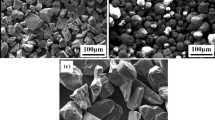

Powder metallurgy (PM) Fe (steel) products still suffer from abrasion and fatigue, thus reducing their life expectancy. The physical vapor deposition (PVD) technique can significantly enhance surface wear and fatigue resistance. On the other hand, ultrasonic shot peening (USSP) treatment is an emerging and effective technique that can enhance surface strength and improve surface density, particularly for PM products. Duplexed PM Fe (steel) samples are expected to have excellent mechanical properties and long service life. In this work, PM Fe (steel)-based samples (ρ = 6.9) were prepared as substrates for CrN coatings with and without USSP treatment. Holes sized about 35 μm can be observed on CrN coatings deposited on as-sintered substrates, while the CrN coatings on USSP-treated substrates were very compact. According to the results of scanning electron microscopy (SEM), X-Ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), and transmission electron microscopy (TEM), the crystal structures and chemical bonds of CrN coatings on different substrates are the same. Nevertheless, CrN coatings were found to be discontinued on sintered substrates because of holes in the surface. In friction tests, such specific structures created plenty of “steps” in the coating, increasing residual stress, which crushed the coatings into fragments and led to severe abrasive wear. Additionally, wear rates would increase with load. Nevertheless, USSP treatment can generate a compact layer, about 700 μm thick, to offer strong support to CrN coatings. Therefore, CrN coatings on the USSP-treated substrates exhibited lower and more stable coefficients of friction and wear rates. This generally describes a simple method to enhance the surface strength and densities of PM Fe (steel) products. Besides, it offers a new way of prolonging the service lives of PM Fe (steel) products by USSP and PVD duplex treatment.

Similar content being viewed by others

References

X. Liu, Z.Y. Xiao, H.j. Guan, W. Zhang, and F.L. Li, “Friction and wear behaviors of surface densified powder metallurgy Fe–2Cu–0.6C material,” Powder Metall., 59, No. 5, 329–334 (2016).

S. Manchoul, R. Ben Sghaier, R. Seddik, and R. Fathallah, “Comparison between conventional shot peening and ultrasonic shot peening,” Mechan. Industry, 19, No. 6, 1–8 (2019).

J. Badreddine, E. Rouhaud, M. Micoulaut, R. Sébastien, V. Desfontaine, and P. Renaud, “3D model of shot dynamics for ultrasonic shot peening,” Mater. Sci. Forum, 768–769, 503–509 (2013).

S. Kumar, G. Sudhakar Rao, K. Chattopadhyay, G.S. Mahobia, N.C. Santhi Srinivas, and V. Singh, “Effect of surface nanostructure on tensile behavior of superalloy IN718,” Mater. Design (1980–2015), 62, 76–82 (2014).

J. Marteau, M. Bigerelle, P.E. Mazeran, and S. Bouvier, “Relation between roughness and processing conditions of AISI 316L stainless steel treated by ultrasonic shot peening,” Tribology Int., 82, 319–329 (2015).

K. Rzepiejewska-Malyska, M. Parlinska-Wojtan, K. Wasmer, S. Hejduk, and J. Michler, “In-situ SEM indentation studies of the deformation mechanisms in TiN, CrN and TiN/CrN,” Micron, 40, No. 1, 22–27 (2009).

H. Zhang, S.W. Duo, X.M. Xu, H. Ke, T.Z. Liu, X.Y. Fei, and Z.H. Zhou, “Influence of substrate temperature and bias voltage on structure and mechanical properties of CrN coatings,” Key Eng. Mater., 591, 99–103 (2013).

X. Cai, Y. Gao, F. Cai, L. Zhang, and S.H. Zhang, “Effects of multilayer structure on microstructure, wear and erosion performance of the Cr/CrN films on Ti alloy substrate,” Appl. Surf. Sci., 483, 661–669 (2019).

J.W. Du, L. Chen, J. Chen, and Y. Du, “Mechanical properties, thermal stability and oxidation resistance of TiN/CrN multilayer coatings,” Vacuum, 179,109468 (2020).

Z.B. Qi, B. Liu, Z.T. Wu, E.P. Zhu, Z.C. Wang, and C.H. Wu, “A comparative study of the oxidation behavior of Cr2N and CrN coatings,” Thin Sol. Films, 544, 515–520 (2013).

Y. Zhu, M. Dong, J. Li, and L.P. Wang, “Wear failure mechanism of TiSiN coating at elevated temperatures,” Appl. Surf. Sci., 487, 349–355 (2019).

M. Dong, Y. Zhu, C. Wang, L. Shan, and J. Li, “Structure and tribocorrosion properties of duplex treatment coatings of TiSiCN/nitride on Ti6Al4V alloy,” Ceram. Int., 45, No. 9, 12461–12468 (2019).

S.N. Chen, Y.M. Zhao, Y.F. Zhang, L. Chen, B. Liao, X. Zhang, and X.P. Ouyang, “Influence of carbon content on the structure and tribocorrosion properties of TiAlCN/TiAlN/TiAl multilayer composite coatings,” Surf. Coat. Technol., 411,126886-1–12 (2021).

L. Shan, Y. Wang, J. Li, X. Jiang, and J.M. Chen, “Architecture of multilayer Cr/CrN coatings for wear protection in seawater: Cr/CrN ratio and total thickness,” Tribology Trans., 58, No. 5, 914–923 (2015).

J.L. Tijerina-Gonzaleza, M.A.L. Hernandez-Rodriguez, D.E. Lozano, G.M. Martinez-Cazares, Y. Bedolla-Gil, “Tribological characterization of AlCrN, AlTiN, AlTiON, and AlCrON coatings on CoCrMo alloy,” Tribology Trans., 64, No. 1, 119–125 (2021).

D. Yang, H. Chen, Y. Ye, C.T. Wang, H.C. Zhao, and D.R. Gong, “Doping silicon to enhance the anticorrosion and anti-wear abilities of chromium nitride coating in seawater,” Surf. Topography: Metrol. Propert., 6, No. 4, 044001-1–11 (2018).

J.-Z. Kong, T.-J. Hou, Q.-Z. Wang, L. Yin, F. Zhou, Z. Zhou, and L. Li, “Influence of titanium or aluminum doping on the electrochemical properties of CrN coatings in artificial seawater,” Surf. Coat. Technol., 307, 118–124 (2016).

J.L. Mo and M.H. Zhu, “Tribological oxidation behaviour of PVD hard coatings,” Tribology Int., 42, No. 11–12, 1758–1764 (2009).

Y. Zhu, M. Dong, X. Zhao, J. Li, K. Chang, and L. Wang, “Self-healing of TiSiN/Ag coatings induced by Ag,” J. Am. Ceram. Soc., 102, No. 12, 7521–7532 (2019).

H. Wang, Y. Ye, G. Zhang, and W. Liu, “Silicon content design of CrSiN films for good anti-corrosion and anti-wear performances in NaOH solution,” Surf. Topography: Metrol. Propert., 6, No. 2, P. 100389 (2018).

P. Wen, F. Zhang, Y. Chen, S. Guo, S. Zhou, Y. Ye, and H. Chen, “Comparative study on tribological behavior of CrAlN coating in atmosphere, deionized water and 5 wt.% NaCl solution,” Surf. Topography: Metrol. Propert., 7, No. 4, 045102-1–10 (2019).

X. Zhou, X.Y. Li, and K. Lu, “Enhanced thermal stability of nanograined metals below a critical grain size,” Science, 360, 526–530 (2018).

Z.B. Qi, P. Sun, F.P. Zhu, Z.C. Wang, D.L. Peng, and C.H. Wu, “The inverse Hall–Petch effect in nanocrystalline ZrN coatings,” Surf. Coat. Technol., 205, No. 12, 3692–3697 (2011).

X.-f. Qin, D.-l. Sun, T. Wang, X. Zhao, L. Xie, and Q. Wu, “Hall–Petch and inverse Hall–Petch effects accompany the long-term use of backup roll material,” J. Alloys Compd., 640, 497–500 (2015).

A.V. Naumkin, A. Kraut-Vass, S.W. Gaarenstroom, and C.J. Powell, NIST X-ray Photoelectron Spectroscopy Database (2012).

D. Mandrino and B. Podgornik, “XPS investigations of tribofilms formed on CrN coatings,” Appl. Surf. Sci., 396, 554–559 (2017).

K. Huang, X. Cao, L. Kong, Z. Lu, G. Zhang, Q. Ding, and H. Hu, “Effect of Ag content on friction and wear properties of Ag and V co-doped CrN coatings at 25–700°C,” Ceram. Int., 47, No. 24, 35021–35028 (2021).

A. Conde, A.B. Cristóbal, G. Fuentes, T. Tate, J. de Damborenea, “Surface analysis of electrochemically stripped CrN coatings,” Surf. Coat. Technol., 201, No. 6, 3588–3595 (2006).

Acknowledgment

This work was not supported by any funds.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Published in Poroshkova Metallurgiya, Vol. 62, Nos. 1–2 (549), pp. 94–105, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, W., Zhu, Y., Wang, H. et al. Enhanced Tribological Properties of CrN Coatings on Densified Surfaces of Fe-Based Porous Materials Obtained Through Powder Metallurgy and Ultrasonic Shot Peening Treatment. Powder Metall Met Ceram 62, 77–85 (2023). https://doi.org/10.1007/s11106-023-00371-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00371-8