Abstract

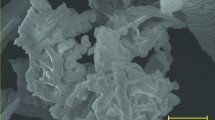

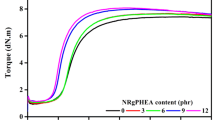

Influences of silane coupling agent loading (e.g. 0–6%) on properties of sepiolite-filled natural rubber (NR) composites were investigated in this study. The amount of silane addition on properties of phenolic resin-crosslinked NR filled with sepiolite composite was optimised. A rheometer was used to evaluate the curing characteristics of the composites while morphological properties were studied by scanning electron microscopy. Fourier-transform infrared spectrometer, temperature scanning stress relaxation, and Mooney–Rivlin model were used to assess the interactions between sepiolite filler and rubber matrix, and the tensile properties and strain-induced crystallisation behaviour were investigated by tensile testing and wide-angle X-ray scattering, respectively. Incorporating a silane coupling agent reduced the size of sepiolite aggregates from ~ 0.4–10 to 0.4–5 μm and decreased filler–filler interaction as well as the curing time of the composite. The silane also improved adhesion between the filler and the rubber by the additional interactions between silane and sepiolite filler. These interactions slowed down the rate at which NR polymer molecules relax, increased tensile strength, and facilitated strain-induced crystallisation. The strongest interactions between filler and rubber, evidenced by maximal tensile strength that was 20% over the non-silanised NR composites, were attained at 4% silane coupling agent relative to the sepiolite by mass.

Similar content being viewed by others

Data availability

The data presented in this study are available on request.

References

Morton M (1999) Rubber technology. Springer Science & Business Media, Dordrecht

Xu T, Jia Z, Li J, Luo Y, Jia D, Peng Z (2018) Study on the dispersion of carbon black/silica in SBR/BR composites and its properties by adding epoxidized natural rubber as a compatilizer. Polym Compos 39:377–385. https://doi.org/10.1002/pc.23946

Masa A, Krem-ae A, Ismail H, Hayeemasae N (2020) Possible use of sepiolite as alternative filler for natural rubber. Mater Res 23:e202001003. https://doi.org/10.1590/1980-5373-MR-2020-0100

Mohanty TR, Neeraj P, Ramakrishnan S, Amarnath S, Lorenzetti D, Mohamed P, Tyres A (2021) Sepiolite nanoclay: a reinforcing filler in the natural rubber/butadiene rubber (NR/BR) matrix for tire tread compound application. Rubber World 263:32–44

Bokobza L (2018) Natural rubber nanocomposites: a review. Nanomaterials 9:12. https://doi.org/10.3390/nano9010012

Locatelli D, Pavlovic N, Barbera V, Giannini L, Galimberti M (2020) Sepiolite as reinforcing filler for rubber composites: from the chemical compatibilization to the commercial exploitation. KGK Kautsch Gummi Kunstst 73:26–35

Hayeemasae N, Adair A, Masa A (2022) Comparative study on viscosities, stress relaxation, curing and mechanical properties of sepiolite and silica filled natural rubber composites. Malays J Anal Sci 26:176–190

Hayeemasae N, Adair A, Rasidi MSM, Jitsopin P, Masa A (2022) Influence of sepiolite addition methods and contents on physical properties of natural rubber composites. Indones J Sci Technol 7:140–148. https://doi.org/10.26554/sti.2022.7.2.140-148

Murray HH (2007) Applied clay mineralogy: occurrences, processing and application of kaolins, bentonites, palygorskite-sepiolite, and common clays. Elsevier, Amsterdam

Alves L, Ferraz E, Santaren J, Rasteiro MG, Gamelas JA (2020) Improving colloidal stability of sepiolite suspensions: effect of the mechanical disperser and chemical dispersant. Minerals 10:779. https://doi.org/10.3390/min10090779

Kumar KD, Tsou AH, Bhowmick AK (2010) Unique tackification behavior of needle-like sepiolite nanoclay in brominated isobutylene-co-p-methylstyrene (BIMS) rubber. Macromolecules 43:4184–4193. https://doi.org/10.1021/ma100472r

Hayeemasae N, Soontaranon S, Masa A (2023) Influence of different vulcanizing agents on structures and properties of sepiolite-filled natural rubber composites. Express Polym Lett 17:181–195. https://doi.org/10.3144/expresspolymlett.2023.13

Soontaranon S, Rugmai S (2012) Small angle X-ray scattering at Siam photon laboratory. Chin J Phys 50:204–210

Frost K, Kaminski D, Kirwan G, Lascaris E, Shanks R (2009) Crystallinity and structure of starch using wide angle X-ray scattering. Carbohydr Polym 78:543–548. https://doi.org/10.1016/j.carbpol.2009.05.018

Sae-oui P, Sirisinha C, Thepsuwan U, Hatthapanit K (2006) Roles of silane coupling agents on properties of silica-filled polychloroprene. Eur Polym J 42:479–486. https://doi.org/10.1016/j.eurpolymj.2005.09.003

Sengloyluan K, Sahakaro K, Dierkes WK, Noordermeer JW (2016) Reinforcement efficiency of silica in dependence of different types of silane coupling agents in natural rubber-based tire compounds. KGK Kautsch Gummi Kunstst 69:44–53

Kim KJ, White JL (2002) Silica surface modification using different aliphatic chain length silane coupling agents and their effects on silica agglomerate size and processability. Compos Interfaces 9:541–556. https://doi.org/10.1163/15685540260494119

Matchawet S, Kaesaman A, Vennemann N, Kummerlowe C, Nakason C (2017) Optimization of electrical conductivity, dielectric properties, and stress relaxation behavior of conductive thermoplastic vulcanizates based on ENR/COPA blends by adjusting mixing method and ionic liquid loading. Ind Eng Chem Res 56:3629–3639. https://doi.org/10.1021/acs.iecr.7b00252

Maria HJ, Lyczko N, Nzihou A, Joseph K, Mathew C, Thomas S (2014) Stress relaxation behavior of organically modified montmorillonite filled natural rubber/nitrile rubber nanocomposites. Appl Clay Sci 87:120–128. https://doi.org/10.1016/j.clay.2013.10.019

Sengloyluan K, Sahakaro K, Dierkes WK, Noordermeer JW (2014) Silica-reinforced tire tread compounds compatibilized by using epoxidized natural rubber. Eur Polym J 51:69–79. https://doi.org/10.1016/j.eurpolymj.2013.12.010

Sombatsompop N (1998) Practical use of the Mooney–Rivlin equation for determination of degree of crosslinking of swollen NR vulcanizates. J Sci Soc Thail 24:199–204

Wu J, Huang G, Li H, Wu S, Liu Y, Zheng J (2013) Enhanced mechanical and gas barrier properties of rubber nanocomposites with surface functionalized graphene oxide at low content. Polymer 54:1930–1937. https://doi.org/10.1016/j.polymer.2013.01.049

Masa A, Saito R, Saito H, Sakai T, Kaesaman A, Lopattananon N (2016) Phenolic resin-crosslinked natural rubber/clay nanocomposites: influence of clay loading and interfacial adhesion on strain-induced crystallization behavior. J Appl Polym Sci 133:43214. https://doi.org/10.1002/app.43214

Masa A, Soontaranon S, Hayeemasae N (2020) Influence of sulfur/accelerator ratio on tensile properties and structural inhomogeneity of natural rubber. Polym Korea 44:519–526. https://doi.org/10.7317/pk.2020.44.4.519

Carretero-Gonzalez J, Verdejo R, Toki S, Hsiao BS, Giannelis EP (2008) Real-time crystallization of organoclay nanoparticle filled natural rubber under stretching. Macromolecules 48:2295–2298. https://doi.org/10.1021/ma7028506

Carretero-Gonzalez J, Retsos H, Verdejo R, Toki S, Hsiao BS, Giannelis EP, Lopez-Manchado MA (2008) Effect of nanoclay on natural rubber microstructure. Macromolecules 41:6763–6772. https://doi.org/10.1021/ma800893x

Acknowledgements

This research was supported by Prince of Songkla University (Grant No. UIC6402030S).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hayeemasae, N., Adair, A., Soontaranon, S. et al. Optimising silane coupling agent content in phenolic-resin-cured sepiolite-filled natural rubber composites. J Rubber Res 26, 303–312 (2023). https://doi.org/10.1007/s42464-023-00210-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-023-00210-w