any MR fluid system. The fluid properties are dependent on shape, size, and magnetic saturation of the magnetic particles. Preliminary characteristics with SEM, particle size analysis (PSA), and vibration sample magnetometer (VSM) on carbonyl iron particles were performed to verify the particle’s feasibility to synthesize the MR fluid in a laboratory. Synthesis and characterization of MR fluids with particle concentrations (PC) of 10% (PC10), 15% (PC15), 20% (PC20), 30% (PC30), and 35% (PC35) by volume are carried out. To show the inherent nonlinearity of the MR fluid, Herschel–Bulkley model is used. The relationship between sedimentation velocity, yield stress, and thermal conductivity is established as a function of particle concentration with experimental uncertainty of 6.15, 5, and 8.96%, respectively. Functional testing of PC15 and PC30 was carried out on an MR damper fabricated on dimensions obtained from the literature for the required size. The results indicate that damping force is 42% more in PC30 than PC15 at higher loading parameters. Finally, the saturation magnetization of the MR fluid depends not only on applied current but also on loading parameters when operating in the system.

Similar content being viewed by others

Abbreviations

- τ:

-

Shear stress (Pa)

- τH :

-

Field (H)-dependent flow stress (Pa)

- \(\dot{\gamma }\) :

-

Rate of shear(s−1)

- K:

-

Consistency index

- n :

-

Flow behavior index

- Kp :

-

Particle thermal conductivity

- Kf :

-

Fluid thermal conductivity

- \(\phi\) :

-

Particle concentration

- N:

-

Particle shape

References

Abd Fatah AY, Mazlan SA, Koga T et al (2015) A review of design and modeling of magnetorheological valve. Int J Mod Phys B 29:1530004

Afrand M (2017) Experimental study on thermal conductivity of ethylene glycol containing hybrid nano-additives and development of a new correlation. Appl Therm Eng 110:1111–1119

Ashtiani M, Hashemabadi SH, Ghaffari A (2015) A review on the magnetorheological fluid preparation and stabilization. J Magn Magn Mater 374:711–715

Batchelor GK (1972) Sedimentation in a dilute dispersion of spheres. J. Fluid Mech 52:245–268

Becnel AC, Hu W, Wereley NM (2012) Measurement of magnetorheological fluid properties at shear rates of up to 25000 s -1. IEEE Trans Magn 48:3525–3528. https://doi.org/10.1109/TMAG.2012.2207707

Bica I, Anitas EM, Averis LME, Bunoiu M (2015) Magnetodielectric effects in composite materials based on paraffin, carbonyl iron and graphene. J Ind Eng Chem 21:1323–1327

Bossis G, Volkova O, Grasselli Y, Ciffreo A (2019) The role of volume fraction and additives on the rheology of suspensions of micron-sized iron particles. Front Mater. https://doi.org/10.3389/fmats.2019.00004

Cheng H, Wang M, Liu C, Wereley NM (2018) Improving sedimentation stability of magnetorheological fluids using an organic molecular particle coating. Smart Mater Struct 27:075030

Chiriac H, Stoian G (2010) Influence of particle size distributions on magnetorheological fluid performances. In: J Phys: Confe Ser. Institute of Physics Publishing 200:072095

Choi Y-T, Xie L, Wereley NM (2016) Testing and analysis of magnetorheological fluid sedimentation in a column using a vertical axis inductance monitoring system. Smart Mater Struct 25:04LT01

De Vicente J, Klingenberg DJ, Hidalgo-Alvarez R (2011) Magnetorheological fluids: a review. Soft Matter 7:3701–3710

de Vicente J, Vereda F, Segovia-Gutiérrez JP et al (2010) Effect of particle shape in magnetorheology. J Rheol (N Y N Y) 54:1337–1362. https://doi.org/10.1122/1.3479045

Desai RM, Jamadar MEH, Kumar H et al (2019) Design and experimental characterization of a twin-tube MR damper for a passenger van. J Brazilian Soc Mech Sci Eng 41:332

Dong X, Tong Y, Ma N et al (2015) Properties of cobalt nanofiber-based magnetorheological fluids. RSC Adv 5:13958–13963

Ekwebelam C, See H (2009) Microstructural investigations of the yielding behaviour of bidisperse magnetorheological fluids. Rheol Acta 48:19–32

Feng Z (2015) Study of sedimentation stability of magnetorheological fluid. Adv Mater 4:1

Forero-Sandoval IY, Vega-Flick A, Alvarado-Gil JJ, Medina-Esquivel RA (2017) Study of thermal conductivity of magnetorheological fluids using the thermal-wave resonant cavity and its relationship with the viscosity. Smart Mater Struct 26:025010

Fu Y, Yao J, Zhao H et al (2018) Bidisperse magnetic particles coated with gelatin and graphite oxide: magnetorheology, dispersion stability, and the nanoparticle-enhancing effect. Nanomaterials 8:714

Ham JM, Homsy GM (1988) Hindered settling and hydrodynamic dispersion in quiescent sedimenting suspensions. Int J Multiph Flow 14:533–546

Jha S, Jain VK (2009) Rheological characterization of magnetorheological polishing fluid for MRAFF. Int J Adv Manuf Technol 42:656–668

Jiang W, Zhang Y, Xuan S et al (2011) Dimorphic magnetorheological fluid with improved rheological properties. J Magn Magn Mater 323:3246–3250

Jönkkäri I, Isakov M, Syrjälä S (2015) Sedimentation stability and rheological properties of ionic liquid–based bidisperse magnetorheological fluids. J Intell Mater Syst Struct 26:2256–2265

Kittipoomwong D, Klingenberg DJ, Ulicny JC (2005) Dynamic yield stress enhancement in bidisperse magnetorheological fluids. J Rheol (N Y N Y) 49:1521–1538

Kordonsky WI, Gorodkfn SP, Demchuk SA (1993) Magnetorheological control of heat transfer. Int J Heat Mass Transf 36:2783–2788

Krishna H, Kumar H, Gangadharan K (2017) Optimization of magneto-rheological damper for maximizing magnetic flux density in the fluid flow gap through fea and ga approaches. J Inst Eng Ser C 98:533–539

Kumar PM, Kumar J, Tamilarasan R et al (2015) Review on nanofluids theoretical thermal conductivity models. Eng J 19:67–83

Kwon SH, Jung HS, Choi HJ et al (2018) Effect of octahedral typed iron oxide particles on magnetorheological behavior of carbonyl iron dispersion. Colloids Surfaces A Physicochem Eng Asp 555:685–690. https://doi.org/10.1016/j.colsurfa.2018.07.060

Lee JY, Kwon SH, Choi HJ (2019) Magnetorheological characteristics of carbonyl iron microparticles with different shapes. Korea-Australia Rheol J 31:41–47

Leong KC, Yang C, Murshed SMS (2006) A model for the thermal conductivity of nanofluids - the effect of interfacial layer. J Nanoparticle Res 8:245–254. https://doi.org/10.1007/s11051-005-9018-9

Li Y, Luo Y, Wang Y et al (2021) Research on characterization method and influencing factors of sedimentation stability of magnetorheological fluid. Korea Aust Rheol J 33:309–320. https://doi.org/10.1007/s13367-021-0024-y

Liu YD, Lee J, Choi SB, Choi HJ (2013) Silica-coated carbonyl iron microsphere based magnetorheological fluid and its damping force characteristics. Smart Mater Struct. https://doi.org/10.1088/0964-1726/22/6/065022

López-López MT, Zugaldía A, González-Caballero F, Durán JDG (2006) Sedimentation and redispersion phenomena in iron-based magnetorheological fluids. J Rheol (N Y N Y) 50:543–560. https://doi.org/10.1122/1.2206716

Mangal SK, Kumar A (2014) Experimental and numerical studies of magnetorheological (MR) damper. Chinese J Eng 2014:1–7. https://doi.org/10.1155/2014/915694

Mangal SK, Kumar A (2015) Geometric parameter optimization of magneto-rheological damper using design of experiment technique. Int J Mech Mater Eng 10:1–9. https://doi.org/10.1186/s40712-015-0031-1

Mistik SI, Shah T, Hadimani RL, Siores E (2012) Compression and thermal conductivity characteristics of magnetorheological fluid-spacer fabric smart structures. J Intell Mater Syst Struct 23:1277–1283. https://doi.org/10.1177/1045389X12447295

Morillas JR, Bombard AJF, De Vicente J (2018) Enhancing magnetorheological effect using bimodal suspensions in the single-multidomain limit. Smart Mater Struct. https://doi.org/10.1088/1361-665X/aac8ae

Murshed SMS, De Castro CAN (2011) Contribution of Brownian motion in thermal conductivity of nanofluids. Proc World Congr Eng 3:1905–1909

Ngatu GT, Wereley NM (2007) Viscometric and sedimentation characterization of bidisperse magnetorheological fluids. IEEE Trans Magn 43:2474–2476. https://doi.org/10.1109/TMAG.2007.893867

Nguyen QH, Han YM, Choi SB, Wereley NM (2007) Geometry optimization of MR valves constrained in a specific volume using the finite element method. Smart Mater Struct 16:2242–2252. https://doi.org/10.1088/0964-1726/16/6/027

Nicolai H, Herzhaft B, Hinch EJ et al (1995) Particle velocity fluctuations and hydrodynamic self-diffusion of sedimenting non-Brownian spheres. Phys Fluids 7:12–23. https://doi.org/10.1063/1.868733

Piao SH, Bhaumik M, Maity A, Choi HJ (2015) Polyaniline/Fe composite nanofiber added softmagnetic carbonyl iron microsphere suspension and its magnetorheology. J Mater Chem C 3:1861–1868. https://doi.org/10.1039/c4tc02491e

Pisuwala MS, Upadhyay RV, Parekh K (2019) Contribution of magnetic nanoparticle in thermal conductivity of flake-shaped iron particles based magnetorheological (MR) fluid. J Appl Phys. https://doi.org/10.1063/1.5109021

Pu H, Jiang F (2005) Towards high sedimentation stability: magnetorheological fluids based on CNT/Fe3O4 nanocomposites. Nanotechnology 16:1486–1489. https://doi.org/10.1088/0957-4484/16/9/012

Reinecke BN, Shan JW, Suabedissen KK, Cherkasova AS (2008) On the anisotropic thermal conductivity of magnetorheological suspensions. J Appl Phys. https://doi.org/10.1063/1.2949266

Richardson JF, Zaki WN (1997) Sedimentation and fluidisation: Part I. Chem Eng Res Des 75:S82–S100. https://doi.org/10.1016/s0263-8762(97)80006-8

Sarkar C, Hirani H (2015) Effect of particle size on shear stress of magnetorheological fluids. Smart Sci 3:65–73. https://doi.org/10.1080/23080477.2015.11665638

Sassi S, Cherif K, Mezghani L et al (2005) An innovative magnetorheological damper for automotive suspension: from design to experimental characterization. Smart Mater Struct 14:811–822. https://doi.org/10.1088/0964-1726/14/4/041

Sedlacik M, Pavlinek V, Lehocky M et al (2011) Plasma-treated carbonyl iron particles as a dispersed phase in magnetorheological fluids. Colloids Surfaces A Physicochem Eng Asp 387:99–103. https://doi.org/10.1016/j.colsurfa.2011.07.035

Shah K, Phu DX, Seong MS et al (2014) A low sedimentation magnetorheological fluid based on plate-like iron particles, and verification using a damper test. Smart Mater Struct. https://doi.org/10.1088/0964-1726/23/2/027001

Shivaram AC, Gangadharan KV (2007) Statistical modeling of a magneto-rheological fluid damper using the design of experiments approach. Smart Mater Struct 16:1310–1314. https://doi.org/10.1088/0964-1726/16/4/044

Steinour HH (1944) Rate of Sedimentation. Ind Eng Chem 36:840–847. https://doi.org/10.1021/ie50417a018

Wang X, Gordaninejad F (2006) Study of magnetorheological fluids at high shear rates. Rheol Acta 45:899–908. https://doi.org/10.1007/s00397-005-0058-y

Wong PL, Bullough WA, Feng C, Lingard S (2001) Tribological performance of a magneto-rheological suspension. Wear 247:33–40. https://doi.org/10.1016/S0043-1648(00)00507-X

Xu ZD, Guo WY, Chen BB (2015) Preparation, property tests, and limited chain model of magnetorheological fluid. J Mater Civ Eng 27:1–10. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001190

Xue Q, Xu WM (2005) A model of thermal conductivity of nanofluids with interfacial shells. Mater Chem Phys 90:298–301. https://doi.org/10.1016/j.matchemphys.2004.05.029

Zhang WL, Liu YD, Choi HJ (2012) Field-responsive smart composite particle suspension: materials and rheology. Korea Aust Rheol J 24:147–153

Zhang Y, Li D, Zhang Z (2019) The study of magnetorheological fluids sedimentation behaviors based on volume fraction of magnetic particles and the mass fraction of surfactants. Mater. Res. Express 6:126127

Acknowledgements

The authors acknowledge the Ministry of Human Resource Development and Ministry of Road Transport and Highways, Government of India, supporting this research through IMPRINT Project Fund No. IMPRINT/2016/7330 titled “Development of Cost-Effective Magnetorheological (MR.) Fluid Damper in Two wheelers and Four Wheelers Automobile to Improve Ride Comfort and Stability.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kariganaur, A.K., Kumar, H. & Arun, M. Impact of increased particle concentration on magnetorheological fluid properties and their damping performance. Korea-Aust. Rheol. J. 34, 223–238 (2022). https://doi.org/10.1007/s13367-022-00029-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-022-00029-8