Abstract

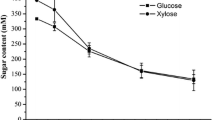

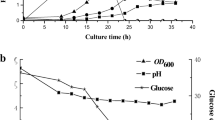

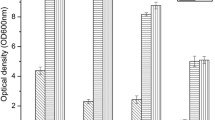

Biobutanol is one of the types of biofuels produced using microbial synthesis (acetone–butanol–ethanol fermentation). It is possible to increase the level of accumulation of the target product due to metabolic changes in producer cells under the influence of stress factors. For this purpose, the effect of such stress factors as allopurinol, furfural, zinc, and oxygen, as well as glycerol as a nonspecific substrate on the functioning of Clostridium sp. cells, was studied. It was demonstrated that the butanol concentration was the highest (1.2 g/L) as compared with the control (0.6 g/L) when adding 0.5 g/L of furfural to the culture medium. The use of ZnSO4 at a concentration of 0.001 g/L increased the butanol concentration to 1.1 g/L, and the highest butanol concentration (1.3 g/L) was obtained when using glucose and glycerol as carbon sources in a ratio of 1 : 3. The butanol concentration in the culture medium increased to 0.8 g/L with the addition of 0.025 g/L of allopurinol. The possibility of using the above-mentioned stress factors to increase the accumulation of the target product by influencing the metabolic pathways in microorganism cells is substantiated.

Similar content being viewed by others

REFERENCES

Agu, V.Ch., Ujor, V., and Ezeji, T.C., Allopurinol supplementation of the growth medium enhances the fermentation of lignocellulose hydrolysates to ethanol by Saccharomyces cerevisiae, Biocatal. Agric. Biotechnol., 2018, vol. 14, pp. 151–159. https://doi.org//10.1016/j.bcab.2018.03.001

Agu, V.Ch., Ujor, V., and Ezeji, T.C., Metabolic engineering of Clostridium beijerinckii to improve glycerol methabolism and furfural tolerance, Biotechnol. Biofuels, 2019, vol. 12, p. 50. https://doi.org/10.1186/s13068-019-1388-9

Agyeman-Duah, E., Kumar, S., Gangwar, B., and Unjor, V., Glycerol utilization as a sole carbon source disrupts the membrane architecture and solventogenesis in Clostridium beijerinckii NCIMB 8052, Fermentation, 2022, vol. 8, p. 339. https://doi.org/10.3390/fermentation8070339

Arbter, Ph., Sabra, W., Utesch, T., et al., Metabolomic and kinetic investigations on the electricityaided production of butanol by Clostridium pasteurianum strains, Eng. Life Sci., 2021, vol. 21, pp. 181–195. https://doi.org/10.1002/elsc.202000035

Bao, T., Jiang, W., Ahmad, Q.-A, and Yang, S.-T., 13-Consolidated bioprocessing for ethanol and butanol production from lignocellulosic biomass: Resent advances in strain and process engineering, A-Z Biorefin., 2022, pp. 473–506. https://doi.org/10.1016/B978-0-12-819248-1.00009-9

Capilla, M., Valles, A., San-Valero, P., et al., Solvent production from rice straw by a co-culture of Clostridium acetobutylicum and Saccharomyces cerevisiae: effect of pH control, Biomass Convers. Biorefin., 2022. https://doi.org/10.1007/s13399-022-02750-4

Cho, Ch., Hong, S., Moon, G.H., et al., Engineering clostridial aldehyde/alcohol dehydrogenase for selective butanol productions, mBio, 2019, vol. 10, no. 1, p. e02683-18. https://doi.org/10.1128/mBio.02683-18

Foulquier, C., Riviere, A., Heulot, N., et al., Molecular characterization for butanol synthesis in Clostridium acetobutylicum, Nat. Commun., 2022, vol. 13, p. 4691. https://doi.org/10.1038/s41467-022-32269-1

Gong, Ch., Meng, X., Jin, C., et al., Green synthesis of cellulose formate and its efficient conversion into 5-hydroxymethylfurfural, Ind. Crops Prod., 2023, vol. 192, p. 115985. https://doi.org/10.1016/jindcrop.2022.115985

Guo, Y., Liu, Y., Guan, M., et al., Production of bu tanol from lignocellulostic biomass: recent advances, challenges, and prospects, RSC Adv., 2022, vol. 12, pp. 18848–18863. https://doi.org/10.1039/D1RA09396G

Jiang, Y., Wu, R., Lu, J., et al., Quantitative proteomic analysis to reveal expression difference for butanol production from glycerol and glucose by Clostridium sp. stain CT7, Microb. Cell Fact., 2021, vol. 20, p. 12. https://doi.org/10.1186/s12934-021-01508-3

Li, D., Meng, Ch., Wu, G., et al., Effect of zinc on the production of alcohol by Clostridium carboxidivorans P7 using model syngas, J. Ind. Microbiol. Biotechnol., 2018, vol. 45, pp. 61–69. https://doi.org/10.1007/s10295-017-1992-2

Li, J., Shen, H., Zhao, Z., et al., Protective effect of Clostridium butyricum against oxidative stress induced by food processing and lipid-derived aldehydes in Caco-2 cells, Appl. Microbiol. Biotechnol., 2020, vol. 104, pp. 9343–9361. https://doi.org/10.1007/s00253-020-10896-2

Luo, H., Liu, Z., Xie, F., et al., Lignocellulose biomass to biobutanol: Toxic effects and response mechanism of the combined stress of lignin-derived phenolic acids and phenolic aldehydes to Clostridium acetobutylicum, Ind. Crops Prod., 2021, vol. 170, p. 113722. https://doi.org/10.1016/jindcrop.2021.113722

Mahalingam, L., Abdulla, R., Sani, A.S., et al., Lignocellulosic biomass – a sustainable feedstock for acetone-butanol-ethanol fermentation, Period Polytech. Chem. Eng., 2022, vol. 66, no. 2, pp. 279–296. https://doi.org/10.3311/PPch.18574

Molognoni, D., Vega, M., de Vrije, T., et al., Enhancing butanol production by Clostridium beijerinckii through cathodic electrofermentation approach, J. Chem. Technol. Biotechnol., 2023, vol. 98, no. 4, pp. 856–864. https://doi.org/10.1002/jctb.7324

Molnar-Nagy, V., Tso, K.-H., Hall, J.W., et al., Effect of different nutritional zinc forms on the proliferation of beneficial commensal microorganisms, Microbiol. Res., 2022, vol. 13, pp. 500–513. https://doi.org/10.1002/jctb.7324

Mukherjee, M., Sarkar, P., Goswami, G., and Das, D., Regulation of butanol biosynthesis in Clostridium acetobutylicum ATCC 824 under the influence of zinc supplementation and magnesium starvation, Enzyme Microb. Technol., 2019, vol. 129, p. 109352. https://doi.org/10.1016/j.enzmictec.2019.05.009

Qureshi, N., Bowmana, M.J., Sahaa, B.C., et al., Effect of cellulosic sugar degradation products (furfural and hydroxymethyl furfural) on acetone-butanol-ethanol (ABE) fermentation using Clostridium beijerinckii P260, Food Bioprod. Bioprocess., 2012, vol. 90, pp. 533–540. https://doi.org/10.1016/j.fbp.2011.09.002

Riaz, S., Mazhar, S., Abidi, S.H., et al., Biobutanol production from sustainable biomass process of anaerobic ABE fermentation for industrial applications, Arch. Microbiol., 2022, vol. 204, p. 11. https://doi.org/10.1007/s00203-022-03284-z

Saqr, A.A., Aldawsari, F.M., Khafagy, E.-S., et al., A novel use of allopurinol as a quorum-sensing inhibitor in Pseudomonas aeruginosa, Antibiotics, 2021, vol. 10, no. 11, p. 1385. https://doi.org/10.3390/antibiotics10111385

Tigunova, O., Shulga, S., and Blume, Y.B., Biobutanol as an alternative type of fuel, Cytol. Genet., 2013, vol. 47, no. 6, pp. 366–382. https://doi.org/10.3103/s0095452713060042

Tigunova, O., Andrijash, G., Beyko, N., et al., Rape biomass (Brassica napus) as raw materials for biobutanol production, Biotechnol. Acta, 2019, vol. 12, no. 1, pp. 75–80. https://doi.org/10.15407/biotech12.01.075

Tigunova, O.O., Kamenskyh, D.S., Tkachenko, T.V., et al., Biobutanol production from plant biomass, Open Agric. J., 2020, vol. 14, pp. 187–197. https://doi.org/10.2174/1874331502014010187

Torres, L.G.F., Nunes, E.V., and Guerrero, C.E.M., Technoeconomic analysis of broccoli biofineries for polyphenol extraction and biobutanol production, REB&S, 2022, vol. 4, no. 1, pp. 23–37. https://doi.org/10.56845/rebs.v4i1.70

Yao, X., Zhang, Q., Fan, Y., et al., Butanol-isopropanol fermentation with oxygen-tolerant Clostridium beijerinckii XN29, AMB Express, 2022, vol. 12, p. 57. https://doi.org/10.1186/s13568-022-01399-6

Ujor, V., Okonkowo, Ch., and Ezeji, Th.Ch., Unorthodox methods for enhancing solvent production in solventogenic Clostridium species, Appl. Microbiol. Biotechnol., 2016, vol. 100, pp. 1089–1099. https://doi.org/10.1007/s00253-015-7166-0

Wu, Y., Bai, Y., Zhang, D., et al., Pleiotropic regulation of a glucose-specific PTS in Clostridium acetobutylicum for high-efficient butanol production from corn stover without detoxification, Biotechnol. Biofuels, 2019, vol. 12, p. 264. https://doi.org/10.1186/s13068-019-1604-7

Zborowska, H., Waliszewska, B., Waliszewska, S., et al., Conversion of carbohydrates in lignocellulosic biomass after chemical pretreatment, Energies, 2021, vol. 15, no. 1, pp. 1–14. https://doi.org/10.3390/en15010254

Zhang, Y., Han, B., and Ezeji, T.C., Biotransformation of furfural and 5- hydroxymethyl furfural by Clostridium acetobutylicum ATCC 824 during butanol fermentation, New Biotechnol., 2012, vol. 29, pp. 345–351. https://doi.org/10.1016/j.nbt.2011.09.001

Zhou, Z., Jing, Y., Wei, S., et al., Enhancement of butanol production in Clostridium acetobutylicum SE 25 through oxidation-reduction potential regulation and analysis of its metabolic mechanisms, Fuel, 2023, vol. 331, no. 1, p. 125708. https://doi.org/10.1016/j.fuel.2022.125708

Funding

This study was supported by the institutional topic Creation of Strains of Overproducers of Secondary Metabolites (Amino Acids, Alcohols, Vitamins), state registration no. 0119U101489.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest. This article does not contain any studies involving human participants or animals performed by any of the authors.

Additional information

Translated by A. Barkhash

About this article

Cite this article

Tigunova, O.O., Bratishko, V.V. & Shulga, S.M. An Increase in the Production of Butanol by Clostridium sp. Cells under the Influence of Stress Factors. Cytol. Genet. 57, 239–245 (2023). https://doi.org/10.3103/S009545272303009X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S009545272303009X