Abstract

The components’ lightweighting has been pursued, especially in the transport industry, for greenhouse gas reduction. Topology optimization, being able to allocate the material within a provided design space, is a mathematical method that can support the design of lightweight components, preserving, at the same time, their mechanical performances. In this paper, a standard shape of a component, specifically an automotive bracket, was topology optimized by estimating the impacts of the new designs from an eco-friendly point of view. A subtractive, an additive and a casting manufacturing process were considered as possible manufacturing routes achieving an optimized geometry of the component for each of them. The topology optimizations were performed considering each processes’ peculiarities, introduced as constraints. Same strength for a given set of loads and boundary conditions was the target of each analysis. The component’s lightening can be considered environmentally friendly just after assessing the impacts associated with all the stages of the product’ life cycle. Indeed, each phase of the product’ life cycle can be affected, differently, by the performed topology optimization taking into account the peculiarities of the employed manufacturing process. The overall considerations on the most environmentally safe strategies can, therefore, change according to the specificities of the optimized shapes. The topology optimization showed its utmost potentiality, from a sustainable point of view, if applied to additive manufacturing techniques for the advantages arisen by the capability to manufacture complex shapes benefiting also of reduction time process owing to less material to be deposited.

Similar content being viewed by others

Introduction

Topology optimization (TO), widely used in aerospace, mechanical, bio-chemical and civil engineering, has been developed to provide a mathematical tool to the designers helping them in the minimization of the amount of used material in parts’ construction [1]. Specifically, TO aims at maximizing the component performances taking into account specific sets of structural loads, boundary conditions and constraints [2]. Furthermore, the TO analyses have to be fine-tuned taking into account restrictions related to the manufacturing strategies chosen for the part production [3]. Hence, considering the constraints introduced by the selected manufactured process, the TO can propose different geometries of a component, characterized by different weights. This is a relevant matter considering that, generally, material reduction in component’s production is often strictly related to the greenhouse gas (GHG) emissions, especially if components for the transport industry have to be produced [3]. Focusing the attention, as a matter of fact, on the transport sector, currently, the average emission target for the entire EU fleet for new passenger cars is 95 g CO2eq per km and terms such as 20 g CO2eq per km or also zero emissions per km have been discussed [4]. Indeed, the strategy adopted by the European Union (EU) for adapting to climate change will lead Europe to become climate neutral by 2050 [5].

Therefore, optimizing the parts’ geometry results in improving environmental performances [6]. Specifically, Upadhyayula et al. [7] claimed that fuel consumption in internal combustion engine vehicles is reduced by 6% for each 10% reduction in weight of the vehicle. Luk et al. [8] introduced the concept of part functionality claiming that the reduction of the vehicle weight and the related fuel saving have to be strongly associated to the capacity of the part to fulfill its assignment. Finally, Bian et al. [9] implemented a lightweight design in commercial vehicles to reduce fuel consumption by 20%.

The components’ environmental performance must take into account not only the product design, but also its production, use and disposal phases. In this way, a complete impact’s assessment can be achieved [10]. Eco-design by topology optimization moved in this direction considering the sustainability analysis criteria such as carbon emission reduction, energy efficiency and carbon footprint reduction [11]. Furthermore, artificial intelligence technology makes possible the development of increasingly sophisticated optimisation software to design sustainable, efficient and environmentally effective products [12, 13]. In this context, De Boer et al. [14] carried out an LCA analysis of 3 different additive manufacturing processes.

The novelty of the proposed work is the implementation of the topology optimization combined with a Life Cycle Assessment (LCA) analysis taking into account different production routes for manufacturing a specific component. An automobile part, i.e., a bracket was the selected component to be optimized, topologically. Several studies have been proposed aiming at quantifying the environmental impact of vehicles [15]. The LCA was chosen because it allows including all phases of the product’s life cycle, from the extraction of raw materials to its manufacturing phase, from the use phase of the produced component to its EOL [16].

Specifically, Subtractive Manufacturing (SM) [1, 17], Additive Manufacturing (AM) [18, 19] and Casting Process (CP) [20, 21] were proposed as possible process routes to produce the component. In detail, SM is performed by a 5-axis standard milling machine, AM employs the laser sintering 3d printer and the CP makes use of steel molds. The bracket’s geometries with and without topology optimization were analyzed considering the restrictions related to each of the manufacturing processes. As a result, three optimized geometries were obtained guaranteeing for each of them the same mechanical strength of the starting shape. Subsequently, the LCA analysis was implemented for each geometry considering the related process employed in its construction. In addition, focusing on significant impact categories, considerations on the performance of each process taking into account the number of the parts to be produced were also provided.

Method

Design of the case study

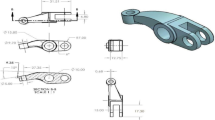

A bracket is a component generally used to improve the reliability and accuracy of adjacent mechanical components reducing vibrations and oscillations. Damping brackets can reduce noise and material wear helping in preventing critical components from breaking or malfunctioning [22]. The brackets ‘number required in an automotive can vary from none to two or more [23]. The initial geometry of the investigated bracket’s typology, whose weight is of 0.140 kg, was extracted by literature [24].The main sizes of the box required to envelop this geometry are: 135 × 60x80 mm (Fig. 1). The material, constraints and structural loads, applied in a single condition, were also extracted by literature [24], see Fig. 1.

Three topology optimized shapes, reported in Fig. 2, were designed starting with the geometry extracted by literature. The simulations were performed by Autodesk Fusion 360 software [25] with the aim of reducing the mass of the component guaranteeing a minimum allowable space and preserving a safety factor of 2 compared to the yield strength of the material. The finite element simulations were set by meshing the parts by Inventor Professional. This pre-processor employs just solid elements for the geometry’s discretization. Specifically, tetrahedron elements (4 physical points and 10 nodes for interpolation) were utilised. The average element size of the mesh is 0,1. The number of elements was: 2682 for the standard shape and 23,127, 23,889 and 26,249 for the shapes optimised respectively for the additive, machining and casting process. In Fig. 3, the distributions of the stress generated on these parts, due to the imposed loads and constraints, were calculated and displayed as proof of comparable mechanical strength for each of the designed shapes. The weight of each geometry employed in the study was reported in Table 1. A relevant information that affects the LCA analysis is the total material’s weight that has to be considered for each manufacturing process considering the wasted part, too. According to that, the initial volume of the billet used in machining was calculated considering the volume required to envelop the machined part. The material wasted to create the supports in the additive process was, instead, numerically estimated by Markforged Eiger software [26] and added to the net-weight of the additively manufactured shapes. No waste material was considered for the casting process [27]. This information is also reported in Table 1. Furthermore, the impact of raw material in casting was compared to the one resulting from the production of the billet or of the powder used, respectively, in the SM and AM processes.

Life cycle assessment

Comparative LCA of 3 different process routes, namely SM, AM and CM processes, in manufacturing an automotive component was conducted. The comparison included the topology optimisation modelled for the 3 different processes assessing optimised versus non-optimised shapes extracted by considering the constraints ascribable to each manufacturing route. Mid-point evaluation focused on global warming potential (GWP) and cumulative energy demand (CED), and end-point damage on human health and ecosystems were reported. The LCA study involves four main phases detailed as follows.

Goal and scope

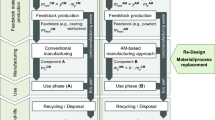

The product system studied is an automotive component that is manufactured by different manufacturing routes. The functional unit, chosen for the present study, is a yield stress-constrained formulation inside this component, named bracket. The bracket is constrained by the space, within which it has to be installed in accordance with the applied loads and constraints. The yield strength can not exceed a limit tied to the properties of the material, which the bracket is made of. The system boundary includes all the unit processes: raw materials extraction, product manufacturing, use phase and EOL, as schematized in Fig. 4. The study excludes the transport impact between the unit processes. Material recycling was assumed in closed-loop and avoided impacts were allocated to the same manufacturing process [28].

Life Cycle Inventory (LCI)

LCI consists of an inventory list of data collected for all the processes indicated in the system boundaries. The Ecoinvent V.3 database provided by SimaPro 9.3 software and information extracted by literature were combined as well as data modelled and calculated for the different geometries, e.g., detailed values of energy and masses, as summarized in Table 2.

Life Cycle Impact Assessment (LCIA)

Selected methods for the impact assessment are, the Cumulative Energy Demand (CED), the Ecological Footprint (EF) Method (adapted) V1.01 / Global (2010)/with tox categories (midpoint) and the IMPACT 2002 + V2.15 / IMPACT 2002 + (endpoint), all available in the SimaPro 9.3 software used for the evaluation [32].

The analysis focused on the quantification of the energy required for the materials extraction employed in each manufacturing process by using the code library. Once extracted, the material is processed to get a billet to be machined or powders to be laid down, additively. The demanded energy required to perform this transformation before SM or AM was detected in literature (Table 3). The energy ascribable for making the CP billets was neglected assuming that the material is melted directly before filling the mould. For CP, instead, the impact of the mould, made of H13 tool steel, on the energy demand, was quantified and taken into account in the analysis [30]. The energy required for the mould was considered as constant for both standard and optimized brackets, being related to the component's three dimensions, which were constrained in the performed topology optimization.

The energies for manufacturing a single bracket by each of the investigated processes were summarized in Table 4. Specifically, the SM energy impact was quantified considering the power of a standard milling machine [33] and the working time extracted by Denkena et al. [34].The times of the different printing phases and the required powder were quantified by Gao et al. [35]. Finally, the energy demand for casting was quantified considering the required energy per mass of the produced component [30]. Specifically, the energy for the mould’s production was quantified considering both its weight, which is based on the dimensions of the bracket’s geometry, extracted by Autodesk Inventor software [25], and the machining phase required for its manufacturing [31].

To complete the analysis of the product manufacturing, the finishing phase was also considered having the same impact, proportionally to the component weight, for each designed bracket. The energy related to the finishing phase was quantified by Cecchel et al. [36]. The percentages of recycled materials in each manufacturing process were investigated for both aluminium [37] and H13 steel [38].

The impact of the products’ use phase was evaluated considering that each bracket, mounted on an economic car, which is powered by a diesel engine, covers a distance of 250,000 km in its life [39].The fuel consumption was quantified in 0,3 L per 100 kg mass transported for 100 km [4]. The density of the fuel was taken from literature [40]. Finally, the product’s EOL phase was also considered. The percentages of materials, which can be recoverable, considering both aluminium for the brackets and steel for the moulds, were estimated according to literature [30, 38].

Interpretation

GWP results are schematized in the networks of Figs. 5, 6, 7, 8, 9, 10 that report the unit processes involved in manufacturing technique. CED results are synthesized in Table 5, where the contributions of the four phases are detailed. According to that, the electricity market of Norway was considered to align the consumed energy in manufacturing to the other CED’s contributions.

In Table 5, the consumed and the recovered, by recycling, energies were labelled by OUT and IN, respectively. Furthermore, the contributions related to the produced component and to the used moulds for CP were also distinguished. Looking at Table 5, therefore, the from-cradle-to-grave CED can be evaluated, in detail. The charted data in Fig. 11 allow observing how the volume of the manufactured components affects the considerations on the processes’ CED performances, deeply.

For the initial bracket’s geometry, the CP, reported without the moulds’ contribution for a first examination, resulted to be the process that burdens less on the environmental resources. This observation changed if the optimized geometry was considered. Making explicit the CED subdivision, the following considerations emerge:

-

a)

Material production: this is energy-intensive for the initial shape of the SM process being impacted by the processed mass. The CED ascribable to SM passes from 53,68 MJ to 24,43 MJ moving from the initial to the optimized shape. This reduction moves SM to be closer to CP (16,30 MJ), which does not take consistent benefit from the optimization being 21,50 MJ its CED required for the initial shape. The AM, instead, owing to the process capability of taking the product’s shape to its extreme, in terms of volume reduction, resulted in a relevant CED reduction passing to be higher than CP’s CED for the initial shape (23,72 MJ) to a reduction quantifiable in about 65% (8,14 MJ).

-

b)

Production manufacturing: the CED for this LCA phase, at least for AM and SM, is strictly related to the time required to complete the process. For that reason, manufacturing of the optimized shape results in an increasing of CED for the SM respect to the initial shape, respectively 13,35 MJ and 11,08 MJ, considering that, more material needs to be removed if the part is obtained by the same billet size, being this a function constraint to be respected. The contrary happens for AM, where less material needs to be deposited because of the reduced volume of the optimized shape. Specifically, AM’s CED passed from 24,19 MJ for the initial shape to 8,29 MJ for the optimized shape. Finally, the impact of this phase weighs marginally for CP’s CED, respectively 0,46 MJ for the initial shape and 0,37 MJ for the optimized one, being considered just the energy portion required to cast the material.

-

c)

Use-Phase: this LCA phase is strictly related to the mass of the component. Therefore, the optimization shapes impact less than the initial one on CED aside from the considered process. The demanded energy reduction is more evident for AM, arriving at 17,32 MJ, owing to the process capability to achieve a stressed material distribution. This phase for SM and CP weighs 30,31 MJ and 39,30 MJ, respectively. The CED is affected in the amount of 50,52 MJ from the initial bracket’s dimension.

-

d)

End-of-Life: the considerations, effective for the Use-Phase, can be mirrored for this last LCA phase. In this case, the values have to be considered as recovered energy that, therefore, reduces the demanded energy of the product life cycle. More is the mass of the bracket, more is the gotten back energy considering a proper waste management without considering landscape as possible choice. In detail, the recovered energy is equal to -13,85 MJ, -8,33 MJ, -4,76 MJ and -11,89 MJ respectively for initial and optimized SM, AM and CP shapes.

-

e)

From-Cradle-to-Grave: a complete view of the impact for each process considering initial and optimized shapes can be achieved adding up the detailed energy aliquots of each LCA phase. Herein, the advantages arisen by topology optimization for AM result to be evident with a CED reduction of about 65% respect to about 41% and 25% for SM and CP, respectively.

As written above, the considerations were performed without considering the impact of the moulds for CP’CED to be able to get a comparison to AM and SM without taking into account the number of parts to be produced. Anyway, CP is environmentally affected by the energy contribution related to the moulds, which weigh on the production of few parts, consistently as shown in Table 5. The study was, therefore, completed considering also the contribution of the moulds and weighing it with respect to the batch size (Fig. 12).

Focusing the attention on CP, it results clear how this manufacturing solution is not competitive from a sustainable point of view up to a consistent number of parts is produced.

Other midpoint categories are reported in Table 6.

Finally, taking to into account the IMPACT 2002 + V2.15 / IMPACT 2002 + (endpoint) method, four damage categories were assessed, which are detailed in Figs.13, 14.

Conclusion

Topology optimization allows to properly distribute the material within a defined domain with the aim to achieve a specific target, i.e., the minimization or maximization of a previously established goal, by fulfilling provided constraints. These constraints can be also related to the manufacturing process’ specificities selected for the production. The impact that the topology optimization method can have on the sustainability of a specific component was evaluated by considering different manufacturing strategies. Specifically, an automotive bracket was investigated, and its mass minimized guaranteeing a minimum strength value of the part.

The proposed bracket’s shapes, derived by the topology optimization constrained by machining, additive and casting processes, were analysed considering their environmental impacts in their entire life. The topology optimization applied to additive manufacturing emphasizes the advantages of this process if compared to machining in terms of sustainability. This consideration is mainly justified by the capability of manufacturing more pronounced topology optimized shapes by AM resulting in a more impacting component lightening and related environmental advantages during its use-phase. Furthermore, optimized shape for AM means reduction of process time due to the effect on the lengthening of the tool path with a reduction of CED related to product manufacturing phase. This is not valid for SM being necessary to remove more material from a standard billet’s volume to achieve the designed final shape. However, to emphasize this influence and to weigh the contribution of each phase, further studies are required to stress the LCA analysis to different shapes changing the percentage of volume to be removed by the initial billet before achieving the desired product. Indeed, in general, the sustainability of the machining process comes to be competitive compared to AM if the shape to be produced is simple and, therefore, far to be topology optimized.

Regarding the casting process, the topology optimization results to be, slightly, advantageous for this solution from an environmental point of view having a notable effect just on material production and use-phase of the LCA. Compared to AM, by the performed analysis, CP performed on an optimized shape resulted to be less eco-friendly regardless the number of parts to be produced showing, anyway, an increasing competitiveness, that has to be evaluated in relation to the type of the shape to be manufactured, for larger batch sizes. This is the production scenario, where casting is often chosen by the power of its more elevated productivity.

References

Umbrello D, Matsumura T, Arrazola PJ et al (2022) Mini symposium on cutting and machining: 25 years of ESAFORM activity. Int J Mater Form 15:35. https://doi.org/10.1007/s12289-022-01680-w

Ahn H, Gingerich MB, Hahnlen R et al (2021) Numerical modeling of mechanical properties of UAM reinforced aluminum hat sections for automotive applications. Int J Mater Form 14:917–928. https://doi.org/10.1007/s12289-020-01607-3

Ingarao G, Deng Y, Marino R et al (2016) Energy and CO 2 life cycle inventory issues for aluminum based components: the case study of a high speed train window panel. J Clean Prod 126:493–503. https://doi.org/10.1016/j.jclepro.2016.03.070

Gagliardi F, la Rosa AD, Filice L, Ambrogio G (2021) Environmental impact of material selection in a car body component – The side door intrusion beam. J Clean Prod 318 https://doi.org/10.1016/j.jclepro.2021.128528

Knez S, Štrbac S, Podbregar I (2022) Climate change in the Western Balkans and EU Green Deal: status, mitigation and challenges. Energy Sustain Soc 12:1. https://doi.org/10.1186/s13705-021-00328-y

Rousseau M, Pabst T (2022) Topology optimization of in-pit codisposal of waste rocks and tailings to reduce advective contaminant transport to the environment. Struct Multidiscip Optim 65:168. https://doi.org/10.1007/s00158-022-03266-1

Upadhyayula VKK, Parvatker AG, Baroth A, Shanmugam K (2019) Lightweighting and electrification strategies for improving environmental performance of passenger cars in India by 2030: A critical perspective based on life cycle assessment. J Clean Prod 209:1604–1613 https://doi.org/10.1016/j.jclepro.2018.11.153

Luk JM, Kim HC, de Kleine RD et al (2018) Greenhouse gas emission benefits of vehicle lightweighting: Monte Carlo probabalistic analysis of the multi material lightweight vehicle glider. Transp Res D Transp Environ 62:1–10. https://doi.org/10.1016/j.trd.2018.02.006

Bian J, Mohrbacher H, Zhang J-S et al (2015) Application potential of high performance steels for weight reduction and efficiency increase in commercial vehicles. Adv Manuf 3:27–36. https://doi.org/10.1007/s40436-015-0102-9

Duriez E, Morlier J, Azzaro-Pantel C, Charlotte M (2022) Ecodesign with topology optimization. Procedia CIRP 109:454–459. https://doi.org/10.1016/j.procir.2022.05.278

Lee AWL, Chung SY, Low JSC, Lu WF (2023) Beyond light weighting, adapting topology optimisation to support ecodesign. Procedia CIRP 116:366–371. https://doi.org/10.1016/j.procir.2023.02.062

Habeeb HA, Wahab DA, Azman AH, Alkahari MR (2023) Design optimization method based on artificial intelligence (Hybrid Method) for repair and restoration using additive manufacturing technology. Metals (Basel) 13:490. https://doi.org/10.3390/met13030490

Deal EG, Gailhofer P, Herold A et al (2021) The role of Artificial Intelligence in the European Green Deal. European Union. http://www.europarl.europa.eu/supporting-analyses

DeBoer B, Nguyen N, Diba F, Hosseini A (2021) Additive, subtractive, and formative manufacturing of metal components: a life cycle assessment comparison. Int J Adv Manuf Technol 115:413–432. https://doi.org/10.1007/s00170-021-07173-5

Challa R, Kamath D, Anctil A (2022) Well-to-wheel greenhouse gas emissions of electric versus combustion vehicles from 2018 to 2030 in the US. J Environ Manage 308:114592 https://doi.org/10.1016/j.jenvman.2022.114592

Ingarao G, Priarone PC (2020) A comparative assessment of energy demand and life cycle costs for additive- and subtractive-based manufacturing approaches. J Manuf Process 56:1219–1229. https://doi.org/10.1016/j.jmapro.2020.06.009

Slamani M, Karabibene N, Chatelain J-F, Beauchamp Y (2021) Edge trimming of flax fibers and glass fibers reinforced polymers composite – An experimental comparative evaluation. Int J Mater Form 14:1497–1510. https://doi.org/10.1007/s12289-021-01644-6

He B, Bi C, Li X et al (2023) Residual stresses and deformations of laser additive manufactured metal parts: a review. Int J Mater Form 16:7. https://doi.org/10.1007/s12289-022-01729-w

Quaranta G, Haug E, Duval JL, Chinesta F (2020) Parametric evaluation of part distortion in additive manufacturing processes. Int J Mater Form 13:29–41. https://doi.org/10.1007/s12289-018-01462-3

Jalouli Z, Caillaud A, Artozoul J et al (2021) Modelling of shrinkage formation in casting by the phase field method. Int J Mater Form 14:885–899. https://doi.org/10.1007/s12289-020-01602-8

Niu L, Liang Z, Tian T et al (2023) Simulation and experiment research on integrated casting and forging process of automobile control arm. Int J Mater Form 16:3. https://doi.org/10.1007/s12289-022-01726-z

Aathif Akmal SM, Bharathiraja G (2022) Analysis of engine mount material for automotive vibration and noise reduction. Mater Today Proc 62:2235–2239. https://doi.org/10.1016/j.matpr.2022.03.462

Yu Y, Naganathan NG, Dukkipati RV (2001) A literature review of automotive vehicle engine mounting systems. Mech Mach Theory 36:123–142. https://doi.org/10.1016/S0094-114X(00)00023-9

Bassoli E, Defanti S, Tognoli E et al (2021) Design for additive manufacturing and for machining in the automotive field. Appl Sci 11:7559. https://doi.org/10.3390/app11167559

Shih RH (2022) Learning Autodesk Inventor (2022) Autodesk Inventor. SDC Publications

Markforged (2020) Eiger user manual. https://support.markforged.com

Hsia SY, Su YH (2020) Zero waste process for direct forming process of nail spikes. Solid State Phenom 311:27–32. https://doi.org/10.4028/www.scientific.net/SSP.311.27

Obrecht TP, Jordan S, Legat A et al (2021) An LCA methodolody for assessing the environmental impacts of building components before and after refurbishment. J Clean Prod 327:129527 https://doi.org/10.1016/j.jclepro.2021.129527

Althaus HJ, Bauer C, Doka B et al (2010) Implementation of life cycle impact assessment methods. t report No. 3, v2.2. Swiss Centre for Life Cycle Inventories, Dübendorf.

Ashby MF (2009) Materials and the Environment Eco-Informed Material Choice. Elsevier, Oxford

Liu ZY, Li C, Fang XY, Guo YB (2018) Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf 26:834–845. https://doi.org/10.1016/j.promfg.2018.07.104

Various authors, PRé Sustainability (2020). SimaPro database manual – Methods library. http://www.pre-sustainability.com/

Ingarao G, Priarone PC, Gagliardi F et al (2014) Environmental comparison between a hot extrusion process and conventional machining processes through a life cycle assessment approach. Key Eng Mater 622–623:103–110. https://doi.org/10.4028/www.scientific.net/KEM.622-623.103

Denkena B, Helmecke P, Hülsemeyer L (2014) New production technologies in aerospace industry - 5th machining innovations conference (MIC 2014) energy efficient machining with optimized coolant lubrication flow rates. Procedia CIRP 25–31:24 Garbsen, Germany

Gao C, Wolff S, Wang S (2021) Eco-friendly additive manufacturing of metals: Energy efficiency and life cycle analysis. J Manuf Syst 60:459–472. https://doi.org/10.1016/j.jmsy.2021.06.011

Cecchel S, Cornacchia G, Panvini A (2016) Cradle-to-gate impact assessment of a high-pressure die-casting safety-relevant automotive component. JOM 68:2443–2448. https://doi.org/10.1007/s11837-016-2046-3

Capuzzi S, Timelli G (2018) Preparation and melting of scrap in aluminum recycling: A review. Metals (Basel) 8:249. https://doi.org/10.3390/met8040249

van Straten B, Dankelman J, van der Eijk A, Horeman T (2021) A Circular Healthcare Economy; a feasibility study to reduce surgical stainless steel waste. Sustain Prod Consum 27:169–175. https://doi.org/10.1016/j.spc.2020.10.030

Gutowski V, Li S, Filippou C et al (2015) Rapid structural bonding of dissimilar lightweight materials: polyolefins, composites and metals. Conference: Plastics In Motion Dearborn, Michigan/USA

Alawa B, Chakma S (2022) Investigation in compression ignition engine performance using alternative fuels produced from waste packaging materials. Resour Conserv Recycl Adv 14:200075 https://doi.org/10.1016/j.rcradv.2022.200075

Funding

Open access funding provided by Università della Calabria within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Non-financial interests are directly or indirectly related to the work submitted for publication.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Borda, F., La Rosa, A.D., Filice, L. et al. Environmental impact of process constrained topology optimization design on automotive component’ life. Int J Mater Form 16, 48 (2023). https://doi.org/10.1007/s12289-023-01771-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-023-01771-2