Abstract

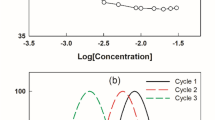

In foam products, awareness of sustainable approaches has focused attention on the replacement of synthetic surfactants with natural alternatives. However, commonly used natural surfactants are sensitive to acidity and high temperature, which reduce the foaming property. In this study, the physicochemical and foam properties of natural saponins from Xanthoceras sorbifolium Bunge leaves (XLs) as foam agents under industry-relevant conditions were studied. Results found that XLs saponins exhibited remarkable foaming ability and foam stability and resistance to low-pH and high-temperature. Further, the decrease in pH and the increase in temperature could decrease the surface tension. In addition, conductivity, particle size and zeta potential results showed that decreasing pH and increasing temperature could reduce the critical micelle concentration values of XLs saponins, thus forming additional micelles and increasing the viscoelasticity of the saponins solution. The enhancement of these properties contributed to forming a foam with favorable stability at low-pH and high-temperature. Such XLs saponins are promising natural alternatives to traditional food or cosmetic foaming agents.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

A. Arzhavitina, H. Steckel, Int. J. Pharmaceut. 394(1–2), 1–17 (2010)

W. Li, L. Zhu, F. Zhang, C. Han, H. Xiang, J. Jiang, Surf. Interfaces 29, 101707 (2022)

D.J. McClements, S.M. Jafari, Adv. Colloid Interface 251, 55–79 (2018)

C. Hill, J. Eastoe, Adv. Colloid Interface 247, 496–513 (2017)

E. Rio, W. Drenckhan, A. Salonen, D. Langevin, Adv. Colloid Interface 205, 74–86 (2014)

A.K. Asghari, I. Norton, T. Mills, P. Sadd, F. Spyropoulos, Food Hydrocoll. 53, 311–319 (2016)

A. Saint-Jalmes, M.L. Peugeot, H. Ferraz, D. Langevin, Colloid Surf. A 263(1–3), 219–225 (2005)

D. Lundberg, G. Lafitte, H. Ljusberg-Wahren, P. Lennernaes, K. Thuresson, J. Disper. Sci. Technol. 30(6), 920–928 (2009)

A. Pradhan, S. Bhuyan, K. Chhetri, S. Mandal, A. Bhattacharyya, Colloid Surf. A 643, 128778 (2022)

B. Chassaing, O. Koren, J.K. Goodrich et al., Nature 519(7541), 92-U192 (2015)

D.J. McClements, C.E. Gumus, Adv. Colloid Interface 234, 3–26 (2016)

M. Nooshkam, M. Varidi, F. Alkobeisi, Food Hydrocoll. 126, 107488 (2022)

L. Ma, Q. Li, Z. Du et al., Adv. Mater. Interfaces 6(14), 1900417 (2019).

Y. Lang, Y. Sun, Y. Feng, Z. Qi, M. Yu, K. Song, Bot. Rev 86(2), 136–148 (2020)

X. Chen, Z. Lei, J. Cao et al., J. Ethnopharmacol. 283, 114747 (2022)

X. Chen, Z. Lei, F. Cao, Q. Guo, J. Wang, J. Food Meas. Charact. 17(1), 916–932 (2022)

M. Hadidi, A. Ibarz, J. Pagan, Food Chem. 309, 125786 (2020)

T.B. Schreiner, G. Colucci, A. Santamaria-Echart et al., Colloid Surf. A 623, 126748 (2021)

J. Zhu, Z. Qian, M. Eid et al., Food Hydrocoll. 112, 106275 (2021)

A. Dan, G. Gochev, J. Kraegel, E.V. Aksenenko, V.B. Fainerman, R. Miller, Curr. Opin. Colloid In. 18(4), 302–310 (2013)

J. Sun, C. Chang, Y. Su, L. Gu, Y. Yang, J. Li, Food Hydrocoll. 122, 107088 (2022)

P.J. Gonzalez, P.M. Sorensen, Food Hydrocoll. 101, 105541 (2020)

I.B. Cam, A. Topuz, J. Food Process. Eng. 41(1), e12605 (2018)

M. Dabestani, S. Yeganehzad, R. Miller, Colloid Surf. A 630, 127594 (2021)

E.A. Foegeding, J.P. Davis, Food Hydrocoll. 25(8), 1853–1864 (2011)

D. McClements, Curr Opin Colloid In. 9(5), 305-313(2004)

J. Surh, E.A. Decker, D.J. McClements, Food Hydrocoll. 20(5), 596–606 (2006)

C. Leal, E. Moniri, L. Pegado, H. Wennerstrom, J. Phy. Chem. B 111(21), 5999–6005 (2007)

K. Golemanov, S. Tcholakova, N. Denkov, E. Pelan, S.D. Stoyanov, Soft Matter 9(24), 5738–5752 (2013)

D. Glikman, N. Garcia Rey, M. Richert, K. Meister, B. Braunschweig, J. Colloid Interface Sci. 607(Pt 2), 1754–1761 (2022)

M.G. Cabezas, A. Bateni, J.M. Montanero, A.W. Neumann, Langmuir 22(24), 10053–10060 (2006)

B.D. Ribeiro, D.S. Alviano, D.W. Barreto, M.A. Zarur Coelho, Colloid Surf. A 436, 736–743 (2013)

S.-T. Muntaha, M.N. Khan, J. Clean. Prod. 93, 145–150 (2015)

S. Balakrishnan, S. Varughese, A.P. Deshpande, Tenside Surf. Det. 43(5), 262–268 (2006)

R. Shi, Y. Liu, Y. Ma, P. Zhao, Z. Jiang, J. Hou, J. Agric. Food Chem. 70(10), 3252–3262 (2022)

R. Shi, W. Chen, F. Pan et al., Food Hydrocoll. 124, 107259(2022)

S. Tsibranska, S. Tcholakova, K. Golemanov, N. Denkov, E. Pelan, S.D. Stoyanov, J. Colloid Interface Sci. 564, 264–275 (2020)

Funding

This study has been supported by National key research and development program of China (No. 2022YFD1300902) and the Research Institute of X. sorbifolia from Weifang City, China.

Author information

Authors and Affiliations

Contributions

Xianqiang Chen: Conceptualization, Methodology, Software, Investigation, Writing - Original Draft. Xinyu Chu and Xue Li: Validation, Formal analysis, and Writing- Review & Editing. Fuliang Cao: Funding acquisition. Erzheng Su: Funding acquisition. Wangsheng Zhu, Funding acquisition. Shouke Li, Funding acquisition. Jiahong Wang: Conceptualization, Writing- Review & Editing, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 4.45 MB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, X., Chu, X., Li, X. et al. Insight Into Foam Properties of Natural Saponins with Low-pH and High-Temperature Tolerance from Xanthoceras sorbifolium Bunge Leaves for Industry Applications. Food Biophysics 18, 545–555 (2023). https://doi.org/10.1007/s11483-023-09798-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-023-09798-3