Abstract

Soil stabilization is the art and science of improving the engineering properties of soils. The properties of problematic soils can be improved by blending appropriate amount of insitu soil, aggregates and bioenzymes. In the present study, four bacterial strains: Sporosarcina pasteurii, Bacillus paramycoides, Citrobacter sedlakii, and Enterobacter bugadensis were used to produce bioenzymes using urea supplemented molasses as a substrate via submerged fermentation. The crude bioenzyme was mixed with modified soil blended with 40% black cotton soil, 30% aggregate and 30% river sand; then tested after curing for 7 days. The test results revealed that except soil samples treated with bioenzyme of Enterobacter bugadensis, all treated soil samples showed improved plasticity index (18–55%) and liquid limit (5–44%). Soil samples treated with bioenzyme of Bacillus paramycoides, Citrobacter sedlakii and Sporosarcina pasteurii showed higher CBR values of 12.9%, 12.27%, and 11.95% respectively. On the other hand, free swell showed reduction in soil samples treated with bioenzymes of Sporosarcina pasteurii (47.37%), Bacillus paramycoides (30%), and Citrobacter sedlakii (10.53%). The highest percentage improvement of linear shrinkage was recorded for soil sample treated with bioenzymes of Sporosarcina pasteuri (39.65%), followed by Permazyme (10.44%), Citrobacter sedlakii (8.4%) and Bacillus paramycoides (8.34%). Whereas, the highest percentage improvement in MDD was recorded in permazyme treated soil (11.92%) followed by molasses (8.29%), Bacillus paramycoides (1.92%), and Enterobacter bugadensis (0.73%). The lowest optimum moisture content (9.3%) was recorded in soil treated with permazyme. Triaxial test analysis also showed improvement in both cohesion and angle of friction in bioenzyme treated soils. From the test results it was concluded that it is possible to treat expansive black cotton soils using bioenzymes produced from low cost substrates such as molasses and reduce the cost of construction and environmental carbon emission.

Similar content being viewed by others

Introduction

Soil stabilization is the alteration of soils to enhance their physical and chemical properties [1]. It is aimed to enhance load-bearing capacity through strength improvement, to control dust, and to preserve the natural or constructed strength of a soil and minimize the entry of surface water by waterproofing [2]. Mechanically, it enables the soil to resist shearing, avoid excessive deflections that cause fatigue cracking within the layer or in overlying layers, and prevent excessive permanent deformation through densification [3]. Soil stabilization process requires huge machineries with a great deal of earthen work. Hence, it is a costly and capital intensive investment.

Currently, there is a growing demand to identify new and cost effective materials that can improve construction techniques and enable expansion of the road network. Especially, the search for new and cheaper soil stabilizers and techniques that use local construction materials has received increased attention. Bioenzymes are natural, non-toxic, non-flammable, and non-corrosive liquid enzyme formulations that can be obtained from fermented sugars. They are known to improve the engineering qualities of soil, facilitate higher soil compaction densities, and increase stability [4]. Bioenzymes are hypothesized to catalyze the reactions between the clay and large organic cations and accelerate the cationic exchange process to reduce the adsorbed layer thickness [5].

Certain soil microorganisms make use of enzymes to stabilize their environment. They produce specific enzymes that catalyze the reactions between clay particles and organic cations, producing clods of stable soil around the roots of the vegetation [5]. Such microorganisms include ureolytic bacteria. The urease producing bacteria have been potentially studied from various genera including: Citrobacter, Enterobacter, Pseudomonas, Serratia, and Yersinia [6]; Lactobacillus, Streptococcus, Arthrobacter, Weissella, Enteroccocus, Enterobacter, Provi-dencia rettgeri [7]; Bacillus, Sporosarcina, Sporolactobacillus, Clostridium and Desulfotomaculum [8]. In addition to producing urease, these microbes produce plurality of enzyme groupings including hydrolase, amidohydrolase, oxido reductase, transferase, lyase, aspartase, L. glutaminase, dehydrogenase, acid phosphatase, alkaline phosphatase, arylsulfatase, betaglucosidase, amylase, catalase, alkaline phosphomonoesterase, phosphodiesterase, deaminase, invertase, cellulase, protease, asparaginase, amidase, chitinase, lipase, carbohydrase, phenoloxidase, peroxidase, laccase, lipase, aminopeptidase, and glucoseoxidase.

Even though, conventional soil stabilizers such as cement, fly ash, and lime have been widely used in soil stabilization [9,10,11], and experience of using commercial enzyme formulations for soil stabilization in road construction [12] is at its infant stage in several parts of the world, no research attempt has been done in the production of soil stabilizing bioenzyme using bacteria and characterization of the enzyme products. Thus, the present study was aimed at producing soil stabilizing bioenzyme consortia through submerged fermentation of cane molasses using selected ureolytic bacteria.

Bacterial strains used in the study

Three bacterial isolates belonging to the bacterial species, Bacillus paramycoides, Citrobacter cedlakii, and Enterobacter bugadensis were respectively isolated from Ethiopian soil. From which Bacillus paramycoides and Citrobacter cedlakii were isolated from Ethiopian rift valley area (soil pH = 7.56, soil temperature = 33 °C, 101.5 km south east of Addis Ababa, 8°27ʹN 39°16ʹE, and at an elevation of 1584.28 m above sea level). While, Enterobacter bugadensis was isolated from Ethiopian highland soil (Soil pH = 6.7, soil temperature = 30 °C, 501 km West of Addis Ababa, 9°30′N 35°30′E, and at an elevation of 1821 m above sea level). A standard bacterial isolate of known ureolytic activity, Sporosarcina pasteurii (NCTC-4822) was purchased for comparative analysis.

Crude bioenzyme of the strains was used for testing the engineering properties of the modified soil and the soil samples were prepared in accordance with the method described in AASHTO T87-86 [13]. The soil samples were mixed with crude bioenzymes, considering their optimum moisture content value (16%) (Table 7). Treated samples were stored in plastic bags, cured for 14 days. At the end of curing period samples were properly air dried to pulverize soil boulders using rubber covered mallet and quartered to get representative samples.

Cane molasses collection and physicochemical analysis

Black strap cane molasses sample was collected from national alcohol factory (NALF), Ethiopia and transported to Addis Ababa Science and Technology University; sealed and stored in a cool and dry place. The collected cane molasses was tested for its physicochemical properties such as color, pH, moisture, crude protein, crude fat, crude ash, crude fiber, carbohydrate, and total energy, cations and heavy metals as per standard procedure set by AOAC (2005) [14].

Pretreatment of cane molasses

A commonly used molasses pretreatment technique; clarification followed by acid treatment was conducted as per explained by Kundu et al. and Malika et al. [15, 16].

Determination of optimum molasses fermentable sugar concentration for bacterial growth

The optimum fermentable sugar concentration at which the selected bacterial strains could grow was determined in triplicates of cultures under aerobic conditions. The test was conducted in treated molasses diluted at different fermentable sugar concentrations [5, 10, 15 and 20% (v/v)] supplemented with 5% (w/v), urea (Thermo Fisher Scientific), filter sterilized using 0.45 μm sterile syringe. One milliliter of overnight grown bacteria culture, (OD = 0.5) of each selected isolate was inoculated in a 250 mL conical flask containing 100 mL of each urea supplemented diluted molasses. The cultures were incubated at 35 °C with shaking at 200 rpm. The cell growth was monitored by measuring the optical density of the samples at OD600 using a GENESYS™ 20 spectrophotometer (Thermo Fisher Scientific). The recording was done at 2 h interval and was conducted between 0 and 24 h. Un inoculated molasses medium was used as a blank. The growth curve was constructed as time vs Log OD for each fermentable sugar concentration and growth rate was calculated. The fermentable sugar concentration with the maximum growth rate at the log-phase was taken as the best concentration.

Production of crude extracellular enzymes through submerged fermentation

The production of crude extracellular enzymes consortium was performed under submerged fermentation using 1000 mL capacity Erlenmeyer flasks incubated in incubator shaker adjusted at 35 °C. Inocula was prepared by introducing 1 mL of a stock bacterial culture preserved at − 20 °C into 100 mL Erlenmeyer flask containing 50 mL nutrient broth and incubating it for 24 h at 37 °C. Subsequently, for each isolate 1000 mL pretreated molasses supplemented with 5% (v/v) of 40% urea (HiMedia, sterile filtered 0.45 µm; added post-autoclaving) was prepared in triplicate 2000 mL Erlenmeyer flasks. Following molasses preparation, 1% (v/v) of inoculum of each isolate (OD = 0.5) was introduced from the 24 h old seed culture. The inoculum was adjusted at pH = 6.8 and 10% fermentable molasses sugar then incubated for 5 days in shaker incubator (Wise Cube) at 35 °C with agitation speed of 150 rpm. To determine the fermentation progress, the brix of the fermentation syrup was tested periodically via refractometer.

Expansive black cotton soil sampling

The expansive soil sample used for this research work was collected from Addis Ababa, Science and Technology University Akaki kality sub-city, Kilinto area from one test pit (8.889 °N, 38.380 °E). To avoid the influence of fertilizers and plant roots, all of the bulk soils were collected after the top 1.5 m of the soil was removed from the ground surface [17]. The soils were classified as highly plastic clay (CH) as per the Unified Soil Classification System (USCS) (Table 7).

Analysis of the chemical properties of untreated and treated soil

The chemical properties of the natural and treated soil samples were tested for their pH (potentiometric method) [18], electrical conductivity (cell potentiometric method), exchangeable cations, and cations exchange capacity were determined by ammonium acetate method and organic matter content was determined by Walklay Black test method [19].

Modification of black cotton soil

The native black cotton soil used in this research had high amount of clay (72.0%) content and it was classified as A-7-5(20) according to AASHTO soil classification. To make the soil suitable for bioenzyme activity; i.e. with clay proportion of 12–35% [20, 21] the native soil was subjected to amendment using supplementary materials (aggregate and sand). To obtain appropriate clay proportion the native soil was blended in three mix-ratio trials [(30% black cotton soil + 35% aggregate + 35% sand), (40% black cotton soil + 30% aggregate + 30% sand) and (50% black cotton soil + 25% sand + 25% aggregate)]. This was done by wet sieve analysis and by hydrometer test then classification of the soil was done based on AASHTO and USCS standards.

Laboratory testing for engineering properties

Engineering properties tests were made according to AASHTO (2010) [13] and ASTM (2009) [22] laboratory standards. The selected tests were atterberg limits (AASHTO T-89 and T-90), hydrometer analysis, soil classification (AASHTO M-145), modified proctor density (AASHTO T-180), standard compaction (AASHTO T-99), soaked California Bearing Ratio (CBR) (AASHTO T-193), specific gravity (ASTM D-854), free swell (IS-2720)(IS 1978) [23], linear shrinkage (BS1377)(BS 2003) [24].

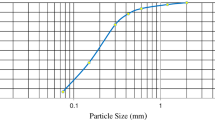

Grain size analysis

The grain-size analysis of both treated and untreated soil samples was carried out to determine the percentage of different grain sizes contained within soil. Primarily, wet sieve analysis was performed to determine the distribution of the coarser, larger-sized particles (≥ 75 µm retained on the No. 200 sieve). Sedimentation process using hydrometer analysis method was carried out to determine the distribution of the finer particle size smaller than 75 µm (usually silt and clay). The test was conducted according to ASTM D422 (Standard Test Method for Particle size analysis of soils) [22].

Determination of california bearing ratio (CBR)

The 96 h soaked CBR value of bioenzyme treated and untreated soil samples were tested after 14 days of curing, as per standard test procedure set by AASHTO T-193 [13].

Moisture density relation (modified compaction/proctor) test

Modified proctor density was analyzed as per standard procedure AASHTO T-180 [13].

Test for atterberg limits

The water contents at which soil passes through one of these states to the next (liquid, plastic, semi-solid, and solid) have been arbitrarily designated as ‘consistency limits’–Liquid limit, Plastic limit and plasticity index. These are called ‘Atterberg limits’ in honor of the originator of the concept [24]. The liquid limit values were determined in accordance with AASHTO T89-10. Similarly, the plastic limit and plasticity index of the soil samples are determined in accordance with AASHTO T90-10 [13].

Test for linear shrinkage

Linear shrinkage test was conducted to measure how a sample will reduce in length upon complete drying as compared to percentage of the original length. The test was conducted according to standard procedure ASTM D-854 [22].

Free swell index test

Free swell of a soil is defined as the ratio of the difference in volume of the sample to the original volume [24]. The test helps to know the expansiveness of a soil by measuring the volume of soil sample that is soaked and settled down in water for 24 h [25]. The test was conducted in accordance with IS: 2720 (Part 40) [23].

Results and discussion

Proximate analysis of raw cane molasses

The proximate analyses of raw undiluted black strap molasses are shown in Table1. The analysis showed that it contained 79.1% brix, 51.22% fermentable sugar, 18.76% moisture, 2.41% crude protein, 1.06% crude fat, 15.18% crude ash < 1.00% crude fiber, 62.59% carbohydrates and 369.54% energy.

Minerals and heavy metals content analysis of raw cane molasses

The composition analysis of minerals and heavy metals is shown in Table 2. Molasses had a very high concentration (mg/kg) of potassium (12,653.73), and moderate to high concentrations of calcium (3839.12), magnesium (477.52), and sodium (130.13). The least available metal was zinc with value of 1.9 mg/kg. Heavy metal composition showed < 0.1 mg/kg values for Pb, Cd, As and Hg and < 0.2 mg/kg for Cobalt and Chromium.

Determination of optimum fermentable sugar concentration for bacterial growth

The optimum and range of fermentable sugar concentration was tested in molasses supplemented with 5% (V/V) of 40% urea and 5 g/L of NaCl at 35 °C. For optimal molasses concentration, different concentrations of fermentable sugar were applied (viz., 5, 10, 15 and 20%) to production media. The molasses media was autoclaved and supplemented with filter sterilized urea. The cell growth was monitored by measuring the optical density of the samples at OD600 using a spectrophotometer (GENESYS™ 20, Thermo Fisher Scientific). The recording was done at 2 h interval and was conducted between 0 and 24 h (Fig. 1).

After 24 h of incubation, all the three strains were able to grow within molasses fermentable sugar concentrations of 5–15%. The optimum growth; defined as ≥ 75% of the highest growth rate achieved [26] was recorded at sugar concentrations of 10%. Therefore, 10% fermentable sugar dilution was taken as a dilution factor for bacterial growth and production of bioenzyme through submerged fermentation.

Proximate analysis of molasses and bioenzymes

The proximate analysis of the substrate (molasses) and bioenzymes was analyzed and presented in the following table.

The proximate analysis showed that the pH of bioenzymes was slightly acidic (pH = 5.6–7.25). The protein concentration in molasses was lower than the bioenzymes, the highest being recorded for Sporosarcina pasteurii (1.22 g/100 g) and the least was recorded for Enterobacter bugadensis (0.84 g/100 g). The carbohydrate and energy content of molasses was higher than the contents in the bioenzymes (Table 3), indicating that much of the carbohydrate was consumed during fermentation.

Exchangeable bases and heavy metals concentration of molasses and bioenzymes

The mineral contents were determined by Flame Atomic Absorption Spectrometry and Graphite Flame Atomic Absorption Spectrometry according to the methods of AOAC (2005) [14].

Concentrations of exchangeable cations and heavy metals in bioenzymes are provided in Table 4. The bioenzymes have very high concentration of potassium (K), and moderately concentrated calcium (Ca) magnesium (Mg) and sodium (Na) (Table 4). The concentrations of toxic heavy metals in bioenzymes were found to be extremely low and were below the WHO/FAO (2001) permissible limit of 50.00 mg/kg, 3 mg/kg, 20.00 mg/kg, 2.00, 0.05 mg/kg for lead, cadmium, arsenic, mercury and chromium respectively [27, 28].

The higher concentrations of exchangeable cations in the bioenzymes may affect the stabilization process and can aggravate the expansion behavior of the problematic soils. It is true that the type of cations available in the soil can influence the nature of the clay soil. For example sodium (Na+) and potassium (K+) are monovalent ions, and their presence usually results in the greatest expansion potential. The expansive nature of soil having an abundance of multivalent cations is much less than that of a soil having only monovalent cations [29]. Sodium (Na +) causes the most of swelling in Illite and montmorillonite minerals [30]. Velasquez [31] reported that commercial bioenzyme stabilizer he studied had potassium (7800 mg/kg), and calcium (719 mg/kg), magnesium (337 mg/kg), and sodium (169 mg/kg) which are less than the results of this study. This could be due to the type of substrate (molasses) used for the fermentation or other production procedures. He also reported protein concentration in the undiluted product A was 9230 mg/L; which is comparable with the results of the present study (840–1220 mg/L) of crude protein.

Soil geotechnical property testing

Modification of the native soil

In the process of hardening and rendering soil to be a water resistant, measuring and ensuring the clay content of the soil at a minimum of 12–30% is a crucial procedure [20, 21, 29] In consequence, to bring the clay content within this range, the native soil was subjected to amendment using supplementary materials (aggregate and sand). After the soil blends were prepared, grain size distribution analysis was done and the results are presented below (Table 5).

As it is shown in the table above, trial 1 and 2 yielded clay proportion in the recommended range of 12–30%. Thus, for the purpose of this study 40:30:30 mix ratio was selected as it is economical in requiring only 30% sand 30% aggregates and yielded 24.99% clay proportion which is best supported by the literature. Literatures showed that enzymatic emulsions could be applied on a wide variety of soils on condition of a minimum clay content presence. Rauch et al. [20] reported that liquid stabilizer products for treating road base materials work best in soils containing cohesive fines (finer than the No. 200 mesh size) between 18 and 30% and at a moisture content of 2–3% below optimum. According to Stan and Ciobanu [21], the minimum clay content has to be in common conditions of at least 10%, and best results were usually obtained in soils having clay content between 12 and 24% and even between 25 and 30% in some products, presenting plasticity indexes between 8 and 35%. Quackenboss et al. [65] claimed that in a process for hardening a roadbed with enzyme emulsions, the clay content of the road bed soil should be a minimum of 12%. Therefore, amending the native soil is an important procedure to bring the clay content within this range.

Chemical properties of the natural and treated soils

The chemical properties of treated and untreated soil samples were analyzed at Ethiopian Construction Design and Supervision works corporation, soil fertility testing laboratory. The analysis showed that the natural soil had pH of 7.82, electrical conductivity of 0.28 mS/cm, moisture content of 16.33%, cation exchange capacity of 93.57 meq/100 g and 5.21% of organic matter. The amount of exchangeable bases yielded 16.33, 1.54, 0.81, 66.07, and 15.82 meq/100 g of sodium, potassium, calcium, and magnesium, respectively (Table. 6).

The natural soil was slightly alkaline (pH = 7.82) and the addition bioenzymes reduced the pH of the treated soils (pH = 6.7–7.2) though permazyme treatment brought no pH change. In bioenzymes treated soil samples, both electrical conductivity (EC) and cation exchange capacity (CEC) showed an increase of 7–982% and 2–61% respectively. Exchangeable bases and organic matter content also showed increase in bioenzyme treated soils. Permazyme treated soils showed a very minor change in their chemical properties as compared to the natural soil. Organic matter content also showed an increase (35–193%) in bioenzyme treated soils.

Cation exchange capacity is the most important physico-chemical characteristic of expansive black soils [32]. This property is linked to their chemical activity and common cation substitutions. Cations are attracted and adsorbed onto a charged clay surface or absorbed into of the inter-clay particles via cation exchange activity [33]. The common range of cation exchange capacity of black cotton soil is 70–130 (maximum 145) meq/100 g [34], which is in agreement with the present study (93.57 meq/100 g). On the other hand, black cotton soils have a high surface area of 600–800 m2/g [35]; which is also associated with a high negative surface charge that attracts water and leads to substantial swelling when exposed to water. Owing to the high surface area, the native black cotton soils are prone to have a higher swell potential.

In the present study, the CEC was increased in bioenzyme treated soils, possibly be due to the effects of higher exchangeable cation concentrations in the bioenzymes (Table 6). In general, higher CEC values of soils are correlated with a high swelling potential of a soil and indicates a higher surface activity [36]. Thus, soil samples treated with this bioenzymes are expected to exhibit higher expansion than the native soil. Akbulut and Arasan [62] reported a decrease in CEC of soils treated with fly ash. Organic matter content is also the other factor responsible for expansive properties of soils [32]. In the present study, the higher increase of organic matter content in the bioenzyme treated soils may produced sufficient organic matter that can blanket the clay surface during the stabilization process [5]. Literatures showed that the binding of organic matter to clay mineral particles directly affects the properties of minerals such as cation exchange capacity [64] and their wettability [37]. Nevertheless, it should be noted that additive stabilization (lime and cement) of soils is not particularly effective when more than 2% of organic matter is present in the material being stabilized [30].

Geotechnical properties of the untreated natural and modified soil samples

A series of geotechnical tests were performed on the control soils (natural and modified) to characterize and comprehend the behavior of the soil before treatment. The test results of engineering properties of the natural and modified soils are presented in Table 7.

The natural soil was grayish black in color, 62% of the content had passed through No. 200 sieve; exhibited 96.85%, 49.04%, 47.81%, 22.75%, 125%, 25.71% and 1.62% of a liquid limit, plastic limit, plasticity index, OMC, free swell, linear shrinkage, and CBR respectively (Table 7). The Blended (modified) soil had cohesive fines of 25.16% pass at #200 sieve and showed an improved engineering properties. Dakshanamurthy and Raman [38] classified soils into low, medium, high, and very high degrees of potential expansiveness based on their plasticity index and liquid limit. Thus the native soil under study was classified as soil with very high swelling potential. In addition, clay layers having a high swelling potential, PI > 20, can exhibit considerable change in volume when subjected to a change in moisture content [63]. The soil was classified as A-7-5 and CH (high plastic clay soil) according to AASHTO and USCS, respectively. Soils under this class are generally classified as a material of poor engineering property to be used as a sub-grade material. Swelling characteristics analysis of the soil also showed that soil was highly expansive clay with a free swell of about 115%, maximum dry density of 1.383 g/cm3 and CBR of 1.65%.

The high values of liquid limit (LL), plastic limit (PI), and plasticity index (PI) indicate the high water intake and water holding capacity of the native soil [39]. These characteristics are governed by the presence of monovalent exchangeable cations such as Na+ and the large specific surface areas of the clay particles [40]. The CBR of the natural soil (1.65%) was below 2% and according to ERA pavement design manual this kind of soil is categorized as S2 subgrade class which cannot support structures constructed on it unless special treatment is being made [41]. As a consequence, this kind of soils are considered as problematic and may result in serious damages to any structure constructed over them without appropriate treatment. They can cause extensive damage to any structure by reason of excessive vertical, horizontal, or differential movement.

The modified soil also had higher free swell value (95%), liquid limit (65.1%) and plasticity index (31.17%) which makes it a soil of higher swelling potential and weak soil that needs further treatment to be used as subgrade material.

Geotechnical properties of bioenzyme treated modified soil

Four locally produced crude bioenzymes and a commercial enzyme formulation, permazyme treated soil samples were tested to evaluate the improvement in the engineering properties. The soil samples were prepared at the respective target optimum moisture content (OMC) and uniformly mixed with bioenzymes then were allowed to cure for 14 days.

Testing for the atterberg limits of treated and untreated soil samples

Atterberg limits test is mainly adapted for the determination of plastic limit, liquid limit, and plasticity index of soil samples [42]. It is used to define plasticity characteristics of clays and also plays an important role in soil identification and classification [43]. The test provided some additional information on the soils’ affinity for water, and it was observed that PI and LL values can indirectly reflect the soil’s swell potential before and after treatment.

As it is shown in the figure, all bioenzyme treated soil samples showed a decrease in both plasticity index and liquid limit. The highest decrease of plasticity index (14.25%) and liquid limit (35.58%) was recorded in soil treated with bioenzymes of Sporosarcina pasteurii with percentage reduction of plasticity index by 55.05%, liquid limit by 44.97% and plasticity limit by 35.43% as compared with the untreated modified soil. Improved atterberg results were also recorded for Permazyme with percentage reduction of (PI = 0.79%, LL = 15.04% and PL = 28.55%), Bacillus paramycoides (PI = 16.56%, LL = 8.06% and PL = 0%), Citrobacter sedlakii (PI = 18.61% and LL = 5.83%) and in molasses treated soil sample (LL = 9.12% and PL = 24.69%). Generally, as compared to commercial bioenzyme stabilizer (permazyme), locally produced bioenzymes showed improved atterberg limits (Fig. 2).

The aim of bioenzyme treatment was to reduce the values of LL and PI, so that the soil meets the recommended values for sub-grade material; LL ≤ 60% and PI ≤ 30 [44]. When the value for the PI and LL is higher there is a great tendency of soil to shrink upon drying and swell upon wetting [36]. The test results showed that, the atterberg limits of bioenzyme treated soil samples were substantially improved as compared to the modified untreated soil. Except soil samples treated with bioenzyme of Enterobacter bugadensis, the liquid limits of the treated soil samples were improved from 5 to 55% and the plasticity index showed improvement of 0.7–18%.

The decrease in PI and LL values are generally associated with a reduction in the potential for swelling and water absorption [17]. This implies that amount of water at which the treated soil samples need to behave like a liquid and plastic was decreased as they were treated. The reduction in the plasticity of the soil may be attributed to the reduction in the thickness of the adsorbed water that envelops each of the clay particles of the soil sample due the stabilization effect of the bioenzymes. For the untreated soil, the negatively charged surface of the clay particles attract the positively charged hydrogen ions of soil water, thereby causing a thin-filmed envelop of the clay particles by the water (adsorbed water) [45].

The application of the bio-enzyme could also reduced the electric charge of the hydrogen ions in the adsorbed water molecules, thereby making their bond with the clay particles to be either lost or weakened [31]. This, therefore, reduced the thickness of the film of adsorbed water that enveloped the clay particles. A reduction in the thickness of this film of adsorbed water is known to lead to a reduction in the plasticity of soils [46]. Consequently, the soil became more workable as it was mixed with bio-enzymes.

The results of the present study showed better atterberg values than a report by Admassu [47] who reported (LL = 86.4%, PL = 36.04% and PI = 50%) for black-cotton soil treated with permazyme. In addition, the percentage improvement of the plasticity index values of obtained with bioenzyme of Sporosarcina pasteurii (PI = 55.05%), Bacillus paramycoides (PI = 16.56%), and Citrobacter sedlakii (PI = 18.61%) was shown to be better than a reported result by Ganapathy et al.(2017) [45] who reported reduction of the plasticity index of the untreated clayey sand soil by 11.2%, by the application of 400 mL/m3 of unexplained commercial bioenzyme soil stabilizer. Ravi Shankar et al. [48] in their study of bio-enzyme stabilized lateritic soil as a highway material reported that TerraZyme was found to be ineffective in improving consistency limits. Mgangira [49] also reported that, treatment of the black and reddish brown soil samples with Permazyme-11 × and EarthZyme, lead only to a slight decrease in plasticity index (from 37 to 35%). Eujine et al. [50] reported that clay treated with TerraZyme showed an increase in liquid limit by 28% in the first 2 weeks and later decreased and little effect was observed on the plasticity limit of the treated soil.

California bearing ratio (CBR)

The California Bearing Ratio (CBR) test is used to evaluate the potential strength of sub-grade materials used for in road pavements [13]. It is one of the major factors used in pavement design to determine how thick the pavement should be and to rate the suitability of sub-grade soils to carry the overall pavement load [51]. For the purpose of this study, soaked CBR tests were conducted on the natural soil sample as well as bioenzymes treated soil samples with four locally produced bioenzymes and a commercial bioenzymes stabilizer (Permazyme) in accordance to AASHTO T193 [13]. Soaking of CBR specimen prior to penetration test was used to simulate the field condition of the worst condition because of high rain fall and complete saturation of the entire soil mass in the study area. The Soaked CBR of treated soil samples was tested after 7 days of curing. As it is shown in the figure below, the natural soil had very low CBR value of 1.65% and the modified soil yielded CBR of 8.5%. Molasses treated modified soil showed CBR value of 10.64% and except soil sample treated with bioenzyme of Enterobacter bugadensis (CBR = 6.08%), all bioenzyme treated and cured modified soil samples showed improved CBR values. Accordingly, samples treated with bioenzyme of Bacillus paramycoides, Citrobacter sedlakii and Sporosarcina pasteurii showed higher CBR values of 12.9%, 12.27%, and 11.95% respectively. As compared to untreated modified soil, the CBR was improved by 51.76% (Bacillus paramycoides), 44.35% (Citrobacter sedlakii), 40.59% (Sporosarcina pasteurii), and 36.47% (Permazyme) (Fig. 3).

According to ERA (2002) [10], based on their CBR values sub-grade materials are categorized as very poor (CBR = 0–3%), poor to fair (CBR = 3–7%), fair (CBR = 7–20%), good (CBR = 20–50%) and excellent (CBR > 50%) to be used as a sub-grade material. As it is shown in Fig. 4, except soil treated with bioenzyme of Enterobacter bugadensis (CBR = 6.08%), all bioenzyme treated soils showed CBR values ≥ 7.00%; which greater than the minimum required subgrade strength for minor gravel roads (ERA 2011) [44]. The CBR values of this study were better than the reported values of black cotton-aggregate mix treated with commercial bioenzyme stabilizer permazyme (CBR < 7.00) by Admassu [47] and Gayatri and Shyla [52], who reported CBR improvement for black cotton soil from 1.49% to 9.67% treated with TerraZyme. Eujine et al. [53] reported soaked CBR < 7% for enzyme treated and 4 weeks cured kaolinitic natural soil. The differences in the reported results could be due to differences in the soil type and mixture, type of bioenzyme used, experimental setup and others.

Several researchers tried to explain the possible mechanism of improvement in enzyme treated soils. According to Scholen [5] enzymes might induced the aggregation of clay particles forming an interconnected network of clay, sand and aggregates through organic cation bridging and hydrogen bonds. Enzyme proteins could also be adsorbed to the clay particles modifying the electrochemical properties of clay particle [54]. Pfeiffer [55] explained that enzymes may predominantly attach with the clay substrate, alter the clay molecule, and later reattach itself from the modified clay by returning to its original form after the reaction is concluded.

Free swell index

Expansive soils, especially black cotton soils tend swell-up when the moisture content in the soil mass increases [56]. The free swell test is one of the most frequently used simple tests to estimate the swelling Potential of expansive clays. Free swell test is considered as a measurement of volume change in clay upon saturation. The test was conducted following standard procedure IS: 2720 (Part 40) [23]. The analysis included untreated natural and mixed, bioenzymes treated, and permazyme treated and 7 days cured soil samples. As it is shown in Fig. 5, the untreated natural and modified soil samples had free swell of 125% and 95%. As compared to the untreated modified soil, free swell was reduced in soil samples treated with bioenzymes of Sporosarcina pasteurii (47.37%), Bacillus paramycoides (30%), and Citrobacter sedlakii (10.53%). On the other hand, molasses treated soil showed the highest swell index (192%); which is even higher than the natural soil (125%). The commercial bioezyme stabilizer (Permazyme) couldn’t improve the free swell index and increased it with 42.11% (Fig. 4).

Free swell test is used to study the expansiveness of a soil by measuring the volume of 24 h soaked and settled soil samples. The test was conducted following standard procedure IS: 2720 (Part 40) [23]. Based on their free swell (FS) properties, the degree of expansiveness of soils can be classified as: low (FS < 20%), moderate (FS = 20–35%), high (FS = 35–50%) and very high (FS > 50) [32]. From the results of the present study all bioenzyme treated soil samples showed free-swell potential of FS ≥ 50 and can be categorized as soils with high degree of expansiveness. But, as compared to the modified soil bioenzyme of Sporosarcina pasteurii, Bacillus paramycoides, and Citrobacter sedlakii decreased the free swell 47.37%, 30% and 10.53% respectively. This improvement could be due to attributed to the effects of the bioenzymes, in reducing the surface area of clay minerals which leads to decreasing the quantity of absorbed water by the clay mineral surfaces [5]. Literatures also showed that, free swell of soils is determined by the type and concentration of cations and it was proved that soil swelling potential increases as pore salt concentration, and exchangeable cation valence increase [32]. The lower percentage improvement in free swell properties of the treated soils could be related to the higher concentration of exchangeable metallic cations in the bioenzymes.

The effects of bioenzymes on linear shrinkage

Linear shrinkage is a measure of how a soil sample will reduce in length upon complete drying expressed as a percentage of the original length [32]. In the present study linear shrinkage test was carried out to determine the characteristics of black cotton soil treated with four locally produced bioenzymes and permazyme then cured for 7 days. The test was conducted in accordance with BS1377 Part-2 [24]. The natural soil and modified soils had linear shrinkage values of 25.71% and 17.15%. After treatment linear shrinkage values showed reduction in soils treated with bioenzyme of Sporosarcina pasteuri (10.35%), Permazyme (15.36%), Citrobacter sedlakii (15.71%) and Bacillus paramycoides (15.72%) with percentage improvement of 39.65%, 10.44%, 8.4%, and 8.34% respectively. Molasses and bioenzyme of Enterobacter bugadensis treated soil samples couldn’t improve the linear shrinkage of modified soil (Table 8).

The linear shrinkage values obtained in some of bioenzyme treated soils in this study are better than a report by Admassu [47] who reported linear shrinkage value of 17.5% in black cotton soil treated with permazyme and less effective than a result reported by Taye [57] who reported 3.6–10% shrinkage value for back cotton soil treated with a mixture of molasses and cement.

Compaction characteristics of bioenzyme treated soils

Compaction is the process by which the soil particles are artificially rearranged and packed together into a state of closer contact by mechanical means in order to decrease its porosity and thereby increase its dry density [58]. Modified Proctor test protocol was employed to determine the relationship between maximum dry density and optimum moisture content of soil samples during compaction following standard procedure AASHTO T-180 [13]. The test was intended to determine the optimum moisture content at which the maximum dry density of a soil sample be achieved for a particular compaction effort. The natural soil showed maximum dry density of 1.3 g/cm3 and optimum moisture content of 29.8%. This is the indication that the natural soil have heavy clay and can hold high amount of moisture which makes it weak and unstable [59]. During road construction, the dry density and moisture content of such soil should be modified from its original state by compaction.

As it is shown in the figure above (Fig. 5), permazyme treated soil exhibited the highest maximum dry density (2.16%) with the lowest optimum moisture content (9.3%). Followed by molasses (MDD = 2.09%). The maximum dry density values showed insignificant improvement in bioenzyme treated modified soil samples. The optimum moisture content also showed an increase except bioenzyme of B. paramycoides (14.05%). The same case was reported by Yilmaz et al. [66] where the maximum dry density of enzyme treated soils remains the same after four weeks of curing. Rauch et al. [20] and Admassu [47] also reported insignificant change of MDD in enzyme treated soils.

Unconsolidated-undrained triaxial compression testing

Unconsolidated-undrained triaxial compression test was conducted for the determination of undrained shear strength and stress–strain relationships of a cylindrical specimen of disturbed, remolded and bioenzyme treated soil samples. Sub grade materials are often characterized using unconfined compression tests, but testing in a triaxial cell yields a more reliable measure of strength [20]. The tests were performed on blended black cotton soil samples treated with different bioenzymes. Laboratory testing was done following standard test method for unconsolidated-undrained triaxial compression test on cohesive soils ASTM D2850 [22]. Untreated (natural and modified), molasses, and five bioenzyme treated soil samples were tested and the treated samples were allowed to cure for 7 days then, cohesion and angle of shear resistance values were determined (Table 9).

The natural soil had the highest cohesion (205 kN/m3) and the lowest angle of internal friction (2 °). The modified untreated soil showed 24.57 degrees of angle of internal friction and cohesion of 51.42 kN/m3. As compared to the untreated modified soil, angle of internal friction increased in soil samples treated with bioenzyme of Bacillus paramycoides (7.69%), and Citrobacter sedlakii (6.06%), while it decreased in soil samples treated with molasses (37.61%), permazyme (52.14%), S. pasteuri (15.55%) and E. bugadensis (12.7%). Cohesion showed an increase in all treated soils and the highest cohesion (107.47 kN/m3) was recorded in molasses treated soil while the lowest cohesion (46.5 kN/m3) was recorded with soil treated with Bacillus paramycoides. As compared to permazyme, both angle of internal friction and cohesion showed better improvement in locally produced bioenzymes (Table 9).

Measure of angle of internal friction and cohesion are vital parameters which control the shear strength of soil. Das and Maharana [60] reported angle of internal friction from 7 to 10 °and cohesion of 29–42 kN/m3 in TerraZyme treated expansive soil which is lower than the results of the present study. The results of the present study were lower than a report by Fraser et al. [61] who reported angle of internal friction of 37.02 degrees of angle of internal friction and 122 kPa of cohesion for permazyme treated native brown clay soil blended with 50% aggregates. The difference in the results could be due to the difference in the soil samples used, the percentage of the blended aggregates and sand, the laboratory setup and the difference in the type of bioenzymes used for treatment.

Conclusion

It is possible to produce soil stabilizing bioenzymes using ureolytic bacteria under submerged fermentation. It was also concluded that bioenzyme treatment of expansive soils can improve the subgrade quality for use as road pavement layer material but such it was observed that the improvements were not sufficient to make the soil suitably used as sub-base or base course materials. Bioenzyme treated soils fulfilled the minimum requirement as subgrade for low volume roads. Therefore it is possible to use them for light rural gravel roads, pedestrian walkways and bicycle tracks. Therefore, it was recommend that exploring the potentials of other microbes will be helpful to exploit the gift of nature, conducting field trial tests at different climatic conditions and different soil types is mandatory to establish specification manual to enable large scale production and usage, fermentations trials should be conducted using alternative cheap substrates, and trials tests should be done with a combination of a bioenzyme and portland cement which may produce higher percentage improvement in their plasticity, strength and permeability characteristics.

Abbreviations

- AACRA:

-

Addis Ababa City Roads Authority

- AASHTO:

-

American Association of State Highway and Transportation Officials

- ALBC:

-

Afghan Lever Brothers Group Companies

- AOAC:

-

Association of Official Analytical Chemists

- ASTM:

-

American Society for Testing and Materials

- BCS:

-

Black cotton soil

- BSA:

-

Bovine serum albumin

- CBR:

-

California bearing ratio

- CEC:

-

Cation exchange capacity

- DAAD:

-

German academic exchange service

- DSMZ:

-

Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH

- EC:

-

Electrical conductivity

- ERA:

-

Ethiopian roads authority

- FAO:

-

Food and agricultural organization

- FS:

-

Free swell

- LL:

-

Liquid limit

- MDD:

-

Maximum dry density

- OMC:

-

Optimum moisture content

- OVAT:

-

One variable at a time

- PCR:

-

Polymerase chain reaction

- PI:

-

Plasticity index

- PL:

-

Plasticity limit

- PLC:

-

Private limited company

- rRNA:

-

Ribosomal ribose nucleic acid

- UNESCO:

-

United Nations Educational, Scientific and Cultural Organization

- USA:

-

United States of America

- USCS:

-

Unified Soil Classification System

- WHO:

-

World Health Organization

References

Afrin H (2017) A review on different types soil stabilization techniques. Int J Transp Eng Technol 3(2):19–24. https://doi.org/10.11648/j.ijtet.20170302.12

Amu OO, Owokade OS, Shitan OI (2011) Potentials of coconut shell and husk ash on the geotechnical properties of lateritic soil for road works. Int J Eng Technol 3(2):87–94

Onyelowe K, Igboayaka C, Orji F, Ugwuanyi H (2018) Rheology of mechanical properties of soft soil and stabilization protocols in the developing countries—Nigeria. Niger Mater Sci Energy Technol. https://doi.org/10.1016/j.mset.2018.10.001

Vijay R, Kaur S (2014) A review on stabilization of soil using bioenzyme. Int J Res Eng Technol 03(1):75–78. https://doi.org/10.1623/ijret.2014.0301011

Scholen DE (1995) Stabilizer mechanisms in nonstandard stabilizers. In: Conference proceedings 6 sixth international conference on low-volume roads II (TRB National research council Washington DC), pp 252–260

Alizadeh H, Kandula D, Hampton J, Stewart A, Leung D, Edwards Y (2014) Screening and identification of urease producing microorganisms from New Zealand pasture soils. Bio Protect 11:78–85. https://doi.org/10.1016/j.geodrs.2017.10.003

Phang IR, Chan YS, Wong KS, Lau SY (2018) Isolation and characterization of urease-producing bacteria from tropical peat. Biocatal Agric Biotechnol 13:168–175. https://doi.org/10.1016/j.bcab.2017.12.006

Dejong JT, Fritzges MB, Nüsslein K (2006) Microbially induced cementation to control sand response to undrained shear. J Geotech Geoenviron Eng 11:1381–1392. https://doi.org/10.1061/(ASCE)1090-0241(2006)132:11(1381)

Tesema G, Worrell E (2015) Energy efficiency improvement potentials for the cement industry in Ethiopia. Energy 93:2042–2052. https://doi.org/10.1016/j.energy.2015.10.057

ERA (2002) Cement and Lime Stabilized Materials. Pavement Des Man Flex Pavement Gravel Roads 1(7):1–5

Negawo W, Di Emidio G, Bezuijen A, Verastegui D, François B (2017) Lime-stabilisation of high plasticity swelling clay from Ethiopia. Eur J Environ Civ Eng 23(4):504–514. https://doi.org/10.1080/19648189.2017.1304272

Tesfahun A (2010) Performance of unconventional soil stabilizers in stabilization of substandard materials for road subgrade & subbase. Msc Thesis, Addis Ababa University

AASHTO (2010) Standard specifications for transportation materials and methods of sampling and testing, 14th edn. American association of state highway and transportation officials, Washington

AOAC (2006) Official methods of analysis of AOAC International. In: W liam Horwitz, G W Latimer (eds) 18th ed. Gaithersburg, Official Method 2005.08: AOAC International

Kundu S, Tapobrata Panda SK, Barun G, Bandyopadhyay KK (1984) Pretreatment of indian cane molasses for increased production of citric acid. Biotechnol Bioeng 26(9):1114–1121

Malika M, Abdelkader EH (2013) Lactic Acid Fermentation of a Diluted Molasses Medium by Two Strains of Lactococcus lactis ssp. Immobilized on Pouzzolane and Bone Bovine, in: Locals and Naturals Bio-Resources Laboratory. Faculty of Sciences, University Hassiba Benbouali Chlef. BP. Chlef (02000), Algeria, Chief Algeria, pp. 774–784.

He S (2019) Chemical Stabilization of Expansive Soils Using Liquid Ionic Soil Stabilizers. Phd Dissertation, University of Texas

Popescu ME (1986) A comparison between the behavior of swelling of clayey soils. Geotech Eng 12:19–39

Rayment GE, Lyons DL (2011) Soil chemical methods—Australasia soil use and management, vol 27. CSIRO Publications, Melbourne. https://doi.org/10.1111/j.1475-2743.2010.00322.x

Rauch AF, Katz LE, Liljestrand, (2003) An analysis of the mechanisms and efficacy of theree liquid chemical soil stabilizers: a report center for transportation research. The University of Texas, Austin

Stan C, Ciobanu V (2012) Using enzymatic emulsions to reinforce road layers. Bulletin of the Transilvania University of Braşov. Transilvania University of Braşov, Braşov

ASTM (2009) American society for testing and materials, annual book of astm standards (Standard T). ASTM International, West Conshohocken

IS (1978) Determination of free swell index of soils method of test for soils. Manak Bhavan. Bureau of Indian Standards, New Delhi

BS (2003) Methods of test for: soils for civil engineering purposes. British Standards, London

Gratchev I, Saeidi S (2018) Free swell of compacted plastic soils. Int J Geotech Eng. https://doi.org/10.1080/19386362.2018.1550922

Pascual J, Foesel U, Geppert A, Hube KJ, Boedeker C, Luckner M et al (2018) Member of the under-represented phylum Gemmatimonadetes. Int J Syst Evol Microbiol 68:1028–1036. https://doi.org/10.1099/ijsem.0.002619

Hellen LE, Othman OC (2014) Levels of selected heavy metals in soil tomatoes and selected vegetables from Lushoto district Tanzania. Int J Environ Monit Anal 2(6):313–319. https://doi.org/10.11648/j.ijema.20140206.13

Fosu-mensah BY, Addae E, Yirenya-tawiah D, Nyame F (2017) Heavy metals concentration and distribution in soils and vegetation at Korle lagoon area in Accra. Cogent Environ Sci 2016:1–14. https://doi.org/10.1080/23311843.2017.1405887

Nelson DJ, Chao KC, Overton DD, Nelson DJ (2015) Foundation engineering for expansive soils, 1st edn. John Wiley Sons Inc, Hoboken

Lay MG (2009) Handbook of road technology, 4th edn. Spon Press, Londan

Velasquez R, Marasteanu MO, Clyne A (2005) Preliminary laboratory investigation of enzymes, Technical Report nesota Department of Civil Engineering 500 Pillsbury Drive S

Al-Rawas AA, Goosen MF (2006) Expansive soils: recent advances in characterization and treatment. Taylor and Francis Group, Londan

Yunan D, Xianliang Q, Xiaochen W (2018) Study on cation exchange capacity of agricultural soils. IOP Conf Series Mater Sci Eng 392(4):42039. https://doi.org/10.1088/1757-899X/392/4/042039

Pollard CE, Weaver LD (1973) The chemistry of clay minerals developments in sedimentology geological magazine. Elsevier Scientific Publishing Company, Amsterdam

Mitchell JK, Soga K (2005) Fundamentals of soil behaviour Canada. . John Wiley & Sons Inc, Hoboken

Nelson JD, Mille DJ (1993) Expansive soils—problems and practice in foundation and pavement engineering. Int J Numer Anal Methods Geomechan 17(10):1–27. https://doi.org/10.1002/nag.1610171006

Chenu C, Le Bissonnais Y, Arrouays D (2000) Organic matter influence on clay wettability and soil aggregate stability. Soil Sci Soc Am J. https://doi.org/10.2136/sssaj2000.6441479x

Dakshanamurthy V, Raman V (1973) A simple method of identifying an expansive soil soils and foundations. Jpn Soc SMFE 13:97–104

Azam S Al-Shayea N (1999) Clayey behavior of calcareous soils. In: 2nd International conference on engineering for calcareous sediments, Bahrain. pp 199–208

Van Olphen H (1977) An introduction to clay colloid chemistry for clay technologists geologists and soil scientists. Wiley-Interscience, New York

ERA (2013) Pavement Design Manual: Flexible Pavements, vol I. Ethiopian Roads Authority, Addis Ababa

Das BM (2010) Geotechnical engineering hand book, 1st edn. J Ross Publishing, Florida

Ahmed H (2006) Treatment and improvement of the geotechnical properties of different soft fine-grained soils using chemical stabilization. Thesis, Der Martin-Luther-Universität Halle-Wittenberg eingereicht.

ERA (2011) Design manual for low volume roads: road maintenance booklet (part-G). Ethiopian Roads Authority, Addis Ababa

Ganapathy GP et al (2017) Bio-enzymatic stabilization of a soil having poor engineering properties. Int J Civil Eng 15(3):401–409. https://doi.org/10.1007/s40999-016-0056-8

Akinwumi I (2014) Soil modification by the application of steel slag. Period Polytech 58(4):371–377. https://doi.org/10.3311/PPci.7239

Admassu F (2017) Evaluation on the effect of bio-enzymatic and lime soil stabilization for black cotton soil, in Case of AASTU Road Bio-Enzyme Pilot Project 2017. Thesis, Addis Ababa Scienc and Technology University

Shankar R (2009) HK (2016) Bio-enzyme stabilized lateritic soil as a highway material as a highway material. J Indian Roads Congr 70:2

Mgangira MB (2009) Evaluation of the effects of enzyme based liquid chemical stabilizers on subgrade soils. In: Proceedings of the 28th Southern African Transport conference, Document Transformation Technologies CC, Pretoria

Eujine GN, Somervell LTCS, Sankar N (2014) Enzyme stabilization of high liquid limit clay. EJGE 19:6989–6985

VDOT (2019) Soils and aggregate compaction. The Virginia Department of Transportation (VDOT) Materials Division, Virginia

Gayatri N, Shyla J (2016) Effect of bioenzyme and geotextile on strength characteristics of subgrade soil. Int Res J Eng Technol 03(08):1891–1897

Eujine GN, Chandrakaran S, Sankar N (2017) Accelerated subgrade stabilization using enzymatic lime technique. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001923

Franchi MP, Ferris J, Gallori E (2003) Cations as mediators of the adsorption of nucleic acids on clay surfaces in prebiotic environments origins of life and evolution of the biosphere. J Int Soc Study Origin Life 33:1–16. https://doi.org/10.1023/A:1023982008714

Pfeiffer J (1954) Enzymes, the physics and chemistry of life. Simonand Schuster, NewYork

Gourley CS, Newill D, Schreiner HD (1993) Expansive soils TRL's research strategy. In: Proceedings of the first international symposium on engineering characteristics of arid soils, City University, London

Taye B (2015) Stabilization of expansive clay soil with sugar cane molasess and cement. MSc. Thesis, Addis Ababa University. Ethiopia

Venkataramaiah L (2003) Building on expansive clay with special reference to trinidad. West Indian J. Eng 25:43–53

Boyle A, Brennan MJ, Knapton J, Khalid HA, McElvaney J, McMullen D et al (2002) Highways: the location, design, construction, and maintenance of pavements. CAO Flaherty (eds) (4th ed). Elsivier Ltd., Burlington

Das and Maharana (2017) AN investigation on behaviour of bio enzyme stabilized expansive soil. Int J Recent Sci Res 8(2000):19029–19034. https://doi.org/10.24327/IJRSR

Fraser B, Cheng D, Hicks G (2010) Permazyme Testing, vol I. Final Summary Report, California

Akbulut S, Arasan S (2010) The variations of cation exchange capacity, ph, and zeta potential in expansive soils treated by additives. Int J Civ Struct Eng 1(2):139–154. https://doi.org/10.6088/ijcser.00202010012

Duncan CI (1992) Soils and foundations for architects and engineers, 1st edn. Springer Science and Business Media PLC, New York. https://doi.org/10.1007/978-1-4757-6545-8

Holtz DR, Kovacs DW (1981) Contribution of organic matter to cation exchange capacity and specific surface area of fractionated soil materials. Soil Sci. https://doi.org/10.1097/00010694-198910000-00003

Quackenboss JS, Lockwood EF, Lujan TR, Stone DK, Dennis KS (2013) Waterproof Roadbed Construction. US Patent, 8:348,547 B2.US 8,348,547 B2. United States patent. USA

Yilmaz YA, Avsar C (2009) Stabilization of clays using liquid enzymes. In: Erol T, Imad AQ (eds) International conference on the bearing capacity of roads. CRC Press, Florida. https://doi.org/10.1201/9780203865286.ch8

Acknowledgements

We acknowledge Addis Ababa Science and Technology, Ethiopia for providing laboratory facilities during soil sample collection, bacterial isolation and culturing work. We also acknowledge Leibniz-Institute DSMZDeutscheSammlung von Mikroorganismen und Zellkulturen, Braunschweig, Germany for providing facility during molecular and physiological characterization of the isolates. This work was supported by Ministry of Science and Higher education (Ethiopia), Ministry of Science and Technology (Ethiopia), DAAD [Grant Number: 57381332, 2018]. Finally we declare that there is no conflict of interest in this piece of work.

Author information

Authors and Affiliations

Contributions

This research is being done with the effort of five authors. First author had carried out the study and wrote the manuscript under the guidance of fifth author. Second and third authors supervised field soil sampling and geotechnical studies. The fourth author supervised bioenzyme fermentation and mixing experiments. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Consent for publication

Authors agreed that the findings to be published in the Springer’s “International Journal of Geo-Engineering”.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mekonnen, E., Amdie, Y., Etefa, H. et al. Stabilization of expansive black cotton soil using bioenzymes produced by ureolytic bacteria. Geo-Engineering 13, 10 (2022). https://doi.org/10.1186/s40703-022-00175-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-022-00175-6