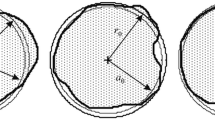

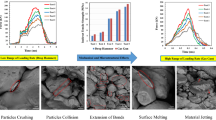

The densification of a fine-grained tungsten carbide cermet containing 36 wt.% copper binder during impact assisted sintering in a vacuum at thermodynamic temperatures of 1023, 1123, and 1223 K with an initial impact velocity of 6.4 m/s was studied. Based on the experimental data and calculated elastic properties of the samples and the impact machine, computational modeling of the densification dynamics with a trial and error method was carried out using a third-order dynamic system in combination with the rheological model of Maxwell’s viscoelastic body, and as a result previously unknown values of shear viscosity for material cermet matrices were obtained. The time dependences of force, compression, velocity, and acceleration of the system, as well as shrinkage, root-mean-square stress, and strain rate, of the cermet samples during impact assisted sintering were determined. The calculated phase trajectory of the dynamic system movement showed that the initial kinetic energy of the impact was not completely exhausted for the irreversible densification of the cermet samples. Part of the energy dissipated in the environment after the rebound of the machine’s impact parts. At the initial stage, the system exhibited nonperiodic (atemporal) damping during its movement at high ratios between the system’s stiffness and the cermet samples’ viscous resistance. As the ratio decreased, the movement transformed into damping oscillations. The work of densification and the thermomechanical effect, which significantly increased the temperature of porous samples, were evaluated. The estimated activation energy of the viscous flow for the porous cermet matrix was 0.34 eV or 33 kJ/mol that indicated the dislocation mechanism of sintering. The samples produced by impact assisted sintering showed significantly higher strength values compared to pressureless sintered samples at a higher temperature.

Similar content being viewed by others

References

I. Smid, M. Akiba, G. Vieider, and L. Plöchl, “Development of tungsten armor and bonding to copper for plasma-interactive components,” J. Nucl. Mater., 258–263, 160–172 (1998).

S. Temborius, M. Lindmayer, and D. Gentsch, “Comparison of the properties of WC–Ag and WC–Cu as contact materials for vacuum contactors,” in: 20th Int. Symposium on Discharges and Electrical Insulation in Vacuum, IEEE Xplore publ. July 1–5, 247–253 (2002), DOI: https://doi.org/10.1109/ISDEIV.2002.

N. Zhao, J. Li, and X. Yang, “Influence of the P/M process on the microstructure and properties of WC reinforced copper matrix composite,” J. Mater. Sci., 39, No. 15, 4829–4834 (2004).

R. Grill, P. Klausler, F.E.-H. Mueller, O. Schrott, and H. Hauser, “WC/Ag contact materials with improved homogeneity,” in: Proc. 16 Int. Plansee Seminar, Reutte, 200–211 (2005).

P.K. Deshpande, Wear Resistance and Electrical Property of Infrared Processed Copper/Tungsten Carbide Composites, Thesis of PhD Degree, University of Cincinnati (2006).

J.P. Stobrawa and Z.M. Rdzawski, “Characterization of nanostructured copper–WC materials,” J. Achiev. Mater. Manuf. Eng., 32, No. 2, 171–178 (2009).

M. Ardestani, H. Arabi, H. Razavizadeh, H.R. Rezaie, and H. Mehrjoo, “Synthesis of WC–20 wt. Cu composite powders using co-precipitation and carburization process,” Mater. Sci. Pol., 28, No. 2, 413–420 (2010).

E. Hong, B. Kaplin, T. You, M.S. Suh, Y.S. Kim, and H. Choe, “Tribological properties of copper alloybased composites reinforced with tungsten carbide particles,” Wear, 270, No. 9–10, 591–597 (2011).

M. Yusoff and Z. Hussain, “Effect of sintering parameters on microstructure and properties of mechanically alloyed copper-tungsten carbide composite,” Int. J. Mater. Mech. Manuf., 1, No. 3, 283–286 (2013).

F.D.G. Guerreiro, WC–Cu Cermet Materials: Production and Characterization, Thesis of Master of Science, Técnico Lisboa (1915), https://fenix.tecnico.ulisboa.pt.

M.S. Kovalchenko and A.V. Laptev, “Dynamics of WC–Co hard alloy compaction with hot pulsed pressing,” Powder Metall. Met. Ceram., 43, No. 3–4, 117–126 (2004).

H. Lamb, Hydrodynamics, Cambridge University Press (1932).

M.S. Kovalchenko, “Rheology and kinetics of pressure sintering,” Mater. Sci. Forum, 835, 76–105 (2016).

M.S. Kovalchenko, V.B. Vinokurov, R.V. Litvin, and L.I. Klimenko, “The densification kinetics of porous zirconium diboride in vacuum pressure sintering,” Powder Metall. Met. Ceram., 60, No. 5–6, 278–290 (2021).

A.S. Eddington, The Nature of the Physical World, The University Press, Cambridge, England (1928), 361 pp.

D. Kondepudi and I. Prigogine, Modern Thermodynamics: From Heat Engines to Dissipative Structures, John Wiley & Sons Ltd, Chichester–New York–Weinheim–Brisbane–Toronto–Singapore (1998), 506 pp.

M.S. Kovalchenko, “The dynamics of mechanical actions on materials. I. General theory,” Powder Metall. Met. Ceram., 32, No. 7, 596–601 (1993).

M.S. Kovalchenko, “The dynamics of mechanical actions on materials. V. Damped oscillations in a thirdorder dynamic system,” Powder Metall. Met. Ceram., 33, No. 5–6, 244–248 (1995).

M.S. Kovalchenko, “The dynamics of mechanical actions on materials. VI. Periodic and aperiodic movements of an autonomous dynamic system,” Powder Metall. Met. Ceram., 36, No. 3–4, 217–225 (1997).

A. Angot, Mathematics for Electrical and Telecommunications Engineers [in French], Éditions de la Revue d’Optique, Paris (1949), 660 pp.

G.V. Samsonov (ed.), Handbook of the Physicochemical Properties of the Elements, IFI/Plenum, New York, Washington (1968), 941 pp.

G.V. Samsonov and I.M. Vinnitskii, Refractory Compounds: Handbook [in Russian], 2nd issue, Metallurgiya, Moscow (1976), 560 pp.

R.B. Kotelnikov, S.N. Bashlykov, Z.G. Galiakbarov, and A.I. Kashtanov, Especially Refractory Elements and Compounds: Handbook [in Russian], Metallurgiya, Moscow (1969), p. 376.

Powder Metallurgy, Materials, Technology, Properties, and Applications [in Russian], Naukova Dumka, Kyiv (1985), p. 624.

V.S. Chirkin, Thermal Physical Properties of Materials: Handbook [in Russian], Fizmatgiz, Moscow (1959), p. 356.

Densities of the Elements (data page). Wikipedia, https://en.wikipedia.org/wiki/Densities_of_the_elements_(data_page).

J. Garcia, V.C. Cipres, A. Blomqvist, and B. Kaplan, “Cemented carbide microstructures: a review,” Int. J. Refract. Met. Hard Mater., 80, 40–68 (2019).

Z. Hashin and S. Shtrikman, “A variational approach to the theory of the elastic behavior of multiphase materials,” J. Mech. Phys. Solids, 11, No. 2, 127–140 (1963).

P.W. Bridgman, “The compressibility of thirty metals as a function of pressure and temperature,” Proc. Am. Acad. Arts Sci., 58, No. 5, 165–242 (1923).

P. Hidnert, “Thermal expansion of cemented tungsten carbide,” J. Res. Natl. Bur. Stand., 18, 47–52 (1937).

M.S. Kovalchenko, “Pressure sintering kinetics of tungsten and titanium carbides,” Int. J. Refract. Met. Hard Mater., 39, 32–37 (2013).

M.S. Kovalchenko and L.F. Ochkas, “Densification dynamics of copper and iron powder billets in hot shock compaction: simulation and analysis,” Powder Metall. Met. Ceram., 47, No. 5–6, 273–283 (2008).

J. Friedel, Dislocations, Pergamon Press, Oxford–London–Edinburgh–New York–Paris–Frankfurt (1964), 512 pp.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 61, Nos. 11–12 (548), pp. 16–32, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kovalchenko, M.S., Laptiev, A.V. & Tolochyn, O.I. Densification Dynamics of WC–36 wt.% Cu Cermet During Impact Assisted Sintering in Vacuum. Powder Metall Met Ceram 61, 644–656 (2023). https://doi.org/10.1007/s11106-023-00353-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00353-w