Abstract

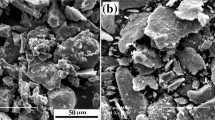

In this study, microstructure, recrystallization texture, and mechanical properties of Al/WO3/SiC hybrid nanocomposite was investigated by electron backscatter diffraction (EBSD), analysis of orientation distribution function (ODF), and uniaxial tensile test during accumulative roll bonding (ARB) process. Microstructural observations show that the recrystallized grains are elongated in the rolling direction (RD) due to the Zener-pinning of nanoparticles at high angle grain boundaries and therefore growth is inhibited in the normal direction (ND) during the ARB process. The ODF investigation confirmed that after 5 cycles of ARB process, recrystallization is associated with nucleation of Goss, Q, and P components. When the number of ARB cycle was increased, Goss and Q recrystallization textures were eliminated, but on the other hand, the P, B and B* texture components were strongly developed. The ND-Cube and RT-Goss recrystallization texture is also formed with low intensity at the last stages. Also, the A and A* shear textures which formed in the fifth cycle, shifted towards the Dillamor and Cu textures with increasing the number of ARB cycles. Furthermore, the samples were heated using DSC under Argon atmosphere with four different heating rates. The Kissinger, Ozawa, Boswell, and Starink methods were used to determine the recrystallization kinetics. It can be seen that recrystallization temperature and thereby activation energy (Ea) decreases with increasing the number of ARB cycles. Furthermore, the tensile strengths and elongation of the hybrid nanocomposite increased and decreased by increasing the number of ARB cycle and reached to a maximum value of 204.5Mpa and 6.1% at the end of 9th cycle, respectively.

Similar content being viewed by others

References

Jamaati R, Toroghinejad MR, Dutkiewicz J, Szpunar JA (2012) Investigation of nanostructured Al/Al2O3 composite produced by accumulative roll bonding process. Mater Des 35:37–42

Alizadeh M (2010) Comparison of nanostructured Al/B4C composite produced by ARB and Al/B4C composite produced by RRB process. Mater Sci Eng A 528:578–582

Jamaati R, Toroghinejad MR, Najafizadeh A (2010) An alternative method of processing MMCs by CAR process. Mater Sci Eng A 527:2720–2724

Farajzadeh Dehkordi H, Toroghinejad MR, Raeissi K (2013) Fabrication of Al/Al2O3/TiC hybrid composite by anodizing and accumulative roll bonding processes and investigation of its microstructure and mechanical properties. Mater Sci Eng A 585:460–467

Wang J, Li Z, Fan G, Pan H, Chen Z, Zhang D (2012) Reinforcement with graphene nanosheets in aluminum matrix composites. Scripta Mater 66:594–597

Sree Manu KM, Sreeraj K, Rajan TPD, Shereema RM, Pai BC, Arun B (2015) Structure and properties of modified compocast microsilica reinforced aluminum matrix composite. Mater Des 88:294–301

Rao TB (2021) Microstructural, mechanical, and wear properties characterization and strengthening mechanisms of Al7075/SiCnp composites processed through ultrasonic cavitation assisted stir-casting. Mater Sci Eng A 805:140553

Song HY, Wang GD, Liu HT (2021) Effect of cold rolling on microstructure and texture evolution in strip casting Fe-36%Ni invar alloy foil. J Alloy Compd 888:161519

Naseri M, Hassani A, Tajally M (2015) Fabrication and characterization of hybrid composite strips with homogeneously dispersed ceramic particles by severe plastic deformation. Ceram Int 41:3952–3960

Baazamat S, Borhani E, Tajally M (2020) The correlation of microstructure, recrystallization texture and mechanical properties with second–phase content in Al/WO3/SiC hybrid nanocomposite during ARB process. Mater Sci Eng A 798:140060

Toroghinejad MR, Jamaati R, Nooryan A, Edris H (2014) Hybrid composites produced by anodizing and accumulative roll bonding (ARB) processes. Ceram Int 40:10027–10035

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ, Juul Jensen D, Kassner ME, King WE, McNelley TR, McQueen HJ, Rollett AD (1997) Current issues in recrystallization: a review. Mater Sci Eng A 238:219–274

Papadopoulou S, Gavalas E, Vourlakou C, Papaefthymiou S (2022) The influence of second phase particles on texture during rolling of Al 3104. Int J Mater Form 15:70

Zhang WL, Gu MY, Wang DZ, Yao ZK (2004) Rolling and annealing textures of a SiCw/Al composite. Mater Lett 58:3414–3418

Poorganji B, Sepehrband P, Jin H, Esmaeili S (2010) Effect of cold work and non-isothermal annealing on the recrystallization behavior and texture evolution of a precipitation- hardenable aluminum alloy. Scripta Mater 63:1157–1160

Wang X, Shi T, Jiang Z, Chen W, Guo M, Zhang J, Zhuang L, Wang Y (2019) Relationship among grain size, texture and mechanical properties of aluminums with different particle distributions. Mater Sci Eng A 753:122–134

Sidor JJ, Petrov RH, Kestens LAI (2012) Recrystallization textures in aluminum alloys: experimental study and modelling. Mater Sci Forum 702–703:611–614

Liu J, Morris JG (2003) Recrystallization textures of continuous cast AA 3015 Alloy: development of the P orientation {011}<566>. Metall Trans A 34:2029–2032

Liu WC, Morris JG (2005) Evolution of recrystallization and recrystallization texture in continuous-cast AA 3015 aluminum alloy. Metall Trans A 36:2829–2848

Liu WC, Morris JG (2007) Recrystallization textures of the M {113}<110> and P{011}<455> orientations in a supersaturated Al–Mn alloy. Scripta Mater 56:217–220

Ashby MF (1970) The deformation of plastically non-homogeneous materials. Phil Mag 21:399–424

Tóth LS, Neale KW, Jonas JJ (1989) Stress response and persistence characteristics of the ideal orientations of shear textures. Acta Metall 37:2197–2210

Naseri M, Reihanian M (2016) Borhani E (2016) Effect of strain path on microstructure, deformation texture and mechanical properties of nano/ultrafine grained AA1050 processed by accumulative roll bonding (ARB). Mater Sci Eng A 673:288–298

Fellah L, Boumerzoug Z (2018) Measurements of recrystallization kinetics by isochronal DSC in industrial drawn copper wires. Materials Today: Proceedings 5:14912–14917

Takata N, Yamada K, Ikeda K, Yoshida F, Nakashima H, Tsuji N (2007) Change in microstructure and texture during annealing of pure copper heavily deformed by Accumulative Roll Bonding. Mater Transactions 48:2043–2048

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Boswell PG (1980) On the calculation of activation energies using a modified Kissinger method. J Thermal Anal 18:353–358

Ozawa T (1992) Estimation of activation energy by isoconversion methods. Thermochim Acta 203:159–165

Starink MJ (2004) Analysis of aluminum based alloys by calorimetry: quantitative analysis of reactions and reaction kinetics. Int Mater Reviews 49:191–226

Liu YL, Hu H, Hansen N (1995) Deformation and recrystallization of a channel die compressed aluminium bicrystal with (112)<11-1>/(123)<41-2> orientation. Acta Metall Mater 43:2395–2405

El-Danaf E, Kalidindi SR, Doherty RD, Necker C (2000) Deformation texture transition in brass: critical role of micro-scale shear bands. Acta Mater 48:2665–2673

Tsivoulas D, Prangnell PB (2014) The effect of Mn and Zr dispersoid-forming additions on recrystallization resistance in Al–Cu–Li AA2198 sheet. Acta Mater 77:1–16

Borhani E, Jafarian HR (2014) Effect of pre-existing nano sized precipitates on microstructure and mechanical property of Al-0.2Wt% Sc highly deformed by ARB process. J Ultrafine Grained Nanostruct Mater 47:1–7

Borhani E, Jafarian HR, Terada D, Adachi H, Tsuji N (2012) Microstructural Evolution during ARB Process of Al–0.2 mass% Sc Alloy Containing Al3Sc Precipitates in Starting Structures. Mater Trans 53:72–80

Nes E, Ryum N, Hunderi O (1985) On the zener drag. Acta Met 33:11–22

Baazamat S, Tajally M, Borhani E (2015) Fabrication and characteristic of Al-based hybrid nanocomposite reinforced with WO3 and SiC by accumulative roll bonding process. J Alloy Compd 653:39–46

Jamaati R, Toroghinejad MR, Edris H (2013) Effect of stacking fault energy on nanostructure formation under accumulative roll bonding (ARB) process. Mater Sci Eng A 578:191–196

Khodabakhshi F, Mohammadi M, Gerlich AP (2021) Stability of ultra-fine and nano-grains after severe plastic deformation: a critical review. J Mater Sci 56:15513–15537

Engler O (2001) An EBSD local texture study on the nucleation of recrystallization at shear band in the alloy Al-3%Mg. Scripta Mater 44:229–236

Driver J (2018) The limitations of continuous dynamic recrystallization (CDRX) of aluminium alloys. Mater Lett 222:135–137

Friedman PA, Liao KC, Pan J, Barlat F (1999) Texture development and hardening characteristics of steel sheets under plane-strain compression. JMEPEG 8:225–235

Jia N, Raabe D, Zhao X (2014) Texture and microstructure evolution during non-crystallographic shear banding in a plane strain compressed Cu–Ag metal matrix composite. Acta Mater 76:238–251

Heason CP, Prangell PB (2002) Texture evolution and grain refinement in Al deformed to ultra-high strains by accumulative roll bounding (ARB). Mater Sci Forum 408–412:733–738

Jung J, Yoon JI, Lee DN, Kim HS (2017) Numerical analysis on the formation of P-orientation near coarse precipitates in FCC crystals during recrystallization. Acta Mater 131:363–372

Huang K, Zhang K, Marthinsen K, Logé RE (2017) Controlling grain structure and texture in Al-Mn from the competition between precipitation and recrystallization. Acta Mater 141:60–373

Baker I, Martin JW (1980) The effect of particle size and spacing on the retardation of recrystallization in two-phase copper crystals. J Mater Sci 15:1533–1538

Humphreys FJ (1979) Recrystallization mechanisms in two-phase alloys. Metal Sci 13:136–145

Salimi A, Borhani E, Emadoddin E (2015) Evaluation of mechanical properties and structure of 1100-Al reinforced with ZrO2 nano-particles via accumulatively roll-bonded. Procedia Mater 11:67–73

Roghani H, Borhani E, Shams SAA, Lee CS, Jafarian HR (2021) On the Microstructure, Texture and Mechanical Properties Through Heat Treatment in Al-CuO Nanocomposite Fabricated by Accumulative Roll Bonding (ARB). Mater Sci Eng A 828:142080

Jafarian HR, Mahdavian MM, Shams SAA, Eivani AR (2021) Microstructure analysis and observation of peculiar mechanical properties of Al/Cu/Zn/Ni multi-layered composite produced by Accumulative-Roll-Bonding (ARB). Mater Sci Eng A 805:140556

Amirkhanlou S, Ketabchi M, Parvin N, Khorsand S, Bahrami R (2013) Accumulative press bonding; a novel manufacturing process of nanostructured metal matrix composites. Mater Des 51:367–374

Imanian Ghazanlou S, Eghbali B, Petrov R (2021) Microstructural evolution and strengthening mechanisms in Al7075/graphene nano-plates/carbon nano-tubes composite processed through accumulative roll bonding. Mater Sci Eng A 807:140887

Liu CY, Wang Q, Jia YZ, Zhang B, Jing R, Ma MZ, Jing Q, Liu RP (2012) Effect of W particles on the properties of accumulatively roll-bonded Al/W composites. Mater Sci Eng A 547:120–124

Borhani E, Azad B (2016) A study on the effect of nano-precipitates on fracture behavior of nano-structured Al-2wt%Cu alloy fabricated by accumulative roll bonding (ARB) process. J Min Metal Section B 52:93–98

Roghani H, Borhani E, Jafarian HR (2021) Effect of a trace amount addition of CuO on aluminum sheet processed by accumulative roll bonding with the common roots and rapid annealing. J Mater Res Technol 15:4257–4271

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations

We wish to draw the attention of the Editor to the following facts, which may be considered as potential conflicts of interest and to significant financial contributions to this work:

The nature of potential conflict of interest is described below:

Conflict of interest

We wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Intellectual property

We confirm that we have given due consideration to the protection of intellectual property associated with this work and that there are no impediments to publication, including the timing of publication, with respect to intellectual property. In so doing we confirm that we have followed the regulations of our institutions concerning intellectual property.

Contact with the editorial office

The Corresponding Author declared on the title page of the manuscript is: Dr. Ehsan Borhani.

We understand that this Corresponding Author is the sole contact for the Editorial process. He is responsible for communicating with the other authors about progress, submissions of revisions and final approval of proofs.

We the undersigned agree with all of the above.

Author’s name (Fist, Last): Saeed Baazamat, Signature: Saeed Baazamat, Date:September 22, 2022. Author’s name (Fist, Last): Ehsan Borhani, Signature: Ehsan Borhani, Date:September 22, 2022.Author’s name (Fist, Last): Mohammad Tajally, Signature: Mohammad Tajally, Date:September 22, 2022.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baazamat, S., Borhani, E. & Tajally, M. On the microstructure, recrystallization texture, and mechanical properties of Al/WO3/SiC hybrid nanocomposite during accumulative roll bonding (ARB) process. Int J Mater Form 16, 53 (2023). https://doi.org/10.1007/s12289-023-01777-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-023-01777-w