Abstract

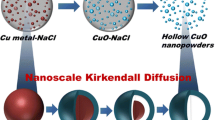

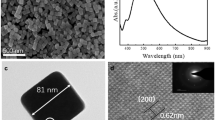

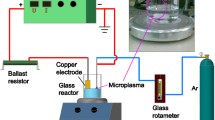

Hollow metallic particles have a lower density than their bulk counterparts with an equivalent apparent volume; therefore, they are expected to be applied in fields requiring low density and large surface area materials. This study proposes a method for synthesizing hollow metallic Cu particles in an aqueous solution. An aqueous suspension of hollow metallic Cu particles was prepared by placing metallic Zn particles in an aqueous Cu acetate solution. Based on the displacement plating related to the standard electrode potential difference between Cu and Zn, Cu2+ ions were reduced to metallic Cu by receiving electrons from metallic Zn, while metallic Zn dissolved into the aqueous solution. Consequently, metallic Cu with a shell-like shape formed near the surface of the original metallic Zn particles before Zn dissolution, yielding hollow metallic Cu particles. Thus, this study revealed that the Cu acetate concentration should be appropriately controlled to fabricate hollow particles. Moreover, the developed method can easily fabricate hollow metallic particles in one step without adding external reducing agents.

Similar content being viewed by others

Data availability

No data was used for the research described in the article.

References

Kim SW, Kim M, Lee WY, Hyeon T (2002) Fabrication of hollow palladium spheres and their successful application to the recyclable heterogeneous catalyst for Suzuki coupling reactions. J Am Chem Soc 124:7642–7643. https://doi.org/10.1021/ja026032z

Kim SH, Bazin N, Shaw JI, Yoo JH, Worsley MA, Satcher JH Jr, Sain JD, Kuntz JD, Kucheyev SO, Baumann TF, Hamza AV (2016) Synthesis of nanostructured/macroscopic low-density copper foams based on metal-coated polymer core-shell particles. ACS Appl Mater Interfaces 8:34706–34714. https://doi.org/10.1021/acsami.6b12320

Ding Y, Yan Y, Wang H, Wang X, Hu T, Tao S, Li G (2018) Preparation of hollow Cu and CuOx microspheres with a hierarchical structure for heterogeneous catalysis. ACS Appl Mater Interfaces 10:41793–41801. https://doi.org/10.1021/acsami.8b16246

Hu T, Wang H, Zhang L, Tao S (2019) Preparation of hollow silver-polymer microspheres with a hierarchical structure for SERS. Appl Surf Sci 490:293–301. https://doi.org/10.1016/j.apsusc.2019.06.061

Zhang J, Zhan P, Liu H, Wang Z, Ming N (2006) A facile colloidal templating method to monodisperse hollow Ag and Ag/Au submicrometer spheres. Mater Lett 60:280–283. https://doi.org/10.1016/j.matlet.2005.08.041

Wang W, Jiang Y, Wen S, Liu L, Zhang L (2012) Preparation and characterization of polystyrene/Ag core-shell microspheres—A bio-inspired poly(dopamine) approach. J Colloid Interface Sci 368:241–249. https://doi.org/10.1016/j.jcis.2011.10.047

Abdollahia SN, Naderia M, Amoabediny G (2013) Synthesis and characterization of hollow gold nanoparticles usingsilica spheres as templates. Colloids Surf A 436:1069–1075. https://doi.org/10.1016/j.colsurfa.2013.08.028

Wu X, Li M, Zeng Q, Yu Q (2022) Dense copper azide synthesized by in-situ reaction of assembled nanoporous copper microspheres and its initiation performance. Def Technol 18:1065–1072. https://doi.org/10.1016/j.dt.2021.05.004

Mou Y, Cheng H, Peng Y, Chen M (2018) Fabrication of reliable Cu-Cu joints by low temperature bonding isopropanol stabilized Cu nanoparticles in air. Mater Lett 229:353–356. https://doi.org/10.1016/j.matlet.2018.07.061

Tang L, Zhu L, Tang F, Yao C, Wang J, Li L (2018) Mild synthesis of copper nanoparticles with enhanced oxidative stability and their application in antibacterial films. Langmuir 34:14570–14576. https://doi.org/10.1021/acs.langmuir.8b02470

Granata G, Onoguchi A, Tokoro C (2019) Preparation of copper nanoparticles for metal-metal bonding by aqueous reduction with D-glucose and PVP. Chem Eng Sci 209:115210. https://doi.org/10.1016/j.ces.2019.115210

Majumdar TD, Singh M, Thapa M, Dutta M, Mukherjee A, Ghosh CK (2019) Size-dependent antibacterial activity of copper nanoparticles against Xanthomonas oryzae pv. oryzae—a synthetic and mechanistic approach. Colloid Interface Sci Commun 32:100190. https://doi.org/10.1016/j.colcom.2019.100190

Pham ND, Duong MM, Le MV, Hoang HA, Pham LKO (2019) Preparation and characterization of antifungal colloidal copper nanoparticles and their antifungal activity against Fusarium oxysporum and Phytophthora capsica. C R Chim 22:786–793. https://doi.org/10.1016/j.crci.2019.10.007

Kobayashi Y, Shirochi T, Yasuda Y, Morita T (2011) Preparation of metallic copper nanoparticles in aqueous solution and their bonding properties. Solid State Sci 13:553–558. https://doi.org/10.1016/j.solidstatesciences.2010.12.025

Kobayashi Y, Shirochi T, Yasuda Y, Morita T (2012) Metal-metal bonding process using metallic copper nanoparticles prepared in aqueous solution. Int J Adhes Adhes 33:50–55. https://doi.org/10.1016/j.ijadhadh.2011.11.002

Kobayashi Y, Shirochi T, Maeda T, Yasuda Y, Morita T (2013) Microstructure of metallic copper nanoparticles/metallic disc interface in metal-metal bonding using them. Surf Int Anal 45:1424–1428. https://doi.org/10.1002/sia.5299

Kobayashi Y, Shirochi T, Yasuda Y, Morita T (2013) Preparation of metallic copper nanoparticles by reduction of copper ions in aqueous solution and their metal-metal bonding properties. Int J Mater Met Eng 7:769–772. https://doi.org/10.5281/zenodo.1088612

Kobayashi Y, Nakazawa H, Maeda T, Yasuda Y, Morita T (2017) Synthesis of metallic copper nanoparticles and metal-metal bonding process using them. Adv Nano Res 5:359–372. https://doi.org/10.12989/anr.2017.5.4.359

Suga Y, Nakashima K, Yamauchi N, Yasuda Y, Morita T, Kobayashi Y (2019) Preparation of high-concentration colloid solutions of metallic copper particles and their use in metal-metal bonding processes. SN Appl Sci 1:925. https://doi.org/10.1007/s42452-019-0845-1

Bard AJ, Faulkner LR (1980) Electrochemical methods: fundamentals and applications. Wiley, New York

Suga Y, Yamauchi N, Nakashima K, Kobayashi Y (2022) Fabrication of metallic copper nanoparticles by utilizing a difference in standard electrode potential. Chem Pap 76:595–602. https://doi.org/10.1007/s11696-021-01850-1

Adams S, Thai D, Mascona X, Schwartzberg AM, Zhang JZ (2014) Key factors affecting the reproducibility of synthesis and growth mechanism of near-infrared absorbing hollow gold nanospheres. Chem Mater 26:6805–6810. https://doi.org/10.1021/cm5033892

Falchevskaya AS, Prilepskii AY, Tsvetikova SA, Koshel EI, Vinogradov VV (2021) Facile synthesis of a library of hollow metallic particles through the galvanic replacement of liquid gallium. Chem Mater 33:1571–1580. https://doi.org/10.1021/acs.chemmater.0c03969

Li T, Zhou W, Li B, Li Y, Cao D, Zhou J, Zuo J, Cai J, Wang G, Liu D, Cai H (2022) Enhanced dielectric and thermal properties of Zn/PVDF composites by tailoring core@double-shell structured Zn particles. Compos A 157:106947. https://doi.org/10.1016/j.compositesa.2022.106947

Wang F, Wang X, Mao X, Duan F, Hang C, Chen H, Li M (2022) Die-attach bonding at 230°C using micron Sn-coated Zn particles for high-temperature applications. J Mater Res Technol 21:4490–4499. https://doi.org/10.1016/j.jmrt.2022.11.069

Zhang Z, Zhao W, Hu C, Guo D, Liu Y (2022) Colorimetric copper (II) ions detection in aqueous solution based on the system of 3’3’5’5’-tetramethylbenzidine and AgNPs in the presence of Na2S2O3. J Sci Adv Mater Dev 7:100420. https://doi.org/10.1016/j.jsamd.2022.100420

Trevino KM, Wagner CR, Tamura EK, Garcia J, Louie AY (2023) Small molecule sensors for the colorimetric detection of copper(II): A review of the literature from 2010 to 2022. Dyes Pigm 214:110881. https://doi.org/10.1016/j.dyepig.2022.110881

Chen X, Li Y, Li X, Li R, Ye B (2022) Transition metal copper composite ionic liquid self-built ratiometric sensor for the detection of paracetamol. Anal Chim Acta 1209:338992. https://doi.org/10.1016/j.aca.2021.338992

Alahdal FAM, Qashqoosh MTA, Manea YK, Mohammed RKA, Naqvi S (2023) Green synthesis and characterization of copper nanoparticles using Phragmanthera austroarabica extract and their biological/ environmental applications. Sustain Mater Technol 35:e00540. https://doi.org/10.1016/j.susmat.2022.e00540

Dai D, Huang PY, Wu TY, Shih CH, Chang L (2023) Epitaxial electrodeposition of Cu2O on Ag substrates in sulfate baths. J Cryst Growth 603:126983. https://doi.org/10.1016/j.jcrysgro.2022.126983.

Becerra-Paniagua DK, Torres-Arellano S, Martinez-Alonso C, Luévano-Hipólito E, Sebastian PJ (2023) Facile and green synthesis of Cu/Cu2O composite for photocatalytic H2 generation. Mater Sci Semicond Process 162:107485. https://doi.org/10.1016/j.mssp.2023.107485

Wilkinson N, Metaxas A, Brichetto E, Wickramaratne S, Reineke TM, Dutcher CS, Ionic strength dependence of aggregate size and morphology on polymer–clay flocculation (2017) Colloids Surf. A 529:1037–1046. https://doi.org/10.1016/j.colsurfa.2017.06.085

Wu W, Song R, Xu Z, Jing Y, Dai H, Fang G (2018) Fluorescent cellulose nanocrystals with responsiveness to solvent polarity and ionic strength. Sens Actuators B 275:490–498. https://doi.org/10.1016/j.snb.2018.07.085

Kamrani S, Rezaei M, Kord M, Baalousha M (2018) Transport and retention of carbon dots (CDs) in saturated and unsaturated porous media: role of ionic strength, pH, and collector grain size. Water Res 133:338–347. https://doi.org/10.1016/j.watres.2017.08.045

Acknowledgements

The authors thank Sanyou Co., Ltd., Hitachi Ota, Japan for the SEM analyses.

Author information

Authors and Affiliations

Contributions

RK performed the experiments, and wrote the first manuscript. YK planned the experiments. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kasori, R., Yamauchi, N., Tada, S. et al. Fabrication of hollow metallic copper particles using a standard electrode potential difference. Transit Met Chem 48, 415–424 (2023). https://doi.org/10.1007/s11243-023-00554-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11243-023-00554-7