Abstract

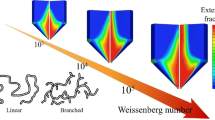

Vortex growth is related to the extensional thickness viscosity of polymer melts flowing through contractions, whereas the shear thinning viscosity results in no significant vortex. The nonlinearity of extensional viscosity in relation to molecular architectures and additive composition compositions is usually more sensitive than shear viscosity. Recently, the proposed GNF-X (Generalized Newtonian Fluid eXtended) of the weighted shear/extensional viscosity has been incorporated in the state-of-the-art CFD (computational fluid dynamics) framework to show the extension-induced vortex growth. Using GNF-X, it is important to investigate the conflicting role of shear thinning and extensional thickening on vortex sizes in 3D (three-dimensional) contraction flow simulations for branched and filled polymers melts. In particular, one demonstrates that the long-branched polymers and fiber-filled polymers strongly increase the vortex size, which is consistent with the related experimental observations.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Astarita G (1979) Objective and generally applicable criteria for flow classification. J Nonnewton Fluid Mech 6:69–76

Bird RB, Armstrong RC, Hassager O (1987) Dynamics of polymeric liquids: fluid mechanics, 2nd edn. Wiley-Interscience, New York

Bird RB, Wiest JM (1995) Constitutive equations for polymeric liquids. Annu Rev Fluid Mech 27:169–193

Boger DV, Crochet MJ, Keiller RA (1992) On viscoelastic flows through abrupt contractions. J Nonnewton Fluid Mech 44:267–279

Chang R-Y, Yang W-H (2001) Numerical simulation of mold filling in injection molding using a three-dimensional finite volume approach. Int J Numer Meth Fluids 37:125–148

Cogswell FN (1972) Converging flow of polymer melts in extrusion dies. Polym Eng Sci 12:64–73

Cross MM (1979) Relation between viscoelasticity and shear-thinning behaviour in liquids. Rheol Acta 18:609–614

Favaloro AJ, Tseng H-C, Pipes RB (2018) A new anisotropic viscous constitutive model for composites molding simulation. Compos A Appl Sci Manuf 115:112–122

Giesekus H (1982) A simple constitutive equation for polymer fluids based on the concept of deformation-dependent tensorial mobility. J Nonnewton Fluid Mech 11:69–109

Hedegaard AT, Gu L, Macosko CW (2015) Effect of extensional viscosity on cocontinuity of immiscible polymer blends. J Rheol 59:1397–1417

Laun HM (1984) Orientation effects and rheology of short glass fiber-reinforced thermoplastics. Colloid Polym Sci 262:257–269

Lipscomb GG II, Denn MM, Hur DU, Boger DV (1988) The flow of fiber suspensions in complex geometries. J Nonnewton Fluid Mech 26:297–325

Luo XL, Mitsoulis E (1990) A numerical study of the effect of elongational viscosity on vortex growth in contraction flows of polyethylene melts. J Rheol 34:309

Ma C-Y, White JL, Weissert FC, Min K (1985) Flow patterns in carbon black filled polyethylene at the entrance to a die. J Nonnewton Fluid Mech 17:275–287

Macosko CW (1994) Rheology: principles, measurements, and applications. WILEY-VCH, New York

Meissner J, Stephenson SE, Demarmels A, Portman P (1982) Multiaxial elongational flows of polymer melts—classification and experimental realization. J Nonnewton Fluid Mech 11:221–237

Mitsoulis E (2001) Numerical simulation of entry flow of the iupac-ldpe melt. J NonNewton Fluid Mech 97:13–30

Mitsoulis E, Kazatchkov IB, Hatzikiriakos SG (2005) The effect of slip in the flow of a branched Pp melt: experiments and simulations. Rheol Acta 44:418–426

Mitsoulis E, Schwetz M, Münstedt H (2003) Entry flow of ldpe melts in a planar contraction. J Nonnewton Fluid Mech 111:41–61

Mobuchon C, Carreau PJ, Heuzey M-C, Sepehr M, Ausias G (2005) Shear and extensional properties of short glass fiber reinforced polypropylene. Polym Compos 26:247–264

Morrison FA (2001) Understanding rheology. Oxford University, New York

Oldroyd JG (1950) On the formulation of rheological equations of state. Proc R Soci Lond 200:523

Park JM (2020) Comment on “a revisitation of generalized newtonian fluids.” J Rheol 64:1497

Petrie CJS (2006) Extensional viscosity: a critical discussion. J Nonnewton Fluid Mech 137:15–23

Phan-Thien N, Tanner RI (1977) A new constitutive equation derived from network theory. J Non-Newtonian Fluid Mech 2:353–365

Sarkar D, Gupta M (2001) Further investigation of the effect of elongational viscosity on entrance flow. J Reinf Plast Compos 20:1473–1484

Schunk PR, Scriven LE (1990) Constitutive equation for modeling mixed extension and shear in polymer solution processing. J Rheol 1085–1119:34

Souza Mendes PR, Padmanabhan M, Scriven LE, Macosko CW (1995) Inelastic constitutive equations for complex flows. Rheol Acta 34:209–214

Tanner RI (2007) Revisitation of Ptt model. J Cent South Univ Technol 14:26–29

Tseng H-C (2020) A revisitation of generalized newtonian fluids. J Rheol 64:493–504

Tseng H-C (2021) A revisitation of white-metzner viscoelastic fluids. Phys Fluids 33:057115

Tseng H-C (2023) Numerical visualization of extensional flows in injection molding of polymer melts. Int Polym Proc 38:175–182

Tseng H-C (2023) Three-dimensional simulation of vortex growth within entry flow of a polymer melt. Int Polym Proc 38:126–132

Tseng H-C, Favaloro AJ (2019) The use of informed isotropic constitutive equation to simulate anisotropic rheological behaviors in fiber suspensions. J Rheol 63:263–274

Wen Y-H, Wang C-C, Cyue G-S, Kuo R-H, Hsu C-H, Chang R-Y (2023) Extensional rheology of linear and branched polymer melts in fast converging flows. Rheol Acta 62:183–204

White JL, Kondo A (1977) Flow patterns in polyethylene and polystyrene melts during extrusion through a die entry region: measurement and interpretation. J Nonnewton Fluid Mech 3:41–64

White JL, Metzner AB (1963) Development of constitutive equations for polymeric melts and solutions. J Appl Polym Sci 7:867–1889

White SA, Gotsis AD, Baird DG (1987) Review of the entry flow problem: experimental and numerical. J Non Newton Fluid Mech 24:121–160

Zheng R, Tanner RI, Fan X-J (2011) Injection molding: integration of theory and modeling methods. Springer, Berlin

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tseng, HC. The conflicting role of shear thinning and extensional thickening on corner vertex within entry flow for branched and filled polymer melts. Korea-Aust. Rheol. J. 35, 349–360 (2023). https://doi.org/10.1007/s13367-023-00068-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-023-00068-9