Abstract

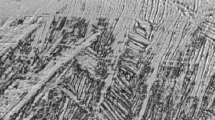

The effect of a pulsed current on titanium tensile deformation obtained by postdeformation annealing after cold rolling of the coarse-grained and ultrafine-grained states has been considered. The effect of the duty cycle of the pulse current over a wide range on the shape of the stress–strain curves and mechanical properties has been studied. It is shown that an increase in the duty cycle results in an enhancement in the thermal effect of the current and a decrease in the flow stresses, strength, and plasticity, as well as in intense necking. A decrease in the duty cycle leads to the absence of heating and the occurrence of the electroplastic effect and an increase in the strength and plasticity, which depends on the structural state of coarse-grained titanium and the method of titanium production. The possible physical mechanisms of hardening associated with twinning, strain aging, and low-cycle fatigue have been considered.

Similar content being viewed by others

REFERENCES

Troitskii, O.A., Baranov, Yu.V., Avraamov, Yu.S., and Shlyapin, A.D., Fizicheskie osnovy i tekhnologii obrabotki sovremennykh materialov (teoriya, tekhnologiya, struktura i svoistva) (Physical Foundations and Technologies for Processing Modern Materials: Theory, Technology, Structure, and Properties), Moscow: Institut Komp’yuternykh Tekhnologii, 2004, vol. 1.

Conrad, H., Effects of electric current on solid state phase transformations in metals, Mater. Sci. Eng., A, 2000, vol. 287, no. 2, pp. 227–237. https://doi.org/10.1016/S0921-5093(00)00780-2

Troitskii, O.A., Electromechanical effect in metals, Zh. Eksp. Teor. Fiz. Pisma Redaktisiyu, 1969, no. 1, p. 18.

Varma, S.K. and Cornwell, L.R., The electroplastic effect in aluminum, Scr. Metall., 1979, vol. 13, no. 8, pp. 733–738. https://doi.org/10.1016/0036-9748(79)90146-7

Roh, J., Seo, J.-J., Hong, S.-T., Kim, M.-J., Han, H.N., and Roth, J.T., The mechanical behavior of 5052-H32 aluminum alloys under a pulsed electric current, Int. J. Plast., 2014, vol. 58, pp. 84–99. https://doi.org/10.1016/j.ijplas.2014.02.002

Xu, X., Zhao, Y., Ma, B., and Zhang, M., Rapid precipitation of T-phase in the 2024 aluminum alloy via cyclic electropulsing treatment, J. Alloys Compd., 2014, vol. 610, pp. 506–510. https://doi.org/10.1016/j.jallcom.2014.05.063

Wu, W., Wang, Y., Wang, J., and Wei, S., Effect of electrical pulse on the precipitates and material strength of 2024 aluminum alloy, Mater. Sci. Eng., A, 2014, vol. 608, pp. 190–198. https://doi.org/10.1016/j.msea.2014.04.071

Li, X., Tang, G., Kuang, J., Li, X., and Zhu, J., Effect of current frequency on the mechanical properties, microstructure and texture evolution in AZ31 magnesium alloy strips during electroplastic rolling, Mater. Sci. Eng., A, 2014, vol. 612, pp. 406–413. https://doi.org/10.1016/j.msea.2014.06.075

Sánchez Egea, A.J., González Rojas, H.A., Celentano, D.J., Travieso-Rodríguez, J.A., and Llumà i Fuentes, J., Electroplasticity-assisted bottom bending process, J. Mater. Process. Technol., 2014, vol. 214, no. 11, pp. 2261–2267. https://doi.org/10.1016/j.jmatprotec.2014.04.031

Guo, D., Deng, W., Song, P., Lv, X., Shi, Y., Qu, Z., and Zhang, G., Effect of strain rate on microstructure and mechanical properties of electroplastic rolled ZrTi alloys, Adv. Eng. Mater., 2022, vol. 24, no. 7, p. 2101366. https://doi.org/10.1002/adem.202101366

Sheng, Yi., Hua, Yo., Wang, X., Zhao, X., Chen, L., Zhou, H., Wang, J., Berndt, C.C., and Li, W., Application of high-density electropulsing to improve the performance of metallic materials:mechanisms, Materials, 2018, vol. 11, no. 2, p. 185. https://doi.org/10.3390/ma11020185

Kim, M.-J., Lee, M.-G., Hariharan, K., Hong, S.-T., Choi, I.-S., Kim, D., Oh, K.H., and Han, H.N., Electric current-assisted deformation behavior of Al–Mg–Si alloy under uniaxial tension, Int. J. Plast., 2017, vol. 94, pp. 148–170. https://doi.org/10.1016/j.ijplas.2016.09.010

Indhiarto, I., Shimizu, T., Furushima, T., and Yang, M., Effect of DC pulsed-current on deformation behavior of magnesium alloy thin sheets, Procedia Manuf., 2018, vol. 15, pp. 1663–1670. https://doi.org/10.1016/j.promfg.2018.07.270

Stolyarov, V., Korolkov, O., Pesin, A., and Raab, G., Deformation behavior under tension with pulse current of ultrafine-grain and coarse-grain CP titanium, Materials, 2023, vol. 16, no. 1, p. 191. https://doi.org/10.3390/ma16010191

Rudolf, C., Goswami, R., Kang, W., and Thomas, J., Effects of electric current on the plastic deformation behavior of pure copper, iron, and titanium, Acta Mater., 2021, vol. 209, no. 1, p. 116776. https://doi.org/10.1016/j.actamat.2021.116776

Stolyarov, V.V., Zhu, Y.T., Alexandrov, I.V., Lowe, T.C., and Valiev, R.Z., Influence of ECAP routes on the microstructure and properties of pure Ti, Mater. Sci. Eng., A, 2001, vol. 299, nos. 1–2, pp. 59–67. https://doi.org/10.1016/S0921-5093(00)01411-8

Rudolf, C., Goswami, R., Kang, W., and Thomas, J., Effects of electric current on the plastic deformation behavior of pure copper, iron, and titanium, Acta Mater., 2021, vol. 209, p. 116776. https://doi.org/10.1016/j.actamat.2021.116776

Demler, E., Gershtein, G., Dalinger, A., Nürnberger, F., Epishin, A., and Molodov, D.A., Effect of electrical pulses on the mechanical behavior of single crystals of nickel-based CMSX-4 superalloy and the mobility of low-angle grain boundary in aluminum bicrystals, Bull. Russ. Acad. Sci.: Phys., 2018, vol. 82, no. 9, pp. 1079–1085. https://doi.org/10.3103/S106287381809006X

Savenko, V.S., Troitskii, O.A., and Gunenko, A.V., Physical aspects of electroplastic deformation of metals, Vestn. Brestskogo Univ. Fiz. Mat., 2018, vol. 4, no. 1, pp. 40–47.

Zhao, Sh., Zhang, R., Chong, Ya., Li, X., Abu-Odeh, A., Rothchild, E., Chrzan, D.C., Asta, M., Morris, Jr., J.W., and Minor, A.M., Defect reconfiguration in a Ti-Al alloy via electroplasticity, Nat. Mater., 2021, vol. 20, pp. 468–472. https://doi.org/10.1038/s41563-020-00817-z

Pakhomov, M.A. and Stolyarov, V.V., Specific features of electroplastic effect in mono-and polycrystalline aluminum, Met. Sci. Heat Treat., 2021, vol. 63, pp. 236–242. https://doi.org/10.1007/s11041-021-00677-7

Lee, H.P., Esling, C., and Bunge, H.J., Development of the rolling texture in titanium, Textures Microstruct., 1988, vol. 7, p. 562818. https://doi.org/10.1155/TSM.7.317

Zherebtsov, S.V., Dyakonov, G.S., Salem, A.A., Malysheva, S.P., Salishchev, G.A., and Semiatin, S.L., Evolution of grain and subgrain structure during cold rolling of commercial-purity titanium, Mater. Sci. Eng., A, 2011, vol. 528, no. 9, pp. 3474–3479. https://doi.org/10.1016/j.msea.2011.01.039

Stolyarov, V.V., Zeipper, L., Mingler, B., and Zehetbauer, M., Influence of postdeformation on CP-Ti processed by equal channel angular pressing, Mater. Sci. Eng., A, 2008, vol. 476, nos. 1–2, pp. 98–105. https://doi.org/10.1016/j.msea.2007.04.069

Lee, T., Magargee, J., Ng, M.K., and Cao, J., Constitutive analysis of electricallyassisted tensile deformation of CP-Ti based on non-uniform thermal expansion, plastic softening and dynamic strain aging, Int. J. Plast., 2017, vol. 94, pp. 44–56. https://doi.org/10.1016/j.ijplas.2017.02.012

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation under agreement no. 075-15-2021-709, project no. RF-2296 61321X0037 (control measurements).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Stolyarov, V.V. Role of the Pulse Current Duty Cycle during Titanium Tension. J. Mach. Manuf. Reliab. 52, 313–319 (2023). https://doi.org/10.3103/S1052618823040167

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618823040167