Abstract

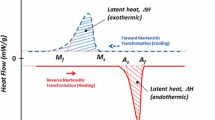

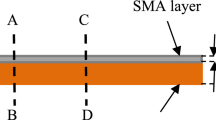

Implementing smart materials as an actuator in fabricating micro-positioning systems has become pervasive in recent years. However, the application of Shape Memory Alloy (SMA) smart materials is limited due to its complex nonlinear mechanical behavior, such as asymmetric hysteresis and saturation characteristics. One of the most potent experimental-based methods of modeling these nonlinearities is the Generalized Prandtl-Ishlinskii (GPI) model. Unlike similar methods such as the Preisach model, this model is analytically invertible. This study aims to develop a micro-positioning stage and identify an experimental-based model describing the system response. The model structure is composed of two cascade sub-models. In the first sub-model, which models the actuator thermal behavior, the parameters of a linear dynamic model are identified. This sub-model predicts the actuator temperature given the electrical current. The second sub-model estimates the phase transformation and consequently the actuator displacement as a function of temperature. The GPI structure has been used for constructing the Wiener sub-model. The experimental and numerical results showed that the proposed black box model can accurately describe the system behavior, although identifying a comprehensive model to adequately describe the SMA actuator is a great challenge.

Similar content being viewed by others

Data Availability

The datasets analyzed during the current study are available from the corresponding author on reasonable request.

References

Wang W et al (2020) A new hysteresis modeling and optimization for piezoelectric actuators based on asymmetric Prandtl-Ishlinskii model. Sensors Actuators A Phys 316:112431. https://doi.org/10.1016/j.sna.2020.112431

Xu Q, Li Y (2008) Structure improvement of an XY flexure micromanipulator for micro/nano scale manipulation. IFAC 41(2):12733–12738. https://doi.org/10.3182/20080706-5-kr-1001.02154

Li Y, Xu Q (2009) Design and analysis of a totally decoupled flexure-based XY parallel micromanipulator. IEEE Trans Robot 25(3):645–657. https://doi.org/10.1109/TRO.2009.2014130

Ding B, Li Y (2014) Design and analysis of a decoupled XY micro compliant parallel manipulator, 2014 IEEE Int. Conf. Robot. Biomimetics, IEEE ROBIO 2014, pp 1898–1903. https://doi.org/10.1109/ROBIO.2014.7090613

AbuZaiter A, Hikmat OF, Nafea M, Ali MSM (2016) Design and fabrication of a novel XY θ z monolithic micro-positioning stage driven by NiTi shape-memory-alloy actuators. Smart Mater Struct 25(10):105004. https://doi.org/10.1088/0964-1726/25/10/105004

Sasaki M, Kamada W, Hane K (1999) Two-dimensional control of shape-memory-alloy actuators for aligning a si micromachined pinhole of spatial filter. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 38(12 B):7190–7193. https://doi.org/10.1143/jjap.38.7190

Shaw JA, Churchill CB, Iadicola MA (2008) Tips and tricks for characterizing shape memory alloy wire: Part 1—differential scanning calorimetry and basic phenomena. Exp Tech 32(5):55–62. https://doi.org/10.1111/j.1747-1567.2008.00410.x

Churchill CB, Shaw JA, Iadicola MA (2009) Tips and tricks for characterizing shape memory alloy wire: Part 2—fundamental isothermal responses. Exp Tech 33(1):51–62. https://doi.org/10.1111/j.1747-1567.2008.00460.x

Churchill CB, Shaw JA, Iadicola MA (2010) Tips and tricks for characterizing shape memory alloy wire: Part 4 — thermo-mechanical coupling. Exp Tech 34(2):63–80. https://doi.org/10.1111/j.1747-1567.2010.00619.x

Mohd Jani J, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

Al Janaideh M, Rakheja S, Su CY (2011) An analytical generalized Prandtl-Ishlinskii model inversion for hysteresis compensation in micropositioning control. IEEE/ASME Trans Mechatron 16(4):734–744. https://doi.org/10.1109/TMECH.2010.2052366

Bassiuny AM, Ismail MA, Bakr EM (2014) Fuzzy incremental controller for SMA smart actuator with application to micro-positioning. J Control Eng Technol 4(1):58–65

Minorowicz B, Leonetti G, Stefanski F, Binetti G, Naso D (2016) Design, modelling and control of a micro-positioning actuator based on magnetic shape memory alloys. Smart Mater Struct 25(7):1–12. https://doi.org/10.1088/0964-1726/25/7/075005

Li J, Tian H (2018) Position control of SMA actuator based on inverse empirical model and SMC-RBF compensation. Mech Syst Signal Process 108:203–215. https://doi.org/10.1016/j.ymssp.2018.02.004

Cortez-Vega R, Chairez I, Feliu-Batlle V (2020) Multi-link endoscopic manipulator robot actuated by shape memory alloys spring actuators controlled by a sliding mode. ISA Trans (xxxx). https://doi.org/10.1016/j.isatra.2020.10.053

Park S, Hwang D (2020) An experimental study on precision positioning characteristics of shape memory alloy actuator. Microsyst Technol 26(9):2801–2807. https://doi.org/10.1007/s00542-020-04853-2

Liu M, Zhao Z, Hao L (2022) Prescribed performance model-free adaptive sliding mode control of a shape memory alloy actuated system. ISA Trans 123:339–345. https://doi.org/10.1016/j.isatra.2021.05.021

Karmakar S, Gaddam V, Kim J, Mishra AK, Sarkar A (2021) Helical SMA actuator based artificial muscle and arm with sliding mode control. ACM Int Conf Proc Ser: 1–5. https://doi.org/10.1145/3478586.3480722

Britz R, Motzki P (2022) Analysis and evaluation of bundled SMA actuator wires. Sensors Actuators A Phys 333:113233. https://doi.org/10.1016/j.sna.2021.113233

Singh D, Choudhury R, Singh Y, Mukherjee M (2021) Workspace analysis of 3-DOF U-shape base planar parallel robotic motion stage using shape memory alloy restoration technique (SMART) linear actuators. SN Appl Sci 3(4):1–22. https://doi.org/10.1007/s42452-021-04490-y

Khan AM, Kim Y, Shin B, Moghadam MH, Mansour NA (2022) Modeling and control analysis of an arc-shaped SMA actuator using PID, sliding and integral sliding mode controllers. Sensors Actuators A Phys 340(January):113523. https://doi.org/10.1016/j.sna.2022.113523

Hu B, Liu F, Mao B, Chen Z, Yu H (2022) Modeling and position control simulation research on shape memory alloy spring actuator. Micromachines 13(2):1–16. https://doi.org/10.3390/mi13020178

Bai F, Zhang X, Xu D (2023) Accurate position tracking control of SMAAs based on low-complexity self-sensing model and compound control strategy. IEEE Sens J 23(3):2280–2290. https://doi.org/10.1109/JSEN.2022.3227293

Choudhury R, Singh Y (2023) Design development and control of a shape memory alloy linear actuation based XYθ motion stage. Eng Res Express 5(2):025011. https://doi.org/10.1088/2631-8695/acca71

Moallem M, Tabrizi VA (2009) Tracking control of an antagonistic shape memory alloy actuator pair. IEEE Trans Control Syst Technol 17(1):184–190. https://doi.org/10.1109/TCST.2008.922506

Pai A, Riepold M, Trächtler A (2016) Precision control of SMA actuators with a real time model-based controller and extended VSC. IFAC-PapersOnLine 49(21):66–73. https://doi.org/10.1016/j.ifacol.2016.10.512

Pai A, Riepold M, Trächtler A (2018) Model-based precision position and force control of SMA actuators with a clamping application. Mechatronics 50:303–320. https://doi.org/10.1016/j.mechatronics.2017.08.011

Choi S (2005) Position control of a single-link mechanism activated by shape memory alloy springs : experimental results. Smart Mater Struct 15:51–58. https://doi.org/10.1088/0964-1726/15/1/034

Nelles O (2020) Nonlinear system identification. Springer International Publishing, Cham. https://doi.org/10.1007/978-3-030-47439-3

Ljung L (1999) System identification. In: Webster JG (ed) Wiley encyclopedia of electrical and electronics engineering. https://doi.org/10.1002/047134608X.W1046

Al Janaideh M (2009) Generalized Prandtl-Ishlinskii hysteresis model and its analytical inverse for compensation of hysteresis in smart actuators. PhD thesis, Concordia University. https://spectrum.library.concordia.ca/id/eprint/976620/

Krejci P, Kuhnen K (2001) Inverse control of systems with hysteresis and creep. IEE Proc Control Theory Appl 148(3):185–192. https://doi.org/10.1049/ip-cta:20010375

Kuhnen K (2003) Modeling, identification and compensation of complex hysteretic nonlinearities: A modified prandtl-ishlinskii approach. Eur J Control 9(4):407–418. https://doi.org/10.3166/ejc.9.407-418

Leang KK, Devasia S (2007) Feedback-linearized inverse feedforward for creep, hysteresis, and vibration compensation in AFM piezoactuators. IEEE Trans Control Syst Technol 15(5):927–935. https://doi.org/10.1109/TCST.2007.902956

Chen X, Hisayama T (2008) Adaptive sliding-mode position control for piezo-actuated stage. IEEE Trans Ind Electron 55(11):3927–3934. https://doi.org/10.1109/TIE.2008.926768

Al Janaideh M, Mao J, Rakheja S, Xie W, Su CY (2008) Generalized Prandtl-Ishlinskii hysteresis model: Hysteresis modeling and its inverse for compensation in smart actuators. Proc IEEE Conf Decis Control, pp 5182–5187. https://doi.org/10.1109/CDC.2008.4739202

Zakerzadeh MR, Sayyaadi H (2013) Precise position control of shape memory alloy actuator using inverse hysteresis model and model reference adaptive control system. Mechatronics 23(8):1150–1162. https://doi.org/10.1016/j.mechatronics.2013.10.001

Wang F (2023) Neural network model for hysteretic characteristic of shape memory alloy. Mater Today Commun 35:105963. https://doi.org/10.1016/j.mtcomm.2023.105963

Chen Y, Shen X, Li J, Chen J (2019) Nonlinear hysteresis identification and compensation based on the discrete Preisach model of an aircraft morphing wing device manipulated by an SMA actuator. Chinese J Aeronaut 32(4):1040–1050. https://doi.org/10.1016/j.cja.2018.09.006

Feng Y, Li Y (2021) System identification of micro piezoelectric actuators via rate-dependent Prandtl-Ishlinskii hysteresis model based on a modified PSO algorithm. IEEE Trans Nanotechnol 20:205–214. https://doi.org/10.1109/TNANO.2020.3034965

Li Z, Shan J, Gabbert U (2021) A direct inverse model for hysteresis compensation. IEEE Trans Ind Electron 68(5):4173–4181. https://doi.org/10.1109/TIE.2020.2984452

Zhou C, Feng C, Aye YN, Ang WT (2021) A digitized representation of the modified prandtl–ishlinskii hysteresis model for modeling and compensating piezoelectric actuator hysteresis. Micromachines 12(8):942. https://doi.org/10.3390/mi12080942

Du YS, Liu HB (2022) Circular tracking performance of a flexure-based micro-motion stage. Exp Tech 46(3):497–507. https://doi.org/10.1007/s40799-022-00544-x

Minorowicz B, Milecki A (2022) Design and control of magnetic shape memory alloy actuators. Materials (Basel) 15(13):4400. https://doi.org/10.3390/ma15134400

Asua E, García-Arribas A, Etxebarria V (2008) Micropositioning using shape memory alloy actuators. Eur Phys J Spec Top 158(1):231–236. https://doi.org/10.1140/epjst/e2008-00680-4

Ashrafiuon H, Jala VR (2009) Sliding mode control of mechanical systems actuated by shape memory alloy. J Dyn Syst Meas Control Trans ASME 131(1):1–6. https://doi.org/10.1115/1.3023121

Shakiba S, Zakerzadeh MR, Ayati M (2018) Experimental characterization and control of a magnetic shape memory alloy actuator using the modified generalized rate-dependent Prandtl-Ishlinskii hysteresis model. Proc Inst Mech Eng Part I J Syst Control Eng 232(5):506–518. https://doi.org/10.1177/0959651818758910

Liu H, Hao L, Liu M, Zhao Z (2022) Data-driven model-free adaptive fractional-order sliding mode control for the SMA actuator with prescribed performance. Proc Inst Mech Eng Part C J Mech Eng Sci 0(0):1–12. https://doi.org/10.1177/09544062211059746

Kolyvas E, Koveos Y, Tzes A (2016) Sliding mode-based control of thin Shape Memory Alloy actuators using a spatial hysteresis approximation. Mechatronics 40:115–127. https://doi.org/10.1016/j.mechatronics.2016.09.005

Copaci D, Moreno L, Blanco D (2019) Two-stage shape memory alloy identification based on the Hammerstein-Wiener model. Front Robot AI 6(September):1–10. https://doi.org/10.3389/frobt.2019.00083

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

Hossein Rahbari developed the mathematical modeling, conducted the experiments and analyzed the empirical results; Alireza Fathi planned the scheme and initiated the project; Morteza Dardel suggested the experiments and examined the theory validation. The manuscript was written through the contribution of all authors. The first draft of the manuscript was written by Hossein Rahbari and all authors discussed the results, reviewed, and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Financial and Non-Financial Interests

The authors have no relevant financial or non-financial interests to disclose.

Employment

All authors certify that they have no affiliations with or involvement in any organization in the subject matter or materials discussed in this manuscript.

Competing Interest (conflict of interest)

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rahbari, H., Fathi, A. & Dardel, M. Parameters Identification of a Generalized Prandtl-Ishlinskii Model for a Micro-Positioning Stage Using Mutual Shape Memory Alloy Actuators. Exp Tech (2023). https://doi.org/10.1007/s40799-023-00680-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40799-023-00680-y