Abstract

Purpose of Review

In the context of COVID-19 sweeping the world, the development of microbial disinfection methods in gas, liquid, and solid media has received widespread attention from researchers. As a disinfection technology that can adapt to different environmental media, microwave-assisted disinfection has the advantages of strong permeability, no secondary pollution, etc. The purpose of this review is to put forward new development requirements for future microwave disinfection strategies by summarizing current microwave disinfection methods and effects. From the perspective of the interaction mechanism of microwave and microorganisms, this review provides a development direction for more accurate and microscopic disinfection mechanism research.

Recent Findings

Compared to other traditional environmental disinfection techniques, microwave-assisted disinfection means have the advantages of being more destructive, free of secondary contamination, and thorough. Currently, researchers generally agree that the efficiency of microwave disinfection is the result of a combination of thermal and non-thermal effects. However, the performance of microwave disinfection shows the differences in the face of different environmental media as well as different types of microorganisms.

Summary

This review highlights the inactivation mechanism of microwave-assisted disinfection techniques used in different scenarios. Suggestions for promoting the efficiency and overcoming the limitations of low energy utilization, complex reactor design, and inaccurate monitoring methods are proposed.

Similar content being viewed by others

Introduction

Microwave (MW) technology has been widely developed and utilized in industrial and household fields. When applied to the field of disinfection, microwave irradiation can effectively inactivate microorganisms and reduce the disinfection byproducts by making enzyme, protein, and membrane denature, and cellular metabolic activity disruption [1]. This particular biophysical effect of microwave field on microorganisms was discovered as early as the 1940s. In the 1960s and 1970s, researchers began to consider the application of microwave in practical production, taking food [2] and wastewater [3] as research objects to explore the sterilization effect of microwave. Subsequently, researchers optimized the microwave treatment parameters and explored the interaction mechanism between microwave and microorganisms. At present, the interaction mechanisms between microwave and microorganisms considered have two effects: thermal effect and non-thermal effect.

Many researches have reported microwave radiation as an efficient disinfection method to inactivate microorganisms in water, solids, and food. For example, Li et al. [4] conducted synergistic activation of peroxydisulfate with a microwave-responsive catalyst (Co-Bi25FeO40) in a microwave field for bacterial inactivation in wastewater treatment, which showed microwave had a positive effect on system disinfection. Plazas et al. [1] synthesized a novel nano-heterostructure material and applied it to water disinfection under microwave irradiation, and the result showed that this nano-heterostructure material combining carbon nanotubes and erbium oxide can effectively absorb microwave energy and inactivate Pseudomonas aeruginosa in water by generating reactive oxygen species, which provides a guideline for the development of new techniques of nano-enabled water disinfection. In respect to solid disinfection, Karlsson et al. [5] developed a pilot system with microwave irradiation and evaluated its pathogen disinfection performance against Escherichia coli, Enterococcus, and Salmonella of sewage sludge. Besides, Mawioo et al. [6] treated fresh blackwater sludge with a laboratory-scale microwave reactor and evaluated the effect of microwave radiation power and duration on sludge volume and pathogen reduction. The experiments showed that MW was an efficient technology that could reduce sludge volume by more than 70% and the concentration of E. coli is below the analytical detection level. Apart from the achievement of microwave disinfection in treating water and solids, it also plays a role in the food industry, such as the sterilization of carrot slices [7], sweet potato puree [8], and milk [9]. However, due to the weak microwave absorption of air, the research and application of microwave in airborne disinfection are very limited. Various airborne biological particles in the form of bioaerosols may transmit a variety of harmful microorganisms and also require effective inactivation and control. In order to realize an efficient and rapid disinfection technology in the air by using microwave, microwave-absorbing materials (MAMs) can be added and utilized. For example, Wang et al. [10•] proposed MAMs (Fe3O4@SiC ceramic foam) and embedded it in microwave device for inactivating airborne microorganisms, noting that microwave radiation has a higher inactivation rate than Fenton and UV disinfection techniques. Laghari et al. [11•] compared the effects of microwave radiation with MAMs and ultraviolet radiation on the inactivation of antibiotic-resistant bacteria (ARBs) and antibiotic-resistant genes (ARGs). By comparing airborne and waterborne disinfection based on microwave radiation, there are distinct mechanisms of microwave inactivation for them. Some researchers think that the mechanism of microwave irradiation on microorganisms in waterborne is mainly the thermal effect, and the non-thermal effect is the main mechanism of microorganism inactivation in airborne [12••]. Based on the relevant researches, microwave disinfection is a promising technology to inactivate airborne microorganisms, but it may be limited by energy efficiency and needs to be optimized for more efficient utilization pathways to degrade airborne microorganism distribution.

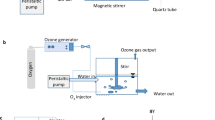

To enhance the disinfection efficiency, microwave-assisted disinfection was also used in combination with other disinfection techniques. For example, in order to compensate the shortcoming of UV disinfection, a combined disinfection with microwave and UV irradiation was proposed to disinfect municipal secondary effluents. The evaluated parameters influencing disinfection included microwave power, irradiation duration, and UV light intensity [13]. By combining microwave irradiation with the chemical disinfection method to treat siloxane impression material, the highest antimicrobial efficacies were shown without adverse effects on the material itself [14]. Microwave irradiation can be also integrated with ozone disinfection [15]. Microwave disinfection technology is a physical disinfection method, having advances in equipment reliability. In addition, microwave-assisted plasma technology has also been reported to disinfect gas samples, waterbody, and solid surface. For example, He-H2 or O2 can be used as a plasma gas to disinfect water which was contaminated by Bacillus globigii spores [16]. A low-temperature microwave-generated atmospheric pressure plasma jet was developed to directly treat bacteria and reduce the number of bacteria to some extent [17].

This perspective states the efficiency and applicability of microwave disinfection techniques to help construct specific disinfection systems targeting inactivated microorganisms in different environmental media. The key factors for the inactivation of various microorganisms by microwave irradiation are discussed, such as absorbing materials, absorbing mechanisms, preparation methods, disinfection effects, and influencing factors in the treatment process. In addition, microwave disinfection scenarios related to microbial disinfection strategies are evaluated and the directions for future research are explored.

Principle and Characteristics of Microwave Heating Technology

Microwave, referring to electromagnetic waves with frequencies between 300 MHz and 300 GHz, has been widely used in domestic and industrial fields for heating food and chemical substances. In response to the alternating electromagnetic field of microwave irradiation, the molecular dipoles rotate along with the direction of the electromagnetic field and generate heat energy in the process of colliding with each other. Therefore, microwave radiation is able to directly interact with the targeted material and lead to a temperature rise inside the center of the matter; this heating mode cannot be achieved by traditional heating methods through thermal conduction, convection, and radiation. The remote and efficient energy-transmitting principle gives microwave heating selective, rapid, and volumetric characteristics, which enable microwave radiation to rapidly denature enzymes, proteins, and membranes and disrupt cellular metabolic activity in the field of disinfection, bringing about an expected sterilization effect and reducing unwanted disinfection byproducts.

It should be noted that the systems of microwave-assisted disinfection are commonly heterogeneous; the interaction between microwave and substances includes reflection, absorption, and transmission, which depends on the properties of the substances themselves. On the one hand, the microwave-absorbing ability of a substance depends on its complex dielectric constant (ε′-jε″). The dielectric constant (ε′) and the dielectric loss (ε″) represent the ability to store electrical energy via molecular polarization and to convert stored electrical energy into thermal energy, respectively. On the other hand, a few studies attributed microwave radiation effects to magnetic fields, which include some magnetic dielectric materials and conductive powder materials. The magnetic loss mainly depends on the permeability (μr = μ′-jμ″), where the μ′ value represents the ability to store magnetic energy, and the μ″ value represents the magnetic loss ability.

Object and Mechanism of Microwave Disinfection

Effect of Microbial Species on Microwave Disinfection

The use of microwave technology for environmental disinfection and food processing disinfection is a common technique. The microorganisms in disinfection objects mainly include three main groups, namely, bacteria, fungi (spores), and viruses. In addition, foodborne pathogens, such as Salmonella spp., Escherichia coli O157:H7, Staphylococcus aureus, Campylobacter spp., and Listeria monocytogenes, have been the focus of most studies on the safety of microwave food. Many researches have shown that microwave-assisted disinfection can inactivate harmful microorganisms inside the food, while maintaining the important components of food (wheat germ, milk, carrot juice, celery juice) as well as major nutrients without loss [18, 19]. The microwave sterilization of Salmonella spp., E. coli O157:H7, and Listeria monocytogenes in sesame paste was found to be highly effective in sterilization while basically not affecting the physicochemical properties of sesame paste such as color and nutrients [20•]. Besides, the secondary biotoxic substances produced during the sterilization process can also be degraded by microwave. Toxins distributed in the outer cell wall membranes of Gram-negative bacteria and other microorganisms were released into the air after cell lysis and the total endotoxin removal efficiency can be achieved up to 35% [21••]. In addition, microwave technology can also reduce the toxicity of Shiga toxin 2 (Stx2) in milk because exposure to high-power microwave degraded the original structure of protein toxins [22].

The type of microorganism largely influences the sterilization efficiency of microwave disinfection technology. Among microorganisms, bacteria, fungi (spores), and viruses differ in their biological type, cell structure, cell size, and mode of proliferation, which also lead to different inactivation mechanisms. Bacillus subtilis and Pseudomonas fluorescens belong to Gram-positive bacteria and Gram-negative bacteria, respectively. As shown in Fig. 1, compared with Gram-negative bacteria, Gram-positive bacteria have thicker cell walls which can provide more protection against environmental stress [23••]. However, there are also differences among different Gram-negative bacteria. After microwave irradiation of Salmonella Senftenberg, Salmonella Typhimurium, and Salmonella Tennessee, it was found that the inactivation efficiency of Salmonella Tennessee was higher than that of the other two serovars, although they belong to the same Salmonella serovars. The difference in the inactivation process can be attributed to the lower thermal resistance of Salmonella Tennessee than that of the other two serovars due to biological differences [24].

In contrast to bacteria, the main component of the cell wall of fungi is chitin; its complex internal organelle structure makes it more protective than peptidoglycan. Microwave exposure causes a series of damages, such as spore shrinkage and deformation, spore fragmentation and lyses, and rupture of spore membrane. The exposure to 60-s microwave irradiation disrupted the spore core complexes of Clostridium difficile spores, leading to heavy aggregation of cytoplasmic proteins, inner membrane fusion, and the destruction of the outer coat and cortex [25••]. For the spores of biofilms of Bacillus cereus, the loss of membrane integrity caused by microwave treatment is the root cause of its deactivation [26]. In addition, Bacillus licheniformis can produce stress-resistant spores under certain conditions. The spores have a lamellar inner coat and a thick, electron-dense striated outer coat closely opposed to the inner coat. The study shows that the coat and cortex of the spores have ruptured after microwave irradiation [27]. Compared with pure boiling, its ultrastructural changes are more significant (Fig. 1).

The structure of the virus is very simple, with a layer of protein outside, which is called the virus shell. After microwave irradiation of MS2 virus aerosol, it was found that visible damage occurred on the surface of the virus. The viral RNA genes coding for coat proteins are also disrupted, especially the A protein gene [28]. The ability loss of the virus to express the relevant proteins during treatment may be due to varying degrees of damage to the protein genes, which also makes it difficult to identify and infect the host.

Interaction Mechanism Between Microwave and Microorganism

Through the analysis of studies on microwave-assisted disinfection, the effect of microwave irradiation on different kinds of microorganisms (bacteria, fungi, and viruses) is here summarized in Fig. 1. The difference of biological structure leads to the physical damage of microorganisms in different degrees, which ultimately affects the activity of microorganisms. Currently, the mechanism of microwave inactivation of microorganisms is still controversial. The focus has fallen on whether there exist non-thermal effects of microwave irradiation during the inactivation of microorganisms.

Thermal Effect

The thermal effect of microwave irradiation results from the heating of dielectric materials via induced molecular vibrations caused by electromagnetic waves [29]. On this basis, the general process of microwave-assisted sterilization is to rapidly heat water molecules inside the microorganisms, leading to the denaturation of enzymes, proteins, and membranes, and the disruption of cellular metabolic activity [30]. In microwave sterilization, the sterilization part caused by thermal effect is difficult to separate. Different disinfection mechanisms work together on the microstructure of microorganisms. However, when studying the mechanism of microwave sterilization, it is usually necessary to explore the action process of different field effects. Therefore, researchers used water bath heating, boiling, and sterilization equipment (steam cabinet, autoclave, etc.) and other operations to study the effect of temperature increase on the biological activity in an equivalent way [27, 31, 32]. The synergistic effect of temperature (i.e., thermal effect) and non-thermal effect can be explored by analyzing the difference in additional microbial inactivation values between microwave treatment and traditionally thermal treatment. At the same time, higher temperatures induced by microwave can also promote more pronounced microwave non-thermal effects [33].

Non-thermal Effect

Some scientists claimed in the last century that the inactivation mechanism of microorganisms was only due to thermal effect, and there was no difference between microwave disinfection and direct external heating disinfection [34, 35]. However, some special phenomena and results in microwave heating process have been confirmed by existing articles. It is called the non-thermal effect of microwave. The non-thermal effect mainly refers to effects other than the thermal effect, such as electrical effect, magnetic effect, and chemical effect, which is independent of the macroscopic temperature effect [36, 37]. Researchers usually use the method of heating up as the equivalent replacement of the microwave thermal effect and compare this effect with the overall microwave sterilization. The additional sterilization efficiency is attributed to the non-thermal effect. When sterilizing salmon fillets inoculated with Clostridium sporogenes, it was found that the non-thermal effect of the microwave field increased with the duration of microwave radiation and was exacerbated by the increase in temperature [38]. Differences are also found in the non-thermal effect of microorganisms in different environmental media. The study of Wang et al. showed that airborne E. coli exhibited a stronger non-thermal effect compared with waterborne E. coli [12••]. Such a unique inactivation mechanism is due to the difference in electromagnetic fields in the air and water phases. The electric field induced by microwave radiation directly interacts with specific molecules on the surface of bacterial cells at the sample position, causing changes in cell morphology, which further leads to the failure of intracellular oxidative defense mechanisms and DNA damage–mediated inactivation of bacterial cells [39]. Nevertheless, there were still some researchers with different views. Shamis et al. concluded that it was unreasonable to attribute such effects to non-thermal machinery due to poor control protocols and failure to consider the immeasurability of instantaneous temperatures [40•].

The non-thermal effect of microwave technology causes direct structural damage to microorganisms [31, 33], which significantly reduces the culturable activity of microorganisms. Moreover, the cell inactivation caused by microwave treatment is closely related to biological process dysfunction and metabolic imbalance [41]. Cell membranes are bilayer-structure dielectric materials composed of lipid molecules. Under the influence of an applied electromagnetic field, the membrane potentially undergoes conformational changes [42]. The migration of small ions such as K+, Na+, and Ca2+ inside and outside indicates damage to the permeability barrier of the cell [12••]. When the ion channels exceed the adaptive limits of the membrane, the original structure of the membrane is destroyed and cannot be restored. The non-thermal effect under microwave irradiation can induce micro-morphological growth expansion of microorganisms, which also results in the treated cells being more susceptible to antibiotics [43••]. All of the above processes illustrate that the non-thermal effect of microwave cannot be ignored, which is a process requiring cumulative effects.

Microwave Disinfection in Different Environmental Media

Gas Medium

As shown in Table 1, microwave disinfection efficiency varies greatly in different environmental media, which may affect the development of microwave disinfection technology in the future. Biological particles in the air had been posing a great threat to public health and safety because of their strong infectivity. Especially since COVID-19 swept the world, researchers paid more attention on how to control and disinfect airborne microorganisms. Researchers developed a microwave-assisted nanofibrous air filtration system to disinfect air containing airborne pathogens (aerosolized E. coli and Bacillus subtilis endospores). When 500-W microwave irradiation was applied continuously or periodically, it can cause sterilization efficiency of at least 3.7 lg (logarithmic level) to airborne E. coli, while less disinfection efficiency can be achieved at a lower power level [44]. After experiencing microwave radiation at different power levels, it was found that high-power microwave irradiation (31.5 kJ) usually led to less culturable bacterial aerosol richness [45]. Moreover, the change of treatment efficiency with time did not show a simple linear relationship because faster air flow would lead to more heat loss [46]. Under the same irradiation conditions, different humidity also affected the disinfection process [47]. Higher water content contributed to the vibration of water molecules, which led to more effective heating [48]. In addition, another reason was that the dielectric constant of air with different humidity varied greatly [49], which was also an important reason why humidity affected the sterilization efficiency.

The researchers also conducted relevant tests in the actual environment. The results showed that the outdoor bioaerosol was more resistant than the indoor one when exposed to microwave radiation [23••]. However, the inhibition of microwave technology was limited in the atmospheric environment, due to microwave energy was weakly absorbed by air [12••]. This limitation can be overcome by using microwave-absorbing materials (MAMs) to enhance the microwave-absorbing ability [10•, 11•]. Different from direct exposure by microwave, MAMs with good interfacial impedance matching could translate the absorbed microwave energy into thermal heat [55]. Therefore, the complex dielectric (or magnetic) constant and impedance matching ability both determine the microwave-absorbing properties of materials and therefore affect the efficiency to kill microbes [56].

Liquid Medium

The dielectric properties of liquids depend on their components (fat content, salt content, solid content, etc.) [57,58,59]. For example, the dielectric loss varied with the concentration and kinds of salts in liquids [60]. In addition, the viscosity of liquids also affected the loss factor ε″ due to the change of ionic conductivity. The increase of ionic conductivity can be attributed to the decrease of viscosity, which increased the mobility of ions [61]. Moreover, the dielectric properties can affect the value of microwave penetration depth. The power penetration depth of electromagnetic wave was determined to be the depth when the power was reduced to e−1 (e = 2.7183). The power penetration depth can be calculated according to the relative dielectric constant and loss factor value [62•].

where dp is the penetration depth (m) and λ0 = c0/f was the electromagnetic wavelength in free space (m), c0 is the speed of light in free space (c0 = 2.9979 × 108 m/s), and f is the field frequency (Hz).

The smaller the penetration depth is, the easier can the temperature and vibration frequency rise to the specified value [59], which leads to more thorough heating and disinfection. In the process of studying microwave heating disinfection, researchers also found that the uniformity of electromagnetic fields affected the efficiency of microwave disinfection for liquid media. The temperature distribution was affected by the characteristics of the disinfection object (dielectric and thermal parameters) and the characteristics of the microwave heating system (such as the frequency, power, and system geometry of the application) [63••]. Besides, the size and thickness of the water layer also affected the temperature distribution, which can be correctly explained by mathematical modeling [64]. Moreover, microwave power was an important parameter in liquid medium disinfection [65]. In the study on the treatment of fluids containing different kinds of biological pollutants in the continuous microwave system, it was found that in addition to the microwave power, the flow rate also directly affected the efficiency [66]. Since the purification retention time of different organisms can be calculated, this technology might become an effective tool to control/prevent invasive species from entering the local environment [67].

Solid Media

The uneven distribution of temperature in solid media used for microwave disinfection was one of the main issues widely discussed by scholars. Fluctuations in heating capacity raised questions about disinfection level and safety because if microorganisms were found at cold spots, they might not be inactivated [68]. Microwave technology had significant applications, but its commercialization needed more research work. In fact, the properties of sterilized objects greatly affected the efficiency of microwave treatment. When the same disinfection level was required, larger objects usually absorbed more microwave energy than smaller objects. There was basically a positive relationship between density and dielectric constant, which also led to the direct influence of density on the thermal effect of microwave [69]. In addition, the moisture content, bulk density, and surrounding materials all affected the heating uniformity and heating rate [70]. By establishing mathematical models, the temperature distribution of different shapes (slab, cylindrical, and spherical) was found to be quite different. The spherical shape had the smallest surface area and smallest heat loss, while the plate shape had the largest surface area and therefore the largest heat loss among the samples [71••]. Such difference was one of the factors affecting the disinfection effect. Different locations of the same disinfected object were subjected to different heat conditions. The inactivation of target microorganisms was studied from a single temperature measurement at a given location by a modeling approach. The electric field, temperature distribution, and inactivation kinetics were predicted as a function of time and space coordinates [72]. Through experiments and a 3D electromagnetic field simulator (CST microwave studio simulation), the temperature of the front of the sterilized component was higher than that of the back, with the highest temperatures in the middle part. The sterilization temperatures in the upper and middle parts were higher than those in the lower part [73].

Although there was a temperature difference between the central part and the side part of the disinfected solid object, the temperature difference decreased as the power level increases from 1.8 to 4.8 kW, and the temperature distribution became more uniform [53]. When disinfecting dental gypsum casts, it was also found that higher power levels allowed the pathogens to be effectively inactivated in a shorter time [74] because high microwave power was an important factor in improving the degree of cell fragmentation [75]. Besides, the dielectric property was also one of the influencing factors of solid in-depth disinfection [76] and it affected the power penetration depth. The water content in solids was a profound example [77]. Products with low moisture content might also be well heated due to low specific heat capacity, and with the decrease of moisture content, the penetration depth of waves will increase [78]. Researchers used microwave technology to disinfect agricultural soil without using pesticides [79•]. Due to the dielectric constant of the soil being a function of its water content, the absorbed power of the soil and the temperature distribution caused by the contour can be evaluated according to the length of irradiation time, so as to effectively disinfect the treated farmland. Similarly, as a hygroscopic material, the dielectric property of bentonite clay increased linearly with the increase of water content in the system [80].

Summary and Prospect

As an emerging environmental disinfection technology, microwave disinfection has the characteristics of strong penetrability and is not easy to be blocked in the air. Under certain conditions, microwave heating can act on the substance itself and have biological effects to inactivate microorganisms in environmental media. With the continuous development of microwave disinfection technology, it has been widely used in food, solid, and water bodies, and a small amount of researches on air disinfection. Besides, microwave irradiation, as a physical field, can act synergistically with other disinfection techniques, such as UV irradiation and ozone disinfection [13, 15]. The heating rate of sample by microwave is an important factor that may be limiting the application of microwave disinfection technology if the sample has a weak absorbing ability of microwave, such as airborne media. In order to strengthen the disinfection effect of microwave radiation on microorganisms, MAMs can be added and utilized. However, the current research on the use of MAMs in microwave disinfection technology is still in its infancy; only a few researchers proposed MAMs (Fe3O4@SiC ceramic foam) and embedded it in a microwave device for inactivating airborne microorganisms [10•]. Therefore, the development and application of new MAMs, relevant devices, and automatic control need to be systematically discussed to take insights into the future development direction of microwave disinfection technology.

The Development and Application of New MAMs

During microwave irradiation, the addition or doping of MAMs can effectively alleviate problems of microwave transparent materials that are not heated, thereby changing the dielectric properties of the materials themselves and improving the energy efficiency of microwave radiation [81]. The MAMs mainly include three categories, namely, conductive materials, dielectric materials, and magnetic materials. For the conventional absorbing materials, there are carbon materials, ceramics, metal oxides, and magnetic metals. With the in-depth understanding of MAMs, emerging absorbing materials such as conductive polymers [82], nanomaterials [83], and chiral materials [84] were proposed. In addition, multi-component composite absorbers were vigorously developed because they can enhance electromagnetic functions through synergistic effects between components. For example, several combined materials were proposed in recent years, including the FeCo@carbon nanoparticles [85], binary composite including arm symmetrical PbS dendrites and polyvinylidene fluoride [86], and ZnFe2O4 supported on carbonyl iron [87], which can enhance dielectric loss significantly and improve overall attenuation ability towards microwave.

MAMs are widely used in electromagnetic pollution prevention, military stealth technology, microwave heating processes, and chemical reactions. However, there are relatively few studies applying it to microwave disinfection technology, especially microwave disinfection for air. The interfacial impedance matching and the dielectric/magnetic loss are two key parameters to judge the microwave absorption capability of a material. How to effectively modify various materials by optimizing their dielectric properties, microstructures, and heterogeneous surfaces to enable them to act as efficient microwave absorbers for microwave air disinfection is challenging. The in-depth and thorough microwave absorption mechanisms of different MAMs are still at the research stage, and the interaction mechanism between MAMs and microorganisms is rarely reported when it is applied to disinfection, which need to be understood for the wider application of MAMs in this field and promoting the development of microwave disinfection technology.

The Device Design of a Microwave Reactor

Microwave disinfection and sterilization is carried out in microwave reactors. For the device design of a microwave reactor, the cavity geometry, the position of magnetron, and the inlet/outlet opening must be taken into account. In the process of microwave heating, the over-heated or under-heated regions may exist if the design of the microwave equipment is unreasonable or the property change of materials during heating is not considered, so that the microorganisms in certain areas of the microwave field cannot be completely killed [88,89,90,91]. In order to solve this problem, it is necessary to optimize the electromagnetic field in the cavity by rationally designing the microwave equipment. The use of numerical computations for visualizing the electromagnetic waves is feasible to aid in designing the optimized cavity geometry [92, 93]. Another concern in microwave device design is the leakage of microwave during operation, which must be avoidable in batch mode or continuous systems. In addition, the microwave power, irradiation time, and sample volume all need to be optimized, making the designed microwave reactor more efficient and energy-saving in the disinfection application process.

There are some typical microwave reactors, which could be used for disinfecting microorganisms, as shown in Table 2. Through investigation and research, the microwave disinfection equipment currently designed is mostly used for food, but the research in the field of air disinfection is lacking, which may be attributed to weak microwave absorption of air. In order to apply the current microwave disinfection equipment to air disinfection, microwave devices need to be modified to embed MAMs. How to effectively embed MAMs in the microwave cavity and which embedding method is more conducive to the absorption of microwave are challenging and worth exploring. The modified devices mentioned above exist only in the laboratory for proof-of-concept demonstrations and are not yet reliable enough to scale up or commercialize microwave air disinfection technology.

The Operation Monitoring and Optimization

The automatic control of the microwave disinfection should be implemented, such as feeding automation, automatic temperature measurement, and control. The multi-point temperature measurement is needed to accurately control the temperature of the microwave reactor, and display and query the temperature in real time. In order to obtain the expected sterilization effect, it is necessary to accurately measure the temperature with the aim to activate an alarm when the temperature exceeds the critical point, and inaccurate temperature measurements may result in inconsistent results obtained from microwave processing. The controversial arguments about interaction mechanism between microwave and microorganisms (i.e., thermal and non-thermal effects) come from inaccurate temperature measurement. There are temperature inhomogeneity and the generation of hot spots in the microwave heating sometimes. Under microwave radiation, only by accurately measuring the intrinsic temperature of the microorganism, the bulk temperature of the medium and the actual temperature of the absorbing material in the presence of MAMs, can the thermal effect and the non-thermal effect be decoupled, and the effect of microwave on microorganisms be thoroughly revealed.

There are two types of measuring temperature under microwave irradiation, including direct contact (grounded thermocouple, ungrounded thermocouple, and fiber optic probes) and non-contact types (such as infrared pyrometer and ultrasonic thermometer). Compared to non-contact type thermocouple, the direct contact types have the ability to measure the true temperature of the sample in real time by being inserted inside the sample, which makes it distinctly superior. However, direct-contact thermocouples should be further optimized to eliminate their deficiencies as much as possible. For example, an aluminum sheet wrapped by an electrically insulated Teflon® tube/tape to prevent its deformation can cover the surface of the thermocouple to avoid it suffering from its interaction with the electromagnetic field, but Teflon may be melted when the temperature is higher [102]. In order to solve problems of reactivity with some chemicals for fiber optic probes, a glass shield can be added, but the repeatability of measured data decreases as the temperature increases [103]. Some researchers proposed to use both contact and non-contact temperature measurement techniques to check the accuracy of temperature [104]. Through these further optimizations, it is beneficial to more accurately measure the temperature of the medium and microorganisms during the microwave sterilization process. It is worth noting that nano-thermometers fabricated from thermo-sensitive fluorescent materials were proposed to measure the microscopic hot spots under microwave irradiation recently [105•], which may help to measure the actual temperature of microorganisms in microwave fields in the future. Overall, a precise temperature measurement system is still lacking and needs to be developed; the efforts to minimize inconsistent results and enhance the accuracy of temperature measurement must be dedicated and focused. Besides, the industrial microwave processing should not rely solely on the temperature measurements, but also on some control factors such as the total energy absorbed by the sample from the electromagnetic field, the speed of the energy absorption by the sample, and the microwave power density.

Conclusion

Microwave-assisted disinfection is promising in improving human survival environment due to the unique heating characteristics of microwave irradiation. To promote the development of this novel technology, the present review summarizes existing studies that employ microwave to disinfection of microorganisms, including bacteria, fungi, and viruses. Besides, the mechanisms of microwave inactivation of microorganisms are analyzed from the perspective of microwave-organisms interactions (thermal and non-thermal effect) as well as application scenarios (gas, liquid, and solid media). Finally, the three key issues for the extension of microwave-assisted disinfection to practical application are discussed, including developing microwave-absorbing materials, designing microwave devices, and optimizing operation monitoring.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Plazas-Tuttle J, Das D, Sabaraya IV, Saleh NB. Harnessing the power of microwaves for inactivating Pseudomonas aeruginosa with nanohybrids. Environ Sci-Nano. 2018;5:72–82. https://doi.org/10.1039/c7en00702g.

Decareau RV. Microwaves in the food processing industry; 1985.

Devyatkov DN. Influence of millimeter-band electromagnetic radiation on biological objects. Soviet Physics Uspekhi. 1974;16:568–9.

Li S, Wu Y, Zheng H et al. High microwave responsivity Co-Bi25FeO40 in synergistic activation of peroxydisulfate for high efficiency pollutants degradation and disinfection: mechanism of enhanced electron transfer. Chemosphere. 2022; 28: 132558. https://doi.org/10.1016/j.chemosphere.2021.132558.

Karlsson M, Carlsson H, Idebro M, Eek C. Microwave heating as a method to improve sanitation of sewage sludge in wastewater plants. IEEE Access. 2019;7:142308–16. https://doi.org/10.1109/ACCESS.2019.2944210.

Mawioo PM, Rweyemamu A, Garcia HA et al. Evaluation of a microwave based reactor for the treatment of blackwater sludge. Sci Total Environ. 2016;548:72–81. https://doi.org/10.1016/j.scitotenv.2016.01.013.

Roohi R, Hashemi SMB. Experimental, heat transfer and microbial inactivation modeling of microwave pasteurization of carrot slices as an efficient and clean process. Food Bioproducts Process. 2020;121:113–22. https://doi.org/10.1016/j.fbp.2020.01.015.

Zhang H, Patel J, Bhunia K et al. Color, vitamin C, beta-carotene and sensory quality retention in microwave-assisted thermally sterilized sweet potato puree: effects of polymeric package gas barrier during storage. Food Packaging And Shelf Life. 2019; 21: 100324. https://doi.org/10.1016/j.fpsl.2019.100324..

Awuah GB, Ramaswamy HS, Economides A, Mallikarjunan K. Inactivation of Escherichia coli K-12 and Listeria innocua in milk using radio frequency (RF) heating. Innov Food Sci Emerg Technol. 2005;6:396–402. https://doi.org/10.1016/j.ifset.2005.06.002.

• Wang C, Song L, Zhang Z et al. Microwave-induced release and degradation of airborne antibiotic resistance genes (ARGs) from Escherichia coli bioaerosol based on microwave absorbing material. J Hazard Mater. 2020;394:122535. https://doi.org/10.1016/j.jhazmat.2020.122535. This paper introduces in detail the application of microwave irradiation Fe3O4@SiC Foam ceramics can effectively reduce the airborne antibiotic resistance genes.

• Laghari AA, Liu L, Kalhoro DH et al. Mechanism for reducing the horizontal transfer risk of the airborne antibiotic-resistant genes of Escherichia coli species through microwave or UV irradiation. Int J Environ Res Public Health. 2022;19:4332. https://doi.org/10.3390/ijerph19074332. In this paper, the removal mechanism of airborne microorganisms by microwave irradiation is investigated, and the secondary pollution is effectively reduced.

•• Wang C, Hu X, Zhang Z. Airborne disinfection using microwave-based technology: energy efficient and distinct inactivation mechanism compared with waterborne disinfection. J Aerosol Sci. 2019;137:105437. https://doi.org/10.1016/j.jaerosci.2019.105437. This paper compares the role of thermal effect and non-thermal effect in microwave inactivation process of air disinfection and water disinfection based on microwave radiation.

Zhang Y, Zhang G, Wang P, Wang Q. Disinfection of municipal secondary effluents with microwave-induced electrodeless ultraviolet irradiation for water reuse. J Chem Technol Biotechnol. 2017;92:1017–25. https://doi.org/10.1002/jctb.5077.

Alqahtani MA. Decontamination of a siloxane impression material by using 5-aminolevulinic acid activated by photodynamic therapy, microwave irradiation, and hydrogen peroxide. Photodiagn Photodynam Ther. 2022; 38: 102867. https://doi.org/10.1016/j.pdpdt.2022.102867.

Cheng G, Li Z, Sun L, et al. Application of microwave/electrodeless discharge ultraviolet/ozone sterilization technology in water reclamation. Process Saf Environ Protect. 2020;138:148–56. https://doi.org/10.1016/j.psep.2020.03.015.

Kotecha R, Massie S, Szabo J, Shanov V. Disinfection of Bacillus globigii spores using an atmospheric pressure microwave plasma system. J Environ Eng. 2013;139(11):1409–12. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000747.

Fu W, Zhang C, Guan X, Li X, Yan Y. Investigation of sterilization by a microwave-generated low-temperature atmospheric pressure plasma jet. J Microw Power Electromagn Energy. 2022;56(1):58–67. https://doi.org/10.1080/08327823.2022.2029117.

Chandrasekaran S, Ramanathan S, Basak T. Microwave food processing-a review. Food Res Int. 2013;52:243–61. https://doi.org/10.1016/j.foodres.2013.02.033.

Xu B, Zhou S-L, Miao W-J, et al. Study on the stabilization effect of continuous microwave on wheat germ. J Food Eng. 2013;117:1–7. https://doi.org/10.1016/j.jfoodeng.2013.01.031.

• Osaili TM, Al-Nabulsi AA, Al Sheikh YM et al. Inactivation of Salmonella spp., Escherichia coli O157:H7 and Listeria monocytogenes in Tahini by microwave heating. Foods. 2021;10:2972. https://doi.org/10.3390/foods10122972. In this paper, the removal effect of microwave on different kinds of bacteria in Tahini is studied, and a series of environmental changes of microorganisms are explored.

•• Wang C, Zhang ZW, Liu H. Microwave-induced release and degradation of airborne endotoxins from Escherichia coli bioaerosol. J Hazard Mater. 2019;366:27–33. https://doi.org/10.1016/j.jhazmat.2018.11.088. This article investigates the induction of cell lysis by microwave irradiation, with the accompanying endotoxins also being substantially removed.

Rasooly R, Hernlem B, He X, Friedman M. Microwave heating inactivates Shiga toxin (Stx2) in reconstituted fat-free milk and adversely affects the nutritional value of cell culture medium. J Agric Food Chem. 2014;62:3301–5. https://doi.org/10.1021/jf500278a.

•• Wu Y, Yao M. Inactivation of bacteria and fungus aerosols using microwave irradiation. J Aerosol Sci. 2010;41:682–93. https://doi.org/10.1016/j.jaerosci.2010.04.004. This article investigates the membrane surface morphology and intracellular composition of microwave-treated and untreated microorganisms of different species.

Song W-J, Kang D-H. Inactivation of Salmonella Senftenberg, Salmonella Typhimurium and Salmonella Tennessee in peanut butter by 915 MHz microwave heating. Food Microbiol. 2016;53:48–52. https://doi.org/10.1016/j.fm.2015.08.008.

•• Ojha SC, Chankhamhaengdecha S, Singhakaew S, et al. Inactivation of Clostridium difficile spores by microwave irradiation. Anaerobe. 2016;38:14–20. https://doi.org/10.1016/j.anaerobe.2015.10.015. This article examines in detail the removal of Clostridium difficile spores from suspensions by microwave irradiation and conduction heating.

Park HS, Yang J, Choi HJ, Kim KH. Effective Thermal inactivation of the spores of Bacillus cereus biofilms using microwave. J Microbiol Biotechnol. 2017;27:1209–15. https://doi.org/10.4014/jmb.1702.02009.

Kim SY, Shin SJ, Song CH, et al. Destruction of Bacillus licheniformis spores by microwave irradiation. J Appl Microbiol. 2009;106:877–85. https://doi.org/10.1111/j.1365-2672.2008.04056.x.

Wu Y, Yao M. In situ airborne virus inactivation by microwave irradiation. Chin Sci Bull. 2014;59:1438–45. https://doi.org/10.1007/s11434-014-0171-3.

Adair ER, Petersen RC. Biological effects of radio-frequency/microwave radiation. IEEE Transact Microwave Theory Techniques. 2002;50:953–62. https://doi.org/10.1109/22.989978.

Cho WI, Chung MS. Improving the quality of vegetable foodstuffs by microwave inactivation. Food Sci Biotechnol. 2020;29:85–91. https://doi.org/10.1007/s10068-019-00652-2.

Kim SY, Jo EK, Kim HJ, et al. The effects of high-power microwaves on the ultrastructure of Bacillus subtilis. Lett Appl Microbiol. 2008;47:35–40. https://doi.org/10.1111/j.1472-765X.2008.02384.x.

Liu Y, Kumblathan T, Uppal GK et al. A hidden risk: survival and resuscitation of Escherichia coli O157:H7 in the viable but nonculturable state after boiling or microwaving. Water Res. 2020; 183: 116102. https://doi.org/10.1016/j.watres.2020.116102.

Guo C, Wang Y, Luan D. Study the synergism of microwave thermal and non-thermal effects on microbial inactivation and fatty acid quality of salmon fillet during pasteurization process. LWT-Food Sci Technol. 2021; 152: 112280. https://doi.org/10.1016/j.lwt.2021.112280.

Jeng DK, Kaczmarek KA, Woodworth AG, Balasky G. Mechanism of microwave sterilization in the dry state. Appl Environ Microbiol. 1987;53:2133–7. https://doi.org/10.1128/AEM.53.9.2133-2137.1987.

Welt BA, Tong CH, Rossen JL, Lund DB. Effect of microwave radiation on inactivation of Clostridium sporogenes (PA 3679) spores. Appl Environ Microbiol. 1994;60:482–8. https://doi.org/10.1128/AEM.60.2.482-488.1994.

Herrero MA, Kremsner JM, Kappe CO. Nonthermal microwave effects revisited: on the importance of internal temperature monitoring and agitation in microwave chemistry. J Org Chem. 2008;73:36–47. https://doi.org/10.1021/jo7022697.

Ballardin M, Tusa I, Fontana N, et al. Non-thermal effects of 2.45 GHz microwaves on spindle assembly, mitotic cells and viability of Chinese hamster V-79 cells. Mutation Res-Fundam Molec Mech Mutagen. 2011;716:1–9. https://doi.org/10.1016/j.mrfmmm.2011.07.009.

Guo C, Wang Y, Luan D. Non-thermal effects of microwave processing on inactivation of Clostridium sporogenes inoculated in salmon fillets. LWT-Food Sci Technol. 2020;133:109861. https://doi.org/10.1016/j.lwt.2020.109861.

Shaw P, Kumar N, Mumtaz S et al. Evaluation of non-thermal effect of microwave radiation and its mode of action in bacterial cell inactivation. Scientific Reports. 2021;11:14003. https://doi.org/10.1038/s41598-021-93274-w..

• Shamis Y, Croft R, Taube A, et al. Review of the specific effects of microwave radiation on bacterial cells. Appl Microbiol Biotech. 2012;96:319–25. https://doi.org/10.1007/s00253-012-4339-y. This study considers that it is unreasonable to attribute such effects to non-thermal effects because of poor control and the non measurability of instantaneous temperature.

Gao JX, Wang F, Li X et al. The influence of microwave sterilization on the ultrastructure, permeability of cell membrane and expression of proteins of Bacillus cereus. Front Microbiol. 2018;9:1870. https://doi.org/10.3389/fmicb.2018.01870.

Zhou YJ. The Effect And Mechanism Of Urban Domestic Sewage Secondary Sterilization by Microwave. Appl Ecol Environ Res. 2019;17:8655–8666. https://doi.org/10.15666/aeer/1704_86558666.

•• Nakouti I, Hobbs G, Teethaisong Y, Phipps D. A demonstration of athermal effects of continuous microwave irradiation on the growth and antibiotic sensitivity of Pseudomonas aeruginosa PAO1. Biotechnol Prog. 2017;33:37–44. https://doi.org/10.1002/btpr.2392. This study concluded that microorganisms induced by non-thermal effects are more susceptible to antibiotics.

Zhang Q, Damit B, Welch J, et al. Microwave assisted nanofibrous air filtration for disinfection of bioaerosols. J Aerosol Sci. 2010;41:880–8. https://doi.org/10.1016/j.jaerosci.2010.06.001.

Wu Y, Yao M. Effects of microwave irradiation on concentration, diversity and gene mutation of culturable airborne microorganisms of inhalable sizes in different environments. J Aerosol Sci. 2011;42:800–10. https://doi.org/10.1016/j.jaerosci.2011.07.002.

Kang Y, Kato S. Thermal and non-thermal germicidal effects of microwave radiation on microbial agents. Indoor Built Environ. 2014;23:1080–91. https://doi.org/10.1177/1420326X13490180.

Woo MH, Grippin A, Wu CY, Wander J. Microwave-irradiation-assisted HVAC filtration for inactivation of viral aerosols. Aerosol Air Qual Res. 2012;12:295–303. https://doi.org/10.4209/aaqr.2011.11.0193.

Fisher EM, Williams JL, Shaffer RE. Evaluation of microwave steam bags for the decontamination of filtering facepiece respirators. PLOS ONE. 2011;6:e18585. https://doi.org/10.1371/journal.pone.0018585..

Benleulmi A, Boubekeur N, Massicotte D. A highly sensitive substrate integrated waveguide interferometer applied to humidity sensing. IEEE Microwave Wireless Components Lett. 2019;29:68–70. https://doi.org/10.1109/LMWC.2018.2882302.

Celandroni F, Longo I, Tosoratti N, et al. Effect of microwave radiation on Bacillus subtilis spores. J Appl Microbiol. 2004;97:1220–7. https://doi.org/10.1111/j.1365-2672.2004.02406.x.

Park BJ, Takatori K, Lee MH, et al. Escherichia coli sterilization and lipopolysaccharide inactivation using microwave-induced argon plasma at atmospheric pressure. Surf Coat Technol. 2007;201:5738–41. https://doi.org/10.1016/j.surfcoat.2006.07.039.

Takashima H, Miyakawa Y, Kanno Y. Microwave sterilization with metal thin film coated catalyst in liquid phase. Mater Sci Eng C-Biomimetic Supramolec Syst. 2007;27:898–903. https://doi.org/10.1016/j.msec.2006.10.010.

Sung HJ, Kang DH. Effect of a 915 MHz microwave system on inactivation of Escherichia coli O157:H7, Salmonella Typhimurium, and Listeria monocytogenes in salsa. LWT-Food Sci Technol. 2014;59:754–9. https://doi.org/10.1016/j.lwt.2014.05.058.

Shamis Y, Taube A, Shramkov Y et al. Development of a microwave treatment technique for bacterial decontamination of raw meat. Int J Food Eng. 2008; 48. https://doi.org/10.2202/1556-3758.1360.

Chen H, Huang Z, Huang Y, et al. Synergistically assembled MWCNT/graphene foam with highly efficient microwave absorption in both C and X bands. Carbon. 2017. https://doi.org/10.1016/j.carbon.2017.09.007.

Song C, Yin X, Han M, et al. Three-dimensional reduced graphene oxide foam modified with ZnO nanowires for enhanced microwave absorption properties. Carbon. 2017. https://doi.org/10.1016/j.carbon.2017.01.077.

Liu Q, Guo W, He H, Zhu X. Effect of solids-not-fat content on dielectric properties of skim milk. Int J Food Sci Technol. 2018;53:2560–2566. https://doi.org/10.1111/ijfs.13895.

Martins CPC, Cavalcanti RN, Couto SM, et al. Microwave processing: current background and effects on the physicochemical and microbiological aspects of dairy products. Comprehens Rev Food Sci Food Safety. 2019;18:67–83. https://doi.org/10.1111/1541-4337.12409.

Salazar-Gonzalez C, Fernanda San Martin-Gonzalez M, Lopez-Malo A, Sosa-Morales ME. Recent studies related to microwave processing of fluid foods. Food Bioprocess Technology. 2012;5:31–46. https://doi.org/10.1007/s11947-011-0639-y.

Navarkhele VV, Agrawal RS, Kurtadikar ML. Dielectric properties of electrolytic solutions. Pramana J Phys. 1998;51:511–8. https://doi.org/10.1007/BF02828943.

Salvi D, Ortego J, Arauz C, et al. Experimental study of the effect of dielectric and physical properties on temperature distribution in fluids during continuous flow microwave heating. J Food Eng. 2009;93:149–57. https://doi.org/10.1016/j.jfoodeng.2009.01.009.

• Kubo MTK, Curet S, Augusto PED, Boillereaux L. Artificial neural network for prediction of dielectric properties relevant to microwave processing of fruit juice. J Food Process Eng. 2018; 41: e12815. https://doi.org/10.1111/jfpe.12815. This paper introduces that the power penetration depth can be calculated according to the relative dielectric constant and loss factor value.

•• Gerbo NM, Boldor D, Sabliov CM. Design of a measurement system for temperature distribution in continuous-flow microwave heating of pumpable fluids using infrared imaging and fiber optic technology. J Microwave Power Electromagn Energy. 2008;42:55–65. This paper studies the influence of the properties of the disinfected object and the microwave heating system on the temperature distribution.

Cha-um W, Rattanadecho P, Pakdee W. Experimental and numerical analysis of microwave heating of water and oil using a rectangular wave guide: influence of sample sizes, positions, and microwave power. Food Bioprocess Technol. 2011;4:544–58. https://doi.org/10.1007/s11947-009-0187-x.

Barnabas J, Siores E, Lamb A. Non-thermal microwave reduction of pathogenic cellular population. Int J Food Eng. 2010; 69. https://doi.org/10.2202/1556-3758.1878.

Balasubramanian S, Ortego J, Rusch KA, Boldor D. Efficiency of artemia cysts removal as a model invasive spore using a continuous microwave system with heat recovery. Environ Sci Technol. 2008;42:9363–9. https://doi.org/10.1021/es8021107.

Boldor D, Balasubramanian S, Purohit S et al. A continuous microwave system for prevention of invasive species during de-ballasting operation-death kinetics. J Microwave Power Electromagn Energy. 2008;42:61–78. https://doi.org/10.1080/08327823.2007.11688587.

Vadivambal R, Jayas DS. Non-uniform temperature distribution during microwave heating of food materials—a review. Food Bioprocess Technol. 2010;3:161–171. https://doi.org/10.1007/s11947-008-0136-0.

Zheng X, Wang Y, Liu C, et al. Microwave energy absorption behavior of foamed berry puree under microwave drying conditions. Drying Technol. 2013;31:785–94. https://doi.org/10.1080/07373937.2012.761635.

Ozturk S, Kong F, Singh RK, et al. Radio frequency heating of corn flour: heating rate and uniformity. Innov Food Sci Emerg Technol. 2017;44:191–201. https://doi.org/10.1016/j.ifset.2017.05.001.

•• Singh D, Singh D, Husain S. Computational analysis of temperature distribution in microwave-heated potatoes. Food Sci Technol Int. 2020;26:465–4741082013220907000. https://doi.org/10.1177/1082013220907434. This paper shows that the temperature distribution of different shapes (flat, cylindrical and spherical) in the heating system is very different.

De Albuquerque CD, Curet S, Boillereaux L. Influence of heating rate during microwave pasteurization of ground beef products: experimental and numerical study. J Food Process Eng. 2021; 44e13722. https://doi.org/10.1111/jfpe.13722.

Lv Y, Hu G, Liang J et al. Study on microwave sterilization technology of humidifier in central air conditioning system. Build Environ. 2019; 160106220. https://doi.org/10.1016/j.buildenv.2019.106220..

Lu Y, Wu N, Zhu Y, Wang D. Compared efficacy of microwave irradiation with chemical compound in dental gypsum casts. J Biomater Tissue Eng. 2018;8:603–6. https://doi.org/10.1166/jbt.2018.1781.

Onumaegbu C, Alaswad A, Rodriguez C, Olabi A. Modelling and optimization of wet microalgae Scenedesmus quadricauda lipid extraction using microwave pre-treatment method and response surface methodology. Renew Energy. 2019;132:1323–31. https://doi.org/10.1016/j.renene.2018.09.008.

Zeng S, Li M, Li G, et al. Innovative applications, limitations and prospects of energy-carrying infrared radiation, microwave and radio frequency in agricultural products processing. Trends Food Sci Technol. 2022;121:76–92. https://doi.org/10.1016/j.tifs.2022.01.032.

Magee TRA, McMinn WAM, Farrell G, et al. Moisture and temperature dependence of the dielectric properties of pharmaceutical powders. J Thermal Anal Calorimetry. 2013;111:2157–64. https://doi.org/10.1007/s10973-012-2739-y.

Liu C, Zhang L, Peng J, et al. Dielectric properties and microwave heating characteristics of sodium chloride at 2.45 GHz. High Temp Mater Processes. 2013;32:587–96. https://doi.org/10.1515/htmp-2013-0008.

• Spanu M, Fanti A, Lodi MB, et al. Microwaves disinfection of farmland. J Electromagnetic Waves Appl. 2016;30:2165–73. https://doi.org/10.1080/09205071.2016.1249802. This article uses microwave technology to disinfect agricultural soil without using pesticides.

Ellison C, McKeown MS, Trabelsi S, et al. Dielectric characterization of bentonite clay at various moisture contents and with mixtures of biomass in the microwave spectrum. J Microwave Power Electromagn Energy. 2018;52:3–15. https://doi.org/10.1080/08327823.2017.1421407.

Bhattacharya M, Basak T. A review on the susceptor assisted microwave processing of materials. Energy. 2016;97:306–38. https://doi.org/10.1016/j.energy.2015.11.034.

Kadkhodayan H, Alizadeh T. Design and manufacture of efficient microwave protector nanocomposite based on La1.8Sr0.2NiO4, Mx+yFe9x-y+3O15x+4 (0 <= x, y <= 1) and electric conductive materials fillers. J Alloys Compounds. 2021; 878: 160367. https://doi.org/10.1016/j.jallcom.2021.160367.

Zhang P, Han X, Kang L, et al. Synthesis and characterization of polyaniline nanoparticles with enhanced microwave absorption. RSC Adv. 2013;3:12694–701. https://doi.org/10.1039/c3ra40973b.

Xie A, Wu F, Jiang W, et al. Chiral induced synthesis of helical polypyrrole (PPy) nano-structures: a lightweight and high-performance material against electromagnetic pollution. J Mater Chem C. 2017;5:2175–81. https://doi.org/10.1039/c6tc05057c.

Wang F, Wang N, Han X, et al. Core-shell FeCo@carbon nanoparticles encapsulated in polydopamine-derived carbon nanocages for efficient microwave absorption. Carbon. 2019;145:701–11. https://doi.org/10.1016/j.carbon.2019.01.082.

Pan Y-F, Wang G-S, Liu L, et al. Binary synergistic enhancement of dielectric and microwave absorption properties: a composite of arm symmetrical PbS dendrites and polyvinylidene fluoride. Nano Res. 2017;10:284–94. https://doi.org/10.1007/s12274-016-1290-8.

Wu G, Zhang H, Luo X, et al. Investigation and optimization of Fe/ZnFe2O4 as a Wide-band electromagnetic absorber. J Colloid Interf Sci. 2019;536:548–55. https://doi.org/10.1016/j.jcis.2018.10.084.

Zhao H, Li H, Li X, Gao X. Process intensification for improving the uniformity and efficiency of microwave heating reactor by bubbles-enhanced flow method. Appl Thermal Eng. 2021;197:117346. https://doi.org/10.1016/j.applthermaleng.2021.117346.

Metaxas AC, Meredith R. Industrial microwave heating. 1988. https://doi.org/10.1049/pbpo004e.

Shen X, Li H, Zhao Z, Li X, Liu K, Gao X. Imaging of liquid temperature distribution during microwave heating via thermochromic metal organic frameworks. Int J Heat Mass Transfer. 2022;189: 122667. https://doi.org/10.1016/j.ijheatmasstransfer.2022.122667.

Zhang Y, Zhao Z, Li H, Li X, Gao X. Numerical modeling and optimal design of microwave-heating falling film evaporation. Chem Eng Sci. 2021;240: 116681. https://doi.org/10.1016/j.ces.2021.116681.

Basak T. Finite element (GFEM) simulations on the effect of microwave heating for lossy dielectric samples with various shapes (circle, square and triangle). Int J Numer Meth Heat Fluid Flow. 2020;30:4661–96. https://doi.org/10.1108/HFF-07-2019-0601.

Punathil L, Basak T. Microwave heating of food materials: theoretical investigations; 2015. https://doi.org/10.1016/B978-0-08-100596-5.21843-X.

Lespinard AR, Arballo JR, Badin EE, Mascheroni RH. Comparative study between conventional and microwave-assisted pasteurization of packaged milk by finite element modeling. J Food Process Preserv. 2019;43: e14207. https://doi.org/10.1111/jfpp.14207.

Buttress AJ, Binner E, Yi C, et al. Development and evaluation of a continuous microwave processing system for hydrocarbon removal from solids. Chem Eng J. 2016;283:215–22. https://doi.org/10.1016/j.cej.2015.07.030.

Garnage TV, Sanguansri P, Swiergon P, et al. Continuous combined microwave and hot air treatment of apples for fruit fly (Bactrocera tryoni and B. jarvisi) disinfestation. Innovative Food Sci Emerg Technol. 2015;29:261–70. https://doi.org/10.1016/j.ifset.2015.02.009.

Robinson JP, Kingman SW, Snape CE, et al. Remediation of oil-contaminated drill cuttings using continuous microwave heating. Chem Eng J. 2009;152:458–63. https://doi.org/10.1016/j.cej.2009.05.008.

Reverte-Ors JD, Pedreno-Molina JL, Fernandez PS et al. A novel technique for sterilization using a power self-regulated single-mode microwave cavity. Sensors. 2017;17:1309. https://doi.org/10.3390/s17061309..

Ji YG, Gao J. Research on microwave continuous sterilizer. Western Grain Oil Technol. 1996;4:21–24.

Xu YS. A microwave sterilizer. CHN Patent CN2694983. 2003-12-23.

Jie L. Development of microwave sterilization equipment for medical waste and study of microwave sterilization Process. Q. Univ. Sci. Technol. 2022. https://doi.org/10.27264/d.cnki.gqdhc.2022.000278..

Satpathy SK, Tabil LG, Meda V, et al. Torrefaction of wheat and barley straw after microwave heating. Fuel. 2014;124:269–78. https://doi.org/10.1016/j.fuel.2014.01.102.

Durka T, Stefanidis GD, Van Gerven T, Stankiewicz A. On the accuracy and reproducibility of fiber optic (FO) and infrared (IR) temperature measurements of solid materials in microwave applications. Measure Sci Technol. 2010;21:045108. https://doi.org/10.1088/0957-0233/21/4/045108..

Motasemi F, Afzal MT. A review on the microwave-assisted pyrolysis technique. Renew Sustain Energy Rev. 2013;28:317–30. https://doi.org/10.1016/j.rser.2013.08.008.

• Zhao Z, Shen X, Li H et al. Watching microwave-induced microscopic hot spots via the thermosensitive fluorescence of europium/terbium mixed-metal organic complexes. Angewandte Chemie-Int Edition. 2022;61:e202114340. https://doi.org/10.1002/anie.202114340. This study believes that the use of contact and non-contact temperature measurement technology can effectively improve the accuracy of temperature detection.

Acknowledgements

The authors acknowledge financial support from the National Natural Science Founding of China (Nos. 22222809, 21878219), the Key Technologies R&D Program of Tianjin (21JCZDJC00580), Major Science and Technology Project on Public Health of Tianjin (21ZXGWSY00010), the China Postdoctoral Science Foundation (No. 2022TQ0232), and the Haihe Laboratory of Sustainable Chemical Transformations. The authors also thank the reviewers for their insightful comments and suggestions.

Author information

Authors and Affiliations

Contributions

Under the supervision of Can Wang, Zhenyu Zhao and Xin Gao, Liming Liu conducted article search, information analysis and article writing. Na Wang sorted out the information and wrote part of the content. Azhar Ali Laghari cooperatively collected information and compiled some table contents. Hong Li and Qiang Zeng supplemented and revised the details of the article. All authors read and contributed to the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Human and Animal Rights and Informed Consent

This article does not contain any studies with human or animal subjects performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Liming Liu, Na Wang, and Azhar Ali Laghari are co-first authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, L., Wang, N., Laghari, A.A. et al. A Review and Perspective of Environmental Disinfection Technology Based on Microwave Irradiation. Curr Pollution Rep 9, 46–59 (2023). https://doi.org/10.1007/s40726-022-00247-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40726-022-00247-2