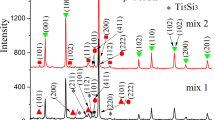

The densification of a powder mixture containing titanium diboride and 20 wt.% molybdenum disilicide during nonisothermal spark plasma sintering was experimentally studied. The sintering process was assisted with an external pressure of 50.93 MPa in vacuum at a controlled constant heating rate of 1.67 and 2.72 K per second. It was established that sintering occurred when the thermodynamic temperature reached 1155 K, which should be taken as the critical brittle–ductile transition temperature for molybdenum disilicide, a less refractory material. The densification kinetics was analyzed using the continuum theory for bulk viscous flow of a porous body, considering the effect of powder particle shape on the rheological properties of the sintered body. In general, the sintering process was characterized by a decrease in the root-mean-square stress within the porous body matrix to the limiting zero value as it approached the nonporous state and by an increase in the root-mean-square strain rate along the curve with a maximum. Computational modeling of the densification kinetics for the powder composite, involving determination of the activation energy for viscous flow of the composite matrix as a function of temperature and root-mean-square stress, allowed the initial, low-temperature, and medium-temperature stages of spark plasma sintering to be identified. At the initial stage up to 1220 K, the activation energy increased nonlinearly and sharply, which can be caused by active spark flashes with the formation of plasma within the loose random packing of the powder particles, as a similar stage is not observed in conventional pressure assisted sintering. At the next low-temperature temperature stage, the activation energy increased as the root-mean square stress decreased. In the temperature range from 1300 to 1389 K, the activation energy for viscous linear flow of the composite matrix was 223 kJ/mol. In the medium-temperature range from 1414 to 1485 K, the activation energy increased to 255 kJ/mol.

Similar content being viewed by others

References

R.M. German, Sintering Science: An Historical Perspective, copyright © 2016 Randall M. German, https://www.academia.edu.

O. Guillon, J. Gonzalez-Julian, B. Dargatz, T. Kessel, G. Schierning, J. Rathel, and M. Herrmann, “Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments,” Adv. Eng. Mater., 16, No. 7, 830–849 (2014), https://doi.org/10.1002/adem.201300409.

P. Tanaji and P.H. Sandip, “Initial stage densification during spark plasma sintering of Fe-based amorphous alloy powder: Analysis of viscous flow,” J. Appl. Phys., 120, 134901 (2016), https://doi.org/10.1063/1.4964330.

M.S. Boldin, A.A. Popov, E.A. Lantsev, A.V. Nokhrin, and V.N. Chuvil’deev, “Investigation of the kinetics of spark plasma sintering of alumina ceramics. Part 1. The initial stage of sintering,” IOP Conf. Ser. Mater. Sci. Eng., 558, 012005 (2019).

M. Stuer, P. Bowen, and Z. Zhao, “Spark plasma sintering of ceramics: From modeling to practice,” Ceramics, 3, 476–493 (2020), https://doi.org/10.3390/ceramics 3040039.

V.V. Skorokhod, Rheological Fundamentals of Sintering Theory [in Russian], Naukova Dumka, Kyiv (1972), p. 151.

M.S. Kovalchenko, “Pressure sintering of powder materials,” Powder Metall. Met. Ceram., 50, No. 1–2, 18–33 (2011).

M.S. Kovalchenko, “Rheological models of pressure sintering of powders,” Powder Metall. Met. Ceram., 52, No. 1–2, 7–19 (2013).

M.S. Kovalchenko, “Rheology and kinetics of pressure sintering,” Mater. Sci. Forum, 835, 76–105 (2016).

M.S. Kovalchenko, Yu.G. Tkachenko, D.Z. Yurchenko, and V.F. Britun, “Nonisothermal pressure sintering kinetics of the B4C–SiC powder mixture, structure and fracture behavior of sintered composite,” Powder Metall. Met. Ceram., 53, No. 3–4, 180–190 (2014).

M.S. Kovalchenko, V.B. Vinokurov, R.V. Litvin, and L.I. Klimenko, “The densification kinetics of porous zirconium diboride in vacuum pressure sintering,” Powder Metall. Met. Ceram., 60, No. 5–6, 278–290 (2021).

O. Zgalat-Lozynskyy, I. Kud, L. Ieremenko, D. Zyatkevych, L. Krushynska, R. Lytvyn, O. Myslyvchenko, O. Tolochyn, and D. Verbylo, “Preparation of TiB2–20 wt.% MoSi2 composite material by mechanochemical synthesis and spark plasma sintering,” Metall. Mater. Trans. A, 52, 2451–2462 (2021), https://doi.org/10.1007/S11661-021-06235-3.

M.S. Kovalchenko, “Pressure sintering kinetics of tungsten and titanium carbides,” Int. J. Refract. Met. Hard Mater., 39, 32–37 (2013).

A. Angot, Mathematics for Electrical and Telecommunications Engineers [in French], Éditions de la Revue d’Optique, Paris (1949), p. 660.

T.D. Shermergor, Elasticity Theory for Microheterogeneous Media [in Russian], Nauka, Moscow (1977), p. 400.

D.S. Wilkinson and M.F. Ashby, “Pressure sintering by power law creep,” Acta Met., 23, 1277–1285 (1975).

J. Friedel, Dislocations, Pergamon Press, Oxford–London–Edinburgh–New York–Paris–Frankfurt (1964), p. 512.

G.P. Cherepanov, “Chapter 4. Physics of sintering,” in: Solid Mechanics and Its Applications. Vol. 51: Methods of Fracture Mechanics: Solid Matter Physics, Kluwer Acad. Publ., Dordrecht (1997), p. 333.

A. Nisar, S. Ariharan, and K. Balani, “Densification kinetics and mechanical properties of tantalum carbide,” Int. J. Refract. Met. Hard Mater., 73, 221–230 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 62, Nos. 1–2 (549), pp. 41–51, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kovalchenko, M.S., Lytvyn, R.V., Kud, I.V. et al. Densification Kinetics of the TiB2–20 wt.% MoSi2 Composite During Nonisothermal Spark Plasma Sintering. Powder Metall Met Ceram 62, 32–40 (2023). https://doi.org/10.1007/s11106-023-00367-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00367-4