Abstract

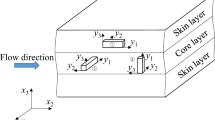

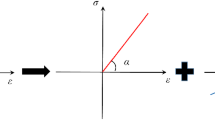

In this paper, a multiscale optimization approach for composite material design is presented. The objective is to find different material designs for a short fiber reinforced polymer (SFRP) with a desired effective (in general anisotropic) viscoelastic behavior. The paper extends the work of Staub et al. (2012) and proposes a combination of material homogenization, surrogate modeling, parameter optimization and robustness analysis. A variety of microstructure design parameters including the fiber volume fraction, the fiber orientation distribution, the linear elastic fiber properties, and the temperature dependent material behavior are considered. For the solution of the structural optimization problem, a surrogate-based optimization framework is developed. The individual steps of that framework consist of using design of experiments (DoE) for the sampling of the constraint material design space, numerical homogenization for the creation of a material property database, a surrogate modeling approach for the interpolation of the single effective viscoelastic parameters and the use of differential evolution (DE) for optimization. In the numerical homogenization step, creep simulations on virtually created representative volume elements (RVEs) are performed and a fast Fourier transform (FFT)-based homogenization is used to obtain the effective viscoelastic material parameters. For every identified optimal design, the robustness is evaluated. The considered Kriging surrogate models of Kriging type have a high prediction accuracy. Numerical examples demonstrate the efficiency of the proposed approach in determining SFRPs with target viscoelastic behavior. An experimental validation shows a good agreement of the homogenization method with corresponding measurements. During the manufacturing of composite parts, the results of such optimizations allow a consideration of the local microstructure in order to achieve the desired macroscopic viscoelastic behavior.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abrate, S.: The mechanics of short fiber-reinforced composites: a review. Rubber Chem. Technol. 59(3), 384–404 (1986). https://doi.org/10.5254/1.3538207

Advani, S.G., Tucker, C.L.: The use of tensors to describe and predict fiber orientation in short fiber composites. J. Rheol 31(8), 751–784 (1987). https://doi.org/10.1122/1.549945

Becker, J., Biebl, F., Glatt, E., Cheng, L., Grießer, A., Groß, M., Linden, S., Mosbach, D., Wagner, C., Weber, A., Westerteiger, R.: GeoDict (Release 2022) [Simulation software], Math2Market GmbH. (2021) https://doi.org/10.30423/release.geodict2022

Bessa, M.A., et al.: A framework for data-driven analysis of materials under uncertainty: countering the curse of dimensionality. Comput. Methods Appl. Mech. Eng. 320, 633–667 (2017). https://doi.org/10.1016/j.cma.2017.03.037

Burgarella, B., Maurel-Pantel, A., Lahellec, N., et al.: Effective viscoelastic behavior of short fibers composites using virtual DMA experiments. Mech. Time Depend Mater. 23, 337–360 (2019). https://doi.org/10.1007/s11043-018-9386-z

Chemie Wirtschaftsförderungs-GmbH, CAMPUS, Published by Altair Engineering GmbH, Germany. https://www.campusplastics.com/. Accessed 01 Aug 2022

Cruz-González, O.L., Ramírez-Torres, A., Rodríguez-Ramo, R., Otero, J.A., Penta, R., Lebon, F.: Effective behavior of long and short fiber-reinforced viscoelastic composites. Appl. Eng. Sci. (2021). https://doi.org/10.1016/j.apples.2021.100037

Cuong-Le, T., Minh, H., Khatir, S., Wahab, M.A., Tran, M.T., Mirjalili, S.: A novel version of Cuckoo search algorithm for solving optimization problems. Expert Syst. Appl. (2021). https://doi.org/10.1016/j.eswa.2021.115669

Das, S., Suganthan, P.N., Differential evolution: a survey of the state-of-the-art. IEEE Trans. Evol. Comput. 15 (1) 4–31 (2011). https://ieeexplore.ieee.org/document/5601760

Dehnavi, F.N., Safdari, M., Abrinia, K., et al.: A framework for optimal microstructural design of random heterogeneous materials. Comput. Mech. 66, 123–139 (2020). https://doi.org/10.1007/s00466-020-01844-y

Frei, S., Andrä, H., Pinnau, R., et al.: Optimizing fiber orientation in fiber-reinforced materials using efficient upscaling. Comput. Optim. Appl. 62, 111–129 (2015). https://doi.org/10.1007/s10589-013-9630-z

Friedrich, K., Almajid, A.: Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 20, 107–128 (2013). https://doi.org/10.1007/s10443-012-9258-7

Garcia-Gonzalez, D., Rodriguez-Millan, M., Rusinek, A., Arias, A.: Investigation of mechanical impact behavior of short carbon-fiber-reinforced PEEK composites. Compos. Struct. 133, 1116–1126 (2015). https://doi.org/10.1016/j.compstruct.2015.08.028

Ghasemi, H., Brighenti, R., Zhuang, X., Muthu, J., Rabczuk, T.: Optimum fiber content and distribution in fiber-reinforced solids using a reliability and NURBS based sequential optimization approach. Struct. Multidisc. Optim. 51, 99–112 (2015). https://doi.org/10.1007/s00158-014-1114-y

Ghasemi, H., Rafiee, R., Zhuang, X., Muthu, J., Rabczuk, T.: Uncertainties propagation in metamodel-based probabilistic optimization of CNT/polymer composite structure using stochastic multi-scale modeling. Comput. Mater. Sci. 85, 295–305 (2014). https://doi.org/10.1016/j.commatsci.2014.01.020

Ghasemi, H., Brighenti, R., Zhuang, X., Muthu, J., Rabczuk, T.: Optimization of fiber distribution in fiber reinforced composite by using NURBS functions. Comput. Mater. Sci. 83, 463–473 (2014). https://doi.org/10.1016/j.commatsci.2013.11.032

Grimm-Strele, H., Kabel, M.: Runtime optimization of a memory efficient CG solver for FFT-based homogenization: implementation details and scaling results for linear elasticity. Comput. Mech. 64(5), 1339–1345 (2019)

Gu, G., Chen, C.: Machine learning for composite materials. MRS Commun. 9(2), 556–566 (2019). https://doi.org/10.1557/mrc.2019.32

Gu, G., Chen, C., Deon, R., Buehler, M.: De novo composite design based on machine learning algorithm. Extreme Mech. Lett. 18, 19–28 (2018). https://doi.org/10.1016/j.eml.2017.10.001

Gu, G., Chen, C., Deon, R., Buehler, M.: Bioinspired hierarchical composite design using machine learning: Simulation, additive manufacturing, and experiment. Mater. Horiz. (2018). https://doi.org/10.1039/C8MH00653A

Hamdia, K., Ghasemi, H.: Quantifying the uncertainties in modeling soft composites via a multiscale approach. Int. J. Solids Struct. (2022). https://doi.org/10.1016/j.ijsolstr.2022.111959

Hamdia, K., Ghasemi, H., Zhuang, X., Rabczuk, T.: Multilevel Monte Carlo method for topology optimization of flexoelectric composites with uncertain material properties. Eng. Anal. Bound Elem. 134, 412–418 (2022). https://doi.org/10.1016/j.enganabound.2021.10.008

Hashin, Z.: Viscoelastic behavior of heterogeneous media. J. Appl. Mech 32(3), 630–636 (1965). https://doi.org/10.1115/1.3627270

Hashin, Z.: Complex modulis of viscoelastic composites-I General Theory and Application. Int. J. Solids Struct. 6(5), 539–552 (1970). https://doi.org/10.1016/0020-7683(70)90029-6

Hilden, J., Rief, S., Planas, B.: FiberGeo User Guide 2022, GeoDict simulation softwareRrelease 2022, Published: Aug 27, 2021, by Math2Market GmbH, Germany, https://doi.org/10.30423/userguide.geodict2022-fibergeo

Ho, L.V., Trinh, T.T., De Roeck, G., Bui-Tien, T., Nguyen-Ngoc, L., Wahab, M.A.: An efficient stochastic-based coupled model for damage identification in plate structures. Eng. Fail. Anal. (2022). https://doi.org/10.1016/j.engfailanal.2021.105866

Holzapfel, G.A., Gasser, T.C.: A viscoelastic model for fiber-reinforced composites at finite strains: Continuum basis, computational aspects and applications. Comput. Methods Appl. Mech. Eng. 190(34), 4379–4403 (2001). https://doi.org/10.1016/S0045-7825(00)00323-6

Hyun, S., Torquato, S.: Designing composite microstructures with targeted properties. J. Mater. Res. 16, 280–285 (2001). https://doi.org/10.1557/JMR.2001.0042

Jin, R., Chen, W., Sudjianto, A.: An efficient algorithm for constructing optimal design of computer experiments. J. Stat. Plan. Inference 134(1), 268–287 (2005). https://doi.org/10.1016/j.jspi.2004.02.014

Kabel, M., Merkert, D., Schneider, M.: Use of composite voxels in FFT-based homogenization. Comput. Methods Appl. Mech. Eng. 294, 168–188 (2015). https://doi.org/10.1016/j.cma.2015.06.003

Kabel, M., Fliegener, S., Schneider, M.: Mixed boundary conditions for FFT-based homogenization at finite strains. Comput. Mech. 57(2), 193–210 (2016). https://doi.org/10.1007/s00466-015-1227-1

Kabel, M., Fink, A., Schneider, M.: The composite voxel technique for inelastic problems. Comput. Methods Appl. Mech. Eng. 322, 396–418 (2017)

Kabel, M., Andrä, H., FeelMath: Fraunhofer Institute for Industrial Mathematics (2022) https://www.itwm.fraunhofer.de/de/abteilungen/sms/produkte-und-leistungen/feelmath.html

Kaliske, M., Rothert, H.: Formulation and implementation of three-dimensional viscoelasticity at small and finite strains. Comput. Mech. 19, 228–239 (1997). https://doi.org/10.1007/s004660050171

Kanit, T., Forest, S., Galliet, I., Mounoury, V., Jeulin, D.: Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int. J. Solids Struct. 40(13–14), 3647–3679 (2003). https://doi.org/10.1016/S0020-7683(03)00143-4

Köbler, J., Schneider, M., Ospald, F., Andrä, H., Müller, R.: Fiber orientation interpolation for the multiscale analysis of short fiber reinforced composite parts. Comput. Mech. 61, 729–750 (2018). https://doi.org/10.1007/s00466-017-1478-0

Kraus, M.A., Schuster, M., Kuntsche, J., et al.: Parameter identification methods for visco- and hyperelastic material models. Glass. Struct. Eng. 2, 147–167 (2017). https://doi.org/10.1007/s40940-017-0042-9

Krige, D.G.: A Statistical Approach to Some Mine Valuation and Allied Problems on the Witwatersrand, University of Witwatersrand (1951), Ph.D. thesis

Lai, J., Bakker, A.: 3-D Schapery representation for non-linear viscoelasticity and finite element implementation. Comput. Mech. 18(3), 182–191 (1996). https://doi.org/10.1007/BF00369936

Lampinen, J.: A Constraint handling approach for the differential evolution algorithm, Proceedings of the 2002 Congress on Evolutionary Computation (2002). CEC'02 (Cat. No.02TH8600), Vol. 2, P. 1468–1473, https://doi.org/10.1109/CEC.2002.1004459

Liu, Y., Zhao, T., Ju, W., Shi, S.: Materials discovery and design using machine learning. J. Materiomics 3(3), 159–177 (2017). https://doi.org/10.1016/j.jmat.2017.08.002

Mármol, G., Ferreira, D.G., Fangueiro, R.: Automotive and construction applications of fiber reinforced composites. Fiber Reinf. Compos. (2021). https://doi.org/10.1016/B978-0-12-821090-1.00009-0

McKay, M., Beckman, R., Conover, W.: A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 42(1), 55–61 (2000). https://doi.org/10.1080/00401706.1979.10489755

Mirkhalaf, S.M., Eggels, E.H., van Beurden, T.J.H., Larsson, F., Fagerström, M.: A finite element based orientation averaging method for predicting elastic properties of short fiber reinforced composites. Compos. b. Eng. (2020). https://doi.org/10.1016/j.compositesb.2020.108388

Montgomery, D.C.: Design and Analysis of Experiments, 6th edn. Wiley, London (2004)

Montgomery-Smith, S., He, W., Jack, D.A., Smith, D.E.: Exact tensor closures for the three-dimensional Jeffery’s equation. J. Fluid Mech. 680, 321–335 (2011). https://doi.org/10.1017/jfm.2011.165

Morgan, D., Jacobs, R.: Opportunities and challenges for machine learning in materials science. Ann. Rev. Mater. Res. 50, 71–103 (2020). https://doi.org/10.1146/annurev-matsci-070218-010015

Moulinec, H., Suquet, P.: A fast numerical method for computing the linear and nonlinear mechanical properties of composites. Comptes Rendus De L’académie Des Sciences, Série II, Mécanique, Physique, Chimie, Astronomie 318(11), 1417–1423 (1994)

Moulinec, H., Suquet, P.: A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 157(1–2), 69–94 (1998). https://doi.org/10.1016/S0045-7825(97)00218-1

Sacks, J., Welch, W.J., Mitchell, T.J., Wynn, H.P.: Design and analysis of computer experiments. Stat Sci. 4, 409–423 (1989). https://doi.org/10.1214/ss/1177012413

Sang-To, T., Hoang-Le, M., Wahab, M.A., Cuong-Le, T.: An efficient planet optimization algorithm for solving engineering problems. Sci. Rep. (2022). https://doi.org/10.1038/s41598-022-12030-w

Schneider, M.: The sequential addition and migration method to generate representative volume elements for the homogenization of short fiber reinforced plastics. Comput. Mech. 59(2), 247–263 (2017). https://doi.org/10.1007/s00466-016-1350-7

Schneider, M.: A review of nonlinear FFT-based computational homogenization methods. Acta Mech. 232, 2051–2100 (2021). https://doi.org/10.1007/s00707-021-02962-1

Simpson, T., Poplinski, J., Koch, N.P., Allen, J.: Metamodels for computer-based engineering design: survey and recommendations. Eng. Comput. 17, 129–150 (2001a). https://doi.org/10.1007/PL00007198

Simpson, T.W., Lin, D.K., Chen, W.: Sampling strategies for computer experiments: design and analysis. Int. J. Reliab. 2(3), 209–240 (2001b)

Simpson, T., Mauery, T., Korte, J., Mistree, F.: Kriging models for global approximation in simulation-based multidisciplinary design optimization. AIAA J. 39(12), 2233–2241 (2001c). https://doi.org/10.2514/3.15017

Staub, S., Andrä, H., Kabel, M., Zangmeister, T.: Multi-scale simulation of viscoelastic fiber-reinforced composites. Tech. Mech. 12(1), 70–83 (2012)

Staub, S., Andrä, H., Kabel, M.: Fast FFT based solver for rate-dependent deformations of composites and nonwovens. Int. J. Solids Struct. 154, 33–42 (2018). https://doi.org/10.1016/j.ijsolstr.2016.12.014

Storn, R., Price, K.: Differential evolution-a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Opt. 11, 341–359 (1997). https://doi.org/10.1023/A:1008202821328

Thobiani, F.A., Khatir, S., Benaissa, B., Ghandourah, E., Mirjalili, S., Wahab, M.A.: A hybrid PSO and Grey wolf optimization algorithm for static and dynamic crack identification. Theor. Appl. Fract. Mech. (2022). https://doi.org/10.1016/j.tafmec.2021.103213

Torquato, S.: Optimal design of heterogeneous material. Annu. Rev. Mater. Res. 40(1), 101–129 (2010). https://doi.org/10.1146/annurev-matsci-070909-104517

Tran, A.B., Yvonnet, J., He, Q., Toulemonde, C., Sanahuja, J.: A simple computational homogenization method for structures made of heterogeneous linear viscoelastic materials. Comput. Methods Appl. Mech. Eng. 200(45–46), 2956–2970 (2011). https://doi.org/10.1016/j.cma.2011.06.012

Virtanen, P., Gommers, R., Oliphant, T. E., Haberland, M., Reddy, T., Cournapeau, D., Burovski, E., Peterson, P., Weckesser, W., Bright, J., van der Walt, S.J., Brett, M., Wilson, J., Millman, K.J., Mayorov, N., Nelson, A.R.J., Jones, E., Kern, R., Larson, E., Carey, C.J., Polat, İ., Feng, Y., Moore, E.W., VanderPlas, J., Laxalde, D., Perktold, J., Cimrman, R., Henriksen, I., Quintero, E.A., Harris, C.R., Archibald, A.M., Ribeiro, A.H., Pedregosa, F., van Mulbregt, P., and SciPy, 1.0 Contributors, SciPy, 1.0: Fundamental Algorithms for Scientific Computing in Python, Nat Methods (2020), Vol. 17, P. 261–272, https://doi.org/10.1038/s41592-019-0686-2

Wang, Z., Smith, D.E.: Numerical analysis on viscoelastic creep responses of aligned short fiber reinforced composites. Compos. Struct. (2019). https://doi.org/10.1016/j.compstruct.2019.111394

Xu, H., Li, Y., Brinson, C., Chen, W.: A descriptor-based design methodology for developing heterogeneous microstructural materials system. J. Mech. Des. (2014). https://doi.org/10.1115/1.4026649

Yang, J.L., Zhang, Z., Schlarb, A.K., Friedrich, K.: On the characterization of tensile creep resistance of polyamide 66 nanocomposites. Part I. Experimental results and general discussions. Polymer 47, 2791–2801 (2006). https://doi.org/10.1016/j.polymer.2006.02.065

Yang, J.L., Zhang, Z., Schlarb, A.K., Friedrich, K.: On the characterization of tensile creep resistance of polyamide 66 nanocomposites part II. Modeling and prediction of long-term performance. Polymer 47, 6745–6758 (2006). https://doi.org/10.1016/j.polymer.2006.07.060

Yvonnet, J., Monteiro, E., He, Q.-C.: Computational homogenization method and reduced database model for hyperelastic heterogeneous structures. Int. J. Multiscale Comput. Eng. 11(3), 201–225 (2013). https://doi.org/10.1615/IntJMultCompEng.2013005374

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Marr, J., Zartmann, L., Reinel-Bitzer, D. et al. Multiscale optimization of the viscoelastic behavior of short fiber reinforced composites. Int J Mech Mater Des 19, 501–519 (2023). https://doi.org/10.1007/s10999-023-09645-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-023-09645-w