Abstract

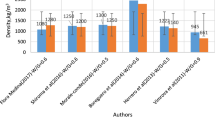

Natural and synthetic fiber-reinforced composites are currently being applied in practically every engineering subfield. Therefore, this study was conducted to compare the static and dynamic behaviors of composite materials produced using jute and glass fiber-reinforced polyesters. This was achieved by evaluating their static mechanical parameters such as elastic modulus, tensile strength, flexural strength, and critical buckling load. Impulse Excitation Method (IET) was also used to determine the dynamic elastic and shear modulus as well as the damping performance of the composite under dynamic response. The results showed that the tensile strength of glass fiber-reinforced polyester (GFRP) was 38.19% higher than the jute fiber-reinforced polyester (JFRP). Meanwhile, both composites had comparable mechanical properties such as almost the same flexural strength. The IET tests conducted also showed that the dynamic shear modulus and damping performance of both composites had a similar level of effectiveness. This means non-destructive tests such as the IET test can be used to determine the properties of a composite board quantitatively as well as to monitor the structural integrity of the board and the quality of its fabrication.

Similar content being viewed by others

References

Cao D, Malakooti S, Kulkarni VN et al (2021) Nanoindentation measurement of core – skin interphase viscoelastic properties in a sandwich glass composite. Mech Time-Dependent Mater 25:353–363

Cao D, Malakooti S, Kulkarni VN et al (2022) The effect of resin uptake on the flexural properties of compression molded sandwich composites. Wind Energy 25:71–93

Gholampour A, Ozbakkaloglu T (2020) A review of natural fiber composites: properties, modification and processing techniques, characterization, applications. J Mater Sci 55:829–892

Azman MA, Asyraf MRM, Khalina A et al (2021) Natural Fiber Reinforced Composite Material for Product Design : A Short Review. Polymers 13:1917

Arpitha GR, Sanjay MR, Senthamaraikannan P et al (2017) Hybridization Effect of Sisal/Glass/Epoxy/Filler Based Woven Fabric Reinforced Composites. Exp Tech 41:577–584

Salman SD (2020) Effects of jute fibre content on the mechanical and dynamic mechanical properties of the composites in structural applications. Def Technol 16:1098–1105

Wang H, Memon H, Hassan EAM et al (2019) Effect of Jute Fiber Modification on Mechanical Properties of Jute Fiber Composite. Materials 12:1226

Chatterjee A, Kumar S, Singh H (2020) Tensile strength and thermal behavior of jute fibre reinforced polypropylene laminate composite. Compos Commun 22:100483

Bucciarelli F, Fierro GPM, Zarrelli M, Meo M (2019) A Non-Destructive Method for Evaluation of the Out of Plane Elastic Modulus of Porous and Composite Materials. Appl Compos Mater 26:871–896

Cui R, di Scalea FL (2019) On the identification of the elastic properties of composites by ultrasonic guided waves and optimization algorithm. Compos Struct 223:110969

Niutta CB, Tridello A, Belingardi G, Paolino DS (2021) Nondestructive determination of local material properties of laminated composites with the impulse excitation technique. Compos Struct 262:113607

Tognana S, Salgueiro W, Somoza A, Marzocca A (2010) Measurement of the Young’s modulus in particulate epoxy composites using the impulse excitation technique. Mater Sci Eng A 527:4619–4623

Song W, Zhong Y, Xiang J (2017) Mechanical parameters identification for laminated composites based on the impulse excitation technique. Compos Struct 162:255–260

Rizal M, Mubarak AZ, Razali A, Asyraf M (2019) Free vibration characteristics of jute fibre reinforced composite for the determination of material properties: numerical and experimental studies. In: AIP Conf Proc 2187:050020

Pittala RK, Dhanaraju G, Ben BS, Ben BA (2022) Damping behaviour and self-healing performance evaluation of microcapsules reinforced epoxy composites by impulse excitation technique. J Reinf Plast Compos 41(21–22):870–881

ASTM D638 (2010) Test Method for Tensile Properties of Plastics. ASTM International, West Conshohocken

ASTM D790 (2010) Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International, West Conshohocken

ASTM E2954 (2022) Standard Test Method for Axial Compression Test of Reinforced Plastic and Polymer Matrix Composite Vertical Members. ASTM International, West Conshohocken

ASTM E1875–13 (2013) Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Sonic Resonance; ASTM International: West Conshohocken, PA, USA, 2013. ASTM International, West Conshohocken

Wang S, Yang Z, Kan J et al (2021) Design and characterization of an amplitude-limiting rotational piezoelectric energy harvester excited by a radially dragged magnetic force. Renew Energy 177:1382–1393

Montecinos S, Tognana S, Salgueiro W (2016) Determination of the Young’s modulus in CuAlBe shape memory alloys with different microstructures by impulse excitation technique. Mater Sci Eng A 676:121–127

Dobah Y, Bourchak M, Bezazi A et al (2016) Multi-axial mechanical characterization of jute fiber/polyester composite materials. Compos Part B 10:450–456

El-wazery MS, El-elamy MI, Zoalfakar SH (2017) Mechanical Properties of Glass Fiber Reinforced Polyester Composites. Int J Appl Sci Eng 14:121–131

Rafiquzzaman M, Islam MM, Rahman MH et al (2016) Mechanical property evaluation of glass – jute fiber reinforced polymer composites. Polym Adv Technol 27:1308–1316

Liu T, Butaud P, Placet V, Ouisse M (2021) Damping behavior of plant fiber composites : A review. Compos Struct 275:114392

Senthamaraikannan C, Ramesh R (2016) Experimental investigation on vibration characteristics of woven carbon fabric-reinforced composite beams of various cross-sectional shapes. Proc Inst Mech Eng Part L J Mater Des Appl 230:64–74

Foroozanfar A, Afridi M, Fayazbakhsh K, Hashemi SM (2022) Experimental and Computational Analysis of Elastic Modulus of 3D Printed Parts Using Impulse Excitation Technique (IET). Exp Tech. https://doi.org/10.1007/s40799-022-00592-3

Lasn K, Echtermeyer AT, Klauson A, Chati F (2015) Comparison of laminate stiffness as measured by three experimental methods. Polym Test 44:143–152

Acknowledgements

The authors are grateful to Universitas Syiah Kuala (USK), Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia with Grant No. 145/UN11/SPK/PNBP/2022, for supporting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rizal, M., Mubarak, A. & Alhaidar, T. A Comparative Study of the Static and Dynamic Characteristics of Jute and Glass Fiber-Reinforced Polyester Composites. Exp Tech 48, 229–237 (2024). https://doi.org/10.1007/s40799-023-00655-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-023-00655-z