Abstract

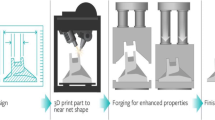

Additive Manufacturing (AM) using Selective Laser Melting (SLM) has gained significant prominence across various industries involved in stainless steel part manufacturing. Selective Laser Melting makes it possible to manufacture parts with very complex geometry and with remarkable mechanical and physicochemical properties by controlling the microstructure via the appropriate choice of process parameters. This study presents a comprehensive literature review aiming to provide the scientific and technical communities with an overview of existing knowledge and experimental data regarding the effects of Selective Laser Melting parameters and conditions on the microstructure and mechanical properties of stainless-steel parts. The objective is to highlight the impact of various factors, such as process parameters, building atmosphere, post-heat treatments and initial powder characteristics on phase transformation, porosity and microcracks formation, microstructure evolution and mechanical properties of SLMed stainless steels. Additionally, the integration of emerging Smart Additive Manufacturing (SAM) requires experimental databases, properties prediction and processing parameters optimization to enhance the entire process spanning from design to final product.

Similar content being viewed by others

Abbreviations

- A(%):

-

Elongation at break

- AI:

-

Artificial Intelligence

- AM:

-

Additive Manufacturing

- D/Z:

-

Ratio related to the building direction

- DLMS:

-

Direct Laser Metal Sintering

- E v :

-

Volumetric heat input

- h:

-

Hatch distance

- Hv:

-

Vickers hardness

- Mf:

-

Martensite finish temperature

- ML:

-

Machine Learning

- Ms:

-

Martensite start temperature

- P:

-

Laser power

- R a :

-

Average surface roughness

- SAM:

-

Smart Additive Manufacturing

- SLM:

-

Selective Laser Melting

- SLS:

-

Selective Laser Sintering

- SPD:

-

Severe Plastic Deformation

- t :

-

Powder layer thickness

- V:

-

Laser scanning velocity

- Z:

-

Building direction

- ρ :

-

Relative density

- σ uts :

-

Ultimate tensile strength

- σ y :

-

Yield strength

References

Deckard C, Beaman JJ, Darrah JF (1989) Method and Apparatus for Producing Parts by Selective Sintering. United States Patent 4(863):538

Hk R, Pal D, Patil N, Star T, Be S (2014) Microstructure and mechanical behavior of 17–4PH precipitation hardenable steel processed by selective laser melting. J Mater Eng Perform 23(12):4421–4428. https://doi.org/10.1007/s11665-014-1226-y

Gunenthiram V (2018) Understanding porosity formation in additive manufacturing (LBM). Experimental analysis of the laser - powder bed - liquid bath interaction. Thesis, ENSAM ParisTech.

Verquin B, Hoguin S, Lavoipierre TC, Le Gall C (2019) Metal additive manufacturing: The fundamentals. Technical Center for Mechanical Industries (Cetim), p16

Hussein A, Hao L, Yan C, Everson R, Young P (2013) Advanced lattice support structures for metal additive manufacturing. J Mater Process Technol 213(7):1019–1026

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components – Process, structure and properties. Prog Mater Sci 92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

Lingbin M, Brandon M, William J, Hye-yeong P, Yeon-gil J, Jehyun L, Jing Z (2020) Machine Learning in Additive Manufacturing: A Review. JOM 72:2363–2377. https://doi.org/10.1007/s11837-020-04155-y

Babu SS, Mourad A-HI, Harib KH, Vijayavenkataraman S (2023) Recent developments in the application of machine-learning towards accelerated predictive multiscale design and additive manufacturing. Virtual Phys Prototyp 18(1):e2141653. https://doi.org/10.1080/17452759.2022.2141653

Rahman MA, Saleh T, Jahan MP, McGarry C, Chaudhari A, Huang R, Tauhiduzzaman M, Ahmed A, Mahmud AA, Bhuiyan MS et al (2023) Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects. Micromachines 14:508. https://doi.org/10.3390/mi14030508

Xia M, Gu D, Yu G, Dai D, Chen H, Shi Q (2016) Selective laser melting 3D printing of Ni-based superalloy: understanding thermodynamic mechanisms. Sci Bull 61:1013–1022. https://doi.org/10.1007/s11434-016-1098-7

AMM M, Garciandia F, Sebastian MS, Álvarez P, Díaz J, Unanue I (2016) Reduction of the residual porosity in parts manufactured by selective laser melting using skywriting and high focus offset strategies. Phys Procedia 83:864–873. https://doi.org/10.1016/j.phpro.2016.08.090

Thijs L, Verhaeghe F, Craeghs T, Van Humbeeck J, Kruth JP (2010) A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater 58:3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

Kruth JP, Badrossamay M, Yasa E, Deckers J, Thijs L, Van Humbeeck J, Zhao W , Ye J, Zhu D (2010) Part and material properties in selective laser melting of metal. 16th International Symposium on Electro machining (ISEM XV) 3-14

Carlton HD, Haboub A, Gallegos GF, Parkinson DY, AA MD (2016) Damage evolution and failure mechanisms in additively manufactured stainless steel. Mater Sci Eng A 651:406–414. https://doi.org/10.1016/j.msea.2015.10.073

Hu Z, Zhu H, Zhang H, Zeng X (2017) Experimental investigation on selective laser melting of 17-4PH stainless steel. Opt Laser Technol 87:17–25. https://doi.org/10.1016/j.optlastec.2016.07.012

Abd-Elghany K, Bourell DL (2012) Property evaluation of 304L stainless steel fabricated by selective laser melting. Rapid Prototyp J 18(5):420–428. https://doi.org/10.1108/13552541211250418

Röttger A, Geenen K, Windmann M, Binner F, Theisen W (2016) Comparison of microstructure and mechanical properties of 316 L austenitic steel processed by selective laser melting with hot-isostatic pressed and cast material. Mater Sci Eng 678:365–376. https://doi.org/10.1016/j.msea.2016.10.012

Gu H, Gong H, Pal D, Rafi K, Starr T & Stucker B (2013) Influences of energy density on porosity and microstructure of selective laser melted 17- 4ph stainless steel. 24th annual international solid freeform fabrication symposium. 474-189. https://doi.org/10.26153/tsw/15572

Roberts D, Zhang Y, Charit I, Zhang J (2018) A comparative study of microstructure and high-temperature mechanical properties of 15-5 PH stainless steel processed via additive manufacturing and traditional manufacturing. Prog Add Manuf 3:183–190. https://doi.org/10.1007/s40964-018-0051-5

Maya J, Sivaprasad K, GVS K, Baitimerov R, Lykov P, Prashanth KG (2022) Microstructure, Mechanical Properties, and Corrosion Behavior of 06Cr15Ni4CuMo Processed by Using Selective Laser Melting. Metals 12:1303. https://doi.org/10.3390/met12081303

Dong D, Chang C, Wang H, Yan X, Ma W, Liu M, Deng S, Gardan J, Bolot R, Liao H (2020) Selective laser melting (SLM) of CX stainless steel: Theoretical calculation, process optimization and strengthening mechanism. J Mater Sci Technol 73:151–164. https://doi.org/10.1016/j.jmst.2020.09.031

Yasa E, Kempen K, Kruth J-P, Thijs L, Van Humbeeck J (2010) Microstructure and mechanical properties of maraging steel 300 after selective laser melting. Solid Freeform Fabrication Symposium Proceedings 383 – 396

Kempen K, Yasa E, Thijs L, Kruth J, Humbeeck V (2011) Microstructure and mechanical properties of Selective Laser Melted 18Ni-300 steel. Phys Procedia 12:255–263. https://doi.org/10.1016/j.phpro.2011.03.033

Vastola G, Pei QX, Zhang YW (2018) Predictive model for porosity in powder-bed fusion additive manufacturing at high beam energy regime. Add Manuf 22:817–822. https://doi.org/10.1016/j.addma.2018.05.042

Laohaprapanon A, Jeamwatthanachai P, Wongcumchang M, Chantarapanich N, Chantaweroad S, Sitthiseripratip K, Wisutmethangoon S (2012) Optimal Scanning Condition of Selective Laser Melting Processing with Stainless Steel 316L Powder. Adv Mater Res 341-342:816–820. https://doi.org/10.4028/www.scientific.net/AMR.341-342.816

Mutua J, Nakata S, Onda T, Chen Z (2018) Optimization of selective laser melting parameters and in fluence of post heat treatment on microstructure and mechanical properties of maraging steel. Mater Des 139:486–497. https://doi.org/10.1016/j.matdes.2017.11.042

Sun Y, Hebert RJ, Aindow M (2018) Non-metallic inclusions in 17-4PH stainless steel parts produced by selective laser melting. Mater Des 140:153–162. https://doi.org/10.1016/j.matdes.2017.11.063

Mercelis P, Kruth JP (2006) Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp J 12(5):254–265. https://doi.org/10.1108/13552540610707013

Suryawanshi J, Prashanth KG, Ramamurty U (2017) Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting. J Alloys Compd 725:355–364. https://doi.org/10.1016/j.jallcom.2017.07.177

Yadollahi A, Shamsaei N, Thompson S, Elwany A, Bian L (2015) Mechanical and microstructural properties of selective laser melted 17–4 PH stainless steel. Adv Manuf 2A. https://doi.org/10.1115/IMECE2015-52362

Rafi HK, Starr TL, Stucker BE (2013) A comparison of the tensile, fatigue, and fracture behavior of Ti-6Al-4V and 15-5 PH stainless steel parts made by selective laser melting. Int J Adv Manuf Technol 69:1299–1309. https://doi.org/10.1007/s00170-013-5106-7

Wu JH, Lin CK (2003) Influence of high temperature exposure on the mechanical behavior and microstructure of 17–4 PH stainless steel. J Mater Sci 38(5):965–971. https://doi.org/10.1023/A:1022377225704

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth JP (2010) A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58:3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

LeBrun T, Nakamoto T, Horikawa K, Kobayashi H (2015) Effect of retained austenite on subsequent thermal processing and resultant mechanical properties of selective laser melted 17-4PH stainless steel. Mater Des 81:44–53. https://doi.org/10.1016/j.matdes.2015.05.026

Zhou Z, Zhang K, Hong Y, Zhu H, Zhang W, He Y, Zhou C, Zheng J, Zhang L (2021) The dependence of hydrogen embrittlement on hydrogen transport in selective laser melted 304L stainless steel. Int J Hydrog Energy 46(29):16153–16163. https://doi.org/10.1016/j.ijhydene.2021.02.035

Guan K, Wang Z, Gao M, Li X, Zeng X (2013) Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater Des 50:581–586. https://doi.org/10.1016/j.matdes.2013.03.056

Zhong Y, Liu L, Wikman S, Cui D, Shen Z (2016) Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J Nucl Mater 470:170–178. https://doi.org/10.1016/j.jnucmat.2015.12.034

Herzog D, Seyda V, Wycisk E, Emmelmann C (2013) Additive manufacturing of metals. Acta Mater 117:371–392. https://doi.org/10.1016/j.actamat.2016.07.019

Fayazfar H, Salarian M, Rogalsky A, Sarker D, Russo P, Paserin V, Toyser-kani E (2018) A critical review of powder-based additive manufacturing of ferrous alloys : Process parameters, microstructure and mechanical properties. Mater Des 144:98–128. https://doi.org/10.1016/j.matdes.2018.02.018

Basak A, Das S (2016) Epitaxy and microstructure evolution in metal additive manufacturing. Ann Rev Mater Res Ann 46(1):125–149. https://doi.org/10.1146/annurev-matsci-070115-031728

Das S (2003) Physical aspects of process control in selective laser sintering of metals. Adv Eng Mater 5(10):701–711. https://doi.org/10.1002/adem.200310099

Elgadari MH (2018) Role of inert gas to reduce mechanical defects of the built object fabricated by SLM process. Thesis, University Of Malaya

Pham MS, Dovgyy B, Hooper PA, Gourlay CM, Piglione A (2020) The role of side-branching in microstructure development in laser powder-bed fusion. Nat Commun 11(1):749. https://doi.org/10.1038/s41467-020-14453-3

Murr LE, Martinez E, Hernandez J, Collins S, Amato KN, Gaytan SM, Shindo PW (2012) Microstructures and properties of 17-4 PH Stainless steel fabricated by selective laser melting. J Mater Res Technol 1(3):167–177. https://doi.org/10.1016/S2238-7854(12)70029-7

Facchini L, Vicente N, Lonardelli JR, Magalini E, Robotti P, Molinari A (2010) Metastable austenite in 17-4 precipitation-hardening stainless steel produced by selective laser melting. Adv Eng Mater 12(3):84–188. https://doi.org/10.1002/adem.200900259

Alnajjar M, Christien F, Wolski K, Bosch C (2019) Evidence of austenite by-passing in a stainless steel obtained from laser melting additive manufacturing. Add Manuf 25:187–195. https://doi.org/10.1016/j.addma.2018.11.004

Cheruvathur S, Lass EA, Campbell CE (2015) Additive Manufacturing of 17-4PH Stainless Steel: Post-processing Heat Treatment to Achieve Uniform Reproducible Microstructure. JOM 68(3):930–942. https://doi.org/10.1007/s11837-015-1754-4

Sun Y, Hebert RJ, Aindow M (2018) Effect of heat treatments on microstructural evolution of additively manufactured and wrought 17-4PH stainless steel. Mater Des 156:429–440. https://doi.org/10.1016/j.matdes.2018.07.015

Le Z, Chaoqun Z, Yiqiang W, Wei G, Daniel W, Xin T, Yingtao T (2020) Laser powder bed fusion of precipitation-hardened martensitic stainless steels: A Review. Metals 2020, 10(2), 255; https://doi.org/10.3390/met10020255

Limousin M (2018) Développement d’inserts de moule pour l’injection plastique en acier inoxydable martensitique et en verre métallique massif produits par Laser Beam Melting (LBF). Thesis, University of Lyon

Wang X, Muñiz-Lerma JA, Sánchez MO, Attarian SM, Brochu M (2018) Microstructure and mechanical properties of stainless steel 316L vertical struts manufactured by laser powder bed fusion process. Mater Sci Eng 736:27–40. https://doi.org/10.1016/j.msea.2018.08.069

Saeidi K, Akhtar F (2018) Subgrain-controlled grain growth in the laser-melted 316 L promoting strength at high temperatures. R Soc Open Sci 5(5):172394. https://doi.org/10.1098/rsos.172394

Krakhmalev P, Yadroitsava I, Fredriksson G, Yadroitsev I (2017) Microstructural and thermal stabi lity of selective laser melted 316L stainless steel single tracks. South African J Industr Eng 28(1):12–19. https://doi.org/10.7166/28-1-1466

Wang YM, Voisin T, JT MK, Ye J, Calta NP, Li Z, Zeng Z, Zhang Y, Chen W, Roehling TT, Ott RT, Santala MK, Depond PJ, Matthews MJ, Hamza AV, Zhu T (2018) Additively manufactured hierarchical stainless steels with high strength and ductility. Nat Mater 17:63–71. https://doi.org/10.1038/nmat5021

Sarkar S, Mukherjee S, Kumar CS, Kumar NA (2020) Effects of heat treatment on microstructure, mechanical and corrosion properties of 15-5 PH stainless steel parts built by selective laser melting process. J Manuf Process 50:279–294. https://doi.org/10.1016/j.jmapro.2019.12.048

Cherry JA, Davies HM, Mehmood S, Lavery NP, Brown SGR, Sienz J (2014) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol 76(5-8):869–879. https://doi.org/10.1007/s00170-014-6297-2

Chen W, Yin G, Feng Z, Liao X (2018) Effect of Powder Feedstock on Microstructure and Mechanical Properties of the 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 8(9):729. https://doi.org/10.3390/met8090729

Van Belle L, Vansteenkiste G, Boyer JC (2012) Comparisons of Numerical Modelling of the Selective Laser Melting. Key Eng Mater 504-506:1067–1072. https://doi.org/10.4028/www.scientific.net/KEM.504-506.1067

Leuders S, Lieneke T, Lammers S, Tröster T, Niendorf T (2014) On the fatigue properties of metals manufactured by selective laser melting – The role of ductility. J Mater Res 29(17):1911–1919. https://doi.org/10.1557/jmr.2014.157

Spierings AB, Starr TL, Wegener K (2013) Fatigue performance of additive manufactured metallic parts. Rapid Prototyp J 19(2):88–94. https://doi.org/10.1108/13552541311302932

Bezuidenhout M, Ter Haar G, Becker T, Rudolph S, Damm O, Sacks N (2020) The effect of HF-HNO3 chemical polishing on the surface roughness and fatigue life of laser powder bed fusion produced Ti6Al4V. Mater Today Commun 25:101396. https://doi.org/10.1016/j.mtcomm.2020.101396

Yang KT, Kim MK, Kim D, Suhr J (2021) Investigation of laser powder bed fusion manufacturing and post-processing for surface quality of as-built 17-4PH stainless steel. Surf Coat Technol 422:127492. https://doi.org/10.1016/j.surfcoat.2021.127492

Barroux M (2021) Correlation between microstructure and corrosion behavior of 17-4 PH stainless steel produced by laser fusion on powder bed. Thesis, National Polytechnic Institute of Toulouse (Toulouse INP)

Hsu TH, Chang YJ, Huang CY, Yen HW, Chen CP, Jen KK, Yeh AC (2019) Microstructure and property of a selective laser melting process induced oxide dispersion strengthened 17-4 PH stainless steel. J Alloys Compd 803:30–41. https://doi.org/10.1016/j.jallcom.2019.06.289

Yin S, Chen C, Yan X, Feng X, Jenkins R, O’Reilly P, Liu M, Li H, Lupoi R (2018) The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel. Add Manuf 22:592–600. https://doi.org/10.1016/j.addma.2018.06.005

Chang C, Yan X, Bolot R, Gardan J, Gao S, Liu M, Deng S (2020) Influence of post-heat treatments on the mechanical properties of CX stainless steel fabricated by selective laser melting. J Mater Sci 55:8303–8316. https://doi.org/10.1007/s10853-020-04566-x

Yan X, Chen C, Chang C, Dong D, Zhao R, Jenkins R, Wang J, Ren Z, Liu M, Liao H, Lupoi R, Yin S (2020) Study of the microstructure and mechanical performance of C-X stainless steel processed by selective laser melting (SLM). Mater Sci Eng 781:139227. https://doi.org/10.1016/j.msea.2020.139227

Yadollahi A, Shamsaei N, Thompson SM, Elwany A, Bian L (2017) Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel. Int J Fatigue 94(2):218–235. https://doi.org/10.1016/j.ijfatigue.2016.03.014

Carneiro L, Jalalahmadi B, Ashtekar A, Jiang Y (2019) Cyclic deformation and fatigue behavior of additively manufactured 17–4PH stainless steel. Int J Fatigue 123:22–30. https://doi.org/10.1016/j.ijfatigue.2019.02.006

Lee J, Lee M, Chae H, Yeol S, Na T, Kim W (2020) Effects of building direction and heat treatment on the local mechanical properties of direct metal laser sintered 15-5 PH stainless steel. Mater Charact 167:110468. https://doi.org/10.1016/j.matchar.2020.110468

Rigal E (2017) hot isostatic pressing (HIP). engineering technique M3310(2):29-32

Lou X, Andresen PL, Rebak RB (2018) Oxide inclusions in laser additive manufactured stainless steel and their effects on impact toughness and stress corrosion cracking behavior. J Nucl Mater 499:182–190. https://doi.org/10.1016/j.jnucmat.2017.11.036

Almangour B, Grzesiak D, Yang JM (2017) Selective laser melting of TiB2/316L stainless steel composites: The roles of powder preparation and hot isostatic pressing post-treatment. Powder Technol 309:37–48. https://doi.org/10.1016/j.powtec.2016.12.073

Yan F, Xiong W, Faierson EJ (2017) Grain Structure Control of Additively Manufactured Metallic Materials. Materials 10(11):1260. https://doi.org/10.3390/ma10111260

Almangour B, Yang JM (2016) Improving the surface quality and mechanical properties by shot-peening of 17-4 stainless steel fabricated by additive manufacturing. Mater Des 110:914–924. https://doi.org/10.1016/j.matdes.2016.08.037

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

None

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sghaier, T.A.M., Sahlaoui, H., Mabrouki, T. et al. Selective Laser Melting of Stainless-Steel: A Review of Process, Microstructure, Mechanical Properties and Post-Processing treatments. Int J Mater Form 16, 41 (2023). https://doi.org/10.1007/s12289-023-01769-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-023-01769-w