Abstract

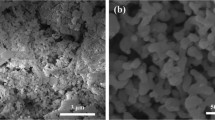

Recently, consumers have shown a growing interest in polymeric products that offer high aesthetic and comfort features, along with superior engineering performance. In response to this demand, we conducted a study on metallic polymer composites, utilizing metal fillers and polymers. To create these composites, micro-sized aluminum flakes and nano-sized spherical aluminum powder were combined with aliphatic polyketone. Furthermore, an ion-beam irradiation process was employed to enhance the surface properties of the products, including surface hardness, modulus, and glossiness. The compounding process was carried out using a twin-screw extruder, and disk-shaped specimens were prepared through injection molding. Subsequently, nitrogen ion-beam irradiation was applied to the prepared specimens. Comprehensive analysis was performed to evaluate the mechanical, aesthetic, structural, and morphological properties of these metal-like composites.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

References

Miller W et al (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng, A 280(1):37–49

Li Y et al (2003) Use of high strength steel sheet for lightweight and crashworthy car body. Mater Des 24(3):177–182

Hussain F et al (2006) Polymer-matrix nanocomposites, processing, manufacturing, and application: an overview. J Compos Mater 40(17):1511–1575

Zhang Y et al (2006) Lightweight design of automobile component using high strength steel based on dent resistance. Mater Des 27(1):64–68

Hirsch J (2011) Aluminium in innovative light-weight car design. Mater Trans 52(5):818–824

Friedrich K, Almajid AA (2013) Manufacturing aspects of advanced polymer composites for automotive applications. Appl Compos Mater 20:107–128

Jeong JW, Song YS (2021) Characterization of hybrid composites reinforced with metal and ceramic nanoparticles. Polym Compos 42(5):2317–2323

Tavman I (1996) Thermal and mechanical properties of aluminum powder-filled high-density polyethylene composites. J Appl Polym Sci 62(12):2161–2167

Busmann H-G, Günther B, Meyer U (1999) Polymer matrix composites filled with nanoporous metal powders: preparation and electrical properties. Nanostruct Mater 12(1–4):531–534

Sofian N et al (2001) Metal powder-filled polyethylene composites. V. Thermal properties. J Thermoplast Compos Mater 14(1):20–33

Balan L, Burget D (2006) Synthesis of metal/polymer nanocomposite by UV-radiation curing. Eur Polymer J 42(12):3180–3189

Santos IO, Pontes AJ, Martins CI (2013) Morphological aspects of injection-molded polypropylene with metallic pigments

Ashok Kumar M et al (2010) Frictional coefficient, hardness, impact strength, and chemical resistance of reinforced sisal-glass fiber epoxy hybrid composites. J Compos Mater 44(26):3195–3202

Park JM, Jeong SJ, Park SJ (2011) Numerical prediction of flake orientation and surface color in injection molding of flake-pigmented thermoplastics. Polym Compos 32(8):1297–1303

Min Park J, Jae Jeong S, Jin Park S (2012) Flake orientation in injection molding of pigmented thermoplastics. J Manuf Sci Eng 134:1

Costantino A et al (2014) Yield, impact and fracture performance of injected metallic looking polypropylene parts

Costantino MA et al (2015) Mechanical performance of double gated injected metallic looking polypropylene parts

Lim JS et al (2020) Development of a noble aluminum-pigmented metallic polymer: recommendations for visible flow and weld line mitigation. J Appl Polym Sci 137(37):49084

Seop LJ et al (2022) Noble aluminum-pigmented metallic polymers II: effects of inorganic filler on weld-and flow-line visibility. Polym Testing 106:107422

O’Brien WJ et al (1984) The surface roughness and gloss of composites. J Dent Res 63(5):685–688

Lawson NC, Burgess JO (2016) Gloss and stain resistance of ceramic-polymer CAD/CAM restorative blocks. J Esthet Restor Dent 28:S40–S45

Cook M, Thomas K (1990) Evaluation of gloss meters for measurement of moulded plastics. Polym Testing 9(4):233–244

Schnabel W, Klaumünzer S (1991) The effects of ion-beam irradiation of polymers. Int J Radiat Appl Instrum 37(1):131–134

Dong H, Bell T (1999) State-of-the-art overview: ion beam surface modification of polymers towards improving tribological properties. Surf Coat Technol 111(1):29–40

Evelyn A et al (1999) Ion beam modification of PES, PS and PVC polymers. Nucl Instrum Methods Phys Res, Sect B 148(1–4):1141–1145

Lee EH (1999) Ion-beam modification of polymeric materials–fundamental principles and applications. Nucl Instrum Methods Phys Res, Sect B 151(1–4):29–41

Guenther M et al (2004) Physical properties and structure of thin ion-beam modified polymer films. Nucl Instrum Methods Phys Res, Sect B 216:143–148

Shah S et al (2009) Structural and chemical modification of polymer composite by proton irradiation. Surf Coat Technol 203(17–18):2595–2599

Awasthi K et al (2010) Optical, chemical and structural modification of oxygen irradiated PET. Radiat Meas 45(7):850–855

Singh N et al (2011) Effect of ion beam irradiation on metal particle doped polymer composites. Bull Mater Sci 34:81–88

Kumar V et al (2012) Carbon ion beam induced modifications of optical, structural and chemical properties in PADC and PET polymers. Radiat Phys Chem 81(6):652–658

Park J-W et al (2012) Dual ion beam irradiation of polymeric materials for the modification of optical properties with improved adhesion. Nucl Instrum Methods Phys Res, Sect B 281:51–55

Acknowledgements

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (2018R1A5A1024127 and 2021R1F1A1051256). Also, the Department of Fiber System Engineering was supported through the Research-Focused Department Promotion & Interdisciplinary Convergence Research Project as a part of the Support Program for University Development for Dankook University in 2023.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jeong, J.W., Song, Y.S. Surface characteristics of metal-like composites fabricated with aliphatic polyketone. Korea-Aust. Rheol. J. 35, 169–178 (2023). https://doi.org/10.1007/s13367-023-00061-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-023-00061-2