Abstract

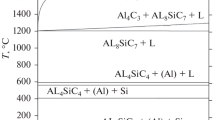

Insufficient understanding of the nature of the interfacial interaction of reinforcing particles with the matrix alloy during repeated remelting of cast composite materials is one of the problems that limit the increase in the volume of their industrial application. This work is aimed at establishing the effect of repeated remelting of AK12 + 10 vol % SiC aluminum matrix composites on the retention and chemical stability of silicon carbide reinforcing particles. It is shown that an increase in the number of remelting iterations was not accompanied by the appearance of new phases at the interfaces between particles and the matrix, which indicates the stability of the SiC reinforcing phase in aluminum–silicon melts under the considered temperature–time and concentration conditions. During repeated remelting of aluminum matrix composites with silicon carbide, the degree of particle distribution uniformity shifts toward a more uniform distribution (on average 0.81046 at the first iteration of remelting, 0.6901 at the second, and 0.5609 at the third) and some decrease in their average sizes occurs (from 70.74 µm at the first iteration to 65.76 µm at the second and 61.21 µm at the third), apparently owing to particle fragmentation, leading to an increase in the amount of a finer fraction. At the same time, the share of the area occupied by particles in the segments of the section under consideration remains practically unchanged (10.9293, 10.9607, and 11.6483% in the first, second, and third iterations of remelting, respectively). In the course of repeated remelting of aluminum matrix composites of the Al–SiC system, processes of redistribution of reinforcing particles occur, leading to the destruction of agglomerates even in the absence of intensive mixing by an impeller. Because of this, the uniformity of particle distribution in the structure of ingots of secondary aluminum matrix composites can be significantly improved.

Similar content being viewed by others

REFERENCES

Rohatgi, P.K., Ajay Kumar, P., Chelliah, N.M., and Rajan, T.P.D., Solidification processing of cast metal matrix composites over the last 50 years and opportunities for the future, JOM, 2020, vol. 72, no. 8, pp. 2912–2926. https://doi.org/10.1007/s11837-020-04253-x

Sharma, A.K., Bhandari, R., Aherwar, A., Rimašauskienė, R., and Pinca-Bretotean, C., A study of advancement in application opportunities of aluminum metal matrix composites, Mater. Today: Proc., 2020, vol. 26, part 2, pp. 2419–2424.

Mavhungu, S.T., Akinlabi, E.T., Onitiri, M.A., and Varachia, F.M., Aluminum matrix composites for industrial use: Advances and trends, Procedia Manuf., 2017, vol. 7, pp. 178–182. https://doi.org/10.1016/j.promfg.2016.12.045

Samal, P., Vundavilli, P.R., Meher, A., and Mahapatra, M.M., Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties, J. Manuf. Processes, 2020, vol. 59, pp. 131–152. https://doi.org/10.1016/j.jmapro.2020.09.010

Kala, H., Mer, K.K.S., and Kumar, S., A review on mechanical and tribological behaviors of stir cast aluminum matrix composites, Procedia Mater. Sci., 2014, vol. 6, pp. 1951–1960.

Reddy Sunil Kumar, K., Kannan, M., Karthikeyan, R., Prashanth, S., and Rohith Reddy, B., A review on mechanical and thermal properties of aluminum metal matrix composites, E3S Web Conf., 2020, vol. 184. p. 01033.

Koli, D.K., Agnihotri, G., and Purohit, R., Advanced aluminium matrix composites: The critical need of automotive and aerospace engineering fields, Mater. Today: Proc., 2015, vol. 2, nos. 4–5, pp. 3032–3041.

Surappa, M.K., Aluminium matrix composites: challenges and opportunities, Sadhana, 2003, vol. 28, nos. 1–2, pp. 319–334.

Midling, O.T. and Grong, O., Processing and properties of particle reinforced Al–SiC MMCs, Key Eng. Mater., 1995, vols. 104–107, part 1, pp. 329–354.

Soltani, S., Azari Khosroshahi, R., Taherzadeh Mousavian, R., Jiang, Z., Fadavi Boostani, A., and Brabazon, D., Stir casting process for manufacture of Al–SiC composites, Rare Met., 2017, vol. 36, no. 7, pp. 581–590.

Hashim, J., Looney, L., and Hashmi, M.S.J., The enhancement of wettability of SiC particles in cast aluminium matrix composites, J. Mater. Process. Technol., 2001, vol. 119, nos. 1–3, pp. 329–335.

Cong, X.-S., Shen, P., Wang, Y., and Jiang, Q., Wetting of polycrystalline SiC by molten Al and Al–Si alloys, Appl. Surf. Sci., 2014, vol. 317, pp. 140–146.

An, Q., Cong, X.-S., Shen, P., and Jiang, Q.-C., Roles of alloying elements in wetting of SiC by Al, J. Alloys Compd., 2019, vol. 784, pp. 1212–1220.

Yang, Y., Li, S., Liang, Y., and Li, B., Effect of temperature on wetting kinetics in Al/SiC system: A molecular dynamic investigation, Compos. Interfaces, 2020, vol. 27, no. 6, pp. 587–600.

Sijo, M.T. and Jayadevan, K.R., Analysis of stir cast aluminium silicon carbide metal matrix composite: A comprehensive review, Procedia Technol., 2016, vol. 24, pp. 379–385. https://doi.org/10.1016/j.protcy.2016.05.052

Carotenuto, G., Gallo, A., and Nicolais, L., Degradation of SiC particles in aluminium-based composites, J. Mater. Sci., 1994, vol. 29, no. 19, pp. 4967–4974.

Sijo, M.T. and Jayadevan, K.R., Characterization of stir cast aluminium silicon carbide metal matrix composite, Mater. Today: Proc., 2018, vol. 5, no. 11, part 3, pp. 23844–23852.

Prabu, S.B., Karunamoorthy, L., Kathiresan, S., and Mohan, B., Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite, J. Mater. Process. Technol., 2006, vol. 171, no. 2, pp. 268–273.

Prusov, E. and Panfilov, A., Influence of repeated remeltings on formation of structure of castings from aluminum matrix composite alloys, Proc. METAL 2013—22nd Int. Conference on Metallurgy and Materials, Brno, 2013, pp. 1152–1156.

Shabaldin, I.V. and Prusov, E.S., Program for mathematical assessment of the degree of uniformity of the distribution of reinforcing particles in the structure of composite materials, PC Software Certificate no. 2021619286, 2021.

Deng, X. and Chawla, N., Modeling the effect of particle clustering on the mechanical behavior of SiC particle reinforced Al matrix composites, J. Mater. Sci., 2006, vol. 41, pp. 5731–5734.

Hashim, J., Looney, L., and Hashmi, M.S.J., Particle distribution in cast metal matrix composites—Part I, J. Mater. Process. Technol., 2002, vol. 123, no. 2, pp. 251–257.

Yang, Z., Pan, L., Han, J., Li, Z., Wang, J., Li, X., and Li, W., Experimental and simulation research on the influence of stirring parameters on the distribution of particles in cast SiCp/A356 composites, J. Eng., 2017, vol. 2017, p. 9413060. https://doi.org/10.1155/2017/9413060

Lee, J.-C., Byun, J.-Y., Park, S.-B., and Lee, H.-I., Prediction of Si contents to suppress the interfacial reaction in the SiCp/2014 Al composite, Acta Mater., 1998, vol. 46, pp. 2635–2643.

Lloyd, D.J., The solidification microstructure of particulate reinforced aluminium/SiC composites, Compos. Sci. Technol., 1989, vol. 35, no. 2, pp. 159–179.

ACKNOWLEDGMENTS

The study was carried out using the equipment of the interregional multispecialty and interdisciplinary center for the collective usage of promising and competitive technologies in the areas of development and application in industrial/mechanical engineering of domestic achievements in the field of nanotechnology (Agreement no. 075-15-2021-692 of August 5, 2021).

Funding

This study was funded by the Russian Science Foundation (project no. 21-79-10432, https://rscf.ru/project/21-79-10432/).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by Sh. Galyaltdinov

About this article

Cite this article

Prusov, E.S., Deev, V.B., Aborkin, A.V. et al. Formation of the Structure and Phase Composition of Cast Aluminum Matrix Composites during Multiple Remelting. Russ. J. Non-ferrous Metals 63, 624–630 (2022). https://doi.org/10.3103/S1067821222060128

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222060128