Abstract

An econometric analysis of the impact of ICT (information and communication technology) investment and adoption of ISO 14000 certification on export performance is undertaken using plant-level data for Indian manufacturing (organized segment) drawn from unit-level data from the Annual Survey of Industries. A panel dataset for 2008–09 to 2017–18 is used for the analysis. The estimates are based on data on about 150 thousand plants (factories), with about 440 thousand observations. The results of econometric analyses show a significant positive effect of ICT investment and adoption of ISO 14000 certification on the export intensity of manufacturing plants. Two other important determinants of the export performance of Indian manufacturing plants identified by the econometric analyses are (a) the extent of outsourcing of manufacturing activity and (b) the share of imported materials in total materials used, both having a positive impact on exports. Another finding is that increases in contract worker intensity lead to better export performance among plants belonging to low technology industries.

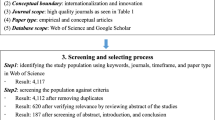

Source: Author’s computations based on unit-level data of ASI, 2008–09 to 2017–18

Source: Author’s computations based on unit-level data of ASI, 2008–09 to 2017–18

Similar content being viewed by others

Data availability

The data used for the analysis in the paper are proprietary and cannot be shared.

Notes

A portion of manufacturing firms have multiple plants located in different regions of the country (Goldar 2022). Hence, if firm-level data are used, it is difficult to incorporate regional aspect into the analysis.

See, for instance, Brynjolfsson and Hitt (2000) and Commander et al. (2011). The study undertaken by Commander and associates covered selected manufacturing industries in India and in Brazil. Other studies in which the effect of ICT on productivity has been examined for Indian manufacturing include Joseph and Abraham (2007), Kite (2012, 2013), Sharma and Singh (2013), Mitra et al. (2016), Goldar (2020) and Krishna et al. (2020). In these studies, a positive effect of ICT on productivity in Indian manufacturing was commonly found. Also see, in this context, Erumban and Das (2016, 2020) and Kite (2020).

The list includes Kumar and Siddharthan (1994), Aggarwal (2002), Goldar and Kato (2009), Franco and Sasidharan (2010), Ranjan and Raychaudhuri (2011), Srinivasan and Archana (2011a), Haidar (2012), Bas (2013), Goldar (2013a, b), Pradhan and Das (2013a, b, 2016), Nagaraj (2014), Mukherjee (2015), Keshari (2016), Sahu and Narayanan (2016a), Thomas and Narayanan (2016), Kapoor et al. (2017), Padmaja and Sasidharan (2017), Goldar et al. (2017), Goldar et al. (2018), Banga and Banga (2020), Mohapatra (2021), and Padmaja and Sasidharan (2021).

In a recent study, Goldar and Majumder (2022) find that exporting to a foreign market has a positive impact on the adoption of ISO 14000 among Indian manufacturing plants.

National Industrial Classification, 2008, National Statistical Office, Ministry of Statistics and Programme Implementation, Government of India.

The reported data on net fixed capital stock of different plants in different years during 2008–09 to 2017–18 show wide variation. In some cases, the reported capital stock is very low, which might be reflecting the fact that, in the balance sheet, the depreciated net value of the existing machinery in those units has declined over time to very low levels even though the machines remain in workable conditions and will fetch a much higher value in the market than the value shown in the balance sheet, or those units are carrying on production activity mostly on the basis of rented premises and rented machinery. To take care of these issues, a floor value of Rs. 5000 has been applied to data on net fixed capital stock, i.e., if the reported value is lower than Rs. 5000, then it has been raised to Rs. 5000. The medium of fixed capita stock in the total sample is about Rs 12 million.

Among the econometric studies on determinants of export performance in Indian manufacturing based on firm-level data, size of the firm has been measured by logarithm of deflated total assets in Goldar et al. (2018), Padmaja and Sasidharan (2021) and Sasidharan and Reddy (2021), and by logarithm of deflated sales in Padmaja and Sasidharan (2017).

This variable has been winsorized at 1st and 99th percentile, which applies also to manufacturing services input intensity. This takes care of the unrealistically high value or unrealistically low value taken by these variables in the dataset, which if not corrected for will affect the model estimates.

Firms might be selling their products to traders who are exporting those products. This component of exports known as indirect exports is not considered in the analysis. See Goldar (2022) on the relative magnitude of indirect exports.

In the ASI unit-level data for 2008–09 and 2009–10, the recorded export share in production exceeds 100 percent in a small number of cases (10–15 cases in a sample of more than 36 thousand factories belonging to manufacturing with their status recorded as “open”). In these cases, the recorded export share has been capped at 100 percent for the purpose of the analysis.

The population estimate of mean export intensity based on sample weights given in the datasets comes to about 4 percent which is less than the unweighted sample mean of this variable by more than one percentage point. The population estimate is expected to be relatively lower than unweighted sample mean of export intensity because of the sample design in the survey. While the census sector of ASI is completely enumerated, the sample sector which contains relatively smaller plants, much larger in number (say, three to four times) than the number of plants belonging to the census sector, are covered on the basis of probability sampling—the overall sampling fraction was 10.5% in the survey for 2018–19. This needs to be seen in conjunction with the fact that export intensity is relatively lower in relatively small sized plants.

It should be noted that when sample weights are applied, the proportion of plants that participate in exports comes down to about seven percent. This is consistent with gap between the unweighted sample mean of export intensity and population estimate of mean export intensity presented in Table 2.

See ISIC Rev.3 Technology Intensity Definition, document of the Economic Analysis and Statistics Division, Directorate of Science, Technology and Industry, OECD, dated 2011.

It will be noticed that the number of observations in the estimates in Table 7 are substantially lower than that in Table 6. The reason lies in the fact that when some variables are taken with one year lag, an observation will be included in the estimate only if the previous year’s observation for the plant is available in the dataset. This does not occur for plants belonging to the sample sector of ASI (barring a small fraction). See footnote 15 in this connection.

Das et al. (2016) have used manufacturing industries’ plant-level (panel) data of ASI for 4 years, 2008–09 to 2011–12. They find a positive relationship between plant size and export intensity. This is broadly consistent with the findings of this study. Goldar and Mukherjee (2016) have used ASI unit-level data for 2011–12 to study determinants of export intensity and have found a positive effect of plant size (measured in terms of logarithm of total net fixed assets) on export intensity. This is in line with the findings of this study. In the study of export participation based on ASI plant level data undertaken by Majumder and Sawhney (2020), a positive effect of plant size on exports is found. Again, this is broadly consistent with the findings of this study.

The determinants of exports performance of firms in India have been studied by Pradhan and Das (2013a, b, 2016) who take into account the influence of the conditions prevailing in the states where the firms are located. How state level infrastructure and other state level factors impact export participation by manufacturing plants has been studied by Majumder and Sawhney (2020). The location aspect is brought into the analysis of export performance through the use of infrastructure variables in Srinivasan and Archana (2011b). The impact of operational efficiency of India’s ports on manufactured exports is discussed in Goldar and Paul (2019), which has a regional dimension.

See in this context, Banga (2019), who emphasizes the need for a digitally-informed foreign trade policy in India in order to improve India’s trade competitiveness in the digital era. According to her, some important components of the required digital initiatives include: (1) building digit infrastructure for trade, (2) enhancing the digital content in exports, and (3) developing digital skills (e.g., designing using computer-aided design) especially in traditional export industries such as textiles, clothing and leather products.

References

Aggarwal, A. 2002. Liberalisation, Multinational Enterprises and Export Performance: Evidence from Indian Manufacturing. Journal of Development Studies 38 (3): 119–137.

Banga, R. 2019. Is India Digitally Prepared for International Trade? Economic and Political Weekly 54 (5): 53–62.

Banga, R., and K. Banga. 2020. Digitization and India’s Losing Export Competitiveness. In Accelerators of India’s Growth—Industry, Trade and Employment: Festschrift in Honor of Bishwanath Goldar, ed. S.C. Aggarwal, D.K. Das, and R. Banga, 129–158. Springer Nature: Indian Studies in Business and Economics.

Bas, M. 2013. Does services liberalization affect manufacturing firms’ export performance? Evidence from India. CEPII working paper no. 2013-17, CEPII, http://www.cepii.fr/pdf_pub/wp/2013/wp2013-17.pdf.

Bellesi, F., D. Lehrer, and A. Tal. 2005. Comparative Advantage: The Impact of ISO 14001 Environmental Certification on Exports. Environmental Science and Technology 39 (7): 1943–1953.

Bhat, S. 2015. Information Technology Investments and Export Performance of Firms: A Study of Pharmaceutical Industry in India. In Proceedings of the 10th Annual Conference of the Forum for Global Knowledge Sharing co-organized by the Indian National Academy of Engineering held during 27–28 November 2015 at the National Institute of Advanced Studies, India.

Blyde, J. 2022. The ISO 14001 environmental standard and exports. International Trade Journal. https://doi.org/10.1080/08853908.2022.2155270.

Brynjolfsson, E., and L.M. Hitt. 2000. Beyond Computation: Information Technology, Organizational Transformation and Business Performance. Journal of Economic Perspectives 14 (4): 23–48.

Cassetta, E., U. Monarca, I. Dileo, C. Di Berardino, and M. Pini. 2020. The relationship between digital technologies and internationalisation: Evidence from Italian SMEs. Industry and Innovation 27 (4): 311–339.

Clarke, G.R.G. 2008. Has the internet increased exports for firms from low and middle-income countries? Information Economics and Policy 20 (1): 16–37.

Cole, M.A., R.J.R. Elliott, and K. Shimamoto. 2006. Globalization, firm-level characteristics, and environmental management: A study of Japan. Ecological Economics 59 (3): 312–323.

Commander, S., R. Harrison, and N. Menezes-Filho. 2011. ICT and Productivity in Developing Countries: New Firm-level Evidence from Brazil and India. Review of Economics and Statistics 93 (2): 528–541.

Das, P., A. Halder, and R. Dutt. 2016. Export Competitiveness and Intensity of Technology in Indian Manufacturing Industries—Analysis with ASI Unit Level Data. Journal of Industrial Statistics 5 (2): 226–239.

Erumban, A.A., and D.K. Das. 2016. Information and Communication Technology and Economic Growth in India. Telecommunications Policy 40 (5): 412–431.

Erumban, A.A., and D.K. Das. 2020. ICT Investment and Economic Growth in India: An Industry Perspective. In Digitization and Development: Issues for India and Beyond, ed. D. Maiti, F. Castellacci, and A. Melchior, 89–117. Springer.

Fernandes, A.M., A. Mattoo, H. Nguyen, and M. Schiffbauer. 2019. The Internet and Chinese Exports in the Pre-Alibaba Era. Journal of Development Economics 138: 57–76.

Franco, C., and S. Sasidharan. 2010. MNEs, technological efforts and channels of export spillover: An analysis of Indian manufacturing industries. Economic Systems 34 (3): 270–288.

Goldar, B. 2013a. Determinants of Import Intensity of India’s Manufactured Exports Under the New Policy Regime. Indian Economic Review 48 (1): 221–237.

Goldar, B. 2013b. R&D intensity and exports: A study of Indian pharmaceutical firms. Innovation and Development 3 (2): 151–167. https://doi.org/10.1080/2157930X.2013.828878.

Goldar, B. 2018. Use of Contract Labour in India’s Organized Manufacturing: Role of Import Competition and Labour Regulations. In Role of Public Policy in Development Process: Emerging Socioeconomic Scenario in the Indian Economy, ed. N. Mehta and A. Arya, 251–282. Academic Foundation.

Goldar, B. 2020. Services input and productivity in Indian manufacturing plants. Indian Growth and Development Review 13 (1): 99–124. https://doi.org/10.1108/IGDR-11-2018-0117.

Goldar, B. 2022. Export Performance of India’s Organized Manufacturing Enterprises: Assessment Based on Firm-level Data versus Plant-level data. Available at SSRN. Abstract=4056342.

Goldar, B., and A. Kato. 2009. Export Intensity of Indian Industrial Firms in the Post-Reform Period. In Indian Industrial Development and Globalisation: Essays in Honour of Professor S.K. Goyal, ed. S.R. Hashim, K.S. Chalapati Rao, K.V.K. Ranganathan, and M.R. Murthy, 471–98. New Delhi: Academic Foundation, New Delhi in association with the Institute for Studies in Industrial Development.

Goldar, B., and P. Majumder. 2022. What factors drive industrial plants in emerging economies to adopt ISO 14000 environmental management standards: Evidence from the Indian organized manufacturing sector. Environmental Development 44.

Goldar, B., and S. Mukherjee. 2016. Export Orientation, Import Competition and Plant Survival in Indian Manufacturing. Journal of International Trade 1: 72–90. http://wtocentre.iift.ac.in/journal/pdf/Article4_Goldar_Mukherjee.pdf

Goldar, B., and Y. Parida. 2021. Productivity, Competitiveness and Export Performance: A Plant-Level Analysis of India’s Wearing Apparel Industry. In Agro and Food Processing Industry in India: Inter-sectoral Linkages, Employment, Productivity and Competitiveness, ed. S. Bathla and E. Kannan. Springer. https://doi.org/10.1007/978-981-15-9468-7_16.

Goldar, B., and M. Paul. 2019. How operational efficiency of India’s ports impacts its manufacturing exports. Ideas for India. Available at: https://www.ideasforindia.in/topics/trade/how-operational-efficiency-of-indias-ports-impacts-its-manufacturing-exports.html.

Goldar, B., Y. Parida, and D. Sehdev. 2017. Reduction in Carbon Emissions Intensity and Impact on Export Competitiveness: Evidence from Indian Manufacturing Firms. Journal of International Commerce, Economics and Policy 8 (2): 1–30. https://doi.org/10.1142/S1793993317500120.

Goldar, B., R. Banga, and K. Banga. 2018. India’s Linkages into Global Value Chains: The Role of Imported Services. In India Policy Forum 2017–18, vol. 14, ed. S. Shah, B. Bosworth, and K. Muralidharan, 107–164. New Delhi: National Council of Applied Economic Research, Sage Publications.

Hagsten, E., and P. Kotnik. 2017. ICT as facilitator of internationalisation in small- and medium-sized firms. Small Business Economics 48 (2): 431–446.

Haidar, J.I. 2012. Trade and productivity: Self-selection or learning-by-exporting in India. Economic Modelling 29 (5): 1766–1773.

Haini, H. 2021. ICT, Innovation and SME Export Likelihood: Evidence from the SMEs in the ASEAN Economies. Singapore Economic Review. https://doi.org/10.1142/S0217590821500478.

Hainmueller, J. 2012. Entropy Balancing for Causal Effects: A Multivariate Reweighting Method to Produce Balanced Samples in Observational Studies. Political Analysis 20: 25–46.

He, W., C. Liu, J. Lu, and J. Cao. 2015. Impacts of ISO 14001 adoption on firm performance: Evidence from China. China Economic Review 32: 43–56.

Imbens, G.W. 2015. Matching Methods in Practice: Three Examples. Journal of Human Resources 50 (2): 373–419.

Joseph, K.J., and V. Abraham. 2007. Information technology and productivity: Evidence from India’s manufacturing sector. Working Paper 389, Centre for Development Studies, Thiruvananthapuram, Kerala.

Kapoor, M., P. Ranjan, and J. Raychaudhuri. 2017. The impact of credit constraints on exporting firms: Evidence from the provision and subsequent removal of subsidised credit. World Economy 40 (12): 2854–2874.

Keshari, P.K. 2016. Role of Technological and Knowledge Resources in a Firm’s Decision to Export: The Case of Inward Oriented Indian Industrie. In Globalization of Indian Industries: Productivity, Exports and Investment, ed. F. De Beule and K. Narayanan, 141–170. Springer.

Kite, G. 2012. The impact of information technology outsourcing on productivity and output: New evidence from India. Procedia Economics and Finance 1: 239–248.

Kite, G. 2013. The role of information technology outsourcing on output, productivity and technical efficiency: Evidence from Indian firms. Journal of European Economy 12 (3): 260–285.

Kite, G. 2020. IT Enabling Indian Firms: The Importance of IT Outsourcing Companies. In Digitization and Development: Issues for India and Beyond, ed. D. Maiti, F. Castellacci, and A. Melchior, 145–159. Springer.

Kotnik, P., and E. Hagsten. 2018. ICT use as a determinant of export activity in manufacturing and service firms: Multi-country evidence. Zb. rad. Ekon. fak. Rij. University of Rijeka, Faculty of Economics and Business 36(1): 103–128.

Krishna, K.L., B. Goldar, D.K. Das, S.C. Aggarwal, A.A. Erumban, and P.C. Das. 2020. Manufacturing productivity in India: The role of foreign sourcing of inputs and domestic capacity building. In Measuring Economic Growth and Productivity: Foundations, KLEMS Production Models, and Extensions, ed. B.M. Fraumeni, 95–116. Academic Press.

Kumar, N., and N.S. Siddharthan. 1994. Technology, Firm Size and Export Behaviour in Developing Countries: The Case of Indian Enterprises. Journal of Development Studies 31 (2): 289–309.

Lal, K. 1999. Information Technology and Exports: A Case Study of Indian Garments Manufacturing Enterprises. ZEF—Discussion Papers on Development Policy No. 15, Center for Development Research, Bonn.

Lal, K. 2002. E-business and export behaviour: Evidence from Indian firms. WIDER Discussion Paper, No. 2002/68, The United Nations University World Institute for Development Economics Research (UNU-WIDER), Helsinki.

Liston-Heyes, C., and A. Heyes. 2021. Is there evidence for export-led adoption of ISO 14001? A review of the literature using meta-regression. Business & Society 60 (3): 764–805.

Majumder, P., and A. Sawhney. 2020. Manufacturing agglomeration and export dynamics across Indian states. Indian Economic Review 55: 3–26.

Mitra, A., C. Sharma, and M.-A. Véganzonès-Varoudakis. 2016. Infrastructure, ICT and Firms’ Productivity and Efficiency: An Application to the Indian Manufacturing. In Globalization of Indian Industries: Productivity, Exports and Investment, ed. F. De Beule and K. Narayanan, 17–41. Springer.

Mohapatra, S.M. 2021. Export Performance: A Study of Labour and Capital Intensive Manufacturing Industries in India. IEG Working Paper no. 445, Institute of Economic Growth, Delhi.

Mukherjee, S. 2015. The Role of Services in Enhancing Indian Manufacturing Exports: A Firm Level Analysis, 2000–01 to 2011–12. Discussion Paper no.15–08, Centre for International Trade and Development, School of International Studies, Jawaharlal Nehru University, New Delhi.

Nagaraj, P. 2014. Financial constraints and export participation in India. International Economics 140: 19–35.

Padmaja, M., and S. Sasidharan. 2017. Sunk Costs, Firm Heterogeneity, Export Market Entry and Exit: Evidence from India. Journal of Quantitative Economics 15: 367–393.

Padmaja, M., and S. Sasidharan. 2021. Financing constraints and exports: Evidence from India. Journal of Economics and Finance 45: 118–145.

Pradhan, J.P., and K. Das. 2013a. Determinants of Regional Patterns of Manufacturing Exports: Indian Firms since the Mid-1990s. Working Paper no. 213, Gujarat Institute of Development Research, Ahmedabad.

Pradhan, J.P., and K. Das. 2013b. Exporting by Indian small and medium enterprises: Role of regional technological knowledge, agglomeration and foreign direct investment. Innovation and Development 3 (2): 239–257.

Pradhan, J.P., and K. Das. 2016. Manufacturing Exports from Indian States: Determinants and Policy Imperatives, India Studies in Business and Economics, Springer.

Ranjan, P., and J. Raychaudhuri. 2011. Self-Selection vs learning: Evidence from Indian exporting firms. Indian Growth and Development Review 4 (1): 22–37.

Ricci, L.A., and F. Trionfetti. 2012. Productivity, Networks, and Export Performance: Evidence from a Cross-country Firm Dataset. Review of International Economics 20 (3): 552–562.

Sahu, S.K., and K. Narayanan. 2015. Technology Import, R and D Spillover and Export: A Study of Automobile Sector in India. Working Paper no.98/2015, Madras School of Economics, Chennai.

Sahu, S.K., and K. Narayanan. 2016a. Exports and Participation in CDM in Technology Intensive Industries in India. In Globalization of Indian Industries: Productivity, Exports and Investment, ed. F. De Beule and K. Narayanan, 121–140. Springer.

Sahu, S.K., and K. Narayanan. 2016b. Environmental Certification and Technical Efficiency: A Study of Manufacturing Firms in India. Journal of Industry, Competition and Trade 16: 191–207.

Sasidharan, S., and K. Reddy. 2021. The Role of Digitalisation in Shaping India’s Global Value Chain Participation. ERIA Discussion Paper Series No. 376, Economic Research Institute for ASEAN and East Asia, Jakarta.

Sharma, S., and N. Singh. 2013. Information Technology and Productivity in Indian Manufacturing. In India policy forum, 2012–13, vol. 9, ed. S. Shah, B. Bosworth, and A. Panagariya, 189–231. Sage Publications: National Council of Applied Economic Research and Brookings Institution.

Singh, N. 2013. Influence of outward-foreign direct investment and technological efforts on exports: Indian auto component firms. Innovation and Development 3 (2): 205–221.

Singh, P., and D. Maiti. 2020. ICT, Access to Finance and Firm Exports: A Cross-Country Study. In Digitization and Development: Issues for India and Beyond, ed. D. Maiti, F. Castellacci, and A. Melchior, 161–181. Springer.

Sojoodi, S. 2016. The Impact of Information and Communication Technology (ICT) on the Firms’ Export Behavior in Manufacturing Firms of Iran Using Tobit and Heckman Method. International Business Management 10 (6): 908–916.

Srinivasan, T.N., and V. Archana. 2011a. Determinants of Export Decision of Firms. Economic and Political Weekly 46 (7): 49–58.

Srinivasan, T.N., and V. Archana. 2011b. Determinants of Export Decision of Indian Firms: A Primary Data Analysis. Journal of Quantitative Economics 9 (2): 6–35.

Thomas, R., and K. Narayanan. 2016. Productivity Heterogeneity and Export Market Participation: A Study of Indian Manufacturing Firms. In Globalization of Indian Industries: Productivity, Exports and Investment, ed. F. De Beule and K. Narayanan, 97–120. Springer.

Tran, T.M. 2022. Environmental benefit gain from exporting: Evidence from Vietnam. World Economy 45(4): 1081-1111. https://doi.org/10.1111/twec.13177.

Zaclicever, D. 2019. Imported inputs and export performance: Evidence from Chilean manufacturing industries. International Trade series, No. 149 (LC/TS.2019/90), Santiago, Economic Commission for Latin America and the Caribbean (ECLAC).

Zhao, Q., and D. Percival. 2017. Entropy balancing is doubly robust. Journal of Casual Inference 5 (1): 20160010. https://doi.org/10.1515/jci-2016-0010.

Funding

The author did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author has no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Goldar, B. ICT Investment, Adoption of ISO 14000 Certification, and Export Performance in Indian Manufacturing Plants. J. Quant. Econ. 21, 523–553 (2023). https://doi.org/10.1007/s40953-023-00350-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40953-023-00350-1