Abstract

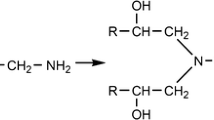

The automobile industry is incorporating more lightweight content in car designs to boost fuel-economy. New structural adhesives are needed to mitigate the corrosion and thermal expansion issues associated with joining dissimilar lightweight materials, but adhesive developers lack a fundamental understanding of the chemistry that occurs in the adhesive as the joint ages. In this study, we developed structural adhesive molecular models and applied classical molecular dynamics simulations and density functional theory calculations to gain molecular insights into the influence of water molecules on the properties of epoxy-based adhesives (DGEBA + Jeffamine (JD230)). The simulations were complemented by experimental synthesis and characterization. Our work underscores the impact of water molecules on the local structure of the epoxy network as well as resulting mechanical properties. Water molecules were mainly coordinated with hydroxyls, primary amines and secondary amines, but also weakly coordinated with ether linkages, which were found most probable to be labile. Simulated stress–strain data indicates that increasing the water content deteriorates the mechanical properties. The Young’s modulus decreased by ~ 30% when the water content increased to 3 wt%. This integration of molecular-level chemical insights with mechanical property simulations of the hydrated epoxy system and experimental validation holds the promise to advance lightweight joint technologies.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

May CA (1988) Introduction to epoxy resins. Epoxy Resins Chemistry Technology, pp 1–8

Soles CL et al (1998) Contributions of the nanovoid structure to the moisture absorption properties of epoxy resins. J Polym Sci Part B Polym Phys 36(17):3035–3048

Mathew J, Joy J, George SC (2019) Potential applications of nanotechnology in transportation: a review. J King Saud Univ Sci 31(4):586–594

Beardmore P, Johnson C (1986) The potential for composites in structural automotive applications. Compos Sci Technol 26(4):251–281

Lyu M-Y, Choi TG (2015) Research trends in polymer materials for use in lightweight vehicles. Int J Precis Eng Manuf 16(1):213–220

Arafat Y, Dutta I, Panat R (2016) On the deformation mechanisms and electrical behavior of highly stretchable metallic interconnects on elastomer substrates. J Appl Phys 120(11):115103

Arafat Y, Dutta I, Panat R (2015) Super-stretchable metallic interconnects on polymer with a linear strain of up to 100%. Appl Phys Lett 107(8):081906

Patel V, Mahajan Y (2014) Polymer nanocomposites: emerging growth driver for the global automotive industry. In: Handbook of polymernanocomposites. Processing, performance and application. Springer, pp 511–538

Ratna D (2009) Handbook of thermoset resins. iSmithers, Shawbury, UK

Lee H, Neville K (1967) Handbook of epoxy resins. McGraw-Hill

Barton JM (1985) The application of differential scanning calorimetry (DSC) to the study of epoxy resin curing reactions. Epoxy Resins Compos I:111–154

Meyer F et al (1995) The effect of stoichiometry and thermal history during cure on structure and properties of epoxy networks. Polymer 36(7):1407–1414

Chen X, Ellis B (1993) Coatings and other applications of epoxy resins. In: Chemistry and technology of epoxy resins. Springer, pp 303–325

Pandiyan S et al (2015) A molecular dynamics study of water transport inside an epoxy polymer matrix. Comput Mater Sci 106:29–37

Yang S et al (2019) Molecular dynamics and micromechanics study of hygroelastic behavior in graphene oxide-epoxy nanocomposites. Compos Part B Eng 164:425–436

Park H et al (2020) Prediction of quasistatic constitutive equations of moisture-absorbed epoxy polymers using atomistic simulations. Extreme Mech Lett 41:100983

Kwon S, Lee MY, Yang S (2019) Molecular dynamics approach on the hygroelastic behavior of epoxy/graphene nanocomposites. Mech Sci Technol 33(2):741–747

Asp L (1998) The effects of moisture and temperature on the interlaminar delamination toughness of a carbon/epoxy composite. Compos Sci Technol 58(6):967–977

O'Brien TK (1991) Delamination of composite materials. In: Composite materials series. Elsevier, pp 181–198

Krakovský I et al (2005) Structure and swelling behaviour of epoxy networks based on α, ω-diamino terminated poly (oxypropylene)-block-poly (oxyethylene)-block-poly (oxypropylene). Polymer 46(1):109–119

Krakovský I, Pleštil J, Almásy L (2006) Structure and swelling behaviour of hydrophilic epoxy networks investigated by SANS. Polymer 47(1):218–226

Carfagna C, Apicella A, Nicolais L (1982) The effect of the prepolymer composition of amino-hardened epoxy resins on the water sorption behavior and plasticization. J Appl Polym Sci 27(1):105–112

Botelho EC et al (2006) A review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures. Mater Res 9(3):247–256

Pecht M (1990) A model for moisture induced corrosion failures in microelectronic packages. IEEE Trans Compon Hybrids Manuf Technol 13(2):383–389

Chowdhury SC et al (2020) Epoxy resin thermo-mechanics and failure modes: effects of cure and cross-linker length. Compos B Eng 186:107814

Ogata S, Uranagase M (2018) Unveiling the chemical reactions involved in moisture-induced weakening of adhesion between aluminum and epoxy resin. J Phys Chem C 122(31):17748–17755

Nizin DR et al (2019) Natural climatic aging of epoxy polymers taking into account the seasonality impact. In: Key engineering materials. Trans Tech Publ

Uthaman A et al (2020) Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymers 12(3):614

Ulus H et al (2020) Halloysite nanotube reinforcement endows ameliorated fracture resistance of seawater aged basalt/epoxy composites. J Compos Mater 54(20):2761–2779

Ogata S, Takahashi YJ (2016) Moisture-induced reduction of adhesion strength between surface oxidized Al and epoxy resin: dynamics simulation with electronic structure calculation. J Phys Chem C 120(25):13630–13637

Sun H, Ren P, Fried J (1998) The COMPASS force field: parameterization and validation for phosphazenes. Comput Theor Polym Sci 8(1–2):229–246

Meunier M (2012) Introduction to materials studio. In: EPJ web of conferences. EDP Sciences

Bandyopadhyay A et al (2011) Molecular modeling of crosslinked epoxy polymers: The effect of crosslink density on thermomechanical properties. Polymer 52(11):2445–2452

Masoumi S, Arab B, Valipour HJP (2015) A study of thermo-mechanical properties of the cross-linked epoxy: an atomistic simulation. Polymer 70:351–360

Martínez L et al (2009) PACKMOL: a package for building initial configurations for molecular dynamics simulations. J Comput Chem 30(13):2157–2164

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Jorgensen WL, Maxwell DS, Tirado-Rives J (1996) Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J Am Chem Soc 118(45):11225–11236

Levitt M et al (1997) Calibration and testing of a water model for simulation of the molecular dynamics of proteins and nucleic acids in solution. J Phys Chem B 101(25):5051–5061

Devanathan R, Venkatnathan A, Dupuis M (2007) Atomistic simulation of nafion membrane: I. Effect of hydration on membrane nanostructure. J Phys Chem B 111(28):8069–8079

Shin Y et al (2019) Highly selective supported graphene oxide membranes for water-ethanol separation. Sci Rep 9(1):1–11

Swope WC et al (1982) A computer simulation method for the calculation of equilibrium constants for the formation of physical clusters of molecules: application to small water clusters. J Chem Phys 76(1):637–649

Bussi G, Donadio D, Parrinello MJ (2007) Canonical sampling through velocity rescaling. J Chem Phys 126(1):014101

Nosé SJ (1984) A unified formulation of the constant temperature molecular dynamics methods. J Chem Phys 81(1):511–519

Hoover WG (1985) Canonical dynamics: equilibrium phase-space distributions. Phys Rev A 31(3):1695

Kresse G, Hafner J (1993) Ab initio molecular dynamics for liquid metals. Phys Rev B 47(1):558

Kresse G, Hafner J (1994) Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys Rev B 49(20):14251

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54(16):11169

Blöchl PE (1994) Projector augmented-wave method. Phys Rev B 50(24):17953

Kresse G, Joubert D (1999) From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B 59(3):1758

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77(18):3865

Wang J, Hou T (2011) Application of molecular dynamics simulations in molecular property prediction II: diffusion coefficient. J Comput Chem 32(16):3505–3519

Yang C et al (2020) A comprehensive review on water diffusion in polymers focusing on the polymer–metal interface combination. Polymers 12(1):138

Mark P, Nilsson L (2001) Structure and dynamics of the TIP3P, SPC, and SPC/E water models at 298 K. J Phys Chem A 105(43):9954–9960

Lin Y, Chen X (2005) Moisture sorption–desorption–resorption characteristics and its effect on the mechanical behavior of the epoxy system. Polymer 46(25):11994–12003

Wunderle B et al (2009) Molecular dynamics approach to structure-property correlation in epoxy resins for thermo-mechanical lifetime modeling. In: 2009 59th electronic components and technology conference. IEEE

Pethrick RA et al (1996) Dielectric, mechanical and structural, and water absorption properties of a thermoplastic-modified epoxy resin: poly(ether sulfone)−amine cured epoxy resin. Macromolecules 29(15):5208–5214

Parker FS (1983) Applications of infrared, Raman, and resonance Raman spectroscopy in biochemistry. Springer, Berlin

Herzberg G, Crawford B Jr (1946) Infrared and Raman spectra of polyatomic molecules. J Phys Chem 50(3):288–288

Manzanares IC et al (1991) Overtone spectra of C-H bonds and vibrational abinitio study of methoxy boranes. J Chem Phys 95(5):3031–3039

Iwamoto R, Nara A, Matsuda T (2006) Near-infrared combination and overtone bands of the CH2 sequence in CH2X2, CH2XCHX2, and CH3(CH2)5CH3 and their characteristic frequency zones. Appl Spectrosc 60(4):450–458

González MG, Cabanelas JC, Baselga J (2012) Applications of FTIR on epoxy resins-identification, monitoring the curing process, phase separation and water uptake. Infrared Spectrosc Mater Sci Eng Technol 2:261–284

Kroonblawd MP, Goldman N, Lewicki JP (2018) Chemical degradation pathways in siloxane polymers following phenyl excitations. Phys Chem B 122(50):12201–12210

Foreman JP et al (2006) Thermodynamic and mechanical properties of amine-cured epoxy resins using group interaction modelling. J Mater Sci 41(20):6631–6638

Acknowledgements

This work was supported by the High-Performance Computing for Energy Innovation (HPC4EI) Initiative, managed by U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE). The project was funded by EERE Vehicle Technologies Office. Pacific Northwest National Laboratory is operated for the U.S. Department of Energy by Battelle under Contract DE-AC06-76RLO1830. This research used resources of the National Energy Research Scientific Computing Center (NERSC), a U.S. Department of Energy Office of Science User Facility located at Lawrence Berkeley National Laboratory, operated under Contract No. DE-AC02-05CH11231.

Author information

Authors and Affiliations

Contributions

MFNT and ML have equal contribution as first author. MFNT performed MD simulations, analyzed the results, and wrote the manuscript. ML built monomer molecular models of epoxy and curing agents, constructed the cross-linked models and performed MD simulations with different crosslinking densities. MJD performed analysis of NIR spectral data and LP, DW, and MT acquired MIR and NIR data, respectively. NG and SH performed DFT-MD calculations. RD provided technical expertise to MD simulated data, interpreted the results, and reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Taufique, M.F.N., Losada, M., Hamel, S. et al. Molecular Dynamics Simulation of Hygroscopic Aging Effects in Epoxy Polymer. Integr Mater Manuf Innov 12, 185–195 (2023). https://doi.org/10.1007/s40192-023-00296-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-023-00296-5