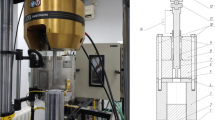

Reliable operation of products made of high-strength alloy steels is ensured by the availability of effective methods and equipment for studying their mechanical properties during manufacturing and operation. One of the most important properties of such products is resistance to impact damage. The implementation of such tests is limited by the high financial costs of manufacturing specimens and impactors (ammunition), the complexity of conducting them, recording the results, and the lack of initial data. Recently, alternative methods have been developed, such as static and dynamic pressing of plate specimens. In this case, the shape of the impactors (punches) is similar to the shape of the impactors used in punching due to similar material behavior. The pressing tests make it possible to confirm the parameters of the models of material deformation and fracture, which are necessary for numerical calculations of complex structures under various types of loads. The equipment and methodology for studying the behavior of high-strength materials under static pressing are presented. It is established that recording the punch movement using a strain gauge can significantly reduce the elastic deformation component of the power chain of the test machine and fixture loading. A series of tests were performed on specimens cut from Armox 500T steel sheets with thicknesses of 3, 5, and 10 mm for static pressing by different punches (conical, flat, and hemispherical). It was shown that the plastic properties of the material decrease with increasing thickness of rolled steel, regardless of the type of punch. The obtained results confirmed the operability of the presented equipment and methodology and can be used in numerical modeling of deformation and fracture processes of high-strength steels.

Similar content being viewed by others

References

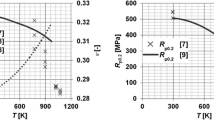

A. Popławski, P. Kędzierski, and A. Morka “Identification of Armox 500T steel failure properties in the modeling of perforation problems,” Mater Design, 190, 1–28 (2020). https://doi.org/10.1016/j.matdes.2020.108536

S. Koubaa, J. Mars, M. Wali, and F. Dammak, “Numerical study of anisotropic behavior of aluminum alloy subjected to dynamic perforation,” Int J Impact Eng, 101, 105–114 (2017). 10.1016/ j.ijimpeng.2016.11.017

A. Banerjee, S. Dhar, S. Acharyya, et al., “Determination of Johnson–Cook material and failure model constants and numerical modelling of Charpy impact test of armour steel,” Mater Sci Eng A, 640, 200–209 (2015). https://doi.org/10.1016/j.msea.2015.05.073

M. A. Iqbal, K. Senthil, P. Sharma, and N. K. Gupta, “An investigation of the constitutive behavior of Armox 500T steel and armor piercing incendiary projectile material,” Int J Impact Eng, 96, 146–164 (2016). https://doi.org/10.1016/j.ijimpeng.2016.05.017

P. Skoglund, M. Nilsson, and A. Tjernberg, “Fracture modelling of a high performance armour steel, J Physique IV (Proceedings), 134, 197–202 (2006). https://doi.org/10.1051/jp4:2006134030

M. Saleh, M. M. Kariem, V. Luzin, et al., “High strain rate deformation of ARMOX 500T and effects on texture development using neutron diffraction techniques and SHPB testing,” Mater Sci Eng A, 709, 30–39 (2018). https://doi.org/10.1016/j.msea.2017.09.022

S. Choudhary, P. K. Singh, S. Khare, et al., “Ballistic impact behaviour of newly developed armour grade steel: An experimental and numerical study,” Int J Impact Eng, 140, 03557 (2020). https://doi.org/10.1016/j.ijimpeng.2020.103557

M. Saleh, V. Luzin, M. A. Kariem, et al., “Experimental measurements of residual stress in ARMOX 500T and evaluation of the resultant ballistic performance,” J Dyn Behav Mater, 6, 78–95 (2020). https://doi.org/10.1007/s40870-019-00231-w

V. Mishra and V. Kukshal, “Numerical analysis for estimating ballistic performance of armour material,” Mater Today-Proc, 44, No. 6, 4731–4737 (2021). https://doi.org/10.1016/j.matpr.2020.11.221

S. Khare, K. Kumar, S. Choudhary, et al., “Determination of Johnson–Cook material parameters for armour plate using DIC and FEM,” Met Mater Int, 27, 4984–4995 (2020). https://doi.org/10.1007/s12540-020-00895-3

R. V. Kravchuk, “Numerical simulation of static punching tests of thin-sheet specimens,” in: Proc. Int. Young Scientists Conf. on Materials Science and Surface Engineering (Lviv, Ukraine, 2021), pp. 137–140.

V. V. Kharchenko, E. O. Kondryakov, O. A. Katok, and R. V. Kravchuk, “Numerical simulation of the processes of deformation and fracture of high-strength materials during static and dynamic perforation of thin plates,” Struct Int Procedia, 36, 131–144 (2021). https://doi.org/10.1016/j.prostr.2022.01.015

A. V. Kravchuk, R. V. Kravchuk, E. O. Kondryakov, et al. “Deformation and failure of thin-sheet specimens made of high-strength steel Armox 500T under static and dynamic punching,” Strength Mater, 55, 35–43 (2023). https://doi.org/10.1007/s11223-023-00500-z

DSTU 8788:2018. Personal Protective Equipment. Body Armor. Methods of Controlling Protective Properties [in Ukrainian], Valid since July 1, 2019.

A. L. Gurson, “Continuum theory of ductile rupture by void nucleation and growth: Part I–Yield criteria and flow rules for porous ductile,” J Eng Mater Tech, 99, No. 1, 2–15 (1977). https://doi.org/10.1115/1.3443401

A. Needleman and J. R. Rice, “Limits to ductility set by plastic flow localization,” in: D. P. Koistinen and N. M. Wang (Eds.), Mechanics of Sheet Metal Forming, Plenum Press, New York (1978), pp. 237–265. https://doi.org/10.1007/978-1-4613-2880-3_10

V. Tvergaard and A. Needleman, “Analysis of the cup-cone fracture in a round tensile bar,” Acta Metall, 32, No. 1, 157–169 (1984). https://doi.org/10.1016/0001-6160(84)90213-X

G. R. Johnson and W. N. Cook, “A constitutive model and data for metals subjected to large strains, high rates and high temperatures,” in: Proc. 7th Int. Symp. Ballistics, (Olanda, 1983), pp. 541–547.

G. R. Johnson and W. H. Cook, “Fracture characteristics of three metals subjected to various strains, strain rates, temperatures, and pressures,” Eng Fract Mech, 21, No. 1, 31–48 (1985). https://doi.org/10.1016/0013-7944(85)90052-9

DSTU ISO 6892-1:2019. Metal Materials. Tensile Tests. Room-Temperature Test Method (ISO 6892-1:2016, IDT) [in Ukrainian], Valid since July 1, 2020.

O. A. Katok, M. R. Muzyka, V. P. Shvets’, et al., “Determination of hardness of high-strength steels by the Brinell method. Part 1. Improvement of measurement accuracy,” Strength Mater, 53, 902–908 (2021). https://doi.org/10.1007/s11223-022-00358-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 4, pp. 74 – 83, July – August, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sereda, A.V., Kravchuk, R.V., Katok, O.A. et al. Equipment and Methodology for Studying the Behavior of High-Strength Steels Under Static Pressing of Plate Specimens. Strength Mater 55, 743–750 (2023). https://doi.org/10.1007/s11223-023-00564-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00564-x