Abstract

Purpose

Styrene–isoprene–styrene (SIS) block copolymer-based pressure-sensitive adhesives (PSAs) are used in many applications with various additives. These PSAs can provide proper adhesion and high cohesive strength in tape formulations. Potential advantages of increasing the content of LP are that the PSAs become more flexible, resulting in easier deforming along the body surface shape, which improves adhesion to the skin surface. However, it is important to maintain an appropriate balance between SIS copolymer and LP because an excessive amount of LP may reduce the adhesiveness and cohesive strength of the PSAs. Here we investigated the effect of varying percentages of liquid paraffin (LP) on SIS copolymer-based PSA formulations with the proportion of alicyclic saturated hydrocarbon resin fixed at 30%.

Methods

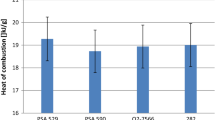

These formulations were assessed for their adhesion and peeling characteristics by measuring their viscoelasticity in the linear range and using peel adhesion and texture analysis tests. In addition, we evaluated the intermolecular interactions in these PSAs using differential scanning calorimetry and Fourier transform infrared spectroscopy.

Results

As the LP/SIS ratio exceeded 2.5, the adhesion performance of PSA declined. However, the 180° peel adhesion test and texture analysis revealed that peel adhesion decreased nonlinearly with increasing LP/SIS copolymer ratio. The adhesion distance remained unchanged, and no cohesive breakdown of the probe was observed when the LP/SIS copolymer ratio exceeded 2.5.

Conclusion

These results provide valuable information for regulating adhesion and peel characteristics of tape formulations by varying their LP/SIS copolymer ratio as the amount of adhesive agent remains fixed.

Similar content being viewed by others

Data Availability

The datasets generated and/or analyzed during the current study are not publicly available but are available from the corresponding author on reasonable request.

References

Pastore MN, Kalia YN, Horstmann M, Roberts MS. Transdermal patches: history, development, and pharmacology. Br J Pharmacol. 2015;172:2179–209. https://doi.org/10.1111/bph.13059.

Alexander A, Dwivedi S, Ajazuddin, Giri TK, Saraf S, Saraf S, et al. Approaches for breaking the barriers of drug permeation through transdermal drug delivery. J Control Release. 2012;164:26–40. https://doi.org/10.1016/j.jconrel.2012.09.017.

Prausnitz MR, Mitragotri S, Langer R. Current status and future potential of transdermal drug delivery. Nat Rev Drug Discov. 2004;3:115–24. https://doi.org/10.1038/nrd1304.

Cilurzo F, Gennari CG, Minghetti P. Adhesive properties: a critical issue in transdermal patch development. Expert Opin Drug Deliv. 2012;9:33–45. https://doi.org/10.1517/17425247.2012.637107.

Suksaeree J, Pichayakorn W, Monton C, Sakunpak A, Chusut T, Saingam W. Rubber polymers for transdermal drug delivery systems. Ind Eng Chem Res. 2014;53:507–13. https://doi.org/10.1021/ie403619b.

Sakurai S, Sakamoto J, Shibayama M, Nomura S. Effects of microdomain structures on the molecular orientation of poly (styrene-block-butadiene-block-styrene) triblock copolymer. Macromolecules. 1993;26:3351–6. https://doi.org/10.1021/ma00065a018.

Feldstein MM, Dormidontova EE, Khokhlov AR. Pressure-sensitive adhesives based on interpolymer complexes. Prog Polym Sci. 2015;42:79–153. https://doi.org/10.1016/j.progpolymsci.2014.10.006.

Satas D, editor. Handbook of pressure sensitive adhesive technology: Vol. 1. New York: Van Nostrand Reinhold; 1989.

Benedek I, Feldstein MM, editors. Handbook of pressure-sensitive adhesives and products: -three volume set. CRC Press; 2019.

Sasaki M, Fujita K, Adachi M, Fujii S, Nakamura Y, Urahama Y. The effect of tackifier on phase structure and peel adhesion of a triblock copolymer pressure-sensitive adhesive. Int J Adhes Adhes. 2008;28:372–81. https://doi.org/10.1016/j.ijadhadh.2007.11.002.

Zhao Z, Zhou Y, Zhang C, Li Z. Optimization of SIS-based hot-melt pressure-sensitive adhesives for transdermal delivery of hydrophilic drugs. Int J Adhes Adhes. 2016;68:256–62. https://doi.org/10.1016/j.ijadhadh.2016.04.003.

Ma J, Wang C, Luo H, Zhu Z, Wu Y, Wang H. Design and evaluation of a monolithic drug-in-adhesive patch for testosterone based on styrene–isoprene–styrene block copolymer. J Pharm Sci. 2013;102:2221–34. https://doi.org/10.1002/jps.23576.

Yu Z, Liang Y, Liang W. Development and evaluation of α-asarone transdermal patches based on hot-melt pressure-sensitive adhesives. AAPS PharmSciTech. 2013;14:294–300. https://doi.org/10.1208/s12249-012-9915-z.

Wang C, Liu R, Tang X, Han W. A drug-in-adhesive matrix based on thermoplastic elastomer: evaluation of percutaneous absorption, adhesion, and skin irritation. AAPS PharmSciTech. 2012;13:1179–89. https://doi.org/10.1208/s12249-012-9849-5.

da Silva SA, Marques CL, Cardozo NS. Composition and performance of styrene-isoprene-styrene (SIS) and styrene-butadiene-styrene (SBS) hot melt pressure sensitive adhesives. J Adhes 2012;88(2):187–199.

Ho KY, Dodou K. Rheological studies on pressure-sensitive silicone adhesives and drug-in-adhesive layers as a means to characterize the adhesive performance. Int J Pharm. 2007;333:24–33. https://doi.org/10.1016/j.ijpharm.2006.09.043.

Mazzeo FA. Characterization of pressure sensitive adhesives by rheology. TA Instruments report RH082. 2002. p. 1–8.

Dahlquist CA, Patrick RL. Treatise on adhesion and adhesives. Marcel Dekker N Y. 1969;2:219.

Derail C, Allal A, Marin G, Tordjeman P. Relationship between viscoelastic and peeling properties of model adhesives. Part 1. Cohesive fracture. J Adhes. 1997;61:123–57. https://doi.org/10.1080/00218469708010519.

Deplace F, Carelli C, Mariot S, Retsos H, Chateauminois A, Ouzineb K, et al. Fine tuning the adhesive properties of a soft nanostructured adhesive with rheological measurements. J Adhes. 2009;85:18–54. https://doi.org/10.1080/00218460902727381.

Gal A, Nussinovitch A. Plasticizers in the manufacture of novel skin-bioadhesive patches. Int J Pharm. 2009;370:103–9. https://doi.org/10.1016/j.ijpharm.2008.11.015.

O’Connor AE, Willenbacher N. The effect of molecular weight and temperature on tack properties of model polyisobutylenes. Int J Adhes Adhes. 2004;24:335–46. https://doi.org/10.1016/j.ijadhadh.2003.11.005.

Funding

This study was funded by Dojin Iyaku-Kako Co., Ltd.

Author information

Authors and Affiliations

Contributions

T. Terukina, S. Muramoto, K. Osanai, M. Inoue, H. Watanabe, Y. Hakamata, H. Hikichi, and H. Kondo were involved in the study design and data interpretation. T. Terukina, S. Muramoto, K. Osanai, and M. Inoue were involved in the data analysis. All authors critically revised the report, commented on drafts of the manuscript, and approved the final report.

Corresponding author

Ethics declarations

Conflict of Interest

H. Kondo and T. Terukina received a research grant from Dojin Iyaku-Kako Co., Ltd.; H. Watanabe, Y. Hakamata, and H. Hikichi are employees of Dojin Iyaku-Kako Co., Ltd.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Summary: This study investigated the effect of different percentages of liquid paraffin (LP) on characteristics of styrene–isoprene–styrene (SIS) block copolymer-based pressure-sensitive adhesives in tape formulations. Adhesion and cohesiveness were assessed through viscoelasticity, peel adhesion tests, and texture analysis. Results showed that the adhesion performance decreased when the LP/SIS copolymer ratio increased. The viscoelasticity test suggested that the cohesive strength decreased as the LP ratio in the PSA increased. The study provides valuable insights into regulating adhesion, peel characteristics, and cohesiveness in tape formulations by adjusting the LP/SIS copolymer ratio while keeping the tackifier amount constant.

Teaser: Effect of liquid paraffin (LP) on styrene–isoprene–styrene (SIS) block copolymer-based tape formulations: LP/SIS ratio affected adhesion performance, providing valuable information to design tape formulations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Terukina, T., Muramoto, S., Osanai, K. et al. Effect of Liquid Paraffin on the Characteristics of Pressure-Sensitive Adhesives Applied to Medical Tape Formulations. J Pharm Innov 18, 2110–2119 (2023). https://doi.org/10.1007/s12247-023-09777-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-023-09777-8