Abstract

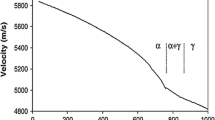

This work provides the description of an experimental study for assessing the hardness of metallic test samples, subjected to the Jominy End-Quench Hardenability Test, by employing typical microhardness tests. Additionally, experimental measurements of the propagation velocity of ultrasound in the test samples were correlated with the microhardness results. A systematic protocol is presented for undergraduate mechanical engineering lectures, addressing the development of experiments, including the sorting and analysis of the resulting data; also, its impact on the expected competencies and abilities of the students is discussed. Several test samples of AISI 4140 steel were used for three experimental sets: heat-treated with the Jominy End-Quench Hardenability Test, fully tempered, and non-treated samples. All samples were evaluated by using typical microhardness tests and ultrasonic pulse-echo measurements to quantify their hardness at multiple locations. The proposed methodology not only strengthened some of the different required abilities of engineering students but also introduces a new procedure, using ultrasonic signals, to estimate hardness in undergraduate programs. The obtained results show a significant correlation between the experimental data from microhardness and ultrasonic measurements, with a maximum precision of -96.36% (inverse correlation) within the studied range. A discussion is provided regarding the means of improving the skills of undergraduate students in the course of Material Science, including experimental mechanical testing abilities through these systematic methods.

Similar content being viewed by others

Data Availability

The authors declare that the data supporting the findings of this study are available within the paper and in its supplementary information files.

References

Bouda AB, Benchaala A, Alem K (2000) Ultrasonic characterization of materials hardness. Ultrasonics 38(1–8):224–227

Aldeeky H, Al Hattamleh O, Rababah S (2020) Assessing the uniaxial compressive strength and tangent Young’s modulus of basalt rock using the Leeb rebound hardness test. Materiales de Construcción 70(340):e230

ASTM A596/A596M-21 (1999) Standard test method for direct-current magnetic Properties of materials using the point by Point (Ballistic) Method and Ring specimens. ASTM, West Conshohocken

ASTM E 140 (2022) Standard Hardness Conversion tables for MetalsRelationship among Brinell Hardness, Vickers Hardness,Rockwell hardness, superficial hardness, Knoop hardness,and Scleroscope hardness. ASTM International, West Conshohocken

Zeng F, Agnew SR, Raeisinia B, Myneni GR (2010) Ultrasonic Attenuation due to grain boundary scattering in pure Niobium. J Nondestruct Evalaluation 29:93–103

Ukomski T, Stepinski T (2010) Steel hardness evaluation based on ultrasound velocity measurements. Insight-Non-Destructive Test Condition Monit 52(11):592–596

Białobrzeska B, Konat Ł, Jasiński R (2017) The influence of austenite grain size on the mechanical properties of low-alloy steel with boron. Metals 7(26):26

Papadaskis EP (1976) Ultrasonic velocity and attenuation: measurement methods with scientific and industrial applications. Phys Acoust 12:277–374

ASTM Standard A255-20a (2020) Standard test methods for determining hardenability of steel, vol 0105. ASTM International, West Conshohocken

Akinlabi E, Ikumapayi OM, Bodunde OP, Adaramola B, Uchegbu ID, Fatoba SO (2020) Impact of quenching on the hardenability of steels EN-3 (∼ 1015), EN-8 (∼ 1040) and EN-24 (∼ 4340) during jominy end quench technique. Int J Emerg Technol 11(5):290–297

Nunura CR, dos Santos C, Spim J (2015) Numerical–Experimental correlation of microstructures, cooling rates and mechanical properties of AISI 1045 steel during the Jominy end-quench test. Mater Design 76:230–243

Lee S-J, Pavlina EJ, Van Ty CJ (2010) Kinetics modeling of austenite decomposition for an end-quenched 1045 steel. Mater Sci Eng 527(13–14):3186–3194

Athavale VA, Buchely M, Bartlett L, O’Malley R, Van Aken DC (2021) On a modified approach of measuring quench severity and its application. In: HT2021. ASM International, pp 79–82

Boaventura GAS, Santos ROB, Gama RP, Cabette RES, Motta MFB, Botura CA, Rosa ACM, Rosa AM, Muniz WF, Jaeger CD, Honorato LFF, Bimestre TA, Silva EPI, Santos B, Oliveira LVM, Venuto TCG, Sampaio HC, Silva SFV, Calazans IFL, Santos FA, Santos FCF, Oliveira FHA (2021) Feasibility of prototyping the Jominy Test device: corroborating for studies and preliminary results of the heating and data acquisition subsystems. J Mater Sci Chem Eng 9(3):23–38

Dossett J, Totten GE (2013) ASM handbook. Steel Heat Treating Fundamentals and processes, vol 4A. ASM International, New York, NY

Quinn GD, Bradt RC (2007) On the Vickers indentation fracture toughness test. J Am Ceram Soc 90(3):673–680

Ahadi Akhlaghi I, Kahrobaee S, Akbarzadeh A, Kashefi M, Krause TW (2021) Predicting hardness profile of steel specimens subjected to Jominy test using an artificial neural network and electromagnetic nondestructive techniques. Nondestructive Test Evaluation 36(4):459–475

Santa-aho S, Sorsa A, Honkanen M, Vippola M (2020) Detailed barkhausen noise and microscopy characterization of Jominy end-quench test sample of CF53 steel. J Mater Sci 55(11):4896–4909

Geng X, Cheng Z, Wang S, Peng C, Ullah A, Wang H, Wu G (2022) A data-driven machine learning approach to predict the hardenability curve of boron steels and assist alloy design. J Mater Sci 57(23):10755–10768

Toozandehjani M, Matori KA, Mustapha F, Zahari NI, Oskoueian A (2015) On the correlation between microstructural evolution and ultrasonic properties: a review. J Mater Sci 50(7):2643–2665

Cheeke JDN (2002) Fundamentals and applications of Ultrasonic waves, First. CRC Press LLC, Montreal

Rose JL (1999) Ultrasonic waves in solid media, First. Cambridge University Press, Cambridge

Palanichamy P, Joseph A, Jayakumar T, Raj B (1995) Ultrasonic velocity measurements for estimation of grain size in austenitic stainless steel. NDT and E Int 28(3):179–185

Gür CH, Tuncer BO (2005) Characterization of microstructural phases of steels by sound velocity measurement. Mater Charact 55(2):160–166

de Albuquerque VHC, d TA, Melo A, Oliveira DF, Gomes RM, Tavares JMR (2010) Evaluation of grain refiners influence on the mechanical properties in a CuAlBe shape memory alloy by ultrasonic and mechanical tensile testing. Mater Design 31(7):3275–3281

Gür CH, Tuncer BO (2004) Investigating the microstructure-ultrasonic property relationships in steels. In: 16th WCNDTWorld Conference on NDT

Rodulfo-Pontigo R, Amezola-Luna R (2006) Implantación de técnicas de ultrasonido por inmersión en la inspección de ensambles automotrices, in Metrology symposium, Queretaro, México

ASTM Standard A29/A29M-20 (2020) Standard specification for general requirements for steel bars, carbon and alloy, hot-wrought, vol 0105. ASTM International, West Conshohocken, PA

Bendat JS, Piersol AG (2011) Random data: analysis and measurement procedures. John Wiley & Sons

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rojas-Mancera, E., Balvantín, A., Diosdado-De-la-Peña, J.A. et al. Integration of Experimental Methods for the Correlation of Hardness with the Propagation Velocity of Ultrasonic Signals in Steel: A Proposal for an Undergraduate Material Science Lecture. Exp Tech (2023). https://doi.org/10.1007/s40799-023-00674-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40799-023-00674-w