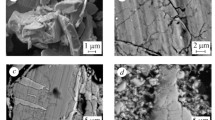

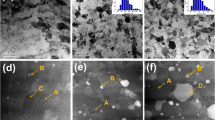

The use of the hydrogenation and disproportionation (HD) and desorption and recombination (DR) route (HDDR) for sintering Nd2Fe14B-based ferromagnetic alloys, such as Nd11.7Fe81.1Zr1.2B6 and Nd16Fe73.9Zr2.1B8, was studied by scanning electron microscopy and energy-dispersive X-ray spectroscopy. The dependence between the production conditions—grinding of the alloys into powders, compaction pressure of the powders, hydrogen pressure and temperature at the first stage of sintering in hydrogen (HD), and temperature at the second stage of sintering in vacuum (DR)—and the porosity and microstructural particle size of the sintered materials was evaluated. The powders were ground in hydrogen in a planetary-ball mill at 200 rpm for 1 h and compacted at 2, 5, and 6 t/cm2. The first sintering stage was carried out at a hydrogen pressure of 0.05 MPa and a temperature of 760°C, and the second stage at 850 and 950°C. The powders were found to sinter at the first stage. The porosity of the sintered materials decreased with increasing compaction pressure. The grain size of the ferromagnetic Nd11.7Fe81.1Zr1.2B6 phase in the sintered materials ranged from 100 to 300 nm. The physical mechanism behind the reduction in the sintering temperature was attributed to an increase in the diffusion rate of alloy components resulting from hydrogen-induced phase transformations, such as disproportionation and recombination, and to the presence of a hydrogen solid solution at both stages of the process, HD and DR. A very important aspect of this research is that the powders were sintered under low hydrogen pressure required to produce magnetically anisotropic materials. Problematic aspects of the properties shown by the sintered materials, particularly microstructural heterogeneity, were analyzed, and approaches to their solution, through homogenizing the particle size of the powders and optimizing the HDDR parameters (hydrogen pressure, temperature, reaction time), were proposed. The process advantages of the new sintering method compared to similar techniques included the temperature lower by more than 100°C, the potential for producing nanostructured anisotropic materials, and the use of technically simpler and cheaper sintering furnaces.

Similar content being viewed by others

References

Y. Yang, A. Walton, R. Sheridan, K. Gűth, R. Gauß, O. Gutfleisch, M. Buchert, B.-M. Steenari, T.V. Gerven, P.T. Jones, and K. Binnemans, “REE recovery from end-of-life NdFeB permanent magnet scrap: A critical review,” J. Sustainable Metall., 3, 122–149 (2017), https://doi.org/https://doi.org/10.1007/s40831-016-0090-4 (open access).

S. Constantinides, “Permanent magnets in a changing world market,” Magn. Mag.: Bus. Technol. (2016) (Spring 2016, Feb 26, 2016), http://www.magneticsmagazine.com/main/articles/permanent-agnets-in-achanging-worldo-market. Accessed May 8, 2016.

T. Tomše, J. Jaćimović, L. Herrmann, F. Greuter, R. Simon, C. Tekavec, J.-M. Dubois, and S. Kobe, “Properties of SPS-processed permanent magnets prepared from gas-atomized Nd–Fe–B powders,” J. Alloys Compd., 744, 132−140 (2018).

Y. Ma, Y. Liu, J. Li, C. Li, and L. Chu, “Die-upset Nd11.5Fe72.4Co9Nb1B6.1 magnets with additions of Zn, Al and Sn,” J. Magn. Magn. Mater., 322, 2419–2422 (2010).

S. Jie, Y. Ming, Z. Jianhua, Z. Zirui, L. Weiqiang, Z. Dongtao, Z. Jiuxing, G. Zhaohui, and L. Wei, “Structure and magnetic properties of bulk nanocrystalline Nd–Fe–B permanent magnets prepared by hot pressing and hot deformation,” J. Rare Earths, 31, 674–678 (2013).

T. Mouri, M. Kumano, H.Y. Yasuda, T. Nagase, R. Kato, Y. Nakazawaand, and H. Shimizu, “Effect of two-stage deformation on magnetic properties of hot-deformed Nd–Fe–B permanent magnets,” J. Scr. Mater., 78–79, 1–4 (2014).

E. Estevez, J. Fidler, C. Shortand, and I.R. Harris, “Microstructural study of hot pressed HDDR Nd–Fe–B magnets,” J. Phys. D: Appl. Phys., 29, 951–956 (1996).

P.J. McGuiness, X.J. Zhang, K.G. Knoch, X.J. Yio, M.J. Wyborn, and I.R. Harris, “HDDR hot-pressed magnets: magnetic properties and microstructure,” J. Magn. Magn. Mater., 104–107, 1169–1170 (1992).

N. Nozawa, H. Sepehri-Amin, T. Ohkubo, K. Hono, T. Nishiuchi, and S. Hirosawa, “Coercivity enhancement of HDDR-processed Nd–Fe–B permanent magnet with the rapid hot-press consolidation process,” J. Magn. Magn. Mater., 323, 115–121 (2011).

D. Lee, S. Bauser, A. Higgins, C. Chen, S. Liu, M.Q. Yuang, Y.G. Heng, and D.E. Laughlin, “Bulk anisotropic composite rare earth magnets,” J. App. Phys., 99, 08B516-1–08B516-3 (2006).

J. Jakubowicz, “Corrosion protection of nanocomposite Nd–Fe–B/α-Fe magnets,” J. Alloys Compd., 314, 305–308 (2001).

J. Jakubowicz and M. Giersig, “Structure and magnetic properties of Nd2(Fe, Co, Al, Cr)14 B/ α -Fe nanocomposite magnets,” J. Alloys Compd., 349, 311–315 (2003).

C.B. Rong, D. Wang, V.V. Nguyen, M.L. Danii, M.A. Willard, Y. Zhang, M.J. Kramerand, and J.P. Liu, “Effect of selective Co addition on magnetic properties of Nd2(FeCo)14B/ α -Fe nanocomposite magnets,” J. Phys. D: Appl. Phys., 46, 1–5 (2013).

J. Jiang and Y. Wang, “Effect of the first hot extrusion temperature on microstructure and magnetic properties of second-extrusion Nd2Fe14B/α-Fe nanocomposite,” J. Magn. Magn. Mater., 332, 76–80 (2013).

M. Lin, H.J. Wang, P.P. Yi, and A.R. Yan, “Effects of excessive grain growth on the magnetic and mechanical properties of hot-deformed NdFeB magnets,” J. Magn. Magn. Mater., 322, 2268–2271 (2010).

H.W. Kwon, Y. Zhang, and G.C. Hadjipanayis, “Effect of host and added alloy composition on magnetic properties of Nd2Fe14B+Nd2Fe14B/α-Fe hybrid magnets,” J. Magn. Magn. Mater., 303, e410–e414 (2006).

H.W. Kwon and G.C. Hadjipanayis, “Magnetic and microstructural study of hybrid magnet consisting of Rrich and R-lean Nd–Fe–B alloys,” J. Magn. Magn. Mater., 310, 2575–2577 (2007).

H.W. Kwon and G.C. Hadjipanayis, “Anisotropy study of hybrid magnet consisting of Nd2Fe14B single phase and nanocomposite alloys,” J. Magn. Magn. Mater., 304, e252–e254 (2006).

A.M. Gabay, Y. Zhang, and G.C. Hadjipanayis, “Effect of Cu and Ga additions on the anisotropy of R2Fe14B/α-Fe nanocomposite die-upset magnets (R = Pr, Nd),” J. Magn. Magn. Mater., 302, 244–251 (2006).

I. Dirba, S. Sawatzki, and O. Gutfleisch, “Net-shape and crack-free production of Nd–Fe–B magnets by hot deformation,” J. Alloys Compd., 589, 301–306 (2014).

L. Xiaoya, L. Yuping, and H. Lianxi, “Nanocrystalline NdFeB magnet prepared by mechanically activated disproportionation and desorption-recombination in-situ sintering,” J. Magn. Magn. Mater., 330, 25–30 (2013).

J.W. Kim, S.H. Kim, S.Y. Song, and Y. Do Kim, “Nd–Fe–B permanent magnets fabricated by low temperature sintering process,” J. Alloys Compd., 551, 180–184 (2013).

O. Gutfleisch and I.R. Harris, “Fundamental and practical aspects of the hydrogenation, disproportionation, desorption and recombination process,” J. Phys. D: Appl. Phys., 29, 2255–2265 (1996).

I.I. Bulyk, V.V. Chabanenko, A. Nabiałek, T. Zajarniuk, A. Szewczyk, R. Puźniak, V.V. Burkhovetskyi, V.Yu. Tarenkov, J. Wróbel, and I.V. Borukh, “Enhanced coercivity in SmCo5 magnet subjected to hydrogen treatment,” J. Alloys Compd., 866, Article No. 158272 (2021), https://doi.org/10.1016/j.jallcom.2020.158272.

I.I. Bulyk, “Use of hydrogen for producing sintered anisotropic nanostructured magnets from rare-earth and transition metal alloys,” Fiz.-Khim. Mekh. Mater., No. 6, 10–23 (2018).

H. Sepehri-Amin, I. Dirba, Xin Tang, T. Ohkubo, T. Schrefl, O. Gutfleisch, and K. Hono, “Development of high coercivity anisotropic Nd–Fe–B/Fe nanocomposite powder using hydrogenation disproportionation desorption recombination process,” Acta Mater., 175, 276–285 (2019), https://doi.org/10.1016/j.actamat.2019.06.017.

A. Trostianchyn, I. Bulyk, and Z. Duriagina, “The influence of iron content on the phase-structural state of the alloy based on Sm2Co17 compound during hydrogen-vacuum treatment,” Funct. Mater., 28, No. 3, 497–504 (2021), https://doi.org/10.15407/fm28.03.497.

CCP14, access mode: http://www.ccp14.ac.uk.

FullProf Suite, access mode: http://www.ill.eu/sites/fullprof.

J. Fidler, J. Bernardi, and T. Schrefl, “Permanent magnets—new microstructural aspects,” Scr. Metall. Mater., 33, 1781–1791 (1995).

A.J. Williams, O. Gutfleisch, and I.R. Harris, “S-HDDR induced cavitation in NdFeB,” J. Alloys Compd., 232, L22−L26 (1996).

N. Cannesan and I.R. Harris, “Aspects of NdFeB HDDR powders: fundamentals and processing,” in: G.C. Hadjipanayis (ed.), Bonded Magnets, NATO Science Series: II. Mathematics, Physics and Chemistry, Vol. 118 (2002), pp. 13–36.

V.A. Goltsov, S.B. Rybalka, D. Fruchart, and V. Didus, “Kinetics and same general features of hydrogen induced diffusive phase transformations in Nd2Fe14B type alloys,” in: V.A. Goltsov (ed.), Progress in Hydrogen Treatment of Materials, Kassiopeya, Donetsk–Coral Gables (2001), pp. 368–390.

V.I. Pokhmurskii and V.V. Fedorov, Effect of Hydrogen on Diffusion Processes in Metals [in Ukrainian], FMI NANU, Lviv (1998), p. 206.

Ya.E. Geguzin, Physics of Sintering [in Russian], Nauka, Moscow (1984), p. 311.

V.V. Skorokhod and S.M. Solonin, Physical and Metallurgical Fundamentals of Powder Sintering [in Russian], Metallurgiya, Moscow (1984), p. 159.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 61, Nos. 11–12 (548), pp. 33–48, 2022

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bulyk, I.I., Borukh, I.V. Sintering of Ferromagnetic Materials at Lower Temperatures in Hydrogen. II. Nd–Fe–B Alloys. Powder Metall Met Ceram 61, 657–669 (2023). https://doi.org/10.1007/s11106-023-00354-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00354-9