Abstract

Purpose of review

Transparent wood (TW) has attracted much interest from researchers as an emerging optical load-bearing material because of its advanced characteristics. These advantages mainly include being renewable, existing abundant reserves, low cost, interesting optical properties, outstanding mechanical performance, and low thermal conductivity. This review summarizes the current research activities that center on the development of transparent wood.

Recent findings

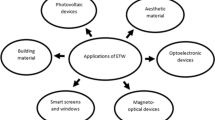

This review first addresses wood structural features and chemical composition. The effects of lignin removal, wood species, and resin types on the properties of transparent wood have been explored by researchers. Moreover, many studies highlight the properties of transparent wood, including optical and thermal properties and mechanical performance. An increasing number of studies have focused on the preparation of functional transparent wood and its commercial application.

Summary

We summarize transparent wood research processes and perspectives on several issues that need further exploration. Lignin removal is one of the most important factors in the processing of transparent wood. Thus, more efficient and greener methods need to be developed to achieve lignin removal or modification to suit the requirements of high-performance transparent wood. The main research objectives would be new functional properties such as electromagnetic shielding, intelligent photoelectric response, high hardness, and electrical conductivity of transparent wood.

Graphical abstract

Similar content being viewed by others

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Shmulsky R, Jones PD. Forest products and wood science: an introduction. John Wiley & Sons, 2019.

Chen W, Yu H, Lee S-Y, Wei T, Li J, Fan Z. Nanocellulose: A promising nanomaterial for advanced electrochemical energy storage. Chem Soc Rev. 2018;47(8):2837–72.

Food and Agriculture Organization of the United Nations. Global production and trade in forest products in 2019. https://www.fao.org/forestry/statistics/80938/en/ (2020). Accessed 2020.

•• Chen C, Kuang Y, Zhu S, Burgert I, Keplinger T, Gong A, et al. Structure–property–function relationships of natural and engineered wood. Nature Reviews Materials. 2020:1–25. (This paper shows how wood can be redesigned by structural engineering, chemical and/or thermal modification to alter its mechanical, fluidic, ionic, optical and thermal properties.)

Song J, Chen C, Zhu S, Zhu M, Dai J, Ray U, et al. Processing bulk natural wood into a high-performance structural material. Nature. 2018;554(7691):224–8.

Tsoumis G. Science and technology of wood: structure, properties, utilization. Vol. 115. New York: Van Nostrand Reinhold, 1991.

Chen F, Gong AS, Zhu M, Chen G, Lacey SD, Jiang F, et al. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment. ACS Nano. 2017;11(4):4275–82.

Hill, Callum AS. Wood modification: chemical, thermal and other processes. John Wiley & Sons, 2007.

Zhang J, Koubaa A, Xing D, Wang H, Wang Y, Liu W, Wang Q. Conversion of lignocellulose into biochar and furfural through boron complexation and esterification reactions. Bioresour Technol. 2020;312:123586.

Ashori A. Wood–plastic composites as promising green-composites for automotive industries! Bioresour Technol. 2008;99(11):4661–7.

Wang J, Zhang D, Chu F. Wood-Derived Functional Polymeric Materials. Adv Mater. 2021;33(28):2001135.

Xu T, Du H, Liu H, Liu W, Zhang X, Si C, et al. Advanced nanocellulose-based composites for flexible functional energy storage devices. Adv Mater. 2021;33(48):2101368.

Li Y, Vasileva E, Sychugov I, Popov S, Berglund L. Optically Transparent Wood: Recent Progress, Opportunities, and Challenges. Advanced Optical Materials. 2018;6(14):1800059. https://doi.org/10.1002/adom.201800059.

Lin C-f, Karlsson O, Martinka J, Rantuch P, Garskaite E, Mantanis GI, et al. Approaching highly leaching-resistant fire-retardant wood by in situ polymerization with melamine formaldehyde resin. ACS Omega. 2021;6(19):12733–45.

He X, Luzi F, Yang W, Xiao Z, Torre L, Xie Y, et al. Citric acid as green modifier for tuned hydrophilicity of surface modified cellulose and lignin nanoparticles. ACS Sustain Chem Eng. 2018;6(8):9966–78.

Yan L, Xu Z, Deng N. Effects of polyethylene glycol borate on the flame retardancy and smoke suppression properties of transparent fire-retardant coatings applied on wood substrates. Prog Org Coat. 2019;135:123–34.

Liu W, Liu K, Du H, Zheng T, Zhang N, Xu T, et al. Cellulose nanopaper: fabrication, functionalization, and applications. Nano-Micro Letters. 2022;14(1):1–27.

da Silva CMS, de Cássia Oliveira Carneiro A, Pereira BLC, Vital BR, Alves ICN, de Magalhaes MA. Stability to thermal degradation and chemical composition of woody biomass subjected to the torrefaction process. Eur J Wood Wood Prod. 2016;74(6):845–50. https://doi.org/10.1007/s00107-016-1060-z.

Esteves BM, Pereira HM. WOOD MODIFICATION BY HEAT TREATMENT: A REVIEW. BioResources. 2009;4(1):370–404.

Tu K, Puertolas B, Adobes-Vidal M, Wang Y, Sun J, Traber J, et al. Green Synthesis of Hierarchical Metal-Organic Framework/Wood Functional Composites with Superior Mechanical Properties. Adv Sci (Weinh). 2020;7(7):1902897. https://doi.org/10.1002/advs.201902897.

Zhang J, Koubaa A, Xing D, Liu W, Wang H, Wang X, Wang Q. High-performance lignocellulose/polycarbonate biocomposites fabricated by in situ reaction: structure and properties. Composites Part A: Appl Sci Manuf. 2020;138:106068.

Li W, Wang H, Ren D, Yu Y, Yu Y. Wood modification with furfuryl alcohol catalysed by a new composite acidic catalyst. Wood Sci Technol. 2015;49(4):845–56.

Gan W, Gao L, Sun Q, Jin C, Lu Y, Li J. Multifunctional wood materials with magnetic, superhydrophobic and anti-ultraviolet properties. Appl Surf Sci. 2015;332:565–72.

Li T, Zhang X, Lacey SD, Mi R, Zhao X, Jiang F, et al. Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting. Nat Mater. 2019;18(6):608–13.

Guan H, Cheng Z, Wang X. Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano. 2018;12(10):10365–10373.

Zhu M, Li T, Davis CS, Yao Y, Dai J, Wang Y, et al. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy. 2016;26:332–9. https://doi.org/10.1016/j.nanoen.2016.05.020.

Wang Y, Heim L-O, Xu Y, Buntkowsky G, Zhang K. Transparent, Stimuli-Responsive Films from Cellulose-Based Organogel Nanoparticles. Adv Funct Mater. 2015;25(9):1434–41. https://doi.org/10.1002/adfm.201403067.

• Qiu Z, Wang S, Wang Y, Li J, Xiao Z, Wang H, et al. Transparent wood with thermo-reversible optical properties based on phase-change material. Compos Sci Technol. 2020;200:108407. (This study presents a new functional TW where its optical properties can be controlled by temperature, promoting the potential application of TW as a smart light control system.)

Gan W, Gao L, Xiao S, Zhang W, Zhan X, Li J. Transparent magnetic wood composites based on immobilizing Fe 3 O 4 nanoparticles into a delignified wood template. J Mater Sci. 2017;52(6):3321–9.

Fink S. Transparent wood–a new approach in the functional study of wood structure. Holzforschung. 1992;46:403–408. https://doi.org/10.1515/hfsg.1992.46.5.403.

• Mi R, Li T, Dalgo D, Chen C, Kuang Y, He S, et al. A Clear, Strong, and Thermally Insulated Transparent Wood for Energy Efficient Windows. Adv Funct Mater. 2020;30(1):1907511. (In this study, transparent wood with high optical transmittance, high clarity with low haze, high toughness, and low thermal conductivity was prepared, which can potentially be employed as energy-efficient and sustainable windows for significant environmental and economic benefits.)

Li T, Zhu M, Yang Z, Song J, Dai J, Yao Y, et al. Wood composite as an energy efficient building material: Guided sunlight transmittance and effective thermal insulation. Adv Energy Mater. 2016;6(22):1601122.

Lang AW, Li Y, Dekeersmaecker M, Shen DE, Österholm AM, Berglund L, Reynolds JR. Transparent Wood Smart Windows: Polymer Electrochromic Devices Based on Poly(3,4‐Ethylenedioxythiophene):Poly(Styrene Sulfonate) Electrodes. ChemSusChem. 2018;11(5):854–863. https://doi.org/10.1002/cssc.201702026.

Li Y, Yu S, Veinot JGC, Linnros J, Berglund L, Sychugov I. Luminescent Transparent Wood. Adv Opt Mater. 2017;5(1):3–7. https://doi.org/10.1002/adom.201600834.

Fang Z, Zhu H, Preston C, Hu L. Development, application and commercialization of transparent paper. Transl Mater Res. 2014;1(1):015004.

Zou M, Chen Y, Chang L, Cheng X, Gao L, Guo W, Tang Q. Toward 90 μm Superthin Transparent Wood Film Impregnated with Quantum Dots for Color-Converting Materials. ACS Sustain Chem Eng. 2022;10(6):2097–2106. https://doi.org/10.1021/acssuschemeng.1c07013.

• Wan C, Liu X, Huang Q, Cheng W, Su J, Wu Y. A Brief Review of Transparent Wood: Synthetic Strategy, Functionalization and Applications. Curr Org Synth. 2021;18(7):615–23. (This paper reviews the functionalization of transparent wood through doping nanomaterials or modifying resins and the relationship between the physicochemical properties and the potential uses.)

Sjostrom E. Wood chemistry: fundamentals and applications. Gulf Professional Publishing. 1993;5–18.

Zhu H, Luo W, Ciesielski PN, Fang Z, Zhu J, Henriksson G, et al. Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev. 2016;116(16):9305–74.

Bowyer JL, Shmulsky R, Haygreen JG. Forest products and wood science: an introduction. Blackwell Publishing. 2003.

Rowell RM. Handbook of wood chemistry and wood composites. CRC Press. 2012. https://doi.org/10.1201/b12487.

Berglund LA, Burgert I. Bioinspired Wood Nanotechnology for Functional Materials. Adv Mater. 2018;30(19):1704285. https://doi.org/10.1002/adma.201704285.

Li T, Li SX, Kong W, Chen C, Hitz E, Jia C, et al. A nanofluidic ion regulation membrane with aligned cellulose nanofibers. Sci Adv. 2019;5(2):eaau4238.

Ahmed SA, Chun SK, Miller RB, Chong SH, Kim AJ. Liquid penetration in different cells of two hardwood species. J Wood Sci. 2011;57(3):179–88.

Emaminasab M, Tarmian A, Oladi R, Pourtahmasi K, Avramidis S. Fluid permeability in poplar tension and normal wood in relation to ray and vessel properties. Wood Sci Technol. 2017;51(2):261–72.

Suleiman B, Larfeldt J, Leckner B, Gustavsson M. Thermal conductivity and diffusivity of wood. Wood Sci Technol. 1999;33(6):465–73.

Wu Y, Tang C, Wu J, Huang Q. Research progress of transparent wood: a review. J For Eng. 2018;3(4):12–8.

Fu Q, Ansari F, Zhou Q, Berglund LA. Wood nanotechnology for strong, mesoporous, and hydrophobic biocomposites for selective separation of oil/water mixtures. ACS Nano. 2018;12(3):2222–30.

Lu M, He W, Li Z, Qiang H, Cao J, Guo F, et al. Effect of Lignin Content on Properties of Flexible Transparent Poplar Veneer Fabricated by Impregnation with Epoxy Resin. Polymers. 2020;12(11):2602.

Yu Z, Yao Y, Yao J, Zhang L, Chen Z, Gao Y, et al. Transparent wood containing Cs x WO 3 nanoparticles for heat-shielding window applications. J Mater Chem A. 2017;5(13):6019–24.

Zou W, Sun D, Wang Z, Li R, Yu W, Zhang P. Eco-friendly transparent poplar-based composites that are stable and flexible at high temperature. RSC Adv. 2019;9(37):21566–71.

Li Y, Fu Q, Rojas R, Yan M, Lawoko M, Berglund L. Lignin-retaining transparent wood. Chemsuschem. 2017;10(17):3445.

•• Xia Q, Chen C, Li T, He S, Gao J, Wang X, et al. Solar-assisted fabrication of large-scale, patternable transparent wood. Sci Adv. 2021;7(5):7342–69. (This paper reports a method to produce optically transparent wood by modifying lignin structure using a solar-assisted chemical brushing approach, leading to scalable production.)

Xia Q, Chen C, Yao Y, He S, Wang X, Li J, et al. In situ lignin modification toward photonic wood. Adv Mater. 2021;33(8):2001588.

Rao A, Nagarajappa GB, Nair S, Chathoth AM, Pandey KK. Flexible transparent wood prepared from poplar veneer and polyvinyl alcohol. Compos Sci Technol. 2019;182(Sep.29):107719.1-.10.

Qin J, Bai T, Shao Y, Zhao X, Li S, Hu Y. Fabrication and characterization of multilayer transparent wood of different species. J Beijing For Univ. 2018;40(7):113–20.

Chen H, Baitenov A, Li Y, Vasileva E, Popov S, Sychugov I, et al. Thickness dependence of optical transmittance of transparent wood: chemical modification effects. ACS Appl Mater Interfaces. 2019;11(38):35451–7.

Mi R, Chen C, Keplinger T, Pei Y, He S, Liu D, et al. Scalable aesthetic transparent wood for energy efficient buildings. Nat Commun. 2020;11(1):1–9.

Wu J, Wu Y, Yang F, Tang C, Huang Q, Zhang J. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos A Appl Sci Manuf. 2019;117:324–31. https://doi.org/10.1016/j.compositesa.2018.12.004.

Li Y, Fu Q, Yu S, Yan M, Berglund L. Optically transparent wood from a nanoporous cellulosic template: combining functional and structural performance. Biomacromol. 2016;17(4):1358–64.

Cai H, Wang Z, Xie D, Zhao P, Sun J, Qin D, et al. Flexible transparent wood enabled by epoxy resin and ethylene glycol diglycidyl ether. J For Res. 2021;32(4):1779–87.

Höglund M, Johansson M, Sychugov I, Berglund LA. Transparent wood biocomposites by fast UV-curing for reduced light-scattering through wood/thiol–ene interface design. ACS Appl Mater Interfaces. 2020;12(41):46914–22.

Kong W, Wang C, Jia C, Kuang Y, Pastel G, Chen C, et al. Muscle-Inspired Highly Anisotropic, Strong, Ion-Conductive Hydrogels. Adv Mater. 2018;30(39):1801934.

Rao ANS, Nagarajappa GB, Nair S, Chathoth AM, Pandey KK. Flexible transparent wood prepared from poplar veneer and polyvinyl alcohol. Compos Sci Technol. 2019;182:107719.

Gan W, Xiao S, Gao L, Gao R, Li J, Zhan X. Luminescent and transparent wood composites fabricated by poly (methyl methacrylate) and γ-Fe2O3@ YVO4: Eu3+ nanoparticle impregnation. ACS Sustain Chem Eng. 2017;5(5):3855–62.

Wang L, Liu Y, Zhan X, Luo D, Sun X. Photochromic transparent wood for photo-switchable smart window applications. J Mater Chem C. 2019;7(28):8649–54.

Wang X, Zhan T, Liu Y, Shi J, Pan B, Zhang Y, et al. Large-size transparent wood for energy-saving building applications. Chemsuschem. 2018;11(23):4086–93.

Montanari C, Li Y, Chen H, Yan M, Berglund LA. Transparent Wood for Thermal Energy Storage and Reversible Optical Transmittance. ACS Appl Mater Interfaces. 2019;11(22):20465–72. https://doi.org/10.1021/acsami.9b05525.

Chen C, Wang Y, Wu Q, Wan Z, Li D, Jin Y. Highly strong and flexible composite hydrogel reinforced by aligned wood cellulose skeleton via alkali treatment for muscle-like sensors. Chem Eng J. 2020;400:125876.

Wang M, Li R, Chen G, Zhou S, Feng X, Chen Y, et al. Highly stretchable, transparent, and conductive wood fabricated by in situ photopolymerization with polymerizable deep eutectic solvents. ACS Appl Mater Interfaces. 2019;11(15):14313–21.

Wu Y, Wang Y, Yang F. Comparison of multilayer transparent wood and single layer transparent wood with the same thickness. Front Mater. 2021;8:41.

ASTM D. 1003-00 Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics. ASTM International. ASTM International, West Conshohoken, PA. 2000.

Xu Y, Zhang Y, Zhu M, YIn X. Research Progress in Transparent Wood and Its Functionalization. China Pulp Paper. 2021;40(5):88–94.

Zhu M, Song J, Li T, Gong A, Wang Y, Dai J, et al. Highly Anisotropic, Highly Transparent Wood Composites. Adv Mater. 2016;28(26):5181–7. https://doi.org/10.1002/adma.201600427.

Li Y, Yang X, Fu Q, Rojas R, Yan M, Berglund L. Towards centimeter thick transparent wood through interface manipulation. J Mater Chem A. 2018;6(3):1094–101.

Wu Y, Zhou J, Huang Q, Yang F, Wang Y, Liang X, et al. Study on the Colorimetry Properties of Transparent Wood Prepared from Six Wood Species. ACS Omega. 2020;5(4):1782–8. https://doi.org/10.1021/acsomega.9b02498.

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A. Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromol. 2009;10(1):162–5.

Tao J, Wang R, Yu H, Chen L, Fang D, Tian Y, et al. Highly transparent, highly thermally stable nanocellulose/polymer hybrid substrates for flexible OLED devices. ACS Appl Mater Interfaces. 2020;12(8):9701–9.

Li T, Chen C, Brozena AH, Zhu J, Xu L, Driemeier C, et al. Developing fibrillated cellulose as a sustainable technological material. Nature. 2021;590(7844):47–56.

Li Y, Cheng M, Jungstedt E, Xu B, Sun L, Berglund L. Optically transparent wood substrate for perovskite solar cells. ACS Sustain Chem Eng. 2019;7(6):6061–7.

• Wang Y, Wu Y, Yang F, Wang J, Zhou J. A multilayer transparent wood prepared by laminating two kinds of tree species. J Appl Polym Sci. 2022;139(13):51872. https://doi.org/10.1002/app.51872. (This paper reports a new type of multilayer transparent wood and its properties can be controlled through the selection of single-layer materials and assembly methods.)

Yaddanapudi HS, Hickerson N, Saini S, Tiwari A. Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum. 2017;146:649–54.

Zhang J, Li Y, Xing D, Wang Q, Wang H, Koubaa A. Reinforcement of continuous fibers for extruded wood-flour/HDPE composites: Effects of fiber type and amount. Constr Build Mater. 2019;228:116718. https://doi.org/10.1016/j.conbuildmat.2019.116718.

Jungstedt E, Montanari C, Östlund S, Berglund L. Mechanical properties of transparent high strength biocomposites from delignified wood veneer. Compos A Appl Sci Manuf. 2020;133:105853.

Kawasaki T, Kawai S. Thermal insulation properties of wood-based sandwich panel for use as structural insulated walls and floors. J Wood Sci. 2006;52(1):75–83.

Zhang L, Jiang Y, Zhou L, Jiang Z, Li L, Che W, Yu Y. Mechanical, thermal stability, and flame retardancy performance of transparent wood composite improved with delaminated Ti3C2Tx (MXene) nanosheets. J Mater Sci. 2022;57(5):3348–3359.

Li M, Pang Y, Li N, Shan J, Liu Y. Interfacial Compatibilization of Silane Coupling Agent Modified Epoxy Resin for Transparent Basswood. China Wood-Based Panels. 2018;8:22–5.

Fu Q, Yan M, Jungstedt E, Yang X, Li Y, Berglund LA. Transparent plywood as a load-bearing and luminescent biocomposite. Compos Sci Technol. 2018;164:296–303.

Vasileva E, Li Y, Sychugov I, Mensi M, Berglund L, Popov S. Lasing from organic dye molecules embedded in transparent wood. Adv Opt Mater. 2017;5(10):1700057.

Xia R, Zhang W, Yang Y, Zhao J, Liu Y, Guo H. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation. J Clean Prod. 2021;296:126598.

Montanari Cl, Li Y, Chen H, Yan M, Berglund LA. Transparent wood for thermal energy storage and reversible optical transmittance. ACS Appl Mater Interfaces. 2019;11(22):20465–72.

Fu Q, Chen Y, Sorieul M. Wood-based flexible electronics. ACS Nano. 2020;14(3):3528–38.

Fink S. Transparent wood–a new approach in the functional study of wood structure. Holzforschung-International J Biol Chem Phys Technol Wood. 1992;46(5):403–8.

Kurihara D, Mizuta Y, Sato Y, Higashiyama T. ClearSee: a rapid optical clearing reagent for whole-plant fluorescence imaging. Development. 2015;142(23):4168–79.

Warner CA, Biedrzycki ML, Jacobs SS, Wisser RJ, Caplan JL, Sherrier DJ. An optical clearing technique for plant tissues allowing deep imaging and compatible with fluorescence microscopy. Plant Physiol. 2014;166(4):1684–7.

Jia C, Chen C, Mi R, Li T, Dai J, Yang Z, et al. Clear wood toward high-performance building materials. ACS Nano. 2019;13(9):9993–10001.

Yang H, Chao W, Di X, Yang Z, Yang T, Yu Q, et al. Multifunctional wood based composite phase change materials for magnetic-thermal and solar-thermal energy conversion and storage. Energy Convers Manage. 2019;200:112029.

Bi Z, Li T, Su H, Ni Y, Yan L. Transparent wood film incorporating carbon dots as encapsulating material for white light-emitting diodes. ACS Sustain Chem Eng. 2018;6(7):9314–23.

Zhang T, Yang P, Li Y, Cao Y, Zhou Y, Chen M, et al. Flexible transparent sliced veneer for alternating current electroluminescent devices. ACS Sustain Chem Eng. 2019;7(13):11464–73.

Acknowledgements

The authors gratefully acknowledge the financial support of the Canada Research Chair Program, Natural science and Engineering Research Council of Canada, Key Laboratory of Bio-based Material Science & Technology (Northeast Forestry University), Ministry of Education (SWZ-ZD202101), and Mitacs Accelerate Proposal (IT23437).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

All authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Wood Structure and Function

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, J., Koubaa, A., Tao, Y. et al. The emerging development of transparent wood: materials, characteristics, and applications. Curr Forestry Rep 8, 333–345 (2022). https://doi.org/10.1007/s40725-022-00172-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40725-022-00172-z