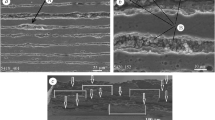

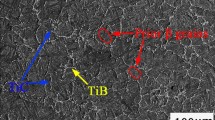

The paper examines three microlayer Ti/TiAl3 materials of initial Ti–Al composition, which were produced through reactive sintering and rolling of packets consisting of alternating titanium and aluminum ribbons of varying thickness at 600, 700, and 770°C. Young’s modulus of these materials was determined under longitudinal vibrations at room temperature with a frequency of about 45 kHz and under resonant bending vibrations at high temperatures ranging from 20 to 820°C with a frequency a hundred times lower. The temperature dependences of the elastic modulus E for the microlayer materials exhibited slopes between those of the dependences for titanium and the well- known VT25U alloy. The Ti/TiAl3 materials were heated and held at 700°C to result in a material with stable E values, surpassing those of the VT25U alloy at temperatures up to 700°C. The dependences of stresses in the samples on the relative power of the test installation were determined at constant temperatures of 650 and 700°C for the microlayer Ti/TiAl3 and VT25U materials. The microlayer materials dissipated a significantly larger portion of mechanical vibration energy than the heat-resistant VT25U material. The difference in the fatigue resistance mechanisms for the microlayer and isotropic materials at high temperatures is not solely attributed to their distinct temperature dependences of Young’s modulus at atomic interaction levels. The difference primarily arises from the variation in temperature-dependent cyclic strains associated with dislocations at microstructural and macrostructural levels. A fatigue crack is shown to delaminate the material in the middle of the intermetallic layers.

Similar content being viewed by others

References

T.P. Pavlova, O.S. Kashapov, and N.A. Nochovnaya, “Titanium alloys for gas turbine engines,” VIAM/2011-205852, July 2011, https://viam.ru/public/files/2011/2011-205852.pdf.

S.O. Firstov, L.D. Kulak, M.M. Kuz’menko, and O.M. Shevchenko, “Alloys of the Ti–Al–Zr–Si system intended for operation at high temperatures,” Mater. Sci., 54, No. 6, 783–788 (2019).

Yu.F. Lugovskoy, L.D. Kulak, N.N. Kuzmenko, O.V. Datskevich, and S.A. Spiridonov, “Effect of the composition, structure, and heat treatment of new heat-resistant titanium alloys in the Ti–Al–Si–Zr system on their mechanical properties,” Elektron. Mikrosk. Prochn. Mater., Issue 21, 107–117 (2015).

Q.B. Kuang, L.M. Zou, Y.X. Cai, X. Liu, and H.W. Xie, “Microstructure and properties of high temperature titanium alloys with a high Si content prepared by powder metallurgy,” Mater. Trans., 58, No. 12, 1735–1741 (2017).

Michael Dahms, “Gamma titanium aluminide research and applications in Germany and Austria,” Adv. Perform. Mater., 1, 157–182 (1994).

D.L. Davidson and J.B. Campbell, “Fatigue crack growth through the lamellar microstructure of an alloy based on TiAl at 25 °C and 800°C,” Metall. Mater. Trans. A, 24A, 1555–1574 (1993).

D.E. Alman, J.C. Rawers, and J.A. Hawk, “Microstructural and failure characteristics of metal–intermetallic layered sheet composites,” Metall. Mater. Trans. A., 26A, 589–599 (1995).

T.E.J. Edwardsa, F.D. Gioacchino, and W.J. Clegg, “High resolution digital image correlation mapping of strain localization upon room and high temperature, high cycle fatigue of a TiAl intermetallic alloy,” Int. J. Fatigue, 142, 105905 (2021).

Xiaohui Zhao, Guilian Xue, and Yu Liu, “Gradient crystalline structure induced by ultrasonic impacting and rolling and its effect on fatigue behavior of TC11 titanium alloy,” Results Phys. (2017), https://doi.org/10.1016/j.rinp.2017.05.026.

E.I. Krasnov, A.S. Shteinberg, A.A. Shavnev, and V.V. Berezovskii, “Study of the layered Ti–TiAl3 metal composite material,” Aviat. Mater. Tekhnol., No. 3, 16–19 (2013).

Yu.F. Lugovskoi, V.A. Nazarenko, N.V. Minakov, S.A. Spiridonov, and V.N. Nishchenets, “Mechanical properties of microlayered Ti–Al materials in static and cyclic loading,” Powder Metall. Met. Ceram., 59, No. 5–6, 350–358 (2020).

K.O. Gogaev, V.A. Nazarenko, and Yu.F. Lugovskoy, Method of Producing Metal Laminate Billets. Ukrainian Utility Patent No. 107192 [in Ukrainian], reg. May 25, 2016; Bulletin No. 10.

Grade Guides for Steels and Alloys [in Russian], http://www.splavkharkov.com/mat_start.php?name_id=3290.

V.A. Kuzmenko, Sonic and Ultrasonic Vibrations under Dynamic Material Testing [in Russian], Izd. AN USSR, Kyiv (1963), p. 152.

Yu.F. Lugovskoy and V.A. Kuzmenko, Method for Determining the Elastic Moduli at High Temperatures. USSR Inventor’s Certificate No. 1769062 [in Russian] (1992), Bulletin No. 38.

A.P. Babichev, N.A. Babushkina, and A.M. Bratkovskii, Physical Quantities: Handbook [in Russian], I.S. Grigoriev and E.Z. Meilikhov (eds.), Energoatomizdat, Moscow (1991), p. 1232.

Yu.F. Lugovskoy, K.Yu. Yakovchuk, and A.V. Mikitchik, Method for Determining the Mechanical Characteristics of Materials. Utility Patent No. 140645, publ. March 10, 2020; Bulletin No. 5.

Yu.F. Lugovskoi, K.Yu. Yakovchuk, and A.V. Mikitchik, “Effectiveness reduction of cyclic stresses in coated samples,” Powder Metall. Met. Ceram., 59, No. 1–2, 68–75 (2020).

Yu.F. Lugovskoy, “Methodology for fatigue bending tests of composite materials produced by electronbeam physical vapor deposition,” Probl. Spets. Elektrometall., No. 4, 61–65 (1987).

B.A. Gryaznov, S.S. Gorodetskii, Yu.S. Nalimov, L.A. Zaslotskaya, I.A. Makovetskaya, L.F. Shestopal, and A.A. Rabinovich, Fatigue of Heat-Resistant Alloys and Blades of Gas Turbine Engines [in Russian], V.T Troshchenko (ed.), Naukova Dumka, Kyiv (1992), p. 264.

Acknowledgments

The authors are grateful to ScD V.P. Solntsev for consultation in developing the studied materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 61, Nos. 11–12 (548), pp. 127–141, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lugovskoy, Y.F., Nazarenko, V.A., Zorin, V.A. et al. Temperature Dependences of the Mechanical Properties of Microlayer Ti/TiAl3 Composites Under Cyclic Loading. Powder Metall Met Ceram 61, 736–747 (2023). https://doi.org/10.1007/s11106-023-00360-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00360-x