Abstract

Purpose of Review

Industrial ecology (IE) methods have been widely applied to understand the sustainability implications of forest product industries, yet a comprehensive review of these applications is not available. We aim to (1) summarize the major questions that the IE methods were applied to answer, (2) highlight the major conclusions, and (3) identify advantages, limitations, and research gaps.

Recent Findings

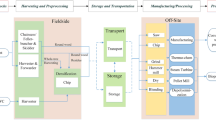

Life cycle assessment (LCA) was the most frequently used among all IE methods reviewed in this study. LCA has primarily applied to evaluate the climate change mitigation potential of forest products. The application of input-output analysis (IOA) is focused on the aggregated forest sector where individual products are not differentiable. The results of IOA can inform the economic implications of changes in supply-demand relationships between the forest sector and other sectors of the economy. System dynamic (SD) modeling is often applied to study the consequences (e.g., economic, environmental) of decision-making along the supply chain of forest bioenergy and biofuels. Material flow analysis (MFA) is applied to estimate the stock and flows of wood in different formats (e.g., timber, residues). Industrial symbiosis (IS) practices are found to minimize waste generation, stabilize material and energy supply, and reduce climate change impacts for the participants from different forest product industries.

Summary

Overall, the LCA studies showed that forest products could reduce climate change impacts compared to the fossil-based benchmark. The IOA studies revealed the important role of forestry and forest product industries in a nation’s economy. The drivers promoting the forest product industries (illustrated by the SD studies) and the detailed flows of wood among different industries (by MFA studies) can provide crucial insights for the design of a forest-based bioeconomy. The applications of these IE methods in forest product industries are expected to grow in the future, considering the global development of bioeconomy where forest products are essential. Data availability and quality, lack of harmonized modeling assumptions, and a need to integrate different methods are the common gaps for future research.

Similar content being viewed by others

Notes

In IOA, sector and industry are the same meaning. Different input-output tables may have different industry classifications, but these classifications are generally based on industry classification standards (e.g., the United Nations International Standard Industrial Classification of All Economic Activities, ISIC Rev.4).

References

Papers of particular interest, published recently, have been highlighted as: • Of importance

Toivanen T. A player bigger than its size: Finnish bioeconomy and forest policy in the era of global climate politics. In: Bioeconomy Glob. Inequalities. 2021. pp 131–149.

Scarlat N, Dallemand JF. Future role of bioenergy. In: Role Bioenergy Emerg. Bioeconomy Resour. Technol. Sustain. Policy. Academic Press. 2018. pp 435–547. https://doi.org/10.1016/B978-0-12-813056-8.00010-8.

Wolfslehner B, Linser S, Pülzl H, Bastrup-Birk A, Camia A, Marchetti M. Forest bioeconomy – a new scope for sustainability indicators. From science to policy 4. Eur Forest Institute. 2016. https://doi.org/10.36333/fs04.

Kons K, Blagojević B, Mola-Yudego B, Prinz R, Routa J, Kulisic B, Gagnon B, Bergström D. Industrial end-users’ preferred characteristics for wood biomass feedstocks. Energies. 2022;15:3721. https://doi.org/10.3390/en15103721.

Julio R, Albet J, Vialle C, Vaca-Garcia C, Sablayrolles C. Sustainable design of biorefinery processes: existing practices and new methodology. Biofuels Bioprod Biorefin. 2017;11:373–95. https://doi.org/10.1002/bbb.1749.

Graedel TE, Allenby BR. Industrial ecology and sustainable engineering. Pearson Education, Inc. 2010. Publishing as Prentice Hall.

Hond F. Industrial ecology: a review. Reg Environ Chang. 2000;1:60–9. https://doi.org/10.1007/PL00011534.

O’Rourke D, Connelly L, Koshland CP. Industrial ecology. A critical review. Int J Environ Pollut. 1996;6(2/3):89–112.

Frosch RA, Gallopoulos NE. Strategies for manufacturing. Readings from Scientific American: managing planet earth, vol. 261. New York: W H Freeman and Co; 1990. p. 144–53.

Frosch R, Gallopoulos N. Towards an industrial ecology. In: Treat. Handl. wastes. 1992.pp 269–292

Allenby B, Graedel T. Industrial ecology. Upper Saddle River N.J: Prentice Hall; 1995.

Ayres R, Ayres L. A handbook of industrial ecology. A Handb Ind Ecol. 2015. https://doi.org/10.4337/9781843765479.

Jelinski LW, Graedel TE, Laudise RA, McCall DW, Patel CKN. Industrial ecology: concepts and approaches. Proc Natl Acad Sci U S A. 1992;89:793–7. https://doi.org/10.1073/pnas.89.3.793.

Graedel TE, Allenby BR. Industrial ecology. 2nd ed. Upper Saddle River N.J: Prentice Hall; 2003.

Miller RE, Blair PD. Input-output analysis: foundations and extensions, 2nd ed. Cambridge University Press. 1985.

Sterman JD. Business dynamics. Modeling and simulation for a complex world. New York: McGraw Hill; 2000.

Fishman T, Heeren N, Pauliuk S, Berrill P, Tu Q, Wolfram P, Hertwich EG. A comprehensive set of global scenarios of housing, mobility, and material efficiency for material cycles and energy systems modeling. J Ind Ecol. 2021;25:305–20. https://doi.org/10.1111/jiec.13122.

Karlsson M, Wolf A. Using an optimization model to evaluate the economic benefits of industrial symbiosis in the forest industry. J Clean Prod. 2008;16:1536–44. https://doi.org/10.1016/j.jclepro.2007.08.017.

ISO. ISO 14044: environmental management - life cycle assessment - requirements and guidelines. Geneva: Int. Organ. Stand. (ISO); 2006.

ISO. ISO 14040: environmental management - life cycle assessment - principles and framework. Geneva: Int. Organ. Stand. (ISO); 2006.

Guo T, Yu Y, Wan Z, Zargar S, Wu J, Bi R, Sokhansanj S, Tu Q, Rojas OJ. Energy pellets from whole-wheat straw processed with a deep eutectic solvent: a comprehensive thermal, molecular and environmental evaluation. Renew Energy. 2022;194:902–11. https://doi.org/10.1016/j.renene.2022.05.143.

Zargar S, Jiang J, Jiang F, Tu Q. Isolation of lignin-containing cellulose nanocrystals: life-cycle environmental impacts and opportunities for improvement. Biofuels Bioprod Biorefin. 2022;16:68–80. https://doi.org/10.1002/bbb.2261.

• Musule R, Bonales-Revuelta J, Mwampamba TH, Gallardo-Alvarez RM, Masera O, García CA. Life cycle assessment of forest-derived solid biofuels: a systematic review of the literature. Bioenergy Res. 2021;1:1–22. https://doi.org/10.1007/s12155-021-10346-5This article systematically reviewed 87 LCA studies with a focus on solid biofuels including firewood, charcoal, wood chips, briquettes, and pellets.

• Gahane D, Biswal D, Mandavgane SA. Life cycle assessment of biomass pyrolysis. Bioenergy Res. 2022;15:1387–406. https://doi.org/10.1007/s12155-022-10390-9This paper assessed the life cycle environmental impact of the pyrolysis process and critically reviewed LCA literature to understand the similarities and differences among their goal and scope, system boundaries, the pretreatment processes, and product upgrading.

• Brassard P, Godbout S, Hamelin L. Framework for consequential life cycle assessment of pyrolysis biorefineries: a case study for the conversion of primary forestry residues. Renew Sust Energ Rev. 2021;138:110549. https://doi.org/10.1016/j.rser.2020.110549This study developed a consequential life cycle assessment framework for evaluating the environmental impacts of pyrolysis biorefineries along with a detailed life cycle inventory of a pyrolysis process. It provided an analytical tool for assessing the environmental feasibility of the application of residual biomass as feedstock for the production of bio-based products and energies in a pyrolysis biorefinery.

Ubando AT, Rivera DRT, Chen WH, Culaba AB. A comprehensive review of life cycle assessment (LCA) of microalgal and lignocellulosic bioenergy products from thermochemical processes. Bioresour Technol. 2019;291:121837. https://doi.org/10.1016/j.biortech.2019.121837.

• Pawar A, Panwar NL, Salvi BL. Comprehensive review on pyrolytic oil production, upgrading and its utilization. J Mater Cycles Waste Manag. 2020;22:1712–22. https://doi.org/10.1007/s10163-020-01063-wThis review article thoroughly discussed the research progress on pyrolysis technologies and the quality of pyrolysis products and their application as well as the possibility of high-quality bio-oil, biogas, and biochar production via pyrolysis.

• Kargbo H, Harris JS, Phan AN. “Drop-in” fuel production from biomass: critical review on techno-economic feasibility and sustainability. Renew Sust Energ Rev. 2021;135:110168. https://doi.org/10.1016/j.rser.2020.110168This study reviewed life cycle assessment and techno-economic analysis studies focusing on drop-in fuel production via major production pathways including pyrolysis, gasification, fermentation, and hydrothermal liquefaction. It discussed the technical barriers to each method and economic considerations of biofuel production.

• Osman AI, Mehta N, Elgarahy AM, Al-Hinai A, Al-Muhtaseb AH, Rooney DW. Conversion of biomass to biofuels and life cycle assessment: a review. Environ Chem Lett. 2021;19:4075–118. https://doi.org/10.1007/s10311-021-01273-0This paper critically reviewed and analyzed LCA studies focusing on biomass to biofuel pathways, and highlighted key methodological approaches, main findings, and progress in biofuel production processes.

IPCC (2013) Climate change 2013: the physical science basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change.

Watson J, Zhang Y, Si B, Chen WT, de Souza R. Gasification of biowaste: a critical review and outlooks. Renew Sust Energ Rev. 2018;83:1–17. https://doi.org/10.1016/j.rser.2017.10.003.

You S, Ok YS, Chen SS, Tsang DCW, Kwon EE, Lee J, Wang CH. A critical review on sustainable biochar system through gasification: energy and environmental applications. Bioresour Technol. 2017;246:242–53. https://doi.org/10.1016/j.biortech.2017.06.177.

García-Velásquez CA, Cardona CA. Comparison of the biochemical and thermochemical routes for bioenergy production: a techno-economic (TEA), energetic and environmental assessment. Energy. 2019;172:232–42. https://doi.org/10.1016/j.energy.2019.01.073.

Liang S, Gu H, Bergman RD. Life cycle assessment of cellulosic ethanol and biomethane production from forest residues. BioResources. 2017;12:7873–83.

Gontia P, Janssen M. Life cycle assessment of bio-based sodium polyacrylate production from pulp mill side streams: case study of thermo-mechanical and sulfite pulp mills. J Clean Prod. 2016;131:475–84. https://doi.org/10.1016/j.jclepro.2016.04.155.

Roy P, Dias G. Prospects for pyrolysis technologies in the bioenergy sector: a review. Renew Sust Energ Rev. 2017;77:59–69. https://doi.org/10.1016/j.rser.2017.03.136.

• Ponnusamy VK, Nagappan S, Bhosale RR, Lay CH, Duc Nguyen D, Pugazhendhi A, Chang SW, Kumar G. Review on sustainable production of biochar through hydrothermal liquefaction: physico-chemical properties and applications. Bioresour Technol. 2020;310:123414. https://doi.org/10.1016/j.biortech.2020.123414This review focuses on biochar production and its physical and chemical properties via the hydrothermal liquefaction process and potential applications. It presents the potential sustainability of biochar production via the life cycle assessment methodology. It also describes the challenges facing biochar production via the hydrothermal liquefaction process.

Patel M, Zhang X, Kumar A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: a review. Renew Sust Energ Rev. 2016;53:1486–99. https://doi.org/10.1016/j.rser.2015.09.070.

• Mishra R, Kumar P, Fuel KM, 2022 U. Hydrothermal liquefaction of biomass for bio-crude production: a review on feedstocks, chemical compositions, operating parameters, reaction kinetics, techno-economic study, and life cycle assessment. Fuel. 2022;316:123377. https://doi.org/10.1016/j.fuel.2022.123377This review article focuses on analyzing the effects of different compositions of biomass and different types of feedstocks on hydrothermal liquefaction and the conditions of the processes systematically with a focus on life cycle assessment and techno-economic analysis methodologies.

Djomo SN, Knudsen MT, Parajuli R, Andersen MS, Ambye-Jensen M, Jungmeier G, Gabrielle B, Hermansen JE. Solving the multifunctionality dilemma in biorefineries with a novel hybrid mass–energy allocation method. GCB Bioenergy. 2017;9:1674–86. https://doi.org/10.1111/gcbb.12461.

Parajuli R, Knudsen MT, Birkved M, Djomo SN, Corona A, Dalgaard T. Environmental impacts of producing bioethanol and biobased lactic acid from standalone and integrated biorefineries using a consequential and an attributional life cycle assessment approach. Sci Total Environ. 2017;598:497–512. https://doi.org/10.1016/j.scitotenv.2017.04.087.

Ahlgren S, Björklund A, Ekman A, Karlsson H, Berlin J, Börjesson P, Ekvall T, Finnveden G, Janssen M, Strid I. Review of methodological choices in LCA of biorefinery systems - key issues and recommendations. Biofuels Bioprod Biorefin. 2015;9:606–19. https://doi.org/10.1002/bbb.1563.

Morales-Mendoza LF, Azzaro-Pantel C. Bridging LCA data gaps by use of process simulation for energy generation. Clean Techn Environ Policy. 2017;19:1535–46. https://doi.org/10.1007/s10098-017-1349-6.

• Zargar S, Yao Y, Tu Q. A review of inventory modeling methods for missing data in life cycle assessment. J Ind Ecol. 2022:1–14. https://doi.org/10.1111/jiec.13305This paper critically reviewed the methods applied for modeling the missing inventory data in the life cycle assessment methodology. It focuses on the proxy selection and data creation in life cycle inventory modeling and how to select a suitable method for filling data gaps.

Leontief W. Input-output analysis. In: The new palgrave. A Dict Econ. 1987;2:860–4.

Mattila T, Leskinen P, Mäenpää I, Seppälä J. An environmentally extended input-output analysis to support sustainable use of forest resources. Open For Sci J. 2011;4:15–23. https://doi.org/10.2174/1874398601104010015.

Ferrão P, Nhambiu J. A comparison between conventional LCA and hybrid EIO-LCA: analyzing crystal giftware contribution to global warming potential. Dordrecht: Springer; 2009. p. 219–30.

Giljum S, Hubacek K. Alternative approaches of physical input-output analysis to estimate primary material inputs of production and consumption activities. Econ Syst Res. 2004;16:301–10. https://doi.org/10.1080/0953531042000239383.

Wiedmann T, Wilting HC, Lenzen M, Lutter S, Palm V. Quo Vadis MRIO? Methodological, data and institutional requirements for multi-region input-output analysis. Ecol Econ. 2011;70:1937–45. https://doi.org/10.1016/j.ecolecon.2011.06.014.

Hoekstra R, van den Bergh JCJM. Constructing physical input-output tables for environmental modeling and accounting: framework and illustrations. Ecol Econ. 2006;59:375–93. https://doi.org/10.1016/j.ecolecon.2005.11.005.

• Wieland H, Lenzen M, Geschke A, Fry J, Wiedenhofer D, Eisenmenger N, Schenk J, Giljum S. The PIOLab: Building global physical input–output tables in a virtual laboratory. J Ind Ecol. 2021. https://doi.org/10.1111/jiec.13215Global physical input-output tables can help to monitor the progress of a sustainable circular economy; however, it deals with incomplete data with high uncertainties making the application of the table time-consuming. Hence, this article tackles this problem by introducing a virtual laboratory for building global physical input-output tables. This new concept is a collaborative research environment with a cloud-based platform helping modelers to develop their large-scale multi-regional input-output mode in a time and cost-efficient manner.

Li Y, Mei B, Linhares-Juvenal T. The economic contribution of the world’s forest sector. For Policy Econ. 2019;100:236–53. https://doi.org/10.1016/j.forpol.2019.01.004.

Parajuli R, Chizmar S, Hoy M, Joshi O, Gordon J, Mehmood S, Henderson JE, Poudel J, Witthun O, Buntrock L. Economic contribution analysis of urban forestry in the northeastern and midwestern states of the United States in 2018. Urban For Urban Green. 2022;69:127490. https://doi.org/10.1016/j.ufug.2022.127490.

Henderson JE, Munn IA. Economic importance of forestry and forest products to Mississippi counties: a publication series to help the forestry community educate local government officials and the public. J For. 2013;111:388–94. https://doi.org/10.5849/jof.12-100.

Suh J. The role of the forestry industry for the success of community forestry: a comparative input-output analysis across India and the Philippines. South For. 2014;76:29–36. https://doi.org/10.2989/20702620.2013.870401.

Bösch M, Jochem D, Weimar H, Dieter M. Physical input-output accounting of the wood and paper flow in Germany. Resour Conserv Recycl. 2015;94:99–109. https://doi.org/10.1016/j.resconrec.2014.11.014.

Bösch M, Elsasser P, Rock J, Rüter S, Weimar H, Dieter M. Costs and carbon sequestration potential of alternative forest management measures in Germany. For Policy Econ. 2017;78:88–97. https://doi.org/10.1016/j.forpol.2017.01.005.

Marques A, Martins IS, Kastner T, et al. Increasing impacts of land use on biodiversity and carbon sequestration driven by population and economic growth. Nat Ecol Evol. 2019;3:628–37. https://doi.org/10.1038/s41559-019-0824-3.

Hung DM, Trinh B. Forestry sector and policies on sustainable development in Vietnam: analyze from the input-output model. Int J Soc Adm Sci. 2019;4:253–66. https://doi.org/10.18488/journal.136.2019.42.253.266.

Chen W, Xu D, Liu J. The forest resources input-output model: an application in China. Ecol Indic. 2015;51:87–97. https://doi.org/10.1016/j.ecolind.2014.09.007.

Zhang X, Huang G, Liu L, Zhai M, Li J. Ecological and economic analyses of the forest metabolism system: a case study of Guangdong Province, China. Ecol Indic. 2018;95:131–40. https://doi.org/10.1016/j.ecolind.2018.07.022.

Liang S, Guo S, Newell JP, Qu S, Feng Y, Chiu ASF, Xu M. Global drivers of Russian timber harvest. J Ind Ecol. 2016;20:515–25. https://doi.org/10.1111/jiec.12417.

Bösch M, Weimar H, Dieter M. Input–output evaluation of Germany’s national cluster of forest-based industries. Eur J For Res. 2015;134:899–910. https://doi.org/10.1007/s10342-015-0898-7.

Hou D, Al-Tabbaa A, Guthrie P, Hellings J, Gu Q. Using a hybrid LCA method to evaluate the sustainability of sediment remediation at the London Olympic Park. J Clean Prod. 2014;83:87–95. https://doi.org/10.1016/j.jclepro.2014.07.062.

• Towa E, Zeller V, Merciai S, Schmidt J, Achten WMJ. Toward the development of subnational hybrid input–output tables in a multiregional framework. J Ind Ecol. 2022;26:88–106. https://doi.org/10.1111/jiec.13085This paper deals with developing a multiregional hybrid input-output table and environmental extensions at the subnational level to disclose a new way of integrating national hybrid and subnational monetary tables, and physical survey-based data.

Hämäläinen S, Näyhä A, Pesonen HL. Forest biorefineries - a business opportunity for the Finnish forest cluster. J Clean Prod. 2011;19:1884–91. https://doi.org/10.1016/j.jclepro.2011.01.011.

Meyer R, Campanella S, Corsano G, Montagna JM. Optimal design of a forest supply chain in Argentina considering economic and social aspects. J Clean Prod. 2019;231:224–39. https://doi.org/10.1016/j.jclepro.2019.05.090.

Baghizadeh K, Zimon D, Jum’a L (2021) Modeling and optimization sustainable forest supply chain considering discount in transportation system and supplier selection under uncertainty. Forests 12:964. https://doi.org/10.3390/f12080964

Roy BB, Tu Q. A review of system dynamics modeling for the sustainability assessment of biorefineries. J Ind Ecol. 2022;26:1450–9. https://doi.org/10.1111/jiec.13291.

Turner BL, Menendez HM, Gates R, Tedeschi LO, Atzori AS. System dynamics modeling for agricultural and natural resource management issues: review of some past cases and forecasting future roles. Resources. 2016;5:40. https://doi.org/10.3390/resources5040040.

Homer JB, Hirsch GB. System dynamics modeling for public health: background and opportunities. Am J Public Health. 2006;96:452–8. https://doi.org/10.2105/AJPH.2005.062059.

Noguchi RY, Soekmadi R, Hikmat A, Kusmana C, Supriyanto AT. Reconciling livelihoods and conservation for rattan sustainable harvesting in Lore Lindu National Park, Indonesia. Small-scale For. 2021;20:175–97. https://doi.org/10.1007/s11842-020-09463-4.

Nazir N, Olabisi LS, Ahmad S. Forest wood consumption and wood shortage in Pakistan: estimation and projection through system dynamics. Pak Dev Rev. 2018;57:73–98.

Chitawo ML, Chimphango AFA, Peterson S. Modelling sustainability of primary forest residues-based bioenergy system. Biomass Bioenergy. 2018;108:90–100. https://doi.org/10.1016/j.biombioe.2017.10.022.

Jin E, Sutherland JW. A proposed integrated sustainability model for a bioenergy system. Procedia CIRP. 2016;48:358–63. https://doi.org/10.1016/j.procir.2016.03.159.

Jin E, Sutherland JW. An integrated sustainability model for a bioenergy system: forest residues for electricity generation. Biomass Bioenergy. 2018;119:10–21. https://doi.org/10.1016/j.biombioe.2018.09.005.

Pauliuk S, Fishman T, Heeren N, Berrill P, Tu Q, Wolfram P, Hertwich EG. Linking service provision to material cycles: a new framework for studying the resource efficiency–climate change (RECC) nexus. J Ind Ecol. 2021;25:260–73. https://doi.org/10.1111/jiec.13023.

Babuka R, Sujová A, Kupčák V. Cascade use of wood in the Czech Republic. Forests. 2020;11:681. https://doi.org/10.3390/F11060681.

Lenglet J, Courtonne JY, Caurla S. Material flow analysis of the forest-wood supply chain: a consequential approach for log export policies in France. J Clean Prod. 2017;165:1296–305. https://doi.org/10.1016/j.jclepro.2017.07.177.

Gonçalves M, Freire F, Garcia R. Material flow analysis of forest biomass in Portugal to support a circular bioeconomy. Resour Conserv Recycl. 2021;169:105507. https://doi.org/10.1016/j.resconrec.2021.105507.

MacArthur E. Circularity indicators: an approach to measuring circularity. Methodology. Isle of Wight. UK: Ellen MacArthur Foundation (EMF); 2015.

• Aryapratama R, Pauliuk S. Life cycle carbon emissions of different land conversion and woody biomass utilization scenarios in Indonesia. Sci Total Environ. 2022;805:150226. https://doi.org/10.1016/j.scitotenv.2021.150226This study conducted a combination of dynamic material flow analysis with dynamic stock modeling and dynamic life cycle assessment to assess the carbon emissions of products derived from wood with different land conversion scenarios.

Kalcher J, Praxmarer G, Teischinger A. Quantification of future availabilities of recovered wood from Austrian residential buildings. Resour Conserv Recycl. 2017;123:143–52. https://doi.org/10.1016/j.resconrec.2016.09.001.

Pakarinen S, Mattila T, Melanen M, Nissinen A, Sokka L. Sustainability and industrial symbiosis-the evolution of a Finnish forest industry complex. Resour Conserv Recycl. 2010;54:1393–404. https://doi.org/10.1016/j.resconrec.2010.05.015.

Frosch RA, Gallopoulos NE. Strategies for manufacturing. Sci Am. 1989;261:144–52.

Lombardi DR, Laybourn P. Redefining industrial symbiosis: crossing academic-practitioner boundaries. J Ind Ecol. 2012;16:28–37. https://doi.org/10.1111/j.1530-9290.2011.00444.x.

Wahrlich J, Simioni FJ. Industrial symbiosis in the forestry sector: a case study in southern Brazil. J Ind Ecol. 2019;23:1470–82. https://doi.org/10.1111/jiec.12927.

Chertow MR. “Uncovering” industrial symbiosis. J Ind Ecol. 2007;11:11–30. https://doi.org/10.1162/jiec.2007.1110.

Rosa M, Beloborodko A. A decision support method for development of industrial synergies: case studies of Latvian brewery and wood-processing industries. J Clean Prod. 2015;105:461–70. https://doi.org/10.1016/j.jclepro.2014.09.061.

Hildebrandt J, O’Keeffe S, Bezama A, Thrän D. Revealing the environmental advantages of industrial symbiosis in wood-based bioeconomy networks: an assessment from a life cycle perspective. J Ind Ecol. 2019;23:808–22. https://doi.org/10.1111/jiec.12818.

Funding

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) (funding reference number RGPIN-2021-02841).

Author information

Authors and Affiliations

Contributions

Shiva Zargar: data curation, writing LCA section, and editing the manuscript; Bidhan Bhuson Roy: writing SD and MFA sections; Qiuping Li: writing IOA section; Jinlu Gan: writing LCA section; Jinming Ke: writing LCA section; Xiaoyu Liu: writing IS section; Qingshi Tu: conceptualization, review and editing the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

All authors declare that they have no conflict of interest.

Human and Animal Rights and Informed Consent

This article does not contain any studies with human or animal subjects performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Wood Structure and Function

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zargar, S., Roy, B.B., Li, Q. et al. The Application of Industrial Ecology Methods to Understand the Environmental and Economic Implications of the Forest Product Industries. Curr Forestry Rep 8, 346–361 (2022). https://doi.org/10.1007/s40725-022-00174-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40725-022-00174-x