Abstract

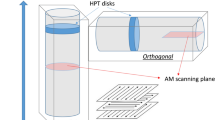

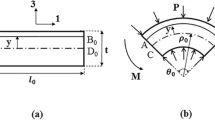

The article discusses the features of radial shear rolling (RSR) of the aluminum alloy Al–Mg–Sc. The modeling of the RSR process by the finite element method in the QForm 3D program with variation of the elongation ratio per pass and the rolling speed has been implemented. On the basis of the results obtained, a study of the temperature field of the rod in the deformation zone has been carried out taking into account the cyclic deformation and the configuration of the flow trajectories. It is found that changes in the temperature field of the rod in the deformation zone are determined by the difference in the trajectory flow of the metal in the surface layers and in the axial zone. When the elongation ratio is varied from 1.6 to 2.4, heating occurs inconsistently from the center to the surface. The largest increase occurs for an area that is approximately 0.3R from the surface. For the axial zone, the temperature change in the deformation zone occurs smoothly and with an insignificant temperature difference of 5–10°C. The temperature on the surface of the rod has the greatest temperature fluctuations, which are explained by deformation heating and simultaneous contact with a cold roll during each deformation cycle. With a decrease in the rolling speed, a picture of the distribution of the temperature field of the rod in the deformation zone is observed, when the temperature of the central layers exceeds the surface temperature. Because of the long contact time of the rod with the roll, the surface temperature fluctuates up to 40–50°C with each deformation cycle. With an increase in the rolling speed, the amplitude of temperature fluctuations on the surface decreases, and the deformation heating increases. The obtained data on the relationship of controlled technological parameters with a change in the temperature field of the rod can be useful in the design of technological modes of rolling.

Similar content being viewed by others

REFERENCES

Totten, G.E. and MacKenzie, D.S., Handbook of Aluminium, vol. 1: Physical Metallurgy and Processes, New York: Marcel Dekker, 2003.

Beletskii, V.M. and Krivov, G.A., Alyuminievye splavy (sostav, svoistva, tekhnologiya, primenenie). Spravochnik (Aluminum Alloys (Composition, Properties, Technology, Application). Handbook) Kyiv: KOMINTEKh, 2005.

Williams, J.C. and Starke, E.A., Progress in structural materials for aerospace systems, Acta Mater., 2003, vol. 51, no. 19, pp. 5775–5799. https://doi.org/10.1016/j.actamat.2003.08.023

Bronz, A.V., Efremov, V.I., Plotnikov, A.D., and Chernyavskii, A.G., Alloy 1570S is a material for sealed structures of promising reusable products of RSC ENERGIA, Kosm. Tekh. Tekhnol., 2014, no. 4 (7), pp. 62–67.

Hirsch, J., Aluminium sheet fabrication and processing, in Fundamentals of Aluminium Metallurgy: Production, Processing and Applications, Cambridge: Woodhead Publ., 2011, pp. 719–746. https://doi.org/10.1533/9780857090256.3.719.

Kleiner, M., Chatti, S., and Klaus, A., Metal forming techniques for lightweight construction, J. Mater. Process. Technol., 2006, vol. 177, nos. 1–3, pp. 2–7. https://doi.org/10.1016/j.jmatprotec.2006.04.085

Dobatkin, S.V., Zakharov, V.V., Perevezentsev, V.N., Rostova, T.D., Kopylov, V.N., and Raab, G.I., Mechanical properties of sub-microcrystalline Al–Mg (AMg6) and Al–Mg–Sc (01570) alloys, Tekhnol. Legk. Splavov, 2010, no. 1, pp. 74–84.

Uazyrkhanova, G.K., Rakhadilov, B.K., Vieleba, V.K., and Uazyrkhanova, Zh.K., Structure and mechanical properties of AMts and AMg6 aluminum alloys after plastic deformation, Vestn. Karagand. Univ. Ser.: Fiz., 2017, no. 3 (87), pp. 38–47.

Sitdikov, O., Avtokratova, E., Sakai, T., Tsuzaki, K., Kaibyshev, R., and Watanabe, Y., Effect of processing temperature on microstructure development during ECAP of Al–Mg–Sc alloy, Mater. Sci. Forum, 2008, vols. 584–586, pp. 481–486. https://doi.org/10.4028/www.scientific.net/msf.584-586.481

Sitdikov, O., Sakai, T., Avtokratova, E., Kaibyshev, R., Kimura, Y., and Tsuzaki, K., Grain refinement in a commercial Al–Mg–Sc alloy under hot ECAP conditions, Mater. Sci. Eng., A, 2007, vol. 444, nos. 1–2, pp. 18–30. https://doi.org/10.1016/j.msea.2006.06.081

Filatov, Yu.A., Alloys of the Al-Mg-Sc system as a special group of wrought aluminum alloys, Tekhnol. Legk. Splavov, 2014, no. 2, pp. 34–41.

Han, X., Wang, S., Wei, B., Pan, S., Liao, G., Li, W., and Wei, Y., Influence of Sc addition on precipitation behavior and properties of Al–Cu–Mg alloy, Acta Metall. Sin. (Engl. Lett.), 2022, vol. 35, pp. 948–960. https://doi.org/10.1007/s40195-021-01328-9

Buranova, Yu., Kulitskiy, V., Peterlechner, M., Mogucheva, A., Kaibyshev, R., Divinski, S.V., and Wilde, G., Al3(Sc,Zr)-based precipitates in Al–Mg alloy: Effect of severe deformation, Acta Mater., 2017, vol. 124, pp. 210–224. https://doi.org/10.1016/j.actamat.2016.10.064

Lathabai, S. and Lloyd, P.G., The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al–Mg alloy, Acta Mater., 2002, vol. 50, no. 17, pp. 4275–4292. https://doi.org/10.1016/S1359-6454(02)00259-8

Arbuz, A., Kawalek, A., Ozhmegov, K., Dyja, H., Panin, E., Lepsibayev, A., Sultanbekov, S., and Shamenova, R., Using of radial-shear rolling to improve the structure and radiation resistance of zirconium-based alloys, Materials, 2020, vol. 13, no. 19, article no. 4306. https://doi.org/10.3390/ma13194306

Patrin, P.V., Karpov, B.V., Aleshchenko, A.S., and Galkin, S.P., Capability process assessment of radial-displacement rolling of heat-resistant alloy HN73MBTYU, Steel Transl., 2020, vol. 50, no. 1, pp. 42–45.

Sheremet’ev, V.A., Kudryashova, A.A., Dinh, X.T., Galkin, S.P., Prokoshkin, S.D., and Brailovskii, V., Advanced technology for preparing bar from medical grade Ti-Zr-Nb superelastic alloy based on combination of radial-shear rolling and rotary forging, Metallurgist, 2019, vol. 63, pp. 51–61. https://doi.org/10.1007/s11015-019-00793-z

Stefanik, A., Szota, P., and Mróz, S., Analysis of the effect of rolling speed on the capability to produce bimodal-structure AZ31 alloy bars in the three-high skew rolling mill, Arch. Metall. Mater., 2020, vol. 65, no. 1, pp. 329–335. https://doi.org/10.24425/amm.2020.131734

Galkin, S.P., Aleschenko, A.S., Romantsev, B.A., Gamin, Yu.V., and Iskhakov, R.V., Effect of preliminary deformation of continuously cast billets by radial-shear rolling on the structure and properties of hot-rolled chromium-containing steel pipes, Metallurgist, 2021, vol. 65, pp. 185–195. https://doi.org/10.1007/s11015-021-01147-4

Lezhnev, S.N., Naizabekov, A.B., Panin, E.A., Volokitina, I.E., and Arbuz, A.S., Graded microstructure preparation in austenitic stainless steel during radial-shear rolling, Metallurgist, 2021, vol. 64, pp. 1150–1159. https://doi.org/10.1007/s11015-021-01100-5

Gamin, Y.V., Galkin, S.P., Romantsev, B.A., Koshmin, A.N., Goncharuk, A.V., and Kadach, M.V., Influence of radial-shear rolling conditions on the metal consumption rate and properties of D16 aluminum alloy rods, Metallurgist, 2021, vol. 65, pp. 650–659. https://doi.org/10.1007/s11015-021-01202-0

Koshmin, A.N., Zinoviev, A.V., Chasnikov, A.Y., and Grachev, G.N., Investigation of the stress-strain state and microstructure transformation of electrotechnical copper buses in the deformation zone during continuous extrusion, Russ. J. Non-Ferrous Met., 2021, vol. 62, pp. 179–189. https://doi.org/10.3103/S1067821221020085

Xuan, T.D., Sheremetyev, V.A., Komarov, V.S., Kudryashova, A.A., Galkin, S.P., Andreev, V.A., Prokoshkin, S.D., and Brailovski, V., Comparative study of superelastic Ti–Zr–Nb and commercial VT6 alloy billets by QForm simulation, Russ. J. Non-Ferrous Met., 2021, vol. 62, pp. 39–47. https://doi.org/10.3103/S1067821221010168

Aleshchenko, A.S., Budnikov, A.S., and Kharitonov, E.A., Metal forming study during pipe reduction on three-high rolling mills, Steel Transl., 2019, vol. 49, pp. 661–666. https://doi.org/10.3103/S0967091219100024

Akopyan, T.K., Gamin, Y.V., Galkin, S.P., Prosviryakov, A.S., Aleshchenko, A.S., Noshin, M.A., Koshmin, A.N., and Fomin, A.V., Radial-shear rolling of high-strength aluminum alloys: Finite element simulation and analysis of microstructure and mechanical properties, Mater. Sci. Eng., A, 2020, vol. 786, article no. 139424. https://doi.org/10.1016/j.msea.2020.139424

Lv, J., Zheng, J.-H., Yardley, V.A., Shi, Z., and Lin, J., A review of microstructural evolution and modelling of aluminium alloys under hot forming conditions, Metals, 2020, vol. 10, no. 11, article no. 1516. https://doi.org/10.3390/met10111516

Kostin, V.A. and Grigorenko, G.M., Modeling of additive process of formation of thin-walled cylindrical shells, Electrometall. Today, 2018, no. 04, pp. 52–61. https://doi.org/10.15407/sem2018.04.04

Pavlov, I.M., Teoriya prokatki (Theory of Rolling), Moscow: Metallurgizdat, 1950.

Samusev, S.V., Fadeev, V.A., and Sidorova, T.Y., Development of effective roll-pass designs for production of longitudinally welded pipes of small and medium diameters, Metallurgist, 2020, no. 64, pp. 658–664. https://doi.org/10.1007/s11015-020-01042-4

Galkin, S.P., Trajectory of deformed metal as basis for controlling the radial-shift and screw rolling, Steel Transl., 2004, no. 7, pp. 63–66.

Galkin, S.P., Theory and technology of stationary helical rolling of blanks and bars made of low-ductility steels and alloys, Extended Abstract of Doctoral Sci. (Eng.) Dissertation, Moscow: Moscow State Institute of Steel and Alloys (Technological Univ.), 1998.

Gamin, Y.V., Akopyan, T.K., Koshmin, A.N., Dolbachev, A.P., and Goncharuk, A.V., Microstructure evolution and property analysis of commercial pure Al alloy processed by radial-shear rolling, Arch. Civ. Mech. Eng., 2020, vol. 20, article no. 143. https://doi.org/10.1007/s43452-020-00143-w

Funding

This study was supported by a grant from the Russian Science Foundation (project no. 21-79-00144).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by Sh. Galyaltdinov

About this article

Cite this article

Gamin, Y.V., Galkin, S.P., Nguyen, X.D. et al. Analysis of Temperature-Deformation Conditions for Rolling Aluminum Alloy Al–Mg–Sc Based on FEM Modeling. Russ. J. Non-ferrous Metals 63, 417–425 (2022). https://doi.org/10.3103/S1067821222040071

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222040071