Abstract

The pollutant control performance of exhaust hoods plays a crucial role in the indoor air quality and energy consumption of ventilation systems in industrial buildings. To better understand the impact of local ventilation on the industrial indoor environment, this paper presents a literature review of exhaust hood performance and its improvement technologies. To create an index for evaluating the performance of exhaust hoods, the capture velocity, capture efficiency, flow ratio of pollutant emissions and exhaust airflow and energy consumption are first introduced. A number of factors affecting exhaust hood performance are assessed such as hood type, hood opening size, exhaust rate, installation distance, pollution source emission and environmental disturbance. Compared to structural improvement methods, the use of active airflow is a more effective way to improve the exhaust hood performance. The most commonly used methods for determining the exhaust rate are the controlled speed method and the flow ratio method. The use of an exhaust hood with an appropriate exhaust rate and jet parameters (for an active air-assisted hood) can effectively improve the pollutant control performance and reduce the energy consumption that would be wasted on the redundant exhaust rate. With more information focused on exhaust hood performance, this work suggests more effective strategies for improving indoor air quality and reducing energy consumption in industrial buildings.

Similar content being viewed by others

References

Andersson L, Hedbrant A, Persson A, et al. (2021). Inflammatory and coagulatory markers and exposure to different size fractions of particle mass, number and surface area air concentrations in the Swedish hard metal industry, in particular to cobalt. Biomarkers, 26: 557–569.

ATSDR (1995). Toxicological profile for polycyclic aromatic hydrocarbons. Agency for Toxic Substances, US Department of Health and Human Services. US Government Printing Office, 1995-639-298.

Awbi HB (2003). Ventilation of Buildings. London: Taylor and Francis.

Bellia L, Betta V, Cascetta F (1998). Description of velocity fields in front of exhaust axisymmetric inlets by means of new empirical equations. Building and Environment, 33: 189–195.

Betta V, Cascetta F, Labruna P, et al. (2004). A numerical approach for air velocity predictions in front of exhaust flanged slot openings. Building and Environment, 39: 9–18.

Betta V, Cascetta F, Palombo A (2007). Push-pull ventilation system: a CFD approach for the performance analysis. International Journal of Ambient Energy, 28: 123–134.

Braconnier R (1988). Bibliographic review of velocity fields in the vicinity of local exhaust hood openings. American Industrial Hygiene Association Journal, 49: 185–198.

Cao Z, Wang Y, Duan M, et al. (2017). Study of the vortex principle for improving the efficiency of an exhaust ventilation system. Energy and Buildings, 142: 39–48.

Cascetta F (1996). Experimental evaluation of the velocity fields for local exhaust hoods with circular and rectangular openings. Building and Environment, 31: 437–449.

Cascetta F, Bellia L (1996). Velocity fields in proximity of local exhaust hood openings: an intercomparison between current recommended formulas and experimental studies. Building and Environment, 31: 451–459.

Cascetta F, Rosano FM (2001). Assessment of velocity fields in the vicinity of rectangular exhaust hood openings. Building and Environment, 36: 1137–1141.

Chen ML, Chen CJ, Yeh WY, et al. (2003). Heat stress evaluation and worker fatigue in a steel plant. AIHA Journal, 64: 352–359.

Chen C, Zhao Y, Zhao B (2018a). Emission rates of multiple air pollutants generated from Chinese residential cooking. Environmental Science & Technology, 52: 1081–1087.

Chen W, Liu J, Mak CM (2018b). Near fields of annular slotted hoods measured via 2D-PIV. Building and Environment, 144: 1–8.

Chen J (2022). Changing patterns of the flow ratio with the distance of exhaust and supply hood in a parallel square push-pull ventilation. International Journal of Environmental Research and Public Health, 19: 2957.

Devienne R, Fontaine JR, Kicka J, et al. (2009). Experimental characterization of a plume of passive contaminant above a thermal source: capture efficiency of a fume extraction hood. The Annals of Occupational Hygiene, 53: 739–748.

Diggs DL, Huderson AC, Harris KL, et al. (2011). Polycyclic aromatic hydrocarbons and digestive tract cancers: A perspective. Journal of Environmental Science and Health Part C, Environmental Carcinogenesis & Ecotoxicology Reviews, 29: 324–357.

Dost AA, Redman D, Cox G (2000). Exposure to rubber fume and rubber process dust in the general rubber goods, tyre manufacturing and retread industries. The Annals of Occupational Hygiene, 44: 329–342.

Dygert RK, Dang TQ (2012). Experimental validation of local exhaust strategies for improved IAQ in aircraft cabins. Building and Environment, 47: 76–88.

Engels LH, Willert G (1973). Kriterien und Moglichkeiten zur Erfassung des Staubes in Industriebetrieben [Criteria and possibilities for the capture of dust in industrial plants]. Staub-Reinhalt Luft, 33: 140–141. (in German)

Fan J, Yang Y, Wang Y, et al. (2022a). Droplet control of a local exhaust hood enhanced by air curtains. Journal of Building Engineering, 59: 105092.

Fan J, Yang Y, Wang Y, et al. (2022b). Emission and local ventilation control of droplets generated by condensation and bubble-bursting during pickling. Sustainable Cities and Society, 76: 103491.

Fletcher B (1977). Centreline velocity characteristics of rectangular unflanged hoods and slots under suction. The Annals of Occupational Hygiene, 20: 141–146.

Fletcher B (1982). Centreline velocity characteristics of local exhaust ventilation hoods. American Industrial Hygiene Association Journal, 43: 626–627.

Fletcher B (1995). The design of local exhaust ventilation hoods for grinding wheels. The Annals of Occupational Hygiene, 39: 535–543.

Fletcher B, Saunders CJ (1991). Private Communication. Sheffield, UK: Health and Safety Executive.

Flynn MR, Ellenbecker MJ (1985). The potential flow solution for air flow into a flanged circular hood. American Industrial Hygiene Association Journal, 46: 318–322.

Flynn MR, Ellenbecker MJ (1986). Capture efficiency of flanged circular local exhaust hoods. The Annals of Occupational Hygiene, 30: 497–513.

Flynn MR (2003). On the inertial range of particles under the influence of local exhaust hoods. The Annals of Occupational Hygiene, 47: 151–156.

Garrison RP, Byers DH (1980a). Static pressure and velocity characteristics of circular nozzles for high velocity/low volume exhaust ventilation. American Industrial Hygiene Association Journal, 41: 803–811.

Garrison RP, Byersb DH (1980b). Static pressure, velocity, and noise characteristics of rectangular nozzles for high velocity/low volume exhaust ventilation. American Industrial Hygiene Association Journal, 41: 855–863.

Garrison RP (1983). Velocity calculation for local exhaust inlets—Empirical design equations. American Industrial Hygiene Association Journal, 44: 937–940.

He X, Lewis BV, Guffey SE (2018). Experimental study on centerline velocities of a rectangular capture hood under realistic conditions. Journal of Occupational and Environmental Hygiene, 15: 125–132.

Huang RF, Chen JL, Chen YK, et al. (2001a). The capture envelope of a flanged circular hood in cross drafts. AIHAJ, 62: 199–207.

Huang RF, Sir SY, Chen YK, et al. (2001b). Capture envelopes of rectangular hoods in cross drafts. AIHAJ, 62: 563–572.

Huang R, Lin, SY, Jan SY, et al. (2005). Aerodynamic characteristics and design guidelines of push-pull ventilation systems. Annals of Occupational Hygiene, 49: 1–15.

Huang Y, Wang Y, Liu L, et al. (2015). Reduced-scale experimental investigation on ventilation performance of a local exhaust hood in an industrial plant. Building and Environment, 85: 94–103.

Huang Y, Wang Y, Ren X, et al. (2016). Ventilation guidelines for controlling smoke, dust, droplets and waste heat: Four representative case studies in Chinese industrial buildings. Energy and Buildings, 128: 834–844.

Huang Y, Lu K, Guo J, et al. (2020a). Study on ventilation performance of lateral exhaust hood under the influence of two high-temperature buoyant jets. Building and Environment, 177: 106849.

Huang Y, Lu K. Wang Y (2020b). Study on limit flow ratio method for a lateral exhaust hood above high-temperature buoyant jets. Sustainable Cities and Society, 54: 101969.

Hunt GR, Ingham DB (1996). Long range exhaustion—A mathematical model for the axisymmetric air flow of a local exhaust ventilation hood assisted by a turbulent radial jet. The Annals of Occupational Hygiene, 40: 171–196.

Julander A, Hindsén M, Skare L, et al. (2009). Cobalt-containing alloys and their ability to release cobalt and cause dermatitis. Contact Dermatitis, 60: 165–170.

Karaismail E, Celik I, Guffey SE, et al. (2008). Numerical and experimental investigations on hood capture and protection efficiencies. In: Proceedings of FEDSM 2008, Jacksonville, FL, USA.

Karimi Zeverdegani S, Mehrifar Y, Faraji M, et al. (2017). Occupational exposure to welding gases during three welding processes and risk assessment by SQRCA method. Journal of Occupational Health and Epidemiology, 6: 144–149.

Kim KH, Jahan SA, Kabir E, et al. (2013). A review of airborne polycyclic aromatic hydrocarbons (PAHs) and their human health effects. Environment International, 60: 71–80.

Kjellstrom T, Crowe J (2011). Climate change, workplace heat exposure, and occupational health and productivity in central America. International Journal of Occupational and Environmental Health, 17: 270–281.

Klasson M, Lindberg M, Bryngelsson IL, et al. (2017). Biological monitoring of dermal and air exposure to cobalt at a Swedish hard metal production plant: does dermal exposure contribute to uptake?. Contact Dermatitis, 77: 201–207.

Kulmala I (1995). Numerical simulation of the capture efficiency of an unflanged rectangular exhaust opening in a coaxial air flow. The Annals of Occupational Hygiene, 39: 21–33.

Kulmala I, Saarenrinne P (1996). Air flow near an unflanged rectangular exhaust opening. Energy and Buildings, 24: 133–136.

Kulmala I (2000). Experimental validation of potential and turbulent flow models for a two-dimensional jet enhanced exhaust hood. AIHAJ, 61: 183–191.

Kulmala I, Hynynen P, Welling I, et al (2007). Local ventilation solution for large, warm emission sources. The Annals of Occupational Hygiene, 51: 35–43.

Lee S, Lee JW (2005). A new local ventilation system using a vortex flow generated with a finned rotating annular disk. ASHRAE Transactions, 111(1): 149–158.

Leikauf GD, Kim SH, Jang AS (2020). Mechanisms of ultrafine particle-induced respiratory health effects. Experimental & Molecular Medicine, 52: 329–337.

Liu L, Dai J, Yang J, et al. (2019). Intelligent simulation experimental study on influence of air velocity of air supply hood and exhaust hood with vertical push-pull ventilation. Journal of Intelligent & Fuzzy Systems, 37: 4819–4826.

Logachev KI, Ziganshin AM, Averkova OA, et al. (2018). A survey of separated airflow patterns at inlet of circular exhaust hoods. Energy and Buildings, 173: 58–70.

Logachev KI, Ziganshin AM, Averkova OA (2019). On the resistance of a round exhaust hood, shaped by outlines of the vortex zones occurring at its inlet. Building and Environment, 151: 338–347.

Logachev KI, Ziganshin AM, Averkova OA (2020). A study of separated flows at inlets of flanged slotted hoods. Journal of Building Engineering, 29: 101159.

Logachev KI, Ziganshin AM, Huang Y, et al. (2022). Investigating changes in geometric dimensions of vortex zones at the inlet of an exhaust hood set over a plane. Building and Environment, 222: 109377.

Logachev KI, Ziganshin AM, Huang Y, et al. (2023). Developing a mathematical simulation method for three-dimensional separated airflow at inlet of local exhaust devices. Journal of Building Engineering, 63: 105490.

Madsena U, Fontaine JR, Nielsenc PV, et al. (1996). A numerical study of dispersion and local exhaust capture of aerosols generated from a variety of sources and airflow conditions. American Industrial Hygiene Association Journal, 57: 134–141.

Marczynski B, Pesch B, Wilhelm M, et al. (2009). Occupational exposure to polycyclic aromatic hydrocarbons and DNA damage by industry: a nationwide study in Germany. Archives of Toxicology, 83: 947–957.

Marzal F, González E, Miñana A, et al. (2002). Influence of push element geometry on the capture efficiency of push-pull ventilation systems in surface treatment tanks. The Annals of Occupational Hygiene, 46: 383–393.

Morteza MM, Hossein K, Amirhossein M, et al. (2013). Designing, construction, assessment, and efficiency of local exhaust ventilation in controlling crystalline silica dust and particles, and formaldehyde in a foundry industry plant. Archives of Industrial Hygiene and Toxicology, 64: 123–131.

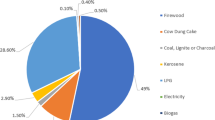

National Bureau of Statistics (2021). China Statistical Yearbook-2021. Beijing: China Statistics Press. (in Chinese)

Nielsen PV, Madsen U, Tveit, DJ (1991). Experiments on an exhaust hood for the paint industry. In: Proceedings of ROOMVENT 1991, Cincinnati, OH, USA.

Oh YK, Kim YS, Yoon HS (2008). A study on improvement capture velocity for increasing inhalation efficiency of hood in local ventilation system. Advanced Materials Research, 47–50: 1039–1042.

Pech O, Pavelek M (2013). Capture efficiency measurement of pollutants over a workbench with the reinforced slot exhaust system. EPJ Web of Conferences, 45: 01072.

Pinelli M, Suman A (2014). A numerical method for the efficient design of free opening hoods in industrial and domestic applications. Energy, 74: 484–493.

Pope CA, Burnett RT, Thurston GD, et al. (2004). Cardiovascular mortality and long-term exposure to particulate air pollution: epidemiological evidence of general pathophysiological pathways of disease. Circulation, 109: 71–77.

Rahman MM, Alam K, Velayutham E (2021). Is industrial pollution detrimental to public health? Evidence from the world’s most industrialised countries. BMC Public Health, 21: 1175.

Rehfisch P, Anderson M, Berg P, et al. (2012). Lung function and respiratory symptoms in hard metal workers exposed to cobalt. Journal of Occupational & Environmental Medicine, 54: 409–413.

Robinson M, Ingham DB (2003). Design and operating parameters for push-pull ventilation of open surface tanks. International Journal of Energy Research, 27: 757–770.

Rota R, Nano G, Canossa L (2001). Design guidelines for push-pull ventilation systems through computational fluid dynamics modeling. AIHAJ, 62: 141–148.

Saunders CJ, Fletcher B (1993). Jet enhanced local exhaust ventilation. The Annals of Occupational Hygiene, 37: 15–24.

Silverman L (1942a). Centerline velocity characteristics of round opening under suction. Journal of Industrial Hygiene Toxicology, 24: 257–266.

Silverman L (1942b). Velocity characteristics of narrow exhaust slots. Journal of Industrial Hygiene Toxicology, 24: 267–276.

Song Y, Yang X, Zhang Z, et al. (2022). A study on the pollutant control effect of a new push-pull exhaust hood under different pollutant velocities. Journal of Building Engineering, 53: 104570.

Stölzel M, Breitner S, Cyrys J, et al. (2007). Daily mortality and particulate matter in different size classes in Erfurt, Germany. Journal of Exposure Science & Environmental Epidemiology, 17: 458–467.

Sun G (1978). The flow ratio method for calculating the exhaust rate of the exhaust hood. Heating Ventilating & Air Conditioning, 197(3): 34–38. (In Chinese)

Tsai FC, Hsieh RH (2006). Oblique effects on the capture ability of a hood under crosswind environments—Numerical method. Building and Environment, 41: 1471–1477.

Dalla Valle JM (1932). Velocity characteristics of hoods under suction. Heating, Piping and Air conditioning, 4: 370–375.

Dalla Valle JM, Hatch T (1932). Studies in the design of local exhaust hoods. Transactions of the American Society of Mechanical Engineers, 54(11): 31–37.

Dalla Valle JM (1952). Exhaust Hoods, 2nd edn. New York: Industrial Press.

Vekteris V, Tetsman I, Mokshin V (2017). Investigation of the efficiency of the lateral exhaust hood enhanced by aeroacoustic air flow. Process Safety and Environmental Protection, 109: 224–232.

Wang P, Feng T, Liu R (2010). Characteristics study of the swirl air curtain exhaust hood. In: Proceedings of 2010 4th International Conference on Bioinformatics and Biomedical Engineering, Chengdu, China.

Wang Y, Yang Y, Wei Y, et al. (2014). Experimental investigation on the flow characteristics of an exhaust hood assisted by a jet. International Journal of Ventilation, 13: 89–100.

Wang Y, Cao Y, Liu B, et al. (2016a). An evaluation index for the control effect of the local ventilation systems on indoor air quality in industrial buildings. Building Simulation, 9: 669–676.

Wang Y, Gao J, Xing X, et al. (2016b). Measurement and evaluation of indoor thermal environment in a naturally ventilated industrial building with high temperature heat sources. Building and Environment, 96: 35–45.

Wang Y, Zou Y, Yang Y, et al. (2016c). Movement and control of evaporating droplets released from an open surface tank in the push-pull ventilation system. Building Simulation, 9: 443–457.

Wang Y, Quan M, Zhou Y (2019). Effect of velocity non-uniformity of supply air on the mixing characteristics of push-pull ventilation systems. Energy, 187: 115962.

Wang Y, Cao L, Huang Y, et al. (2020). Lateral ventilation performance for removal of pulsating buoyant jet under the influence of high-temperature plume. Indoor and Built Environment, 29: 543–557.

Wang J, Huo Q, Zhang T, et al. (2021). Performance evaluation for a coupled push-pull ventilation and air curtain system to restrict pollutant dispersion in a factory building. Journal of Building Engineering, 43: 103164.

Watson SI, Cain JR, Cowie H, et al. (2001). Development of a push-pull ventilation system to control solder fume. The Annals of Occupational Hygiene, 45: 669–676.

Wen X, Ingham DB (1998). A numerical simulation of the removal of contaminated air using an aaberg exhaust hood. Journal of Aerosol Science, 29: S489–S490.

Wen X, Ingham DB (2000). Theoretical and numerical predictions of two-dimensional Aaberg slot exhaust hoods. The Annals of Occupational Hygiene, 44: 375–390.

Wen X, Hunt GR, Ingham DB (2000). A boundary integral technique for the numerical modelling of the air flow for the Aaberg exhaust system. Engineering Analysis With Boundary Elements, 24: 477–484.

Wen X, Ingham DB, Fletcher B (2002). The numerical modelling of a two-dimensional local exhaust system associated with an inclined jet flow. Journal of Engineering Mathematics, 43: 367–384.

Wu X, Liu L, Luo X, et al. (2018). Study on flow field characteristics of the 90° rectangular elbow in the exhaust hood of a uniform push-pull ventilation device. International Journal of Environmental Research and Public Health, 15: 2884.

Yang Y, Wang Y, Song B, et al. (2018). Stability and accuracy of numerical investigation of droplet motion under local ventilation airflow. Building and Environment, 140: 32–42.

Zhang J, Wang J, Gao J, et al. (2020). Critical velocity of active air jet required to enhance free opening rectangular exhaust hood. Energy and Buildings, 225: 110316.

Zhang J, Wang J, Gao J, et al. (2021). Experimental and numerical study of the effect of perimeter jet enhancement on the capture velocity of a rectangular exhaust hood. Journal of Building Engineering, 33: 101652.

Zhao R, Qian H, Liu L, et al. (2020). Comprehensive performance evaluation of a novel Aaberg exhaust system reinforced by a swirling jet. Building and Environment, 167: 106451.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Zhang, J., Wang, J., Gao, J. et al. Exhaust hood performance and its improvement technologies in industrial buildings: A literature review. Build. Simul. 17, 23–40 (2024). https://doi.org/10.1007/s12273-023-1040-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12273-023-1040-2