Abstract

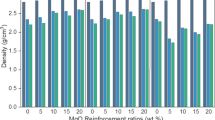

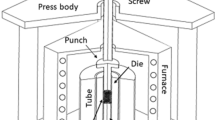

The present study aims to propose a new and non-complex sintering method in powder metallurgy in order to manufacture a light material with high mechanical properties. The proposed new sintering method is based on the principle that compaction is applied to a heated sample following classical sintering method. In this way, microstructure and mechanical properties of new samples manufactured using the proposed post sintering compaction method were compared with the samples manufactured using classical sintering method. In this context, in order to find the most optimal Al–Zn alloy ratio, different weight percentages of Zn (5–15–25–35–45%) were added to Al. When the manufactured alloys with classical sintering and post sintering compaction methods were compared, the most optimal alloy ratio was observed to be 15% Zn (Al–15Zn) manufactured using post sintering compaction method. In the next step, the matrix alloy with the most optimal ratio was reinforced with B4C in different weight percentages (1–2–3%) to manufacture Al matrix composites using post sintering compaction method. The microstructure analysis of the manufactured samples demonstrated that reinforcement particles were generally located at the grain boundaries and these particles caused the presence of porosities around them. In addition, mechanical test results indicated that increasing reinforcement ratio affected mechanical properties negatively. It can be thus concluded that a composite material with 1% B4C reinforcement ratio was superior to matrix alloy (Al–15Zn) in terms of microstructure, density, absorbed energy, hardness and compressive strength, and thus it is a critical reinforcement ratio in improving material properties.

Similar content being viewed by others

REFERENCES

Sap, E., Microstructure and mechanical effects of Co–Ti powder particles on cu matrix composites, Russ. J. Non-Ferrous Met., 2021, vol. 62, no. 1, pp. 107–118. https://doi.org/10.3103/S1067821221010077

Shongwe, B.M. and Olubambi, P.A., Influence of sintering methods on the mechanical properties of aluminium nanocomposites reinforced with carbonaceous compounds : A review, Integr. Med. Res., 2019, vol. 8, no. 2, pp. 2432–2449. https://doi.org/10.1016/j.jmrt.2019.01.026

Hötzer, J., Seiz, M., Kellner, M., Rheinheimer, W., and Nestler, B., Phase-field simulation of solid state sintering, Acta Mater., 2019, vol. 164, pp. 184–195. https://doi.org/10.1016/j.actamat.2018.10.021

Ribeiro, S., Gênova, L.A., Ribeiro, G.C., Oliveira, M.R., and Bressiani, A.H.A., Effect of heating rate on the shrinkage and microstructure of liquid phase sintered SiC ceramics, Ceram. Int., 2016, vol. 42, no. 15, pp. 17398–17404. https://doi.org/10.1016/j.ceramint.2016.08.039

Crossin, E., Yao, J.Y., and Schaffer, G.B., Swelling during liquid phase sintering of Al–Mg–Si–Cu alloys, Powder Metall., 2007, vol. 50, no. 4, pp. 354–358. https://doi.org/10.1179/174329007X223947

Tavoosi, M., Karimzadeh, F., Enayati, M.H., and Heidarpour, A., Bulk Al–Zn/Al2O3 nanocomposite prepared by reactive milling and hot pressing methods, J. Alloys Compd., 2009, vol. 475, nos. 1–2, pp. 198–201. https://doi.org/10.1016/j.jallcom.2008.07.049

Kubota, M., Properties of nano-structured pure Al produced by mechanical grinding and spark plasma sintering, J. Alloys Compd., 2007, vols. 434–435, pp. 294–297. https://doi.org/10.1016/j.jallcom.2006.08.329

Marinel, S. and Savary, E., In situ measurement of the shrinkage during microwave sintering, J. Mater. Process. Technol., 2009, vol. 209, no. 10, pp. 4784–4788. https://doi.org/10.1016/j.jmatprotec.2008.12.005

Pieczonka, T., Kazior, J., Szewczyk-Nykiel, A., Hebda, M., and Nykiel, M., Effect of atmosphere on sintering of Alumix 431D powder, Powder Metall., 2012, vol. 55, no. 5, pp. 354–360. https://doi.org/10.1179/1743290112Y.0000000015

Nogueira, A. and Dias, O., Analysis of the densification of a composite obtained by sintering process of aluminium bronze powders with different carbides, Metall. Mater., 2019, vol. 72, no. 3, pp. 461–467. https://doi.org/10.1590/0370-44672018720148

Sinha, A. and Farhat, Z., Effect of surface porosity on tribological properties of sintered pure Al and Al 6061, Mater. Sci. Appl., 2015, vol. 6, no. 6, pp. 549–566. https://doi.org/10.4236/msa.2015.66059

Herzallah, H., Elsayd, A., Shash, A., and Adly, M., Effect of carbon nanotubes (CNTs) and silicon carbide (SiC) on mechanical properties of pure Al, Integr. Med. Res., 2020, vol. 9, no. 2, pp. 1948–1954. https://doi.org/10.1016/j.jmrt.2019.12.027

Gopienko, V.G., Smagorinsky, M.E., Grigoriev, A.A., and Bellavin, A.D., Sintered Materials Made of Aluminium Powders, Moscow: Metallurgiya, 1993.

Yehia, H.M., Electrochemical surface modification of aluminum sheets prepared by powder metallurgy and casting techniques for printed circuit applications, Trans. Indian Inst. Met., 2019, vol. 72, no. 1, pp. 85–92. https://doi.org/10.1007/s12666-018-1464-z

Huang, G.Q, Wu, J., Hou, W.T., et al., Microstructural evolution and mechanical behavior of powder metallurgy based SiC/Al-Mg-Sc-Zr nanocomposite subjected to multi-pass friction stir processing, Mater. Sci. Eng., A, 2021, vol. 806, pp. 1–14. https://doi.org/10.1016/j.msea.2021.140831

Sameljuk, A.V., Neikov, O.D., Krajnikov, A.V., Milman, Y.V., and Thompson, G.E., Corrosion behaviour of powder metallurgical and cast Al–Zn–Mg base alloys, Corros. Sci., 2004, vol. 46, pp. 147–158. https://doi.org/10.1016/S0010-938X(03)00138-0

Gökçe, A., Findik, F., and Kurt, A.O., Effects of Mg content on aging behavior of Al4CuXMg PM alloy, Mater. Des., 2013, vol. 46, pp. 524–531. https://doi.org/10.1016/j.matdes.2012.10.045

Penchal Reddy, M., Shakoor, R.A., Mohamed, A.M.A., and Gupta, M., Microwave rapid sintering of al-metal matrix composites: A review on the effect of reinforcements, microstructure and mechanical properties, Metals, 2016, vol. 6, no. 7, pp. 1–19. https://doi.org/10.3390/met6070143

Yu, B.C., Bae, K.C., Jung, J.K., Kim, Y.H., and Park, Y.H., Effect of heat treatment on the microstructure and wear properties of Al–Zn–Mg–Cu/Insitu Al–9Si–SiCp/Pure Al composite by powder metallurgy, Met. Mater. Int., 2018, vol. 24, no. 3, pp. 576–585. https://doi.org/10.1007/s12540-018-0035-5

Fan, Y., Tang, X., Wang, S., and Chen, B., Comparisons of age hardening and precipitation behavior in 7075 alloy under single and double-stage aging treatments, Met. Mater. Int., 2021, vol. 27, no. 10, pp. 4204–4215. https://doi.org/10.1007/s12540-020-00875-7

Hekimoğlu, A.P. and Turan, Y.E., Çinko oranının Al–(5–50)Zn alaşımlarının yapısal ve mekanik özelliklerine etkisi, Gümüşhane Üniv. Fen Bilim Enst. Derg., 2019, vol. 9, pp. 16–25. https://doi.org/10.17714/gumusfenbil.381050

Chen, Y., Liu, C.Y., Zhang, B., Qin, F.C., and Hou, Y.F., Precipitation behavior and mechanical properties of Al–Zn–Mg alloy with high Zn concentration, J. Alloys Compd., 2020, vol. 825, pp. 1–7. https://doi.org/10.1016/j.jallcom.2020.154005

Gerchikova, S., Zaitseva, I., Fridlyander, I.N., and Kirkina, N.N., Change in the structure and properties of Al–Zn–Mg alloys, Met. Sci. Heat Treat., 1972, vol. 14, no. 3, pp. 233–236.

Kumar, N. and Manoj, M.K., Influence of B4C on dry sliding wear behavior of B4C/Al-Mg-Si composites synthesized via powder metallurgy route, Met. Mater. Int., 2021, vol. 27, no. 10, pp. 4120–4131. https://doi.org/10.1007/s12540-020-00814-6

Chernyshova, T.A., Kobeleva, L.I., Kalashnikov, I.E., and Bolotova, L.K., Modification of cast aluminum-matrix composite materials by refractory nanoparticles., Russ. Metall. (Engl. Transl.), 2009, vol. 2009, no. 1, pp. 70–76.

Alattar, A.L. and Bazhin, V.Y., Development properties of aluminum matrix composites reinforced by particles of boron carbide, J. Phys.: Conf. Ser., 2021, vol. 1990, pp. 1–7.

Hu, H.M., Lavernia, E.J., Harrigan, W.C., Kajuch, J., and Nutt, S.R., Microstructural investigation on B4C/Al-7093 composite, Mater. Sci. Eng., A, 2001, vol. 297, nos. 1–2, pp. 94–104. https://doi.org/10.1016/S0921-5093(00)01254-5

Shen, Q., Wu, C., Luo, G., et al., Microstructure and mechanical properties of Al–7075/B4C composites fabricated by plasma activated sintering, J. Alloys Compd., 2014, vol. 588, pp. 265–270. https://doi.org/10.1016/j.jallcom.2013.11.089

Park, J., Lee, S., Kang, S., et al., Complex effects of alloy composition and porosity on the phase transformations and mechanical properties of powder metallurgy steels, Powder Technol., 2015, vol. 284, pp. 459–466. https://doi.org/10.1016/j.powtec.2015.07.029

Avci, U. and Güleç, A., Effect of different sintering temperatures on microstructure and mechanical properties for pure al material produced by powder metallurgy, El-Cezerî J. Sci. Eng., 2021, vol. 1, pp. 462–470. https://doi.org/10.31202/ecjse.789587

Wei, X., Ren, L., Geng, X., et al., Nano microstructure development and solidification of Zn–6 wt % Al hypereutectic alloy, Mater. Charact., 2019, vol. 147, pp. 295–302. https://doi.org/10.1016/j.matchar.2018.11.016

Ares, A.E. and Gassa, L.M., Corrosion susceptibility of Zn–Al alloys with different grains and dendritic microstructures in NaCl solutions, Corros. Sci., 2012, vol. 59, pp. 290–306. https://doi.org/10.1016/j.corsci.2012.03.015

Radchenko, A.K., Mechanical properties of green compacts. II. Effect of powder relative bulk density on the strength of compacts with different forming temperature conditions, Powder Metall. Met. Ceram., 2004, vol. 43, nos. 11–12, pp. 552–563. https://doi.org/10.1007/s11106-005-0021-6

Feng, J., Sun, H., Li, X., Zhang, J., Fang, W., and Fang, W., Microstructures and mechanical properties of the ultrafine-grained Mg–3Al–Zn alloys fabricated by powder metallurgy, Adv. Powder Technol., 2016, vol. 27, no. 2, pp. 550–556. https://doi.org/10.1016/j.apt.2016.02.008

Zhou, W.B., Teng, G.B., Liu, C.Y., et al., Microstructures and mechanical properties of binary Al–Zn alloys fabricated by casting and heat treatment, J. Mater. Eng. Perform., 2017, vol. 26, no. 8, pp. 3977–3982. https://doi.org/10.1007/s11665-017-2852-y

Berg, L.K., Gjoønnes, J., Hansen, V., et al., GP-zones in Al–Zn–Mg alloys and their role in artificial aging, Acta Mater., 2001, vol. 49, no. 17, pp. 3443–3451. https://doi.org/10.1016/S1359-6454(01)00251-8

Shin, S.S., Lim, K.M., and Park, I.M., Effects of high Zn content on the microstructure and mechanical properties of Al–Zn–Cu gravity-cast alloys, Mater. Sci. Eng., A, 2017, vol. 679, pp. 340–349. https://doi.org/10.1016/j.msea.2016.09.022

Yuan, X., Qu, X., Yin, H., et al., Effects of sintering temperature on densification, microstructure and mechanical properties of Al-based alloy by high-velocity compaction, Metals, 2021, vol. 11, no. 2, pp. 1–11. https://doi.org/10.3390/met11020218

Yang, Q., Cheng, D.L., Zhang, F.G., et al., Spark plasma sintering mechanisms of the Al–Zn–Mg–Cu alloys and TiB2/Al–Zn–Mg–Cu composites, Mater. Charact., 2021, vol. 172, pp. 1–12. https://doi.org/10.1016/j.matchar.2020.110825

Shin, S.S., Lim, K.M., and Park, I.M., Characteristics and microstructure of newly designed Al–Zn-based alloys for the die-casting process, J. Alloys Compd., 2016, vol. 671, pp. 517–526. https://doi.org/10.1016/j.jallcom.2016.02.127

Lamrous, D., Debili, M.Y., and Boehm-Courjault, E., Microstructure and phase composition of Al–Zn alloys, J. Adv. Microsc. Res., 2013, vol. 8, no. 4, pp. 266–269. https://doi.org/10.1166/jamr.2013.1168

Dębski, A., Gąsior, W., and Szmit, K., Calorimetric measurements of liquid Al–Zn alloys, Metall. Mater. Trans. A, 2016, vol. 47, no. 10, pp. 4933–4940. https://doi.org/10.1007/s11661-016-3643-z

Zhang, S., Kontsevoi, O.Y., Freeman, A.J., and Olson, G.B., First principles investigation of zinc-induced embrittlement in an aluminum grain boundary, Acta Mater., 2011, vol. 59, no. 15, pp. 6155–6167. https://doi.org/10.1016/j.actamat.2011.06.028

Dündar, S. and Ramazan, C., Wear and mechanical properties of Al6061/SiC/B4C hybrid composites produced with powder, J. Mater. Res. Technol., 2019, vol. 8, no. 6, pp. 5348–5361. https://doi.org/10.1016/j.jmrt.2019.09.002

Gao, M., Chen, Z., Li, L., et al., Microstructure and enhanced mechanical properties of hybrid-sized B4C particle-reinforced 6061Al matrix composites, Mater. Sci. Eng., A, 2021, vol. 802, pp. 1–9. https://doi.org/10.1016/j.msea.2020.140453

Pozdniakov, A.V., Zolotorevskiy, V.S., Barkov, R.Y., Lotfy, A., and Bazlov, A.I., Microstructure and material characterization of 6063/B4C and 1545K/B4C composites produced by two stir casting techniques for nuclear applications, J. Alloys Compd., 2016, vol. 664, pp. 317–320.

Pozdniakov, A.V., Lotfy, A., Qadir, A., and Zolotorevskiy, V.S., Effect of the B4C content on the structure and thermal expansion coefficient of the Al–5% Cu alloy-based metal-matrix composite material, Phys. Met. Metallogr., 2016, vol. 117, no. 8, pp. 783–788.

Tayebi, M., Jozdani, M., and Mirhadi, M., Thermal expansion behavior of Al–B4C composites by powder metallurgy, J. Alloys Compd., 2019, vol. 809, pp. 1–7. https://doi.org/10.1016/j.jallcom.2019.151753

Zhang, L., Shi, G., Kun, X., et al., Phase transformation and mechanical properties of B4C/Al composites, J. Mater. Res. Technol., 2019, vol. 9, no. 2, pp. 2116–2126. https://doi.org/10.1016/j.jmrt.2019.12.042

Shikalov, V.S., Vidyuk, T.M., Kosarev, V.F., and Klinkov, S.V., Effect of B4C content on microhardness and sliding wear behavior of cold sprayed aluminum matrix coatings, AIP Conf. Proc., 2021, vol. 2351, pp. 1–6.

Manohar, G., Pandey, K.M., and Maity, S.R., Characterization of boron carbide (B4C) particle reinforced aluminium metal matrix composites fabricated by powder metallurgy techniques, a review, Mater. Today: Proc., 2021, vol. 45, pp. 6882–6888.

Gulec, A., Kose, M.M., and Gogus, M.T., An analysis of the usability of prefabricated cage-reinforced composite beams with self-compacting and lightweight concrete under flexural loads, Constr. Build. Mater., 2020, vol. 255, p. 119274. https://doi.org/10.1016/j.conbuildmat.2020.119274

Gulec, A., Metin, M., and Tolga, M., Experimental investigation of flexural performance of T-section prefabricated cage reinforced beams with self-compacting concrete, Structures, 2021, vol. 33, pp. 2190–2197. https://doi.org/10.1016/j.istruc.2021.05.074

ACKNOWLEDGMENTS

This research was supported by Kahramanmaraş Sütçü İmam University Scientific Research Projects Coordination Unit with the project numbered 2021/1-37 M.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares that he has no conflicts of interest.

Additional information

DATA AVAILABILITY

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

About this article

Cite this article

Avci, U. The Analysis of Microstructure and Mechanical Properties in B4C Reinforced Al–Zn Alloy Matrix Composites Manufactured Using a New Sintering Approach. Russ. J. Non-ferrous Metals 63, 344–359 (2022). https://doi.org/10.3103/S1067821222030129

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222030129