Abstract

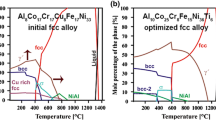

A thermodynamic assessment of the influence of alloying elements (Si, Mg, Cu, Ti) on the processes of phase formation during the production and liquid-phase processing of cast aluminum matrix composite materials with exogenous reinforcement (Al–SiC, Al–B4C) has been carried out. It is shown that without suppression of the formation of Al–Si–C and Al4C3 carbides in the range of carbon concentrations from 0 to 4.5 wt %, the equilibrium phase composition of composites of the Al–SiC system in the solid state at temperatures from 423 to 575ºC lies in the three-phase region (Al) + Si + Al4SiC4, and below a temperature of 423ºC, the Al4SiC4 ternary carbide is replaced by the Al8SiC7 compound. In the Al–SiC–Mg system, the crystallization of composites containing more than 0.58 wt % magnesium ends in the four-phase region (Al) + Al3Mg2 + SiC + Mg2Si. In the Al–SiC–Ti system, the end of crystallization is fixed in the three-phase region (Al) + Al3Ti + SiC. In the Al–B4C system, after suppression of the formation of the Al4C3 phase, with a deviation from the concentrations of elements that provide 10 vol % B4C, aluminum borides are formed in the direction of increasing boron, and free carbon is formed in the direction of decreasing boron. Under equilibrium conditions, with a silicon content of up to 0.67 wt %, the crystallization of the Al–B4C–Si system ends in the four-phase region (Al) + B4C + AlB12 + Al8SiC7, and at a higher silicon content, it ends in the region (Al) + Si + AlB12 + Al8SiC7. In the Al–B4C–Ti system, with a Ti content of less than 0.42 wt %, crystallization ends in the three-phase (Al) + TiB2 + B4C region.

Similar content being viewed by others

REFERENCES

Mortensen, A. and Llorca, J., Metal matrix composites. Annu. Rev. Mater. Res., 2010, vol. 40, pp. 243–270. https://doi.org/10.1146/annurev-matsci-070909-104511

Mavhungu, S.T., Akinlabi, E.T., Onitiri, M.A., and Varachia, F.M., Aluminum matrix composites for industrial use: Advances and trends, Procedia Manuf., 2017, vol. 7, pp. 178–182. https://doi.org/10.1016/j.promfg.2016.12.045

Pramanik, S., Cherusseri, J., Baban, N.S., Sowntharya, L., and Kar, K.K., Metal matrix composites: Theory, techniques, and applications, in Composite Materials, Kar, K., Ed., Berlin, Heidelberg: Springer, 2017, pp. 369–411. https://doi.org/10.1007/978-3-662-49514-8_11.

Prusov, E.S., Panfilov, A.A., and Kechin, V.A., Role of powder precursors in production of composite alloys using liquid-phase methods, Russ. J. Non-Ferrous Met., 2017, vol. 58, no 3, pp. 308–316. https://doi.org/10.3103/S1067821217030154

Kala, H., Mer, K.K.S., and Kumar, S., A Review on mechanical and tribological behaviors of stir cast aluminum matrix composites, Procedia Mater. Sci., 2014, vol. 6, pp. 1951–1960. https://doi.org/10.1016/j.mspro.2014.07.229

Samal, P., Vundavilli, P.R., Meher, A., and Mahapatra, M.M., Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties, J. Manuf. Processes, 2020, vol. 59, pp. 131–152. https://doi.org/10.1016/j.jmapro.2020.09.010

Prusov, E.S. and Panfilov, A.A., Properties of cast aluminum-based composite alloys reinforced by endogenous and exogenous phases, Russ. Metall. (Engl. Transl.), 2011, no. 7, pp. 670–674. https://doi.org/10.1134/S0036029511070123

Panfilov, A.A., Prusov, E.S., and Kechin, V.A., Metallurgiya alyumomatrichnykh kompozitsionnykh splavov (Metallurgy of Aluminum Matrix Composite Alloys), Vladimir: Vladimir State Univ. Named after Alexander and Nikolay Stoletovs, 2017.

Delannay, F., Froyen, L., and Deruyttere, A., The wetting of solids by molten metals and its relation to the preparation of metal-matrix composites, J. Mater. Sci., 1987, vol. 22, pp. 1–16.

Malaki, M., Fadaei Tehrani, A., Niroumand, B., and Gupta, M., Wettability in metal matrix composites, Metals, 2021, vol. 11, no. 7. p. 1034. https://doi.org/10.3390/met11071034

Eustathopoulos, N. and Voytovych, R., The role of reactivity in wetting by liquid metals: A review, J. Mater. Sci., 2016, vol. 51, pp. 425–437. https://doi.org/10.1007/s10853-015-9331-3

Hashim, J., Looney, L., and Hashmi, M.S.J., The wettability of SiC particles by molten aluminium alloy, J. Mater. Process. Technol., 2001, vol. 119, pp. 324–328. https://doi.org/10.1016/S0924-0136(01)00975-X

Egry, I., Ricci, E., Novakovic, R., and Ozawa, S., Surface tension of liquid metals and alloys—recent developments, Adv. Colloid Interface Sci., 2010, vol. 159, pp. 198–212.

Carotenuto, G., Gallo, A., and Nicolais, L., Degradation of SiC particles in aluminium-based composites, J. Mater. Sci., 1994, vol. 29, pp. 4967–4974.

Chernyshova, T.A. and Rebrov, A.V., Interaction kinetics of boron carbide and silicon carbide with liquid aluminium, J. Less-Common Met., 1986, vol. 117, nos. 1–2, pp. 203–207.

Pech-Canul, M.I., Katz, R.N., and Makhlouf, M.M., Optimum parameters for wetting silicon carbide by aluminum alloys, Metall. Mater. Trans. A, 2000, vol. 31, no. 2, pp. 565–573.

Prusov, E.S., Deev, V.B., Shurkin, P.K., and Arakelian, S.M., The effect of alloying elements on the interaction of boron carbide with aluminum melt, Non-Ferrous Met. (Moscow, Russ. Fed.), 2021, vol. 50, no. 1, pp. 27–33. https://doi.org/10.17580/nfm.2021.01.04

Shi, R. and Luo, A.A., Applications of CALPHAD modeling and databases in advanced lightweight metallic materials, Calphad, 2018, vol. 62, pp. 1–17. https://doi.org/10.1016/j.calphad.2018.04.009

Jung J.-G., Cho, Y.-H., Lee, J.-M., Kim, H.-W., and Euh, K., Designing the composition and processing route of aluminum alloys using CALPHAD: Case studies, Calphad, 2019, vol. 64, pp. 236–247. https://doi.org/10.1016/j.calphad.2018.12.010

Belov, N.A., Naumova, E.A., Akopyan, T.K., and Doroshenko, V.V., Phase diagram of the Al–Ca–Fe–Si system and its application for the design of aluminum matrix composites, JOM, 2018, vol. 70, pp. 2710–2715. https://doi.org/10.1007/s11837-018-2948-3

Prusov, E., Deev, V., and Shunqi, M., Thermodynamic assessment of the Al–Mg–Si–Ti phase diagram for metal matrix composites design, Mater. Today: Proc., 2019, vol. 19, no. 5, pp. 2005–2008. https://doi.org/10.1016/j.matpr.2019.07.061

Viala, J.C., Fortier, P., and Bouix, J., Stable and metastable phase equilibria in the chemical interaction between aluminium and silicon carbide, J. Mater. Sci., 1990, vol. 25, no. 3, pp. 1842–1850. https://doi.org/10.1007/BF01045395

Schuster, J.C. and Palm, M., Reassessment of the binary aluminum-titanium phase diagram, J. Phase Equilib. Diffus., 2006, vol. 27, pp. 255–277. https://doi.org/10.1361/154770306X109809

Toptan, F., Kilicarslan, A., and Kerti, I., The effect of Ti addition on the properties of Al-B4C interface: A microstructural study, Mater. Sci. Forum, 2010, vols. 636–637, pp. 192–197. https://doi.org/10.4028/www.scientific.net/msf.636-637.192

Zhang, Z., Fortin, K., Charette, A., and Chen, X.-G., Effect of titanium on microstructure and fluidity of Al–B4C composites, J. Mater. Sci., 2011, vol. 46, pp. 3176–3185. https://doi.org/10.1007/s10853-010-5201-1

Funding

This study was funded by the Russian Science Foundation (project no. 21-79-10432, https://rscf.ru/project/21-79-10432/).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Prusov, E.S., Kechin, V.A., Deev, V.B. et al. Thermodynamics of the Effect of Alloying of Phase Formation during Crystallization of Aluminum Matrix Composites with Exogenous Reinforcement. Russ. J. Non-ferrous Metals 63, 631–640 (2022). https://doi.org/10.3103/S106782122206013X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782122206013X