In this study, nanocrystalline TiAlV alloys were synthesized using the mechanical alloying technique with a high-energy planetary ball mill from pure Ti, Al, and V powders. Various methods, including Vibrating Sample Magnetometry (VSM), Scanning Electron Microscopy and Energy Dispersive Spectroscopy (SEM-EDS), and X-ray Diffraction (XRD), were employed to characterize the synthesized alloys and study their magnetic behavior, morphology, microstructural and structural properties, respectively. Following the XRD analysis, new phases were confirmed, and a significant reduction in crystallite size from 48.73 to 9.38 nm was observed. Moreover, an increase in lattice strain from 0.15% to approximately 0.81% was noted after 60 h of milling. The EDS analysis gave remarkable results, showing the lack of magnetic iron particles before milling. However, after milling, the EDS spectrum revealed the presence of these magnetic iron particles with varying concentrations. This important observation highlights the profound impact of the mechanical alloying process on the sample composition. It emphasizes the sensitivity of EDS analysis by detecting even subtle changes in the elementary composition of a material. A sensitive approach was employed to monitor the progression of the nanocrystalline alloy and identify any potential defects arising during the mechanical milling. A vibrating sample magnetometer was utilized to achieve this objective. This method is highly effective at capturing even subtle changes that may occur during milling, allowing for an accurate evaluation of the chemical composition and integrity of the alloy. This technique made it possible to detect the presence of magnetic particles whose magnetic properties varied from time to time, indicating a change in magnetic behavior due to the reduction in the size of these particles caused by the collision between the steel balls and the milled powder particles. The results suggest that non-destructive magnetic testing using a VSM can be used to monitor the state of the nanocrystalline alloy.

Similar content being viewed by others

References

A. Abada, S. Bergheul, and A. Younes, “Mechanical and structural behavior of TiAlV nanocrystalline elaborated by mechanical milling technique,” Micro Nano Lett., 15, Issue 14, 1023–1027 (2020).

J. Yang, H. Yu, J. Yin, M. Gao, Z. Wang, and X. Zeng, “Formation and control of martensite in Ti–6Al–4V alloy produced by selective laser melting,” Mater. Des., 108, 308–318 (2016).

N. Metidji, N.E. Bacha, A. Younes, and D. Saidi, “The effect of Ti addition on microstructure and magnetic properties of nanocrystalline FeAl40 alloy powders prepared by mechanical alloying,” Powder Metall. Met. Ceram., 59, No. 3–4, 160–170 (2020).

G.M. Ter Haar and T.H. Becker, “Selective laser melting produced Ti–6Al–4V: post-process heat treatments to achieve superior tensile properties,” Materials (Basel), 11, No. 1, 146 (2018).

P. Daswa, Z. Gxowa, M.J.I. Monareng, and K. Mutombo, “Effect of milling speed on the formation of Ti–6Al–4V via mechanical alloying,” IOP Conf. Ser.: Mater. Sci. Eng. (2018).

J. Zhao, H. Ding, Y. Zhong, and C.S. Lee, “Effect of thermo hydrogen treatment on lattice defects and microstructure refinement of Ti6Al4V alloy,” Int. J. Hydrogen Energy, 35, 6448 (2010).

V. López-Dominguez, A. Quesada, J.C. Guzmán-Mínguez, L. Moreno, M. Lere, J. Spottorno, F. Giacomone, J.F. Fernández, A. Hernando, and M.A. García, “A simple vibrating sample magnetometer for macroscopic samples,” Review Sci. Instrum., 89, No. 3, Article No. 034707 (2018).

M. Getzlaff, “Solid state magnetism,” in: Fundamentals of Magnetism, Springer, Berlin, Heidelberg (2008), https://doi.org/10.1007/978-3-540-31152-2_3.

S. Foner, “The vibrating sample magnetometer: Experiences of a volunteer (invited),” J. Appl. Phys., 79, 4740 (1996).

T.M. El-Alaily, M.K. El-Nimr, S.A. Saafan, M.M. Kamel, T.M. Meaz, and S.T. Assar, “Construction and calibration of a low-cost and fully automated vibrating sample magnetometer,” J. Magn. Magn. Mater., 386, 25–30 (2015).

Babu R. Sankhi and Emrah Turgut, “A low-cost vibrating sample magnetometry based on audio components,” J. Magn. Magn. Mater., 502, Article No. 166560 (2020).

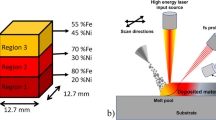

N. Dilmi, N.-E. Bacha, and A. Younes, “Structural and magnetic properties of Fe60–xNix(ZnO)40 nanocomposites produced by mechanical milling and coated by thermal spraying on a steel substrate,” Powder Metall. Met. Ceram., 59, No. 1–2, 35–45(2020).

A. Younes and N. Kherrouba, “Eddy current and magnetic evaluation of nanostructured iron–cobalt produced by ball-milling,” Emerging Mater. Res., 11, No. 2, 268–275 (2022).

F.A. Shah, M. Trobos, P. Thomsen, and A. Palmquist, “Commercially pure titanium (cp-Ti) versus titanium alloy (Ti6Al4V) materials as bone anchored implants - Is one truly better than the other?” Mater. Sci. Eng. C, Mater. Biol. Appl., 62, 960–966 (2016).

A. Mahboubi Soufiani, F. Karimzadeh, and M.H. Enayati, “Formation mechanism and characterization of nanostructured Ti6Al4V alloy prepared by mechanical alloying,” Mater. Des., 37, 152–160 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 61, Nos. 11–12 (548), pp. 73–82, 2022

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abada, A., Younes, A. Analysis of Contamination in the Process of Forming a Titanium-Based Nanocrystalline Alloy Using VSM, SEM-EDS, and XRD Techniques. Powder Metall Met Ceram 61, 691–698 (2023). https://doi.org/10.1007/s11106-023-00356-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00356-7