Abstract

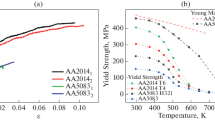

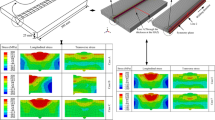

Simulation model accuracy of quench induced residual stress in wrought magnesium alloy Mg‒Gd–Y–Zr–Ag–Er is tested by applying both isotropic and anisotropic criteria models in residual stress FEM simulation. Both hexagonal close-packed (HCP) lattice structure and asymmetry are considered in the manufacturing process. The distributions of residual stress in isotropic and anisotropic criteria models differ both in distribution and in value, which is due to stress-strain nonuniformity in extrusion direction (ED) and long transverse direction (LTD). Comparing the experimental and predicted errors of the two models, the anisotropic model improves the prediction accuracy by 8.3% in ED and 4.8% in LTD. Residual stress in LTD is always larger than that in ED by the XRD method, and the average deviation between the XRD method and the hole-drilling method is reduced through electropolishing.

Similar content being viewed by others

REFERENCES

Jia-Siang, W. and Chih-Chun, H., The relationships between residual stress relaxation and texture development in AZ31 Mg alloys via the vibratory stress relief technique, Mater. Charact., 2015, vol. 99, pp. 248–253. https://doi.org/10.1016/j.matchar.2014.09.019

Zengin, H. and Turen, Y., Evolution of microstructure, residual stress, and tensile properties of Mg–Zn–Y–La–Zr magnesium alloy processed by extrusion, Acta Metall. Sin. (Engl. Lett.), 2019, vol. 32, no. 11, pp. 1309–1319. https://doi.org/10.1007/s40195-019-00901-7

Samman, T. and Gottstein, G., Room temperature formability of a magnesium AZ31 alloy: Examining the role of texture on the deformation mechanism, Mater. Sci. Eng., A, 2008, vol. 488, pp. 406–414. https://doi.org/10.1016/j.msea.2007.11.056

Zhang, F., Liu, Z., and Wang, Y., The modified temperature term on Johnson–Cook constitutive model of AZ31 magnesium alloy with 0002 texture, J. Magnesium Alloys, 2020, vol. 8, no. 1, pp. 172–183. https://doi.org/10.1016/j.jma.2019.05.013

Wencai, L. and Beiping, Z., High temperature mechanical behavior of low-pressure sand-cast Mg–Gd–Y–Zr magnesium alloy, J. Magnesium Alloys, 2019, vol. 7, pp. 597–604. https://doi.org/10.1016/j.jma.2019.07.006

Pan, R., Pirling, T., and Zheng, J., Quantification of thermal residual stresses relaxation in AA7xxx aluminium alloy through cold rolling, J. Mater. Process. Technol., 2019. vol. 264, pp. 454–468. https://doi.org/10.1016/j.jmatprotec.2018.09.034

Yuxun, Z. and Youping, Y., Influence of temperature dependent properties of aluminum alloy on evolution of plastic strain and residual stress during quenching process, Metals, 2017, vol. 7, no. 6, p. 228. https://doi.org/10.3390/met7060228

Yuxun, Z. and Youping, Y., Influence of quenching cooling rate on residual stress and tensile properties of 2A14 aluminum alloy forgings, Mater. Sci. Eng., A, 2016, vol. 674, pp. 658–665. https://doi.org/10.1016/j.msea.2016.08.017

Hai, G. and Yanjie, S., Effect of vibration stress relief on the shape stability of aluminum alloy 7075 thin-walled parts, Metals, 2019, vol. 9, no. 1, p. 27. https://doi.org/10.3390/met9010027

Citarella, R. and Carlone, P., Hybrid technique to assess the fatigue performance of multiple cracked FSW joint, Eng. Fract. Mech., 2016, vol. 162, pp. 38–50. https://doi.org/10.1016/j.engfracmech.2016.05.005

Hosaka, T., Influence of grain refinement and residual stress on corrosion behavior of AZ31 magnesium alloy processed by ECAP in RPMI-1640 medium, Procedia Eng., 2017, vol. 184, pp. 432–441. https://doi.org/10.1016/j.proeng.2017.04.114

Hill, R., A theory of the yielding and plastic flow of anisotropic metals, Proc. R. Soc. A, 1948, vol. 193, no. 1033, pp. 281–297. https://doi.org/10.1098/rspa.1948.0045

Holger, A. and Barlat, F., New convex yield functions for orthotropic metal plasticity, Int. J. Non-Linear Mech., 2013, vol. 51, pp. 97–111. https://doi.org/10.1016/j.ijnonlinmec.2012.12.007

Barlat, F., Linear transformation-based anisotropic yield functions, Int. J. Plast., 2005, vol. 21, no. 5, pp. 1009–1039. https://doi.org/10.1016/j.ijplas.2004.06.004

Zhang, H. and Diehl, M., A virtual laboratory using high resolution crystal plasticity simulations to determine the initial yield surface for sheet metal forming operations, Int. J. Plast., 2016, vol. 80, pp. 111–138. https://doi.org/10.1016/j.ijplas.2016.01.002

Yoon, J. and Cazacu, O., Constitutive modeling of AZ31 sheet alloy with application to axial crushing, Mater. Sci. Eng., A, 2013, vol. 565, pp. 203–212. https://doi.org/10.1016/j.msea.2012.12.054

Masoudpanah, S.M. and Mahmudi, R., Effects of rare-earth elements and Ca additions on the microstructure and mechanical properties of AZ31 magnesium alloy processed by ECAP, Mater. Sci. Eng., A, 2009, vol. 565, nos. 1–2, pp. 22–30. https://doi.org/10.1016/j.msea.2009.08.027

Sheikhani, A., Roumina, R., and Mahmudi, R., Hot deformation behavior of an extruded AZ31 alloy doped with rare-earth elements, J. Alloys Compd., 2021, vol. 852, p. 156961. https://doi.org/10.1016/j.jallcom.2020.156961

Zhang, Y., Yi, Y., and Huang, S., Influence of quenching cooling rate on residual stress and tensile properties of 2A14 aluminum alloy forgings, Mater. Sci. Eng., A, 2016, vol. 674, pp. 658–665. https://doi.org/10.1016/j.msea.2016.08.017

Wang, C., Luo, T., and Zhou, J., Effects of solution and quenching treatment on the residual stress in extruded ZK60 magnesium alloy, Mater. Sci. Eng., A, 2018, vol. 722, pp. 14–19. https://doi.org/10.1016/j.msea.2018.02.047

Schajer, G.S., Practical Residual Stress Measurement Methods, John Wiley and Sons, 2013.

Liu, Y., Mao, P., and Zhang, F., Effect of temperature on the anisotropy of AZ31 magnesium alloy rolling sheet under high strain rate deformation, Philos. Mag., 2018, vol. 98, no. 12, pp. 1068–1086. https://doi.org/10.1080/14786435.2018.1427896

Adrien, C. and Driver, J.H., Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals, Acta Mater., 2011, vol. 59, no. 5, pp. 1986–1994. https://doi.org/10.1016/j.actamat.2010.11.064

Wang, C. and Luo, T., Residual stress and precipitation of Mg–5Zn–3.5Sn–1Mn–0.5Ca–0.5Cu alloy with different quenching rates, J. Magnesium Alloys, 2021, vol. 9, no. 2, pp. 604–612. https://doi.org/10.1016/j.jma.2020.02.021

Yan, J., Pan, Q., and Li, A., Flow behavior of Al–6.2Zn–0.70Mg–0.30Mn–0.17Zr alloy during hot compressive deformation based on Arrhenius and ANN models, Trans. Nonferrous Met. Soc. China, 2017, vol. 27, no. 3, pp. 638–647. https://doi.org/10.1016/S1003-6326(17)60071-2

Zhang, L. and Wang, H., Improved tension/compression asymmetry achieved in high-strength magnesium alloys via compression-extrusion process, Mater. Sci. Eng., A, 2018, vol. 736, pp. 239–247. https://doi.org/10.1016/j.msea.2018.08.110

Jia, Y. and Bai, Y., Experimental study on the mechanical properties of AZ31B-H24 magnesium alloy sheets under various loading conditions, Int. J. Fract., 2016, vol. 197, pp. 25–48. https://doi.org/10.1007/s10704-015-0057-7

Xie, Q., Wu, Y., Zhang, T, et al., Effects of quenching cooling rate on residual stress and mechanical properties of a rare-earth wrought magnesium alloy, Materials, 2022, vol. 15, no. 16, p. 5627. https://doi.org/10.3390/ma15165627

ACKNOWLEDGMENTS

The authors greatly appreciate the support from the National Natural Science Foundation (no. 51975596) and the Project of State Key Laboratory of High-Performance Complex Manufacturing, Central South University under Award ZZYJKT2020-13.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Qiumin Xie, Wu, Y., Yuan, Z. et al. Comparison of Isotropic and Anisotropic Yield Criteria Models in Quenching Residual Stress of Magnesium Alloys. Russ. J. Non-ferrous Metals 63, 701–708 (2022). https://doi.org/10.3103/S1067821222060141

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222060141