Abstract

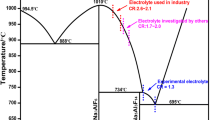

Zirconium is one of the widely demanded materials, while the existing methods of its production are multistage and energy-intensive. The paper proposes a method for extracting zirconium from its oxide by electrolysis of low-temperature oxide-fluoride melt KF–AlF3–Al2O3–ZrO2 with a temperature of 750°C. For this purpose, the potentials for the electroreduction of zirconium and aluminum ions on a glassy carbon electrode have been determined by means of voltammetric methods. It was shown that the electroreduction of aluminum ions in the KF–AlF3–Al2O3 melt occurs at a potential more negative than –0.05 V relative to the aluminum electrode with the formation of a cathode peak in the potential range from –0.18 to –0.2 V. With the addition of 1 wt % of ZrO2, cathode current on the voltammogram begins at a potential more negative than 0 V, and the cathode peak is formed at a potential of about –0.1 V. Similar results were observed in the study of the cathode process in the KF–AlF3–Al2O3 melt with and without the addition of ZrO2 by means of square-wave voltammetry. It has been suggested that, because of the lower bond energy, zirconium-containing electroactive ions are discharged at a potential that is 0.05–0.08 V more positive than the discharge potential of aluminum-containing ions. At a graphite cathode potential of –0.1 and –0.3 V relative to the aluminum electrode, the electrolysis of the KF–AlF3–Al2O3–ZrO2 melt was carried out, and the elemental and phase composition of the obtained deposits was determined by X-ray phase analysis, scanning electron microscopy, and energy dispersive microanalysis. It was shown that, at a potential of –0.1 V, a deposit with 98.5–99.5 wt % zirconium can be obtained. This indicates a reliable possibility of selective extraction of zirconium by the proposed method.

Similar content being viewed by others

REFERENCES

Yadernoe goryuchee i reaktornye metally (Nuclear Fuel and Reactor Metals), Bochvar, A.A., Ed., Moscow: Atomizdat, 1959.

Mansurov, Yu.N., Rakhmonov, J.U., and Aksyonov, A.A., Modified aluminum alloys of Al–Zr system for power transmission lines of Uzbekistan, Non-Ferrous Met. (Moscow, Russ. Fed.), 2020, no. 2, pp. 51–55. https://doi.org/10.17580/nfm.2020.02.06

Belov, N.A., Dostaeva, A.M., Shurkin, P.K., Korotkova, N.O., and Yakovlev, A.A., Impact of annealing on electrical resistivity and hardness of hot-rolled alloyed aluminum sheets with Zr content up to 0.5 wt %, Russ. J. Non-Ferrous Met., 2016, vol. 57, pp. 429–435. https://doi.org/10.17073/0021-3438-2016-3-48-55

Kolobov, G.A., Panov, V.S., and Rakova, N.N., Processes of secondary refractory rare metals (Review), Russ. J. Non-Ferrous Met., 2014, vol. 55, pp. 141–147. https://doi.org/10.17073/0021-3438-2014-1-41-48

Ogorodov, D.V., Popov, D.A., and Trapeznikov, A.V., Methods of obtaining Al-Zr ligature (review), Tr. Vseross. Inst. Aviats. Mater., 2015, no. 11, pp. 2–11. https://doi.org/10.18577/2307-6046-2015-0-11-2-2

Polyakova, L.P. and Stangrit, P.T., Cathodic processes at electrolysis of chloride and chloride-fluoride melts of zirconium, Electrochim. Acta, 1982, vol. 27, pp. 1641–1645. https://doi.org/10.1016/0013-4686(82)80092-3

Girginov, A., Tzvetkoff, T.Z., and Bojinov, M., Electrodeposition of refractory metals (Ti, Zr, Nb, Ta) from molten salt electrolytes, J. Appl. Electrochem., 1995, vol. 25, pp. 993–1003. https://doi.org/10.1007/BF00241947

Mellors, G.W. and Senderoff, S., The electrodeposition of coherent deposits of refractory metals. III. Zirconium, J. Electrochem. Soc., 1966, vol. 113, no. 1, pp. 60–66. https://doi.org/10.1149/1.2423865

Xu, L., Xiao, Y., Xu, Q., Song, Q., and Yang, Y., Electrochemistry of zirconium in molten chlorides, Int. J. Electrochem. Sci., 2017, vol. 12, no. 7, pp. 6393–6403. https://doi.org/10.20964/2017.07.51

Xiang, M., Zhang, Y., Jiang, F., Hong, M., Liu, Z., and Leng, J., Progress in electrodeposition of zirconium coating from molten salts, Chin. J. Rare Met., 2016, vol. 40, no. 6, pp. 620–625. https://doi.org/10.13373/j.cnki.cjrm.2016.06.016

Xu, L., Xiao, Y., Van Sandwijk, A., Xu, Q., and Yang, Y., Production of nuclear grade zirconium: A review, J. Nucl. Mater., 2015, vol. 466, pp. 21–28. https://doi.org/10.1016/j.jnucmat.2015.07.010

Mohandas, K.S. and Fray, D.J., Electrochemical deoxidation of solid zirconium dioxide in molten calcium chloride, Metall. Mater. Trans. B, 2009, vol. 40, pp. 685–699. https://doi.org/10.1007/s11663-009-9263-x

Peng, J., Li, G., Chen, H., Wang, D., Jin, X., and Chen, G.Z., Cyclic voltammetry of ZrO2 powder in the metallic cavity electrode in molten CaCl2, J. Electrochem. Soc., 2010, vol. 157, no. 1, pp. F1–F9. https://doi.org/10.1149/1.3244568

Shurov, N.I., Khramov, A.P., Zaikov, Yu.P., Kovrov, V.A., and Suzdaltsev, A.V., Reduction mechanism of oxides in calcium chloride melts, Russ. J. Non-Ferrous Met., 2015, vol. 56, pp. 267–271. https://doi.org/10.3103/S1067821215030207

Heck, S.C., De Oliveira, M.F., and Radovanovic, E., Ti production from natural rutile sand by the FFC process: Experimental and mathematical modelling study, J. Electroanal. Chem., 2022, vol. 905, p. 115996. https://doi.org/10.1016/j.jelechem.2021.115996

Li, Sh., Che, Yu., Song, J., Shu, Y., He, J., Xu, B., and Yang, B., Preparation of zirconium metal through electrolysis of zirconium oxycarbonitride anode, Sep. Purif. Technol., 2021, vol. 274, p. 118803. https://doi.org/10.1016/j.seppur.2021.118803

Li, Sh., Che, Yu., Shu, Y., He, J., Song, J., and Yang, B. Review–Preparation of zirconium metal by electrolysis, J. Electrochem. Soc., 2021, vol. 168, p. 062508. https://doi.org/10.1149/1945-7111/ac0996

Bao, M., Wang, Z.-W., Gao, B.-L., Shi, Z.-N., Hu, X.-W., and Yu, J.-Y., Electrical conductivity of NaF–AlF3–CaF2–Al2O3–ZrO2 molten salts, Trans. Nonferrous Met. Soc. China, 2013, vol. 23, pp. 3788–3792. https://doi.org/10.1016/S1003-6326(13)62930-1

Nerubashchenko, V.V., Voleinik, V.V., Krymov, A.P., Galochka, V.P., and Napalkov, V.I., Obtaining of aluminium-zirconium ligature in electrolysis baths, Tsvetn. Met. (Moscow, Russ. Fed.), 1978, no. 3, pp. 36–38.

Li, M., Li, Y., and Wang, Zh., Electrochemical reduction of zirconium oxide and co-deposition of Al–Zr alloy from cryolite molten salt, J. Electrochem. Soc., 2019, vol. 166, no. 2, pp. D65–D68. https://doi.org/10.1149/2.1291902jes

Gorlanov, E.S., Bazhin, V.Yu., and Fedorov, S.N., Carbide formation at a carbon-graphite lining cathode surface wettable with aluminum, Refract. Ind. Ceram., 2016, vol. 57, no. 3, pp. 292–296. https://doi.org/10.1007/s11148-016-9971-0

Wang, Z., Li, H., Zhang, C., Xue, J., and Liu, X., The role of TiB2 particles in the creep and penetrating resistance of graphite-based composite, Ceram. Int., 2021, vol. 47, pp. 12096–121031. https://doi.org/10.1016/j.ceramint.2021.01.054

Kontrik, M., Simko, F., Galuskova, D., Nosko, M., Bizovska, V., Hicak, M., Galusek, D., Rakhmatullin, A., and Korenko, M., A corrosion mechanism of titanium diboride in KF–AlF3–Al2O3 melt, J. Eur. Ceram. Soc., 2017, vol. 38, pp. 1143–1151. https://doi.org/10.1016/j.jeurceramsoc.2017.11.030

Sizyakov, V.M., Bazhin, V.Yu., and Vlasov, A.A., Status and prospects for growth of the aluminum industry, Metallurgist, 2010, vol. 54, nos. 7–8, pp. 409–414. https://doi.org/10.1007/s11015-010-9316-z

Suzdaltsev, A.V., Filatov, A.A., Nikolaev, A.Yu., Pankratov, A.A., Molchanova, N.G., and Zaikov, Yu.P., Extraction of scandium and zirconium from their oxides during the electrolysis of oxide-fluoride melts, Russ. Metall. (Engl. Transl.), 2018, vol. 2018, no. 2, pp. 133–138. https://doi.org/10.1134/S0036029518020180

Suzdal’tsev, A.V., Khramov, A.P., and Zaikov, Yu.P., Aluminum electrode for electrochemical studies in cryolite-alumina melts at 700–960°C, Russ. J. Electrochem., 2012, vol. 48, pp. 1153–1159. https://doi.org/10.1134/S1023193512120129

Vorobiev, A., Suzdaltsev, A.V., Pershin, P., Galashev, A., and Zaikov, Yu., Structure of MF–AlF3–ZrO2 (M = K, Na, Li) ionic melts, J. Mol. Liq., 2020, vol. 299, p. 112241. https://doi.org/10.1016/j.molliq.2019.112241

Roine, A., HSC Chemistry® [Software], Pori: Outotec, 2018. https://www.outotec.com/HSC.

Vorob’ov, A.S., Suzdaltsev, A.V., and Galashev, A., Binding energies in the molten M–Al–Zr–O–F systems (M = Li, Na, K), Rus. Metallurgy (Metally), 2019, vol. 2019, no. 8, pp. 781–786. https://doi.org/10.1134/S0036029519080160

Robert, E., Olsen, J.E., Danek, V., Tixhon, E., Ostvold, T., and Gilbert, B., Structure and thermodynamics of alkali fluoride-aluminum fluoride-alumina melts. Vapor pressure, solubility and Raman spectroscopic studies, J. Phys. Chem. B, 1997, vol. 101, pp. 9447–9457. https://doi.org/10.1021/jp9634520

Lyakishev, N.P., Diagrammy sostoyaniya dvoinykh metallicheskikh system. Spravochnik (State Diagrams of Binary Metal Systems. Handbook), Moscow: Mashinostroenie, 1996.

Salyulev, A.B., Moskalenko, N.I., Shishkin, V.Yu., and Zaikov, Yu.P., Selective evaporation of the components of molten (LiCl–KCl)eut–BaCl2–SrCl2–NdCl3 mixtures at low pressures, Russ. Metall. (Engl. Transl.), 2021, vol. 2021, pp. 151–158. https://doi.org/10.1134/S0036029521020233

Kaplan, G.E., Silina, G.F., and Ostroushko, Yu.I., Elektroliz v metallurgii redkikh metallov (Electrolysis for Metallurgy of Rare Metals) Moscow: Metallurgizdat, 1963.

ACKNOWLEDGMENTS

The phase and elemental analysis of cathode deposits was performed on the equipment of the Collective Use Center Composition of Material of the Institute of High Temperature Electrochemistry, Ural Branch, Russian Academy of Sciences (Yekaterinburg).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Chubarova

About this article

Cite this article

Filatov, A.A., Nikolaev, A.Y., Suzdaltsev, A.V. et al. Extraction of Zirconium from Its Oxide during Electrolysis of the KF–AlF3–Al2O3–ZrO2 Melts. Russ. J. Non-ferrous Metals 63, 379–384 (2022). https://doi.org/10.3103/S106782122204006X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782122204006X