Abstract

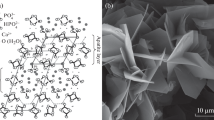

Among the various bone substitutes, carbonate apatite (CO3Ap) has received significant attention in the field of hard tissue regeneration due to its similarity in chemical composition to natural bone and its osteoconductivity and bioresorbability. This study aimed to develop a cost-effective method for fabricating porous CO3Ap blocks while maintaining a balance between porosity and mechanical properties. The level of interconnectivity in the porous structure was achieved by adjusting the pore volume fractions of the starting materials. The phase and microstructure characteristics of the porous CO3Ap blocks were assessed using techniques such as X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM). The diametral tensile strength (DTS) of the blocks was determined using a universal testing machine. The results demonstrated that the mechanical strength of the blocks stayed within a range that was suitable for handling properties. This advantage allows the porous blocks to withstand initial stress during implantation procedures or in the early stages of defect healing.

Similar content being viewed by others

References

LeGeros, R.Z., Trautz, O.R., LeGeros, J.P., Klein, E., Shirra, W.P.: Apatite crystallites: effects of carbonate on morphology. Science. 155(3768), 1409–1411 (1967). http://www.jstor.org/stable/1721190

Deguchi, K., Nomura, S., Tsuchiya, A., Takahashi, I., Ishikawa, K.: Effects of the carbonate content in carbonate apatite on bone replacement. J. Tissue Eng. Regen. Med. 16(2), 200–206 (2022). https://doi.org/10.1002/term.3270

Ishikawa, K., Hayashi, K.: Carbonate apatite artificial bone. Sci. Technol. Adv. Mater. 22(1), 683–694 (2021). https://doi.org/10.1080/14686996.2021.1947120

Hasegawa, M., Doi, Y., Uchida, A.: Cell-mediated bioresorption of sintered carbonate apatite in rabbits. J. Bone Joint Surg. - Series B. 85(1), 142–147 (2003). https://doi.org/10.1302/0301-620X.85B1.13414

Cahyanto, A., Maruta, M., Tsuru, K., Matsuya, S., Ishikawa, K.: Fabrication of bone cement that fully transforms to carbonate apatite. Dent. Mater. J. 34(3), 394–401 (2015). https://doi.org/10.4012/dmj.2014-328

Darus, F., Jaafar, M.: Enhancement of carbonate apatite scaffold properties with surface treatment and alginate and gelatine coating. J. Porous Mater. 27(3), 831–842 (2020). https://doi.org/10.1007/s10934-019-00848-1

Madupalli, H., Pavan, B., Tecklenburg, M.M.J.: Carbonate substitution in the mineral component of bone: discriminating the structural changes, simultaneously imposed by carbonate in A and B sites of apatite. J. Solid State Chem. 255, 27–35 (2017). https://doi.org/10.1016/j.jssc.2017.07.025

Kim, Y.S., Kwon, H.K., Kim, B.I.: Effect of nano-carbonate apatite to prevent re-stain after dental bleaching in vitro. J. Dent. 39(9), 636–642 (2011). https://doi.org/10.1016/j.jdent.2011.07.002

Nagai, H., Kobayashi-Fujioka, M., Fujisawa, K., et al.: Effects of low crystalline carbonate apatite on proliferation and osteoblastic differentiation of human bone marrow cells. J Mater Sci: Mater Med. 26, 99 (2015). https://doi.org/10.1007/s10856-015-5431-5

Hayashi, K., Yanagisawa, T., Shimabukuro, M., Kishida, R., Ishikawa, K.: Granular honeycomb scaffolds composed of carbonate apatite for simultaneous intra- and inter-granular osteogenesis and angiogenesis. Mater. Today Bio. 14, 100247 (2022). https://doi.org/10.1016/j.mtbio.2022.100247

Keiichi, K., Mitsunobu, K., Masafumi, S., Yutaka, D., Toshiaki, S.: Induction of new bone by basic FGF-loaded porous carbonate apatite implants in femur defects in rats. Clin. Oral Implants Res. 20(6), 560–565 (2009). https://doi.org/10.1111/j.1600-0501.2008.01676.x

Hafiyyah, O.A., Lastianny, S.P., Suryono.: Doxycycline incorporated in gelatin-carbonate apatite bone graft material: in vitro evaluation of osteoblastic alkaline phosphatase and porphyromonas gingivalis colonies. Malays. J. Med. Health. Sci. 16(9), 57–61 (2020)

Tram, X.T.N., Ishikawa, K., Hoang Minh, T., Benson, D., Kanji, T.: Characterization of carbonate apatite derived from chicken bone and its in-vitro evaluation using MC3T3-E1 cells. Mater. Res. Express. 8, 025401 (2021). https://doi.org/10.1088/2053-1591/abe018

Hayashi, K., Tsuchiya, A., Shimabukuro, M., Ishikawa, K.: Multiscale porous scaffolds constructed of carbonate apatite honeycomb granules for bone regeneration. Mater Des. 215, 110468 (2022). https://doi.org/10.1016/j.matdes.2022.110468

Putri, T.S., Hayashi, K., Ishikawa, K.: Fabrication of three-dimensional interconnected porous blocks composed of robust carbonate apatite frameworks. Ceram. Int. 46(12), 20045–20049 (2020). https://doi.org/10.1016/j.ceramint.2020.05.076

Keiichi, K., Mitsunobu, K., Masafumi, S., Yutaka, D., Toshiaki, S.: Induction of new bone by basic FGF-loaded porous carbonate apatite implants in femur defects in rats. Clin. Oral Implants Res. 20(6), 560–565 (2009). https://doi.org/10.1111/j.1600-0501.2008.01676.x

Kishida, R., Elsheikh, M., Hayashi, K., Tsuchiya, A., Ishikawa, K.: Fabrication of highly interconnected porous carbonate apatite blocks based on the setting reaction of calcium sulfate hemihydrate granules. Ceram. Int. 47(14), 19856–19863 (2021). https://doi.org/10.1016/j.ceramint.2021.03.324

Daitou, F., Maruta, M., Kawachi, G., et al.: Fabrication of carbonate apatite block based on internal dissolutionprecipitation reaction of dicalcium phosphate and calcium carbonate. Dent. Mater. J. 29(3), 303–308 (2010). https://doi.org/10.4012/dmj.2009-095

Wakae, H., Takeuchi, A., Udoh, K., et al.: Fabrication of macroporous carbonate apatite foam by hydrothermal conversion of α-tricalcium phosphate in carbonate solutions. J. Biomed. Mater. Res. A 87(4), 957–963 (2008). https://doi.org/10.1002/jbm.a.31620

Nomura, S., Tsuru, K., Maruta, M., Matsuya, S., Takahashi, I., Ishikawa, K.: Fabrication of carbonate apatite blocks from set gypsum based on dissolutionprecipitation reaction in phosphate-carbonate mixed solution. Dent. Mater. J. 33(2), 166–172 (2014). https://doi.org/10.4012/dmj.2013-192

Hayashi, K., Kato, N., Kato, M., Ishikawa, K.: Impacts of channel direction on bone tissue engineering in 3D-printed carbonate apatite scaffolds. Mater Des. 204, 109686 (2021). https://doi.org/10.1016/j.matdes.2021.109686

Ishikawa, K., Matsuya, S., Lin, X., Lei, Z., Yuasa, T., Miyamoto, Y.: Fabrication of low crystalline B-type carbonate apatite block from low crystalline calcite block. J. Ceram. Soc. Jpn. 118(1377), 341–344 (2010). https://doi.org/10.2109/jcersj2.118.341

Ana, I.D., Matsuya, S., Ishikawa, K.: Engineering of carbonate apatite bone substitute based on composition-transformation of gypsum and calcium hydroxide. Engineering 02(05), 344–352 (2010). https://doi.org/10.4236/eng.2010.25045

Maruta, M., Matsuya, S., Nakamura, S., Ishikawa, K.: Fabrication of low-crystalline carbonate apatite foam bone replacement based on phase transformation of calcite foam. Dent. Mater. J. 30(1), 14–20 (2011). https://doi.org/10.4012/dmj.2010-087

Takeuchi, A., Munar, M.L., Wakae, H., et al.: Effect of temperature on crystallinity of carbonate apatite foam prepared from α-tricalcium phosphate by hydrothermal treatment. Biomed. Mater. Eng. 19(2–3), 205–211 (2009). https://doi.org/10.3233/BME-2009-0581

Zaman, C.T., Takeuchi, A., Matsuya, S., Zaman, Q.H.M.S., Ishikawa, K.: Fabrication of B-type carbonate apatite blocks by the phosphorization of free-molding gypsum-calcite composite. Dent. Mater. J. 27(5), 710–715 (2008). https://doi.org/10.4012/dmj.27.710

Ueno, H., Fujimi, T.J., Okada, I., Aizawa, M.: Development of biocompatible apatite sheets with various Ca/P ratios and carbonate ion contents for mouse osteoblastic cell culture and their evaluations. J. Aust. Ceram. Soc. 46(2), 14–18 (2010)

Doi, Y., Shibutani, T., Moriwaki, Y., Kajimoto, T., Iwayama, Y.: Sintered carbonate apatites as bioresorbable bone substitutes. J Biomed Mater Res. 39(4), 603–610 (1998). https://doi.org/10.1002/(SICI)1097-4636(19980315)39:4%3c603::AID-JBM15%3e3.0.CO;2-7

Koda, Y.D.T., Wakamatsu, N., Goto, T., et al.: Influence of carbonate on sintering of apatites. J. Dent. Res. 72(9), 1279–1284 (1993). https://doi.org/10.1177/00220345930720090401

Lee, Y., Hahm, Y.M., Matsuya, S., Nakagawa, M., Ishikawa, K.: Characterization of macroporous carbonate-substituted hydroxyapatite bodies prepared in different phosphate solutions. J. Mater. Sci. 42(18), 7843–7849 (2007). https://doi.org/10.1007/s10853-007-1629-3

Nomura, S., Tsuru, K., Maruta, M., Matsuya, S., Takahashi, I., Ishikawa, K.: Fabrication of carbonate apatite blocks from set gypsum based on dissolutionprecipitation reaction in phosphate-carbonate mixed solution. Dent. Mater. J. 33(2), 166–172 (2014). https://doi.org/10.4012/dmj.2013-192

Lee, Y., Hahm, Y.M., Lee, D.H., Matsuya, S., Nakagawa, M., Ishikawa, K.: Preparation and characterization of macroporous carbonate-substituted hydroxyapatite scaffold. Ind. Eng. Chem. Res. 47(8), 2618–2622 (2008). https://doi.org/10.1021/ie071474a

Daitou, F., Maruta, M., Kawachi, G., et al.: Fabrication of carbonate apatite block based on internal dissolutionprecipitation reaction of dicalcium phosphate and calcium carbonate. Dent. Mater. J. 29(3), 303–308 (2010). https://doi.org/10.4012/dmj.2009-095

Jones, J.R., Lee, P.D., Hench, L.L.: Hierarchical porous materials for tissue engineering. Philos. Trans. Royal Soc. A: Math., Phys. Eng. Sci. 2006(364), 263–281 (1838). https://doi.org/10.1098/rsta.2005.1689

Hollister, S.J.: Porous scaffold design for tissue engineering. Nat. Mater. 4(7), 518–524 (2005). https://doi.org/10.1038/nmat1421

Jones, J.R., Hench, L.L.: Regeneration of trabecular bone using porous ceramics. Curr. Opin. Solid State Mater. Sci. 7(4–5), 301–307 (2003). https://doi.org/10.1016/j.cossms.2003.09.012

Belyakov, A.V., Lukin, E.S., Safronova, T.V., Safina, M.N., Putlyaev, V.I.: Porous materials made from calcium phosphates (review). Glass and Ceramics (English translation of Steklo i Keramika). 65(9–10), 337–339 (2008). https://doi.org/10.1007/s10717-009-9086-x

Will, J., Melcher, R., Treul, C., et al.: Porous ceramic bone scaffolds for vascularized bone tissue regeneration. J. Mater. Sci. Mater. Med. 19(8), 2781–2790 (2008). https://doi.org/10.1007/s10856-007-3346-5

Abbasi, N., Hamlet, S., Love, R.M., Nguyen, N.T.: Porous scaffolds for bone regeneration. J. Sci.: Adv. Mater. Devices 5(1), 1–9 (2020). https://doi.org/10.1016/j.jsamd.2020.01.007

Wu, R., Li, Y., Shen, M., et al.: Bone tissue regeneration: the role of finely tuned pore architecture of bioactive scaffolds before clinical translation. Bioact Mater. 6(5), 1242–1254 (2021). https://doi.org/10.1016/j.bioactmat.2020.11.003

Perez, R.A., Mestres, G.: Role of pore size and morphology in musculo-skeletal tissue regeneration. Mater. Sci. Eng., C 61, 922–939 (2016). https://doi.org/10.1016/j.msec.2015.12.087

Zhu, T., Cui, Y., Zhang, M., Zhao, D., Liu, G., Ding, J.: Engineered three-dimensional scaffolds for enhanced bone regeneration in osteonecrosis. Bioact Mater. 5(3), 584–601 (2020). https://doi.org/10.1016/j.bioactmat.2020.04.008

Darus, F., Jaafar, M., Ahmad, N.: Preparation of carbonate apatite scaffolds using different carbonate solution and soaking time. Process. App. Ceram. 13(2), 139–148 (2019). https://doi.org/10.2298/PAC1902139D

Ishikawa, K.: Carbonate apatite bone replacement: learn from the bone. J. Ceram. Soc. Jpn. 127(9), 595–601 (2019). https://doi.org/10.2109/jcersj2.19042

Wang, B., Zhang, Z., Pan, H.: Bone apatite nanocrystal: crystalline structure, chemical composition, and architecture. Biomimetics. 8(1), 90 (2023). https://doi.org/10.3390/biomimetics8010090

Murugan, R., Ramakrishna, S., Panduranga, R.K.: Nanoporous hydroxy-carbonate apatite scaffold made of natural bone. Mater. Lett. 60(23), 2844–2847 (2006). https://doi.org/10.1016/j.matlet.2006.01.104

Ishikawa, K.: Bone substitute fabrication based on dissolution-precipitation reactions. Materials. 3(2), 1138–1155 (2010). https://doi.org/10.3390/ma3021138

Ge, J., Guo, L., Wang, S., et al.: The size of mesenchymal stem cells is a significant cause of vascular obstructions and stroke. Stem Cell Rev Rep. 10(2), 295–303 (2014). https://doi.org/10.1007/s12015-013-9492-x

Su, P., Tian, Y., Yang, C., Ma, X., Wang, X., Pei, J., Qian, A.: Mesenchymal stem cell migration during bone formation and bone diseases therapy. Int. J. Mol. Sci. 19, 2343, (2018). https://doi.org/10.3390/ijms19082343

Matsiko, A., Gleeson, J.P., O’Brien, F.J.: Scaffold mean pore size influences mesenchymal stem cell chondrogenic differentiation and matrix deposition. Tissue Eng. Part A 21(3–4), 486–497 (2015). https://doi.org/10.1089/ten.tea.2013.0545

Cyster, L.A., Grant, D.M., Howdle, S.M., et al.: The influence of dispersant concentration on the pore morphology of hydroxyapatite ceramics for bone tissue engineering. Biomaterials 26(7), 697–702 (2005). https://doi.org/10.1016/j.biomaterials.2004.03.017

Akita, K., Fukuda, N., Kamada, K., et al.: Fabrication of porous carbonate apatite granules using microfiber and its histological evaluations in rabbit calvarial bone defects. J. Biomed. Mater. Res. A 108(3), 709–721 (2020). https://doi.org/10.1002/jbm.a.36850

Baneshi, N., Moghadas, B.K., Adetunla, A., et al.: Investigation the mechanical properties of a novel multicomponent scaffold coated with a new bio-nanocomposite for bone tissue engineering: fabrication, simulation and characterization. J. Market. Res. 15, 5526–5539 (2021). https://doi.org/10.1016/j.jmrt.2021.10.107

Yuliati, A., Merlindika, Y., Munadziroh, E., Ari, A., El Fadhlallah, M.P., Rianti, D., et al.: Mechanical strength and porosity of carbonate apatite-chitosan-gelatine scaffold in various ratio as a biomaterial candidate in tissue engineering. KEM. 829, 173–81 (2019). https://doi.org/10.4028/www.scientific.net/KEM.829.173

Acknowledgements

We acknowledge the support of time and facilities from Ho Chi Minh City University of Technology (HCMUT) for this study.

Funding

This research is funded by Vietnam National University Ho Chi Minh City (VNU-HCM) under grant number C-2022–20-24.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen, X.T.T., Cao, X.T. & Kunio, I. A method of fabrication of porous carbonate apatite artificial bone for biomedical application. J Aust Ceram Soc 60, 399–406 (2024). https://doi.org/10.1007/s41779-023-00954-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00954-z