Abstract

Due to eroding business models, companies are seeking new growth opportunities. Business model innovation (BMI) can enable sustainable competitive advantage and future growth. Yet many companies are struggling to innovate their business models. Recent research reveals that collaboration concerning stakeholder integration and open business model innovation can foster BMI, but research has addressed both topics in isolation. By combining these topics, we establish business model co-innovation (BMCI) as a new perspective. Based on a longitudinal case study of an incumbent retailer and an incumbent electronics supplier, we investigate how both parties contribute to innovating the supplier’s business model. We document a BMCI process model highlighting the direct and indirect business model changes of the retailer and the supplier and we identify BMCI characteristics. We contribute to research with a new perspective on how partners co-innovate a business model.

Similar content being viewed by others

Introduction

Confronted by competitive environments, dynamic markets, fast-changing requirements, and price erosions companies have to constantly renew their business models. Business model innovation (BMI) can be a response to strategic discontinuities and disruptions, convergence, and intense global competition (Doz & Kosonen, 2010). We define BMI as designed, novel, nontrivial changes to the key elements of a firm’s business model and/or the architecture linking these elements (Foss & Saebi, 2017). Firms often leverage new digital technologies to innovate their business model (Chesbrough, 2010). Despite the importance of BMI, many firms are failing to innovate business models because of inhibiting structures, cultures, capabilities, and resources (Christensen et al., 2016; Weking et al., 2020).

Integrating external resources and capabilities by adopting a network or open system perspective can be a successful pathway to BMI (Berglund & Sandström, 2013). The integration of external stakeholders like customers, suppliers, universities, start-ups, and potential competitors might foster successful BMI (Ebel et al., 2016; Zott & Amit, 2015). For example, in cooperation with external technology providers and start-ups, retailers have access to the Internet of Things (IoT) technology and can integrate it into their business model innovation.

Research stresses the importance of collaboration for BMI and is discussing BMI from several perspectives like adopting a network or open systems to get access to external resources (Berglund & Sandström, 2013), external stakeholder integration (Chesbrough & Appleyard, 2007), and open business model innovation (Chesbrough et al., 2018; Randhawa et al., 2016). Research on open business model innovation, for example, indicates that collaboration will support BMI (Weking et al., 2020). However, there is little understanding of the process of collaboratively innovating a business model (Ebel et al., 2016). Although integrating external partners can foster successful BMI, research has not yet addressed how to successfully integrate business partners or suppliers into the process of jointly innovating their business models. To shed light on this phenomenon, we establish business model co-innovation (BMCI) as a new perspective and define our research question as follows:

How do firms co-innovate their business models?

In this paper, we explore how an incumbent retailer (customer) and an incumbent electronics supplier with different competencies jointly co-innovate the supplier’s business model. We, therefore, investigate a 42-month longitudinal BMCI case related to the creation of the digital IoT information and communication system (ICS). We apply the 4I framework (Frankenberger et al., 2013) to structure the three BMCI process episodes related to initiation, ideation, integration, and implementation and we draw on the framework of the business model canvas (Osterwalder & Pigneur, 2010) to document the occurring mutual business model changes. We develop a BMCI process model revealing the direct and indirect business model changes of the supplier and the retailer related to the innovation of the supplier’s business model including the four identified BMCI characteristics organizational factors, direct and indirect business model changes, need and response mechanism, and business formation practices. Related to the derived four BMCI characteristics, we define BMCI as a determined collaboration process of organizations, aiming to create innovation, mutually building, and sharing organizational capabilities, and mutually supporting business model elements, to conduct and achieve business model innovation.

We are contributing to research by providing a unique BMCI process model and a description of BMCI characteristics shedding light on the process of how two collaboration partners can co-innovate a business model. Hence, we are extending the actual BMI view on stakeholder integration and open business model innovation. Our results will give practical guidance to incumbent suppliers on how to transform the business model successfully towards IoT digitalization. Furthermore, we give practical guidance on how to successfully overcome barriers to BMI integration and implementation.

Related work

To build a theoretical ground for the new concept of business model co-innovation (BMCI) we first introduce the concept of business model innovation related to the perspective of collaboration and stakeholder integration followed by the state-of-the-art concept of co-innovation.

Business model innovation and the perspective of stakeholder integration

A business model (BM) is the design or architecture of the value creation, value delivery, and value capture mechanisms (Teece, 2010). Business model innovation (BMI) is defined as designed, novel, nontrivial changes to the key elements of a firm´s business model and/or the architecture linking these elements (Foss & Saebi, 2017). Collaboration is discussed in literature from an eco-system perspective where a focal firm collaborates with business model stakeholders like customers across its ecosystem to craft a unique solution (Zott & Amit, 2015). The need to explore the initiatives of stakeholders related to BMI (Aspara et al., 2013) on the one hand and the integration of stakeholders into the BMI process (Spieth et al., 2014) on the other hand have been highlighted. From a similar perspective the orientation of firms toward an open business model is viewed as being innovative and cost-effective (Chesbrough & Appleyard, 2007).

To adopt the stakeholder perspective, we have evaluated available process models and have selected the broadly adopted 4I-framework (Frankenberger et al., 2013) with its four process phases initiation, ideation, integration, and implementation. This generic BMI process model has been derived based on common characteristics identified in the innovation management literature (Eveleens, 2010). The initiation phase describes activities related to the understanding and monitoring of the ecosystem of the innovating firm. It refers to the understanding of the needs of the players involved, like customers and suppliers, and the identification of change drivers. The ideation phase is describing the generic innovation process related to the generation of ideas for potential new business models and the transformation of opportunities identified in the initiation phase. The integration phase describes the full development and transformation of the new business model with a focus on the integration of all elements of the new business model including the involvement and management of partners. Finally, during the implementation phase, the management of the internal change process as well as the sensitive testing with pilots, trial-and-error approaches, and experimentation are the focus.

Based on the 4I-framework process model (Frankenberger et al., 2013) a recent BMI study about stakeholder integration practices highlights three different modes of stakeholder integration, passive, reactive, and active integration (Weking et al., 2020). Here, the process model phases were mapped as initiation is referring to market discovery and user exploration, ideation points to idea generation and idea selection, integration is referring to prototype building and prototype testing and implementation are related to the minimum valuable product (MVP), creation, and market launch. Therefore, the actual BMI discussion related to customer integration is giving first insights concerning successful stakeholder integration activities and initiatives.

An evolutionary perspective of BMI takes into account the process of changes in and between components of a business model (Demil & Lecocq, 2010). The evolutionary perspectives have been discussed from an industry level (Banda et al., 2018; Bohnsack et al., 2014; Vaccaro and Cohn 2004). From an organizational level, BME literature discusses the need for an evolutionary perspective (Antero et al., 2013). Furthermore, an organization's sustainability depends on the anticipation of a reaction to voluntary and emerging changes between business model components (Demil & Lecocq, 2010). In addition, the challenges of integrating hybrid objectives into value capture have been discussed as well (Davis & Doherty, 2019).

Co-innovation and its theoretical foundations

The theoretical notion of co-innovation has been discussed from several perspectives. The formation of a co-innovation strategy with a partner company, autonomous and co-operative strategy making, the foundation of a co-innovation company, and realization of innovations are distinctive identified stage approaches that have been highlighted (Bossink, 2002). From an eco-system perspective, co-innovation is defined as the act of collaborative actions carried out by various internal and external stakeholders towards creating distinctive, exceptional value in the market (Lee et al., 2012). Co-creation and collaboration enable the integration of multiple stakeholders. This includes value creation for example from firms, partner organizations, outsiders like universities, and customers. For example, IBM collaborates with competitors to combine technological resources and capabilities (Saragih & Tan, 2018). From the value chain perspective, co-innovation is described as the combination of collaborative, complementary, and coordinated innovation (Bitzer & Bijman, 2015). A recent study is synthesizing the theoretical blocks of the concept of co-innovation based on the literature of previous research and empirical evidence from case studies. It highlights the five principal elements of co-innovation in a conceptional framework namely collaboration, coordination, co-creation, convergence, and complementarity. Furthermore, co-innovation outcomes have been identified related to products and services, business models, customer base, customer value, and value chain (Saragih & Tan, 2018).

Bridging the concepts of BMI and co-innovation

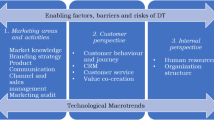

BMCI is bridging the concepts of business model innovation and co-innovation (see Fig. 1). BMCI is the determined collaboration process of organizations, aiming to create innovation, mutually building, and sharing organizational capabilities, and mutually supporting business model elements, to conduct and achieve business model innovation.

The concepts of BMI and co-innovation have yet been discussed in isolation. With our BMCI case study, we aim to give first insights of how BMCI is characterized and how it is bridging the concepts of BMI and co-innovation.

Research design

Case selection

We are presenting an exploratory longitudinal case study from the dyadic perspective of a retailer and supplier to investigate how companies jointly conduct and enable successful business model co-innovation in the area of the Internet of Things (IoT). Case studies are useful for giving insights into theoretical novel phenomena (Edmondson & McManus, 2007) such as the collaboration of supplier and customer, and enable multiple observations of complex relational processes (Eisenhardt, 1989; Eisenhardt & Graebner, 2007). Our longitudinal case study provides a contrasting dyadic perspective on different but complementary competencies of two incumbent players which are a globally acting B2B supplier of electronics with hardware manufacturing competence and a leading national retailer with deep retail IT competence. We follow the theoretical sampling perspective (Glaser & Strauss, 1967) and we selected a case that demonstrates how two companies collaborate and practice business model co-innovation to create an IoT solution. Furthermore, the following factors have motivated the case selection. First, supplier and retailer have initially contradictive but complementary experiences and competencies. Secondly, we have gained excellent insight into the interactive processes based on the available fine-granular database case information and reporting from one of the actors of the initiation team in the case. As the customer perspective in business model innovation research has been neglected yet we collected a dyadic case (Tuli et al., 2007) from the customer and the supplier perspective, with a deep insight on the supplier side, focusing on the business model co-innovation process. The data enabled us to get a deep understanding of the collaboration and the joint co-innovation activities related to the creation of an IoT solution (Yin, 2009).

Data collection

We gathered data mainly through the access to documents from the involved supplier’s business development manager related to detailed and consistent customer meeting reports, project status reports, product roadmaps, development plans, quality reports, management reports, escalation reports, and commercial agreements. Furthermore, mail communication data of supplier and retailer staff, the project team, and from the partner companies were selected. The study period in which the data was collected was 42 months within the time frame July 2010 until December 2013. Within this period 725 documents have been collected and analyzed. To achieve transparency and reliability and to be able to replicate data, we created a schematic case study protocol documenting the major activities and events and we backed all data in a case study database.

Data analysis

We started our data analysis with a thematic analysis approach which enables an approach to identify patterns in large and complex data sets (Braun & Clarke, 2006). Furthermore, links within analytical themes can be identified, a series of iterations and comparisons of overarching constructs and dimensions can be observed and a grounded empirical model can be developed. We also followed an interpretative research method (Clark et al., 2010) which involves people experiencing the events in the interpretation based on a first-order analysis. Therefore we analyzed the data in a three-step approach consisting of an in-depth analysis resulting in first-order categories (step 1), the consecutive formation and condensation of second-order categories (step 2), and the final step of building aggregate dimensions (step 3). The first-order categories were resulting from an analysis of the raw data of the accessed documents. The first author read 725 pages of business development (BD) meeting reports and complementary related documents and categorized them according to the procedure model categories activity, method, role, and tools (Fischer et al., 1998) adding also the category capability. By coding all relevant activities, methods, capabilities, roles, and tools the first author consolidated first-order categories reflecting the content of the documents. To condense the second-order themes, the first author analyzed the first-order categories to identify logical linking arguments, patterns, and more distinct concepts. As a result of this condensing process, the first level of theoretical specific elements could be extracted and sorted under second-order themes. The condensation process was repeated several times to consolidate and confirm the received results. Finally, the second-order themes were carefully reviewed and the further coding was condensed and abstracted. Hence, the first author created aggregate dimensions (see Fig. 2). In addition, the definitions with existing literature were reflected to create results with a strong theoretical dimension. Finally, the links between all three aggregate dimensions were verified again to confirm the theoretical dimensions related to episodes, activities, methods, capabilities, roles, and tools. The applied coding scheme and the aggregations were constantly discussed and aligned within the author team. Figure 2 depicts the interpretative research method according to Clark et al., 2010 and highlights the evolution across the three steps for data analysis according to the result in the theoretical aggregate dimensions. To adapt the process perspective, we understand process theory as a sequence of events leading to an outcome. The understanding of patterns in events is thus key to developing process theory (Langley, 1999). Furthermore, related to a detailed insight into case data we adopt the perspective that process theorization will go beyond surface description to penetrate the logic behind observed temporal progressions, whether simple or complex (Van de Ven, 1992). We have applied a narrative-based style which is the outline of a specification of a process model that lays out a set of mechanisms explaining events and outcomes (Cornelissen, 2017).

Three-step thematic analysis approach (Braun & Clarke, 2006)

Results

In the following, we first provide a short case description to characterize the players' Sigma and Omega. We then provide a narrative of the BMCI case across the identified three episodes New Market Entry, Critical Value Proposition, and Evolutionary Value Proposition, and Strategizing integrating the four process stages initiation, ideation, integration, and implementation (Frankenberger et al., 2013). In addition, Table 1 highlights the direct and indirect business model influence of Sigma (supplier) and Omega (retailer) on the Sigma business model in each episode based on the business model canvas (Osterwalder & Pigneur, 2010). Furthermore, we integrate the identified BMCI characteristics in each episode and we describe and illustrate them with the case (see Table 2). Sigma is an incumbent business-to-business hardware manufacturer for electronic components and modules and belongs to a large group organization that is a leading manufacturer of consumer electronics. The electronics solutions were sold to the group organization but also to other global players in consumer electronics and rivals of the group company. From a strategic perspective, Sigma is trying to enter new business verticals such as retail with unique electronic solutions, by combining the in-house strength of materials, and base technologies and by the willingness to drive business model innovation has initially no competence in the development of software solutions. Omega, on the other side, is an incumbent leading food retailer acting with different brands in the market and is running thousands of stores. The company is threatened by new e-commerce business models driven by a growing number of competitors. Despite the solid software and IT systems’ competence to serve its store infrastructure, Omega is constantly seeking new digital innovations like IoT to further automate and optimize its in-store and logistics processes and to remain competitive. An enterprise persona classification of both companies can be found in the appendix (see Table 3 in the Appendix). Figure 3 depicts an overview of identified key activities and the related BMCI three project episodes in the collaboration process.

The first 13 months project episode consisted of Sigma’s new retail market entry, the implementation of the BD function, and the first BD exploration activities as well as the identification of the Omega retail IoT project. The second 9 months project episode describes the intensive and critical proof of concept (POC) milestone of the Omega IoT solution creation, testing, and approval. The third 20 months project episode highlights Sigma’s strategic change towards its software development attended by an evolutionary value proposition period, where both parties define roll-out requirements, where Sigma offers a high design and support flexibility combined with increasing efforts towards the business formation.

New market entry

The period 07/2010 until 07/2011 is characterized by the establishment of a newly created senior BD position in Sigma, starting of new market exploration activities in retail, and the identification of the Omega project (KR1, CS1). The implementation of an independent BD function changed the organizational design of Sigma. BD acted independently from the existing sales units and core business, started to explore the new retail IoT market, identified the Omega opportunity according to pre-defined selection criteria like retailers’ size and market dominance, and enabled a first introduction meeting with the Omega IT director in 03/2011. BMI prototyping starts with the identification of the value proposition for a specific market segment (Andreini et al., 2021). Activities like opportunity recognition can facilitate experimentation (Guo et al., 2016). On the other side, Omega has started to monitor some of its retail competitors which were already testing and implementing in-store IoT systems, and examined samples of such IoT market versions but was not convinced yet about the market solutions. During the introduction meeting, an initial ICS prototype was introduced (VP1), functional features and the unique value proposition (USP) were shown, and the first technical and commercial feedback by Omega was given. To make a potential collaboration for the retailer attractive it was important to fulfill the initial expectations and ideas of the IT director concerning target costs, initial technical target parameters, the evidence of track record in the retail industry, the strategic long-term supplier commitment, and the willingness to invest in technical design and support competences. Hence, Omega carefully verified the capabilities of Sigma in this early stage. The Sigma ICS feature advancements, the agreement on an initial cost roadmap but also the Omega collaboration readiness for ICS testing led to the short-term decision of Omega to trigger a PoC in 07/2011. The following comment is taken from the official Omega BD manager visit report:

(Sigma, BD manager, December 13th, 2010): …Omega is very interested in the new paper-like IoT device technology which supports the Omega sustainability philosophy…but also the bi-directional communication feature of ICS is unique and was not seen before…

The regular and close communication between the IT director and the BD manager started at this point and was a crucial link during the whole project. Both managers were connecting the organizations from a strategic and operational perspective. Hence, we call this early organizational relationship the initiation team (see Fig. 4).

The competence levels of both players were complementary but different. Sigma initially engaged and coordinated an external software vendor to build the basic ICS software elements (KP1). At the beginning of the collaboration, Omega had no proper knowledge about IoT systems nor any experience with IoT solution testing and implementation. On the other side, Sigma had just entered the retail arena by implementing the first immature IoT PoC with another retail customer and was still trying to understand the retail IT processes and the related software and service requirements.

Critical value proposition

The period 08/2011 until 04/2012 describes the critical 10-month ICS PoC hardware, software, and service deliveries, testing, and approval period. As Sigma had no service partner network at this stage, Omega supported Sigma with the provision of several partner companies for installation and IoT hardware and software integration (KP2). The provided PoC services by Omega were ranging from the ICS hardware fixing and in-store integration, the wireless infrastructure installation and integration, in-store hardware maintenance, back-office IT maintenance, and data interface management. Due to the lack of retail IT partner knowledge and own IT resources, Sigma would not have been able to organize the levels or required services in a short period, and hence the risk of failing the PoC would have been high. The organizational development of the Sigma side continued and the first specialized IT application engineer was hired in 06/2011 (KR2).

(Sigma, IT Application Engineer, Nov. 17th, 2011): …the IT director is one of the most important decision-makers within Omega related to ICS…Omega store process automation is the driver for the ICS implementation…ICS is a very important strategic element for Omega…the IT director believes in the strong technology- and quality competence of the Omega corporate organization…there is much pressure on the IT director as the ICS installations are used to position against a local retail competitor…

Furthermore, the initiation team was extended into the project team where Omega was providing an experienced IT project manager and an external IT software service provider managing all questions around the data interface. Towards the end of episode II, and the beginning of episode III the project was extended once again towards the so-called extended project team (see Fig. 4).

The creation of the first Omega ICS prototype was forcing both parties to set up and perform within an effective need and response cycle. The period 07/2010 to 11/2010 contained 9 co-creation workshops where all relevant hardware-, software-, IT process-, and IT service-specific requirements, as well as constraints, were discussed, and solution concepts were formulated. Hence, regular and efficient project communication and coordination were crucial. The high number of specific Omega requirements given in a short period (R1-R3) was forcing Sigma to properly deliver and perform (VP4). The agile working culture of Sigma was supporting the fast creation of prototypes (VP3). Hence, both parties were contributing to a co-innovation process with need and response elements in the sequence of requirements formulation (Omega), requirements understanding (Sigma), prototyping (Sigma), testing, and approval (Omega) related to R1-R3. R1 was summarizing the specific Omega PoC requirements related to ICS hardware, software, and process jointly discussed during a PoC kick-off workshop in 07/2011 and the following co-creation workshops. R2 was about an intensive software interface workshop on 11/2012 with the Omega third-party software service provider and R3 was summarizing the final specific PoC hardware and software requirements. Integrating customer perceptions is a context-based cognitive process for BMI (Schneckenberg et al., 2019).

Sigma had a lack of software competence at this stage and the coordination of their external software provider was difficult. The software-related issues were growing and the lack of understanding to build and test software related to Omega IT processes was overburdening the Sigma engineering team. Hence, during the software testing stages and the installations of the two instore PoCs on 01/2012 and 02/2012, several escalation meetings on the management level were imposed by Omega. At this time the overall ICS project was threatened and Omega was about to put the collaboration on hold. The following comments have been taken from the mail reports of the BD manager and the IT application engineer:

(Omega, IT Director, Feb. 23rd, 2012): …the look- and feel of the hardware are very good…however, the ICS system maturity is low and we are concerned about the software development capabilities of Sigma…

Omega continued with efforts to support Sigma with resources related to its lack of software competence and they decided to strengthen the role of their third-party software service provider as a communicator, mediator, facilitator, and knowledge provider for Sigma related to the retail IT integration and specific Omega IT processes (KR3). Furthermore, Omega recommended cooperating with the local Omega third-party software service provider related to software development and offered also to share the cost (KR4). Finally, both PoCs were approved by the Omega sales management in 03/2012 based on fulfilling the basic system and process requirements. In summary, the critical value proposition period was a critical milestone for Sigma to demonstrate how to integrate the new value propositions into the new business model.

Evolutionary value proposition and strategizing

The period 05/2012 until 12/2013 describes the third and final stage in the BMCI process which is characterized by evolutionary activities on both sides. In a top management meeting held in early 05/2012, the following citations from the Omega IT director, taken from a BD report, is underlining the growing business perspective for Sigma:

(Omega, IT Director, May 2nd, 2012): …There will be an Omega internal board meeting where I have to introduce an ICS sourcing scenario for the year 2013, based on several million units demand and based on the given Omega target price. In case of board acceptance, the final ICS budgets should be determined by mid-2012 and a contract agreement could be done around 11/2012…

The growing business expectation triggered an evolutionary process of final requirement formulations on both sides to have a proper solution in place for a potentially forthcoming roll-out. Based on the understanding that software development is going to be a future key competence and a new revenue source, the Sigma management decided to develop all relevant ICS software elements with their resources (KR5, RS1). This decision, defined as a self-given requirement (R4, resources) was changing the actual portfolio roadmap significantly again (roadmap II, VP5). Hence, Omega triggered an intensive software requirements workshop on 06/2012 (R5, VP6) to advise Sigma on the features and needs for the new software development. In addition, Omega introduced a new in-store process causing the requirements for a highly functional IoT device and the related software modifications in 09/2012 (R6, VP6) which caused Sigma to change its roadmap again related to R4, R5, and R6 (roadmap III, VP5). Furthermore, Omega decided on a national change towards the Linux store operating system which caused a heavy rework of the Sigma server software again (R7, VP6). In addition, R6 caused Sigma as well to change its RF communication protocol (R8, VP5). The evolutionary value proposition cycles continued by the Omega requirements to request a standard API format in 01/2013 (R9, VP6), to ask for a final modification of standard IoT device and related software in 02/2013 (R10, VP6), and the requirements to verify and potentially design a competitor-like IoT device and the related software elements (R11, VP7). As a technical cause-effect and response to the final Omega requirements, Sigma was forced to improve its server version again in 09/2013 towards high-resolution image processing (R12, VP5) and was documenting this in a final roadmap again (roadmap IV, VP5).

The decision to develop software with its resources along with the massive load of requirements in episode III was overburdening the Sigma engineering team and Omega started to escalate. At this time, Omega proposed to Sigma to cooperate or merge with a promising start-up newcomer company with sufficiently good IoT device hardware and software related to R6 (KP3). During the period 10/2012 until 03/2013, in total 8, escalation meetings on the management level were conducted. Despite the actual escalations, however, Sigma was using the meetings also to improve the relationship on the management level, to exchange ideas, and to sense Omega's readiness to invest in the ICS roll-out. As the national roll-out decision was about to be made, the Omega sales management was now taking the lead ahead of the Omega IT team. In one of the top management meetings on 11/2012, where also the global Sigma CEO and the Omega Group CIO were joining, the strategic long-term vision and cooperation of both companies were the focus of the discussion. Management cognition is about the formation processes of decision makers, their mindsets related to key-business ideas, and their unique view of the business (Gavetti & Rivkin, 2007). One of the concerns Omega was also the proper management of the delivery and implementation services during a forthcoming roll-out and therefore Omega introduced a globally leading system integrator as the sales and supply partner for the ICS roll-out (KP4). Finally, a significant roll-out purchase order was placed on 06/2013 and the nationwide mass roll-out was finally started on 09/2013. Episode III revealed the dynamic evolution of the final Sigma and Omega value propositions, the direct and indirect influence of Omega on the Sigma BM, and also the business formation activities of Sigma. Table 1 summarizes the mutual direct and indirect activities of both players across all three episodes including the identified BMCI characteristics.

Episodic business model changes and BMCI characteristics

In the following, we are presenting an overview of all occurring BM changes in the three episodes from both partners related to the Sigma BM and we are mapping also the relevant BMCI characteristics.

Table 1 depicts the direct and indirect influence of Sigma and Omega related to the new business model of Sigma. Reflecting on the business model canvas framework (Osterwalder & Pigneur, 2010) 17 out of the 19 business model changes are related to the three elements of value proposition (7), key resources (6), and key partner (4) followed by customer segment (1) and revenue stream (1). Business model elements that have not been touched on are key activities, customer relationships, channels, and cost structure. Key activities are mainly mapped with the major business model changes related to value proposition, key resources, and key partners. Customer relationships can be mapped to the activities of business formation. The element channel is not relevant due to the case relation of two collaboration partners and the element cost structure was not discussed. The following BM changes can be seen as critical for the collaboration’s success: VP1, as it provides a basic prototype on very short notice. VP3 delivers the critical hardware, software, and service requirements to run the PoC and gain approval. This was also the moment of truth for Sigma to transform from pure hardware to an IoT hardware, software, and service supplier. KP2, as Sigma had no experience with specific domain partners at this early stage. KR3, as the software expert provided by Omega, was a communicator, mediator, facilitator, and knowledge provider for the technical resources of Sigma. KR5, as is was the key-strategic decision for Sigma to adopt its software development activities as a strategic enabler for future IoT business. Further details and insights on the above-mentioned BM changes are given in the appendix under the headline agile design of the specific Omega IoT (see Table 4 in the Appendix).

Characteristics of business model co-innovation

Based on our three-step thematic analysis approach (Braun & Clarke, 2006) we have gathered the BMCI characteristics organizational factors, direct and indirect business model changes, need and response mechanism, and business formation practices (see Table 2). To see the interdependencies of the BMCI characteristics across the three episodes we have added them to Table 1.

Discussion

The integration of external stakeholders can be a successful way of innovating a business model (Ebel et al., 2016; Zott & Amit, 2015). To overcome the lack of understanding of how to collaboratively innovate a business model we have investigated a longitudinal collaboration case between an incumbent retailer and an incumbent supplier co-innovating the supplier’s business model. We show the process of how retailer and supplier mutually contribute to the BM changes of the supplier’s business model and we highlight the underlying characteristics of business model co-innovation. Our results are contributing to the information systems literature by introducing the new concept of BMCI, highlighting a specific BMCI process model, and revealing four BMCI characteristics. Furthermore, we give practical insights into how BMCI characteristics can foster the creation of new business models.

Contribution to theory

Longitudinal research promises to provide more insights into causal interactions and contingency factors in the emergence of BMI (Demil et al., 2015; Foss & Saebi, 2017; Schneckenberg et al., 2021; De). We are presenting a longitudinal case study revealing unique insights and we are highlighting the new concept of BMCI.

BMI research is pointing to the importance of collaboration in fostering BMI and is discussing several perspectives like the adoption of a network or open systems (Berglund & Sandström, 2013), external stakeholder integration (Chesbrough & Appleyard, 2007), open business model innovation (Chesbrough et al., 2018; Randhawa et al., 2016), and collaboration (Weking et al., 2020). However, the process of how companies collaboratively innovate their business models remains unclear (Ebel et al., 2016). Our research highlights a collaboration case and provides a BMCI process model which shows how a supplier and a retailer successfully co-innovated the suppliers' business model. We, therefore, contribute to the understanding of the process of how business models can be designed in a dyadic constellation of supplier and retailer (Ebel et al., 2016). In addition, we show that the BMCI characteristics organizational factors, mutual direct and indirect business model changes, need and response mechanisms, and business formation practices are substantial elements in this BMCI process.

The examination of sequences of events in BMI and the identification of regularities and recurrent patterns in evolutionary processes are important (Langley et al., 2013). We further reveal a unique non-linear temporal BMCI process model consisting of the three episodes of new market entry, critical value proposition, and evolutionary value proposition and strategizing.

Studies that perceive BMI as a process often take a dynamic approach and investigate the organizational characteristics that facilitate or hinder the process of BMI (Foss & Saebi, 2017). Episodes II and III outline the dynamic and evolutionary provision of solution needs and the flexible adaptive response to the needs as a mechanism for value co-creation. We highlight a need and response mechanism facilitating the successful value proposition interplay of supplier and retailer. Especially during the dynamic evolutionary value proposition cycles in episode III, the need and response mechanism was a crucial optimization and finetuning process, where both parties contributed with voluntary and emerging value propositions (Demil & Lecocq, 2010; Kabalska & Kozarkiewicz, 2020; Teece, 2018). To deliver prototype iterations in a short time, strong technical design and support competencies of the supplier were needed.

Research is pointing to the critical capability perspective for successful BMI (Achtenhagen et al., 2013; Spieth et al., 2014). The suppliers' agile technical design and support competence and the linking communication and coordination activities by the newly established business development function can be seen as critical capabilities supporting BMI. Episode III highlights also the strategic flexibility to adapt the Sigma solution roadmap several times (Schneider & Spieth, 2013). The processual perspective of BMI reveals the interdependence of strategizing, knowledge sharing, and value creation processes of BMI (Andreini et al., 2021; Van de Ven, 1992; Wirtz et al., 2016). Related to episode III we reveal the processual interdependency of BMCI characteristics need and response mechanism related to value creation, critical capabilities as an organizational factor, and strategic decision-making.

Implications for practice

Agile development of an IoT solution requires critical capabilities in the value creation process to cope with the dynamic needs provided by both collaboration partners (Achtenhagen et al., 2013). The identified need and response mechanism was the agile vehicle linking the dynamic provision of requirements, their evaluation, and the fast implementation of prototypes. The technical design and support competence, the availability of engineering resources but also the supplier's capacity for strategic decision-making were crucial for the creation of the new business model. The BMCI collaboration process describes the integration of cross-functional resources from both sides across all three episodes acting as the initiation team, the project team, and the extended project team. To link, orchestrate, and inform the relevant BMCI stakeholders the communication and coordination capabilities of the BD manager were important. In addition, the third-party IT software expert provided by Omega, in the role of communicator, mediator, facilitator, and knowledge provider towards the Sigma engineers was of crucial importance. Firms that lack the capabilities or resources to integrate external stakeholders could turn for assistance to innovation intermediaries that have access to extended networks of firms, partners, experts, and marketing services and which are forming teams of their employees and the clients (Weking et al., 2020).

Companies often struggle to integrate all components of a new business model (Frankenberger et al., 2013). The activities related to initiation, ideation, integration, and implementation in episodes I-III highlight the direct and indirect business model contributions of retailers and suppliers to innovate the supplier’s business model mainly related to value proposition, key resources, and key partners (Osterwalder & Pigneur, 2010). We give a unique insight into how Omega has practically supported Sigma with crucial key partners and key resources. Hence, we can show that BMCI can support, build, and foster an emerging business model.

When it comes to the implementation of a new business model, huge investment needs and internal resistance are remaining major challenges (Frankenberger et al., 2013). The business formation practices of the supplier, especially in episode III, were aimed to build a relationship on the top management level and to get evidence and justification for further investments related to the formation of the new business model. Integrating customer perceptions relates to a profound and genuine interest in and consideration of consumers' needs and expectations (Schneckenberg et al., 2019). The BMCI characteristics of business formation practices have been important to overcome internal resistance to the formation of the supplier’s new business model.

Conclusion

Despite the importance of BMI, many firms are failing to innovate business models because of inhibiting structures, cultures, capabilities, and resources (Christensen et al., 2016; Weking et al., 2020). Recent research on open business model innovation indicates that collaboration will support BMI (Weking et al., 2020). However, there is little understanding of the process of collaboratively innovating a BM (Ebel et al., 2016).

With our research, we are providing deep insight and results of a longitudinal case study where we investigated the phenomena of BMCI related to the collaboration of an incumbent retailer and an incumbent electronics supplier. Our research is highlighting a BMCI process model from a dual perspective which shows how a supplier and a retailer successfully co-innovate the suppliers' business model. In addition, we show how the BMCI characteristics related to organizational factors, mutual direct and indirect business model changes, need and response mechanisms, and business formation practices can foster BMCI. Our research is providing new theoretical ground and a processual understanding of how two companies collaborate and jointly innovate a business model. Furthermore, our research contributes to the growing literature on BMI by extending and complementing the perspectives of stakeholder integration (Aspara et al., 2013; Spieth et al., 2014; Weking et al., 2020), open business model innovation (Chesbrough & Appleyard, 2007).

We are providing the new theoretical BMCI construct as a basis for further discussions and theoretical reflections and we are extending the process theory from a dyadic case perspective (Van de Ven, 1992). Our results confirm also the importance of the processual interdependence of value creation and strategizing (Andreini et al., 2021). From a practical perspective, the case study reveals how incumbent suppliers can successfully overcome barriers to BMI integration and implementation by co-innovating the new business model. Furthermore, we give practical guidance on how incumbent suppliers can successfully transform the business model towards IoT digitalization.

Case studies can give useful insights into theoretical novel phenomena and enable multiple observations of complex relational processes. However, a specific single case study cannot provide general validity for a phenomenon. Gathering detailed data from a participant in the case study contains the risk of being subjective. The results of this longitudinal case study are provided out of the limited perspective of two collaborating incumbent organizations which are characterized in the results section and might therefore not be applicable in other collaboration configurations. For example, the given incumbent size and resource potential of both players is limiting the number of similar collaboration cases. Second, the given strategic fit on both sides and the IT experience of Omega might not be given in other constellations. Third, the decision-making process within a manageable number of decision-makers might not be generalizable. Fourth, the direct allocation and control of resources on both sides might not be given in other cases as well. Finally, the deep technical resource competence of the supplier might not be available in other supplier constellations.

Future research should therefore identify additional cases where the phenomena BMCI can be reflected and the identified BMCI characteristics can be verified, further elaborated, generalized, and potentially categorized. In addition, it should be investigated whether BMCI phases are mainly applied in the early stages of the creation of a new business model or also during consecutive periods. Furthermore, other than dyadic collaboration constellations should be examined. Finally, the interaction mechanisms of role partners related to BMCI should be investigated.

References

Achtenhagen, L., Melin, L., & Naldi, L. (2013). Dynamics of business models-strategizing, critical capabilities, and activities for sustained value creation. Long Range Planning, 46, 427–442. https://doi.org/10.1016/j.lrp.2013.04.002

Andreini, D., Bettinelli, C., Foss, N.J., & Mismetti, M. (2021). Business model innovation: A review of the process-based literature. Journal of Management and Governance. August 2021. https://doi.org/10.1007/s10997-021-09590-w

Antero, M.C., Hedman, J., & Henningsson, S. (2013). Evolution of business models: A case study of SAP. In ECIS 2013 Completed Research, 176. Association for Information Systems. AIS Electronic Library (AISeL). https://aisel.aisnet.org/ecis2013_cr/176

Aspara, J., Lamberg, J.-A., Laukia, A., & Tikkanen, H. (2013). Corporate business model transformation and inter-organizational cognition: The case of Nokia. Long Range Planning, 46, 459–474. https://doi.org/10.1016/j.lrp.2011.06.001

Banda, G., Tait, J., & Mittra, J. (2018). Evolution of business models in regenerative medicine: Effects of a disruptive innovation on the innovation ecosystem. Clinical Therapeutics, 40(7), 1084–1094. https://doi.org/10.1016/j.clinthera.2018.06.003

Berglund, H., & Sandström, C. (2013). Business model innovation from an open systems perspective: Structural challenges and managerial solutions. International Journal of Product Development, 18, 274–272. https://doi.org/10.1504/IJPD.2013.055011

Bitzer, V. & Bijman, J. (2015). From innovation to co-innovation? An exploration of African agrifood chains. British Food Journal, August 2015. https://doi.org/10.1108/BFJ-12-2014-0403

Bohnsack, R., Pinske, J., & Kolk, A. (2014). Business models for sustainable technologies: Exploring business model evolution in the case of electric vehicles. Research Policy, 43(2), 284–300. https://doi.org/10.1016/j.respol.2013.10.014

Bossink, A. G. (2002). The development of co-innovation strategies: Stages and interaction patterns in interfirm innovation. R&D Management, 32(4), 2002. https://doi.org/10.1111/1467-9310.00263

Braun, V., & Clarke, V. (2006). Using thematic analysis in psychology. Qualitative Research in Psychology, 3(2), 77–101. https://doi.org/10.1191/1478088706qp063oa

Chesbrough, H., Lettl, C., & Ritter, T. (2018). Value creation and value capture in open innovation. Journal of Product Innovation Management, 35(6), 930–938. https://doi.org/10.1111/jpim.12471

Chesbrough, H. W. (2010). Business model innovation: Opportunities and barriers. Longe Range Planning, 43(2-3), 354–363. https://doi.org/10.1016/j.lrp.2009.07.010

Chesbrough, H. W., & Appleyard, M. M. (2007). Open innovation and strategy. California Management Review, 50, 57–76. https://doi.org/10.2307/41166416

Christensen, C. M., Bartman, T., & van Bever, D. (2016). The hard truth about business model innovation. MIT Sloan Management Review, 58, 31.

Clark, S. M., Gioia, D. A., Ketchen, D. J., Jr., & Thomas, J. B. (2010). Transitional identity as a facilitator of organizational identity change during a merger. Administrative Science Quarterly, 55(3), 397–438. https://doi.org/10.2189/asqu.2010.55.3.397

Cornelissen, J. (2017). Editor´s comments: Developing propositions, a process model, or a typology? Addressing the challenges of writing theory without a boilerplate. Academy of Management Review, 42, 1–9. https://doi.org/10.5465/amr.2016.0196

Davis, I. A., & Doherty, B. (2019). Balancing a hybrid business model: The search for equilibrium at Cafédirect. Journal of Business Ethics, 157(4), 1043–1066. https://doi.org/10.1007/s10551-018-3960-9

Demil, B., & Lecocq, X. (2010). Business model evolution: In search of dynamic consistency. Long Range Planning, 43, 227–246. https://doi.org/10.1016/j.lpr.2010.02.004

Demil, B., Lecocq, X., Ricart, J. E., & Zott, C. (2015). Introduction of the SEJ special issue on business models: Business models within the domain of strategic entrepreneurship. Strategic Entrepreneurship Journal, 9(1), 1–11. https://doi.org/10.1002/sej.1194

Doz, Y. L., & Kosonen, M. (2010). Embedding strategic agility: A leadership agenda for accelerating business model renewal. Long Range Planning, 43, 370–382. https://doi.org/10.1016/j.lrp.2009.07.006

Ebel, P., Bretschneider, U., & Leimeister, J. M. (2016). Leveraging virtual business model innovation. A framework for designing business model development tools. Information Systems Journal, 26, 519–550. https://doi.org/10.1111/isj.12103

Edmondson, A. C., & McManus, S. E. (2007). Methodological fit in management field research. Academy of Management Review, 32(4), 1155–1179. https://doi.org/10.5465/AMR.2007.26586086

Eisenhardt, K. M. (1989). Building theories from case study research. Academy of Management Review, 14(4), 532–550. https://doi.org/10.2307/258557

Eisenhardt, K. M., & Graebner, M. E. (2007). Theory building from cases: Opportunities and challenges. The Academy of Management Journal, 50(1), 25–32. https://doi.org/10.5465/AMJ.2007.24160888

Eveleens, C. (2010). Innovation management; a literature review of innovation process models and their implications. Advisory Council for Science, Technology, and Innovation (AWTI).

Fischer, T., Biskup, H., & Müller-Luschnat, G. (1998): Begriffliche Grundlagen für Vorgehensmodelle, B. G. Teubner Verlagsgesellschaft, Leipzig 1998. https://doi.org/10.1007/978-3-663-05994-3_1

Foss, N. J., & Saebi, T. (2017). Fifteen years of research on business model innovation: How far have we come, and where should we go? Journal of Management, 43(1), 200–227. https://doi.org/10.1177/0149206316675927

Frankenberger, K., Gassmann, O., & Weiblen, T. (2013). The 4I-framework of business model innovation: Structured view on process phases and challenges. International Journal of Product development, 18, 249–273. https://doi.org/10.1504/IJPD.2013.055012

Gavetti, G., & Rivkin, J. W. (2007). On the origin of strategy: Action and cognition over time. Organization Science, 18(3), 420–439. https://doi.org/10.1287/orsc.1070.0282

Glaser, B., & Strauss, A. (1967). The discovery of grounded theory. London. Weidenfeld and Nicholson, 24(25), 288–304.

Guo, H., Su, Z., & Ahlstrom, D. (2016). Business model innovation: The effects of exploratory orientation, opportunity recognition, and entrepreneurial bricolage in an emerging economy. Asia Pacific Journal of Management, 33(2), 533–549. https://doi.org/10.1007/s10490-015-9428-x

Kabalska, A., & Kozarkiewicz, A. (2020, 2020). The evolution of business models of Polish health resort enterprises. Journal of Economics and Management, 39(1). https://doi.org/10.22367/jem.2020.39.04

Langley, A. N. (1999). Strategies for theorizing from process data. The Academy of Management Review., 24(4), 691–710. https://doi.org/10.2307/259349

Langley, A. N., Smallman, C., Tsoukas, H., & Van de Ven, A. H. (2013). Process studies of change in organization and management: Unveiling temporality activity and flow. Academy of Management Journal, 56(1), 1–13. https://doi.org/10.5465/amj.2013.4001

Lee, S. M., Olson, D. L., & Trimi, S. (2012). Co-innovation: Convergenomics, collaboration, and co-creation for organizational values. Management Decision, 50(5), 817–831. https://doi.org/10.1108/00251741211227528

Markides, C. (2006). Disruptive innovation: In need of better theory. Journal of Product Innovation Management, 23(SI), 19–25.

Osterwalder, A., & Pigneur, Y. (2010). Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers. John Wiley & Sons.

Randhawa, K., Wilden, R., & Hohberger, J. (2016). A bibliometric review of open innovation: Setting a research agenda. Journal of Product Innovation Management, 33(6), 750–772. https://doi.org/10.1111/jpim.12312

Saragih, H., & Tan, J. D. (2018). Co-innovation: A review and conceptual framework. International Journal of Business Innovation and Research, January 2018. https://doi.org/10.1504/IJBIR.2018.095542

Schneckenberg, D., Matzler, K., & Spieth, P. (2021). Theorizing business model innovation: An organizing framework of research dimensions and future perspectives. R&D Management, 52(3), 2022. https://doi.org/10.1111/radm.12506

Schneckenberg, D., Velamuri, V., & Comberg, C. (2019). The design logic of new business models: Unveiling cognitive foundations of managerial reasoning. European Management Review, 16(2), 427–447. https://doi.org/10.1111/emre.12293

Schneider, S., & Spieth, P. (2013). Business model innovation: Towards an integrated future research agenda. International Journal of Innovation Management, 17(01), 1340001. https://doi.org/10.1142/S136391961340001X

Spieth, P., Schneckenberg, D., & Ricart, J. E. (2014). Business model innovation-state of the art and future challenges for the field. R&D Management, 44, 237–247. https://doi.org/10.1111/radm.12071

Teece, D. J. (2010). Business models, business strategy and innovation. Long Range Planning, 43(2-3), 172–194. https://doi.org/10.1016/j.lrp.2009.07.003

Teece, D. J. (2018). Business models and dynamic capabilities. Long Range Planning, 51(1), 40–49. https://doi.org/10.1016/j.lrp.2017.06.007

Tuli, K. R., Kohli, A. K., & Bharadwaj, S. G. (2007). Rethinking customer solutions: From product bundles to relational processes. Journal of Marketing, 71(3), 1–17. https://doi.org/10.1509/jmkg.71.3

Vaccaro, V. L., & Cohn, D. Y. (2004). The evolution of business models and marketing strategies in the music industry. International Journal on Media Management, 6(1-2), 46–58. https://doi.org/10.1080/14241277.2004.9669381

Van de Ven, A. H. (1992). Suggestions for studying strategy process: A research note. Strategic Management Journal, 13(S1), 169–188. https://doi.org/10.1002/smj.4250131013

Weking, J., Hein, A., Böhm, M., & Krcmar, H. (2020). A hierarchical taxonomy of business model patterns. Electronic Markets, 30(3), 447–468. https://doi.org/10.1007/s12525-018-0322-5

Weking, J., Lupberger J., Hermes, S., Hein, A., Böhm, M., & Krcmar, H. (2020) Practises for open business model innovation - An innomediaries perspective. 15th International Conference of Wirtschaftsinformatik, March 2020.

Wirtz, B. W., Pistoia, A., Ullrich, S., & Göttel, V. (2016). Business models: Origin, development, and future research perspectives. Long Range Planning, 49, 36–54. https://doi.org/10.1016/j.lrp.2015.04.001

Yin, R. K. (2009). Case study research: Design and methods. Sage. https://doi.org/10.33524/cjar.v14i1.73

Zott, C., & Amit, R. (2015). Crafting business architecture: The antecedents of business model design. Strategic Entrepreneurship Journal, 9, 331–350. https://doi.org/10.1002/sej.1200

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Responsible Editor: Ioanna Constantiou

Appendix

Appendix

Overview of case companies

Agile design of specific Omega IoT

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sturm, M., Weking, J., Böhm, M. et al. How two leading partners learn to tango: The case of IoT-based business model co-innovation between a retailer and an electronics supplier. Electron Markets 33, 34 (2023). https://doi.org/10.1007/s12525-023-00645-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12525-023-00645-4