Abstract

Drinking water (DW) quality can change during distribution, leading to taste and odor events and microbial regrowth. Pilot plants mimicking distribution networks are crucial for understanding these changes. We present a new pilot plant design, including piping material, sensors, and instrumentation. The three independent loops (100 m each) of the pilot exhibit identical behavior, allowing simultaneous testing of three conditions. Monitoring includes taste and odor compound formation, microorganism regrowth, and dissolved organic carbon changes. Real-time measurements enable continuous monitoring, and inner pipe biofilm sampling is feasible. The pilot’s modularity facilitates studying climate change effects, different piping materials, and source waters on DW quality in the distribution network.

Similar content being viewed by others

Guaranteeing drinking water (DW) quality for customers is essential for DW companies. The hygienic and aesthetic quality of water is influenced by physical-chemical and microbial processes in source water, during production, storage, and distribution. DW is not a sterile product after production, therefore microbial regrowth and conversion of organic components and nutrients in the DW distribution system (DWDS) can potentially lead to odor and taste problems, turbidity, discoloration, damage to pipe material and possible contamination with pathogens under influence of various environmental parameters1,2. To study quality changes in a safe yet realistic environment, pilot plants of DWDS can be used.

In this communication, we present a pilot-scale DWDS design aimed at studying microbial communities, biofilm formation, and taste and odor events. This pilot incorporates innovative features such as online monitoring, volatile organic compounds (VOCs) and biofilm sampling, and modular pipe sections. By integrating these capabilities, we can closely examine the intricate dynamics within the DWDS. Furthermore, our initial experiments demonstrate the reproducibility of the system, highlighting its reliability. Importantly, we found that the presence of sampling valves does not exert any discernible influence on the bacterial composition. These promising results lay a strong foundation for future research endeavors, facilitating a deeper understanding of the factors driving changes in water quality and paving the way for effective mitigation strategies.

The pilot installation consists of a structure of 5.2 m × 2.6 m that contains 3 identical loops of piping (Fig. 1 and Supplementary Fig. 1). For the piping material, PVC-U was chosen after consultation of literature and with different DW companies in Flanders (Supplementary Fig. 2). All the materials used in this pilot comply with the Belgian national DW regulations (Hydrocheck requirements of Belgaqua) (Bode GmbH, Germany).

Each loop has a diameter of DN80 and a total length of 100 m of DN80. The resulting surface to volume ratio is ~50 m−1, well exceeding the minimum of 25 m−1 in order to have sufficient biological activity in the transformation of organic products into odor, taste, color, and DBPs3 and have <5% (25 L) deviation in volume when sampling. Each loop has three 4 m pipe sections in the beginning, middle, and end of the loop that are installed by means of bolted flange connections and LUG-type butterfly valves (Supplementary Fig. 1, red arrows). These valves allow to easily change the piping in the 4 m sections, to test other pipe materials, or to install old pipes with e.g. corroded inner-surfaces or a mature biofilm to examine its influence on the DW quality.

An EA-type anti-pollution check valve is mounted before the connection of the pilot to protect the internal building DW network from any possible contamination caused by the pilot experiments. Non-transparent high-density polyethylene (HDPE) 1 m3 buffering tanks (Mauser, Germany) can be used in the circulation of each loop. These vessels can be easily exchanged with a pallet transporter, so that various batches of other (drinking) water can be connected for experiments.

The pilot can be operated in a closed-loop set-up with or without the use of the buffering tank in an open-loop set-up, and the once-through mode to flush after and prior to new experiments (Supplementary Fig. 1). These flow options allow us to examine the influence of different hydraulic retention times. According to the local drinking water utility, 95% of their DW is delivered to the customer within 5 days, and 35% of customers receive their water within one day (Supplementary Fig. 3).

The median flow velocity in Flemish DWDS is 0.08 m/s (Supplementary Fig. 4), which will be used for the reproducibility experiments. Therefore, we selected the pumps to have a flow velocity ranging between 0 and 0.5 m/s, taking the 100 m length and DN80 pipe diameter into account. Vertical multistage frequency-controlled centrifugal pumps were chosen (Grundfos, Denmark) (Supplementary Fig. 6). Taking into account the desired flow regime (0.00 m/s–0.50 m/s, median value 0.08 m/s) for future experiments, one loop was equipped with a Grundfos CRNE 3-4, with an operating range between 0.5 m3/h (0.03 m/s for DN80) and 5.2 m3/h (0.29 m/s for DN80). Both other loops were equipped with a Grundfos CRNE 5-4 pump, which have an operating range between 1.0 m3/h–10.0 m3/h (0.06–0.55 m/s for DN80).

The high flow rate pump (CRNE 5-4) can also be used as a flush pump at high speed (0.55 m/s) for cleaning after and prior to new experiments. At the pressure side of each pump, a 60 L pressure vessel Wellmate WM4 (Pentair, United States) was installed to compensate for the pressure loss in the system, for example, due to sampling (Supplementary Fig. 1).

In each loop, the flow rate is controlled whereas the system pressure, temperature, pH, and conductivity are automatically logged (Supplementary Fig. 1). For visual control on site, a Picomag electromagnetic flow meter (Endress+Hauser AG, Switzerland) is included in each loop, between the start of the loop and the heat exchangers.

System pressure is monitored both by the above-mentioned pumps, and by an E&H Ceraphant PTP31B pressure switch (Endress+Hauser AG, Switzerland) in each loop. Additionally, all pumps have their generated pressure read-out. pH is monitored using one E&H Memosens (Endress+Hauser AG, Switzerland) sensor per loop, housed in a E&H Flowfit CPA250 (Endress+Hauser AG, Switzerland) (Supplementary Fig. 7).

At the beginning of every loop, there is the possibility to connect to an OnCyt-00 Duo device (Oncyt, Switzerland) that automatically takes a water sample, stains it, and sends it to a flow cytometer (Accuri C6+, BD Biosciences, Belgium) that measures the sample.

Actively pumping water in a closed loop has the risk of heating the water. Since (micro)biological activity and other (bio)chemical transformation processes are influenced by changing temperatures, it is essential to maintain a stable temperature to fully understand these transformations. Additionally, temperature control allows to test the effects of having higher raw water temperatures, or an increase of soil temperatures (and therefore pipe temperature) due to climate change.

There are three E&H TMR31 temperature transmitters (Endress+Hauser AG, Switzerland) in every loop: one measuring the return water right before the pump, whereas the second and third are mounted before and after the heat exchangers. The heat exchangers custom-made are tube-in-tube systems (IEC, Belgium).

Every loop is equipped with six sampling valves; two types of valves at three sampling locations within the loop, in order to sample/measure the water in the beginning, middle and end of the loop (Supplementary Figs. 1 and 8). Stainless steel (SS) ball valves (DN15) allow heat (flame) sterilization of the valve before sampling. As a second sampling valve, SS ball valves with an extra drain cock for hose connections are used to connect tubing for online flow cytometry. Additionally, both the 1 m3 buffering tanks as well as the suction lines of the pumps have their own sampling connections to sample the incoming water.

For control of the system and visualization of the different signals measured, a Siemens PLC 12” HMI (KTP1200) (Siemens, The Netherlands) is used to run the three circulation loops as well as the cooling loops. The HMI is used to visualize the process, the values of the (online) instrumentation, as well as to interact (start/stop/frequency settings) with the circulating pumps and regulating valves. The PLC also allows to store the data by ethernet connection to the central servers. Potential alarms or warnings are visualized on the screen as well as in the field using a signaling column, including light and acoustic signaling (Siemens, The Netherlands).

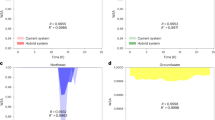

The three loops of the pilot-scale DWDS were operated simultaneously in parallel, by circulating the same water at a flow rate of 23.5 ± 0.5 l/m (1.4 m3/h), at an average temperature of 16.3 ± 0.44 °C, and conductivity of 431 ± 1.5 µS/cm during 7 days (Fig. 2). In order to examine reproducibility between the three loops, the physical-chemical composition of the water was analyzed. Temperature, conductivity, pressure, pH, and flow of the water were measured continuously using the online sensors of the pilot.

The concentrations of the chemical composition ranged between: total N, 2.7 and 3 mg/L; NPOC, 2 and 2.8 mg/L; Cl-, 30.2 and 30.6 mg/L; NO3-, 11.8 and 12.4 mg/L; SO42-, 25.6 and 36 mg/L; Na+, 23 and 23.9 mg/L; K+, 3.5 and 23.1 mg/L; Mg2+, 5.6 and 5.8 mg/L; Ca2+, 54 and 60.7 mg/L (Fig. 3).

Results for (a), non-purgeable organic carbon (NPOC) (b), Cl- (c), NO3- (d), SO42- (e), Na+ (f), K+ (g), Mg2+ (h), and Ca2+ (i). Every day, one sample from every loop was measured during 7 days. For the NPOC measurements, technical triplicates were measured and averaged. Day 0 corresponds to the measurements after the cleaning of the pilot, prior to introducing the water in the loops. Loop 1 = red; loop 2 = green; loop 3 = blue.

These parameters followed similar trends in the three loops (p > 0.05). We can observe peaks of SO42- on day 5 (25.64 mg/L), a peak of K+ in loop 1 on day 2 (23.14 mg/L), a similar peak on loop 2 on day 3 (23.12 mg/L) and a change in Ca2+ concentration in loop 2 on day 4 (53.95 mg/L) (Fig. 3).

The occurrence of taste and odor components was measured in the three loops to examine their behavior in the recirculated DW and to study the reproducibility between the loops. Samples were taken on day 0, day 3, and day 7 in the middle of each loop.

Six of the thirty-two target compounds were quantified (Supplementary Table 3). The other twenty-seven compounds were not detected (i.e., signal-to-noise ratio below 3, for 23 compounds) or not quantifiable (i.e., signal-to-noise ratio below 10, for 4 compounds). For all compounds, the relative standard deviations (RSDs) within and between the loops on day 0 were 4–25% and 10–19%, respectively. The concentration of these compounds over time was significantly similar in the three loops for 3-methylbutanal, 2,6-nonadienal, β-cyclocitral, chloroform, and BHT (Kruskal–Wallis, p > 0.05), but differed for MTBE (Kruskal–Wallis, p > 0.05). There is an increase in occurrence during time for 2,6-nonadienal, MTBE and BHT (Kruskal-Wallis, p < 0.05) and there is no significant increase of 3-methylbutanal, β-cyclocitral and chloroform (ANOVA or Kruskal–Wallis, p > 0.05).

Since DW is circulated from the start of the experiment until day 7, an increase in the bacterial cell concentration can be expected. Yet, the question is if the three loops behave similar and if the results are reproducible over the three loops during the course of the experiment. Therefore, the bacterial (re)growth and fingerprint was simultaneously examined in the three loops, at the sampling valves in the beginning, middle, and end of the piping using flow cytometry.

No significant dissimilarities were found in the microbial counts across the three loops (Fig. 5d) (Kruskal–Wallis, p > 0.05) or the sampling points of any of the loops (Fig. 5a–c) (Kruskal–Wallis, p > 0.05), indicating that there is no influence of the sampling valves as well. The cytometric fingerprint does not significantly change across the loops or the days (PERMANOVA, p > 0.05). However, a non-significant trend can be observed in function of time (Fig. 6), and when comparing day 0 and day 7, a significant difference is observed (PERMANOVA, p < 0.001). These fingerprint shifts could be due to the change in the environment after recirculation, such as nutrient depletion, or leaching from the pipes. To calculate the daily fingerprints for each loop, we pooled the samples collected at the beginning, middle, and end of each day.

Our findings demonstrate that the three identical loops (100 m) of the pilot exhibit consistent behavior throughout a 7-day operational period. The ionic profile, bacterial load, VOCs profile, and overall trends in each loop were similar (Figs. 2–6). We selected a 7-day period as a representative hydraulic retention time (HRT) for DWDS, considering that the majority of customers in Flanders receive their DW with an HRT lower than 5 days (Supplementary Fig. 3). Furthermore, the sampling points within each loop (beginning, middle, and end) did not have a noticeable impact on these parameters (Figs. 2–6), indicating that monitoring DW quality at a single sampling point per loop is sufficient.

Results for (a), 2,6-nonadienal (b), β-cyclocitral (c), methyl tert-butyl ether (MTBE) (d), chloroform (e), and butylated hydroxytoluene (BHT) (f). Whenever the reading was below the detection value, it was recorded as a zero. Day 0 corresponds to the measurements after the cleaning of the pilot, after introducing the water in the loops. Loop 1 = red; loop 2 = green; loop 3 = blue.

Results for (a) loop 1, (b) loop 2, (c) loop 3, (d) and the average density of the beginning, middle, and endpoint of every loop. Samples were measured online twice a day (AM and PM) during 7 days. Day 0 corresponds to the measurements after the cleaning of the pilot, after introducing the water in the loops. Loop 1 = red; loop 2 = green; loop 3 = blue.

Throughout the 7-day period, the VOC profile in the three loops displayed similarities (Fig. 4). The levels of BHT in the water increased over the course of the experiment, significantly exceeding the initial levels by the end of day 7 (p < 0.001, Anova-Tukey) (Supplementary Table 4). Previous studies have reported leaching of PE into the system4,5, and we speculate that leaching from the HDPE buffering tanks may contribute to this increase. However, the observed increase was consistent across all three loops (an average factor of 7), making it a promising model compound for investigating VOC leaching from new plastic piping in future experiments.

The DW used in this experiment was produced from surface water by the local water provider (FARYS). Surface water exhibits lower calcium levels, higher NPOC, and elevated temperatures compared to groundwater (Supplementary Table 2), making it suitable for studying the potential impact of increasing temperatures due to climate change on DW quality. The local DW utility adds free chlorine as a residual disinfectant at the water production facilities, with a maximum concentration of 0.250 mg/L free chlorine according to Flemish DW limits. However, due to the long hydraulic retention time in the DWDS, all free chlorine is consumed before it enters the pilot infrastructure. Measurements of the incoming DW used in the pilot showed no detectable concentrations of free chlorine above the limit of 0.02 mg/L.

There are certain limitations of this pilot plant, such as the relatively short length of the loops (100 m) compared to the pipe lengths typically found in the field. This also affects the accuracy of studying hydraulic retention times. Additionally, this pilot plant cannot replicate DW quality challenges, such as water leakage and infiltrations. Furthermore, the flow rate was maintained at (21.5 ± 9.5) m3/h, corresponding to a pressure of approximately 2 bar. In the DWDS, the typical pressure is 2.5 bar, although it may vary depending on usage throughout the day6. Another local company reports wide variability in terms of pressure (1.5–8 bar) (Waterdruk En Debiet | Farys, n.d.). These pressure differences might have some impact on the growth of the microbial community.

DWDS pilots present an opportunity to study quality changes in a controlled and realistic environment. Below, we mention some of their possible uses.

While disinfection products play a very important role in water sanitation, they generate disinfection byproducts (DBPs) that could potentially damage human health, although the evidence is not conclusive7. This has resulted into optimization in the use of disinfectants, and even the change in disinfection strategies by certain utilities8. A pilot plant of a DWDS could allow to further explore DBPs formation following different water treatments and how they affect the water microorganisms and the formation of VOCs.

Over time, DWDS develop loose deposits, pipe scales, and biofilms. When this environment is disrupted, the material can mobilize and enter the bulk water-creating potentially hazardous situations [35][36]. While environmental disruptions are common in DWDS (e.g., change in the source of water or the mixing ratio of sources, operational changes …), their effects on DW quality are poorly studied9,10. Also, aging pipes are known to be more vulnerable to contamination and have increased biofilm formation and corrosion11. The modular system of the pilot plant presented in this study allows to use the current 4 m sections to introduce aged pipes from the existing DWDS, or made of different materials (Supplementary Fig. 1).

Over 90% of the bacteria in the DWDS are present as a biofilm12. Biofilms can induce the appearance of DBPs, cause taste and odor (T&O) degradation/formation, and host pathogenic microorganisms and invertebrates. To study their formation inside the pipes, we propose the use of a 3D-printed coupon system as described in Supplementary Fig. 9 to observe biofilm formation. These coupons are similar to those described by Fish et al.13: they are removable inserts made out of the same material as the pipes (PVC-U in our case). However, in the system we present, the entire insert can be removed and analyzed, instead of a small part of it. To achieve a stable biofilm, we would recommend to wait around a total of 500 days as suggested by ref. 14.

Odor and taste in DW can affect the consumer’s perception of water safety and disincentivize the consumption of tap water. To test how the appearance and evolution of these events, this pilot plant has the capacity to use stir bar sorptive extraction (SBSE), that can passively sample and preconcentrate (semi-)VOCs. In the middle of each loop, there is a section of six PVC screw threaded holes and corresponding closable caps. In these holes, a PP mesh container is placed, which can contain stir bars for SBSE. The section with the holes can be isolated using DN80 GF LUG-style (type 038) butterfly valves. A bypass is provided to continue the water flow during handling of stir bars (Supplementary Fig. 10). Another important use of pilot plants is to use them to study the appearance of contaminants such as pharmaceuticals, endocrine disruptors, and/or pesticides in DW15,16.

Finally, the pilot plant can serve as a test case for the development, calibration, and validation of mathematical models which can be used for real-time operational support and control of DWDS and are currently underused.

Methods

Cleaning and experimental set-up

To remove any dust and dirt present inside the installation, the pilot plant was cleaned by flushing and sanitizing. Each buffering tank was filled with tap water and circulation was started a low flow rate. NaOCl (VWR, France) was added up to a concentration of 1 mg/L of free chlorine in the system, after which the system was left recirculating for 1 h at the maximum capacity of the pumps. After this cleaning process the system was flushed with tap water for 1 h to remove the remaining chlorine.

Then, the three buffering tanks were filled using local drinking water from the tap (see characteristics in Table S2) and the water was introduced in the loops. The system was then closed and it ran for 7 days, during which samples were taken in the morning (AM, 11 h) and afternoon (PM, 16 h) for every loop at the beginning, middle, and end sampling points. The 7-day period was chosen as a representative HRT of the DWDS, considering that in Flanders 95% of customers receive their drinking water with a HRT lower than 5 days (Fig. S3). The flow velocity was set at 0.08 m/s (24 m3/h) and the temperature was set at 15 °C. During the experiment, the water was recirculated through the loops and buffering tanks at ambient pressure.

NPOC analysis

Water samples were collected in 40 mL TOC-free vials (Sievers, Germany) and stored in a cold room kept at 6 °C prior to analysis. Non-purgeable organic carbon (NPOC) was analyzed with a total organic carbon analyzer (TOC V-CPN, Shimadzu, Japan).

ICP-OES

ICP-OES samples were collected in 50 mL plastic falcon tubes (Greiner, Germany) and 1 v% of a concentrated 65% HNO3 solution (Chem-Lab, Belgium) was added to each sample to keep the metals present in the solution The concentrations of Fe, Mn, and P in the filtrated (0.45 µm) samples were measured using inductively coupled plasma optical emission spectrometry (ICP-OES Thermo Scientific TM iCAPTM 7000, USA).

Ion chromatography

Na+, K+, Mg2+, Ca2+, NH4+, Cl-, NO3-, and SO42 were measured by IC (Ion Chromatography) using a 930 Compact IC Flex, equipped with a Metrosep A Supp 5- 150/4.0 column, a Metrosep A Supp 4/5 guard column/4.0 and a 850 IC conductivity detector (Metrohm, Switzerland). The cations were eluted at a flow rate of 0.7 mL/min using 1.7 mM HNO3 (2 M; ThermoFisher Scientific, USA) and 1.7 mM 2,6-pyridinedicarboxylic acid (≥99.5%; Sigma-Aldrich, USA). The anions were eluted at a flow rate of 0.7 mL/min using 1,0 mM NaHCO3 (≥99.5%; Carl Roth, Germany) and 3.2 mM Na2CO3 (≥99.5%; Carl Roth, Germany).

VOC analysis

Water samples were collected in 500 mL pre-cleaned amber bottles, after running the tap for 10 s and leaving no headspace in the bottles. The samples were then stored at 4 °C in the dark and analyzed within 12 h. Preconcentration of the analytes was performed using SBSE with a polydimethylsiloxane (PDMS) sorbent phase. After thermal desorption at 280 °C in a Unity Thermal Desorption system (Markes UNITY series 2, UK), analytes were transferred via an intermediate cold trap to a gas chromatograph (Focus GC, Thermo Scientific; Column: FactorFour VF1ms (100% PDMS); 30 m × 0,25 mm, 1 µm). Separation was performed under constant helium head pressure (50 kPa), and the oven temperature started at 35 °C and was held for 7 min. Next, the temperature was increased to 60 °C (8 °C/min), then to 170 °C (5 °C/min), and finally to 250 °C (10 °C/min) where it was held for 10 min. The separated compounds were transferred (transfer line at 240 °C) to a mass spectrometer (DSQII, Thermo Scientific), operating with electron ionization (70 eV) and in selected-ion monitoring (SIM) mode. Chromatograms were processed using Thermo Xcalibur 2.2 software and screened for thirty-two T&O compounds. Toluene-d8 was used as an internal standard.

Statistical analysis

The statistical tests were chosen after checking the sample size and normality with the function shapiro.test. Then, ANOVA (function aov) or Kruskal-Wallis (function kruskal.test) where used to test the hypothesis. To test the differences in the phenotypic fingerprint, PERMANOVA was used with the function adonis2.

Flow cytometric monitoring and fingerprinting of the bacterial abundance and community dynamics

An Accuri C6 Plus flow cytometer (BD Biosciences, Belgium) was used, which is equipped with four fluorescence detectors (533/30 nm, 585/40 nm, >670 nm, and 675/25 nm), two scatter detectors, a blue 20 mW 488 nm laser, and a red 12.5 mW 640 nm laser. The flow cytometer was operated with MilliQ (Merck Millipore, Belgium) as sheath fluid. Quality control was performed daily using BDTM CS&T RUO beads (BD Biosciences, Belgium). Samples were run in fixed volume mode (25 μL) at high speed.

The Flow Cytometry Standard (.fcs) files that were generated were imported into R (v 4.1.2) using the flowCore package (v.2.8.0). The intact cells were determined using the gating strategy described in Fig. S5. Background noise caused by artefacts was removed by manually drawing a gate on the FL1 and FL3 fluorescence data. The combination of these two parameters results in the most optimal signal and noise separation for drinking water samples. The flow cytometry data of every sample was transformed, discretized, and concatenated into a one-dimensional vector that serves as the basis for further phenotypic community analysis as described in Props et al. (2016). Phenotypic community analysis was done using the Phenoflow package (v.1.1.2). By means of the flowCore package, the bacterial cell densities were extracted. In the second stage, to determine the changes in the microbial communities over time and to assess the differences between the separate loops, phenotypic community analysis by the use of flow cytometric fingerprinting was performed. From these fingerprints, beta diversity analysis and principal coordinate analysis (PCoA) calculations were executed using the vegan package (v.2.6.2). To evaluate the cause of certain differences in cell density and community fingerprint, all metadata, such as temperature, pressure, flow rate, and conductivity were continuously monitored and processed in R using the ggplot2 package (v.3.3.6).

Data availability

The analysis pipeline and raw data can be found at https://github.com/CMET-UGent/Garcia-Timermans_et_al_2023/.

References

LeChevallier, M. W. Coliform regrowth in drinking water: a review. J. Am. Water Works Assoc. 82, 74–86 (1990).

van der Kooij, D. Assimilable organic carbon as an indicator of bacterial regrowth. J. Am. Water Works Assoc. 84, 57–65 (1992).

Li, W. et al. Effect of disinfectant residual on the interaction between bacterial growth and assimilable organic carbon in a drinking water distribution system. Chemosphere 202, 586–597 (2018).

Skjevrak, I., Due, A., Gjerstad, K. O. & Herikstad, H. Volatile organic components migrating from plastic pipes (HDPE, PEX and PVC) into drinking water. Water Res. 37, 1912–1920 (2003).

Tomboulian, P., Schweitzer, L., Mullin, K., Wilson, J. & Khiari, D. Materials used in drinking water distribution systems: Contribution to taste-and-odor. Water Sci. Technol. 49, 219–226 (2004).

Druk in de woning altijd voldoende | De Watergroep | De Watergroep n.d. https://www.dewatergroep.be/nl-be/drinkwater/veelgestelde-vragen/binneninstallatie/is-de-druk-in-mijn-woning-altijd-voldoende (accessed September 8, 2022).

Villanueva, C. M., Cordier, S., Font-Ribera, L., Salas, L. A. & Levallois, P. Overview of disinfection by-products and associated health effects. Curr. Environ. Health Rep. 2, 107–115 (2015).

Li, X. F. & Mitch, W. A. Drinking water disinfection byproducts (DBPs) and human health effects: multidisciplinary challenges and opportunities. Environ. Sci. Technol. 52, 1681–1689 (2018).

Liu, G. et al. Potential impacts of changing supply-water quality on drinking water distribution: a review. Water Res 116, 135–148 (2017).

Edwards, M. & Triantafyllidou, S. Chloride‐to‐sulfate mass ratio and lead leaching to water. J. AWWA 99, 96–109 (2007).

Makris, K. C., Andra, S. S. & Botsaris, G. Pipe scales and biofilms in drinking-water distribution systems: Undermining finished water quality. Crit. Rev. Environ. Sci. Technol. 44, 1477–1523 (2014).

Liu, S. et al. Understanding, monitoring, and controlling biofilm growth in drinking water distribution systems. Environ. Sci. Technol. 50, 8954–8976 (2016).

Fish, K. E. et al. Characterisation of the physical composition and microbial community structure of biofilms within a model full-scale drinking water distribution system. PLoS ONE 10, e0115824 (2015).

Martiny, A. C., Jørgensen, T. M., Albrechtsen, H. J., Arvin, E. & Molin, S. Long-term succession of structure and diversity of a biofilm formed in a model drinking water distribution system. Appl. Environ. Microbiol. 69, 6899–6907 (2003).

Petrie, B., Barden, R. & Kasprzyk-Hordern, B. A review on emerging contaminants in wastewaters and the environment: Current knowledge, understudied areas and recommendations for future monitoring. Water Res. 72, 3–27 (2015).

Schriks, M., Heringa, M. B., van der Kooi, M. M. E., de Voogt, P. & van Wezel, A. P. Toxicological relevance of emerging contaminants for drinking water quality. Water Res. 44, 461–476 (2010).

Acknowledgements

C.G., B.M., C.D., T.P., Z.M., and F.W. are funded by the Research Foundation – Flanders (FWO) in the FWO-SBO Biostable project [grant number S006221N]. The work is part of the Ghent University-Aquaflanders Chair for Sustainable Drinking Water, which is supported by Aquaflanders, the federation of Flemish companies that are responsible for drinking water and sewer management (www.aquaflanders.be). The authors would like to acknowledge Tom Thijsen of IEC (Innovation Engineering & Construction nv, Riemst, Belgium) and Tobias Broekaart of Eurowater Belgium for their intellectual contribution to the design and technical assistance during start-up of the pilot. Also, the authors would like to thank John Buffel and Mike Taghon of CAPTURE, Tom Vandermarliere of FARYS|TMVW for the technical support during the set-up of the pilot and initial analysis, and Elena Torfs and Emile Cornelissen for their feedback on the manuscript.

Author information

Authors and Affiliations

Contributions

B.G., B.M., C.G., Z.M., F.W., J.A., C.W., and K.D. contributed to the design of the installation. C.G., B.M., B.G., C.D., T.P., Z.M., F.W., and N.B. designed the experimental validation. C.D., T.P., Z.M., and F.W. collected the data. Z.M., T.P., F.W., C.D., and C.G. performed the data analysis. C.G. and B.G. wrote the paper with contributions from B.M., C.D., T.P., Z.M., F.W., J.A., N.B. C.W., and K.D. All authors agreed with the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

García-Timermans, C., Malfroot, B., Dierendonck, C. et al. Pilot-scale drinking water distribution system to study water quality changes during transport. npj Clean Water 6, 52 (2023). https://doi.org/10.1038/s41545-023-00264-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-023-00264-8