Abstract

Purpose

Formulation of customized drug delivery systems is considered as an effective approach to fulfill the individualized needs of the patients.

Methods

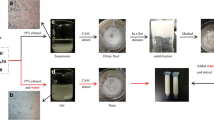

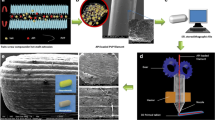

In this study, differential release bilayer tablets containing clarithromycin (CAM) as sustained release (SR) and levofloxacin (LVX) as immediate release (IR) were fabricated by bridging the techniques of hot melt extrusion (HME) and fused deposition modeling (FDM). Both processes were optimized to minimize the drug degradation and to achieve the safe deposition of drugs in their respective layers. This design may offer better clinical efficacy, better patient compliance and may overcome side effects caused by the generalized dosing.

Results

In vitro drug release studies confirmed that almost 100% of LVX was released within 1 h, while CAM showed sustained drug release for up to 24 h. The thermal stability of drugs and polymers was evident from the differential scanning calorimetry (DSC) result. Powder X-ray diffraction (PXRD) and DSC results showed a decrease in the crystalline behavior of drugs after FDM. The Fourier rransform infrared spectroscopy (FT-IR) data showed no significant interactions between drugs and polymers after incorporation in the final formulation.

Conclusion

This work illustrated the potential applications of HME and FDM in formulation of customized drug delivery systems to fulfil the individualized needs of the patients.

Similar content being viewed by others

Availability of Data and Materials

All the data are available within the manuscript.

References

Mohanty S, et al. Fabrication of scalable and structured tissue engineering scaffolds using water dissolvable sacrificial 3D printed moulds. Mat Sci and Eng C. 2015. https://doi.org/10.1016/j.msec.2015.06.002.

Chia HN, Wu BM. Recent advances in 3D printing of biomaterials. J Bio Eng. 2015. https://doi.org/10.1186/s13036-015-0001-4.

Davis R, Bryson HM. Levofloxacin. Drugs. 1994. https://doi.org/10.2165/00003495-199447040-00008.

Fish DN, Chow AT. The clinical pharmacokinetics of levofloxacin. Clin Pharmacokinet. 1997. https://doi.org/10.2165/00003088-199732020-00002.

Azab ET, et al. Levofloxacin versus clarithromycin for Helicobacter pylori eradication: are 14 day regimens better than 10 day regimens? Gut Path. 2022. https://doi.org/10.1186/s13099-022-00502-3.

Buanz AB, et al. Preparation of personalized-dose salbutamol sulphate oral films with thermal ink-jet printing. Pharma res. 2011. https://doi.org/10.1007/s11095-011-0450-5.

Qamar N, et al. Personalized 3D printed ciprofloxacin impregnated meshes for the management of hernia. J Drug Del Sci Tech. 2019. https://doi.org/10.1016/j.jddst.2019.101164.

Ijaz QA, et al. Development of a validated method for simultaneous quantification of clarithromycin and levofloxacin by high-performance liquid chromatography-diode array detector. Acta Pol Pharm. 2020. https://doi.org/10.32383/appdr/131197.

Pietrzak K, Isreb A, Alhnan MA. A flexible-dose dispenser for immediate and extended release 3D printed tablets. Eur J Pharm Biopharm. 2015. https://doi.org/10.1016/j.ejpb.2015.07.027.

Korte C, Quodbach J. Formulation development and process analysis of drug-loaded filaments manufactured via hot-melt extrusion for 3D-printing of medicines. Pharm Dev Tech. 2018. https://doi.org/10.1080/10837450.2018.1433208.

Dizon JRC, et al. Mechanical characterization of 3D-printed polymers. Addit Manuf. 2018. https://doi.org/10.1016/j.addma.2017.12.002.

Zhang J, et al. Hydroxypropyl methylcellulose-based controlled release dosage by melt extrusion and 3D printing: structure and drug release correlation. Carbohydr Polym. 2017. https://doi.org/10.1016/j.carbpol.2017.08.058.

Ritger PL, Peppas NA. A simple equation for description of solute release II. Fickian and anomalous release from swellable devices. J Control Release. 1987. https://doi.org/10.1016/0168-3659(87)90035-6.

Geng P, et al. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J Manuf Proc. 2019. https://doi.org/10.1016/j.jmapro.2018.11.023.

Mirón V, et al. Manufacturing and characterization of 3D printer filament using tailoring materials. Procedia Manuf. 2017. https://doi.org/10.1016/j.promfg.2017.09.151.

Nukala PK, et al. Investigating the application of FDM 3D printing pattern in preparation of patient-tailored dosage forms. J 3D Print Med. 2019. https://doi.org/10.2217/3dp-2018-0028.

Sadia M, et al. Adaptation of pharmaceutical excipients to FDM 3D printing for the fabrication of patient-tailored immediate release tablets. Int J Pharm. 2016. https://doi.org/10.1016/j.ijpharm.2016.09.050.

Kadry H, et al. Multi-purposable filaments of HPMC for 3D printing of medications with tailored drug release and timed-absorption. Int J Pharm. 2018. https://doi.org/10.1016/j.ijpharm.2018.04.010.

Goyanes A, et al. 3D printing of modified-release aminosalicylate (4-ASA and 5-ASA) tablets. Eur J Pharm Biopharm. 2015. https://doi.org/10.1016/j.ejpb.2014.12.003.

Mohammadi G, et al. Physicochemical and anti-bacterial performance characterization of clarithromycin nanoparticles as colloidal drug delivery system. Colloids Surf B Biointerfaces. 2011. https://doi.org/10.1016/j.colsurfb.2011.05.050.

Jana U, et al. Preparation and characterization of nebivolol nanoparticles using Eudragit® RS100. Colloids Surf B Biointerfaces. 2014. https://doi.org/10.1016/j.colsurfb.2013.09.001.

Mano J, et al. Glass transition dynamics and structural relaxation of PLLA studied by DSC: influence of crystallinity. Polymer. 2005. https://doi.org/10.1016/j.polymer.2005.06.096.

Gorman EM, Samas B, Munson EJ. Understanding the dehydration of levofloxacin hemihydrate. J Pharm Sci. 2012. https://doi.org/10.1002/jps.23200.

Pradhan R, et al. Preparation and characterization of spray-dried valsartan-loaded Eudragit® E PO solid dispersion microparticles. Asian J Pharm Sci. 2016. https://doi.org/10.1016/j.ajps.2016.05.002.

Islan GA, et al. Smart lipid nanoparticles containing levofloxacin and DNase for lung delivery. Design and characterization. Colloids Surf B Biointerfaces. 2016. https://doi.org/10.1016/j.colsurfb.2016.03.040.

Chen P, et al. Preparation of high-drug-loaded clarithromycin gastric-floating sustained-release tablets using 3D printing. AAPS PharmSciTech. 2021. https://doi.org/10.1208/s12249-021-01994-z.

Iqbal O, et al. Moxifloxacin loaded nanoparticles of disulfide bridged thiolated chitosan-eudragit RS100 for controlled drug delivery. Int J Biol Macromol. 2021. https://doi.org/10.1016/j.ijbiomac.2021.05.199.

Dorofeev V. Infrared spectra and the structure of drugs of the fluoroquinolone group. Pharm Chem J. 2004. https://doi.org/10.1007/s11094-005-0063-6.

Porfiryeva NN, et al. Acrylated Eudragit® E PO as a novel polymeric excipient with enhanced mucoadhesive properties for application in nasal drug delivery. Int J Pharm. 2019. https://doi.org/10.1016/j.ijpharm.2019.03.027.

Zhang X, et al. Investigation and physicochemical characterization of clarithromycin–citric acid–cyclodextrins ternary complexes. Drug Dev Ind Pharm. 2007. https://doi.org/10.1080/03639040600832801.

Kitaoka H, et al. Effect of dehydration on the formation of levofloxacin pseudopolymorphs. Chem Pharm Bull. 1995. https://doi.org/10.1248/cpb.43.649.

Lamichhane S, et al. Complex formulations, simple techniques: can 3D printing technology be the Midas touch in pharmaceutical industry? Asian J Pharm Sci. 2019. https://doi.org/10.1016/j.ajps.2018.11.008.

Funding

The authors would like to acknowledge Higher Education Commission of Pakistan for providing funds to Mr. Qazi Amir Ijaz (pin no. 50021487).

Author information

Authors and Affiliations

Contributions

The following statements should be used: Conceptualization: Qazi Amir Ijaz and Nasir Abbas; methodology: Qazi Amir Ijaz; software; Muhammad Sarfraz; validation: Amjad Hussain, Nadeem Irfan Bukhari, and Muhammad Sohail Arshad; investigation: Qazi Amir Ijaz and Memoona Rashid; resources: Zeeshan Javaid; writing—original draft preparation: Qazi Amir Ijaz and Nasrullah Jan; writing—review and editing: Sumera Latif and Hafsa Afzal; visualization: Sumaira Irum Khan; supervision: Nasir Abbas. All the authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ijaz, Q.A., Latif, S., Khan, S.I. et al. Fabrication and Evaluation of Differential Release Bilayer Tablets of Clarithromycin and Levofloxacin by 3D Printing. J Pharm Innov 18, 2145–2157 (2023). https://doi.org/10.1007/s12247-023-09780-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-023-09780-z