Abstract

Polyester/cotton (PET/C) blended fabric wastes are produced daily in huge amounts, which constitutes an economic loss and an environmental threat if it is not reused appropriately. Modern textile waste recycling technologies put much effort into developing fabric materials with unique properties, such as bioactivity or new optical goods based on modern technologies, especially nano-biotechnology. In this study, zinc oxide nanoparticles (ZnO-NPs) were biosynthesized using the aqueous extract of Dunaliella sp. and immobilized on PET/C waste fabrics after enzymatically activated with cellulases. The produced Dunaliella-ZnO-NPs (10–20 nm with a spherical shape) were characterized by High-resolution transmission electron microscopy (HRTEM), Fourier-transform infrared spectroscopy (FTIR), X-Ray diffraction analysis (XRD), and Scanning electron microscopy-energy dispersive X-ray analyzer (SEM-EDAX), and some functional groups, such as CH, CO, NH, and CN (due to the presence of carboxyl, proteins and hydroxyl groups), were detected, revealing the biosynthesis of ZnO-NPs. The analysis showed that the resulting ZnO-NPS had potent antimicrobial effects, Ultraviolet (UV) protection capabilities, and no cytotoxic effects on the normal human fibroblast cell line (BJ1). On the other hand, enzymatic treatments of PET/C fabric waste with cellulases enhanced the immobilization of biosynthetic nanoparticles on their surface. Modified PET/C fabrics loaded with Dunaliella-ZnO-NPs showed antibacterial and UV protection capabilities making them an eco-friendly and cost-effective candidate for numerous applications. These applications can include the manufacture of active packaging devices, wastewater treatment units, and many other environmental applications.

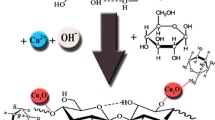

Graphical abstract

Similar content being viewed by others

Introduction

Chemical fibers, especially polyethylene terephthalate, natural fibers, especially cotton, and a mixture of both constitute the largest globally used fibers. Hence, their manufacturing produces a huge amount of waste daily [1]. Polyethylene terephthalate (PET) is a multipurpose fiber due to its high lifelessness, nontoxic property, and moldability in several beneficial products, however, it is a non-biodegradable fiber [2]. Economically and environmentally, polyester/cotton (PET/C) fiber wastes are considered a challenging problem because a huge amount of waste is produced daily. Recycling technology is a set of processes that involves gathering, sorting, processing, and converting waste materials into fundamental goods that can be used to create new materials. The recycling of PET fiber waste is the topic of the current article. To obtain the virtual monomer Bis(2-hydroxyethyl) terephthalate (BHET) in its purest form and use it as a starting point for creating softeners beneficial for the textile industry, it was depolymerized through glycolysis. As a result of previous studies, full recycling of PET trash has been attempted [3, 4]. In 2016, about 21 million tons of solid textile wastes were dumped into landfills, which negatively affected environmental characteristics and wasted valuable raw materials. The reuse of these wastes (textiles and PET/C) is an important environmental and economic benefit that should not be ignored. However, it is unfortunately not widely popularized in the textile industry [5].

Because of the promising results of a wide variety of nanotechnology applications, this subject of research has recently become increasingly active and interesting. The size of particles plays an important role in the characteristics of used materials such as thermal conductivity, catalytic efficiency, and chemical performance, in addition to their antimicrobial properties [6,7,8]. Metal ions were reduced to their nanoform to create metal nanoparticles. A variety of synthetic methods are employed to create nanoparticles with various morphologies and sizes. Even though these processes have produced nanoparticles of higher quality, industrial production still needs improvement [9, 10]. Chemical synthesis of nanoparticle was the most effective and usable method, but it can produce toxic or non-environmental chemicals. For this reason, environmentally friendly green biosynthesis of nanoparticles that utilizes microorganisms, or plant extracts is more acceptable, especially with human foods and biomedical applications or related sectors [11]. Different species of microorganisms, i.e., bacteria, fungi, actinomycetes and microalgae have been reported to be applied in green nanoparticles synthesis [6, 8, 12]. These microbes can create reducing agents that are extracellularly or intracellularly and promote the bioconversion of metal ions into nanoforms [13]. Microalgae are prokaryotic or eukaryotic unicellular or simple multicellular photosynthetic microorganisms living in saline or freshwater environments. Moreover, they may be grown on a large scale in a variety of bioreactors, including open ponds and photo-bioreactors [14].

Microalgae extracts work as reducing agents to create nanoparticles from metal salts without generating any harmful byproducts because they have secondary metabolites like alkaloids, some aromatic compounds, macrolides, peptides, and terpenes as well as pigments, proteins, carbohydrates, lipids, and nucleic acids [15]. Hence, microalgae are considered easy access and efficacious “bionanofactories” for synthesizing metallic nanoparticles [8, 16]. This ability depends on the intracellular and extracellular biomolecules produced during growth that act as reducing agents that convert metal ions into nanoforms. Microalgae have the benefit of quicker multiplication with autotrophic growth and opportunities for large-scale nanomaterials synthesis without needing any safety issues [9, 17]. Thus, it can be used to treat wastewater, fatty acid production, biodiesel production and CO2 sequestration. In addition, it is considered a potential feedstock for the production of biofuels, and value-added products and nanomaterials production with environmental-friendly concerns.

Textile surface activation can be accomplished biologically using enzymes that add functional groups to the fiber surface. Lipases, proteases, cellulases, and chitinases are just a few of the hydrolytic enzymes that have the ability to activate the surfaces of natural fibers [18, 19]. Cellulases are one of the most crucial enzymes utilized in the bio-polishing of cotton textiles to increase their smoothness, softness, and wettability out of the numerous enzymes suited for textile industry uses [20]. Many factors influence the reaction of cellulose enzymes, such as availability of cellulosic substrate, confirmation of enzyme activity, activation/inactivation states, enzyme dose, temperature, pH, coexisting chemicals, reaction time, tissue processing history, as well as mechanical conditions [21, 22]. Enzymes are specific and may be restricted to the surface of the fabric. Therefore, enzymatic treatment results in an increase in free hydroxyl and carboxylic groups, which changes the surface properties of the treated textile. An increase in hydrophilicity is directly caused by the formation of these functional groups. Also, the bulk properties and mechanical stability of the fibers are not impacted, allowing for the conservation of materials and the production of products of higher quality or with new functional capabilities. Moreover, the addition of extra hydroxyl and carboxylic groups makes it easier for nanoparticles to attach to surfaces [23]. Previously, modified smart textiles were produced from normal textiles, but the current work uses the fabrics waste as a source of smart textiles (as novel smart modified textiles). Thus, this article aimed to convert textile fabrics-based wastes to smart textiles by employing an environmentally safe enzymatic process for fabric surface activation that can make it easier to load PET/C blended waste textiles with Dunaliella-ZnO-NPs (nanoparticles). Such textile materials should be produced not only for new functional performance like antimicrobial activity and ultraviolet protection but also to improve their laundering durability to prove the feasibility of applying such biosynthesized nanoparticles for imparting textile material waste smart properties. The use of this technology is considered facile, eco-friendly, and paving the way for the direct application of the produced smart fibrous wastes in many advanced applications such as biosensors, wastewater treatment, and packaging.

Materials and methods

Microalga and cultivation conditions

The microalga, Dunaliella sp. used in this study was previously isolated from the salty lakes, Siwa Oasis, Western Desert, Egypt, identified and stored in the Department of Agricultural Microbiology, National Research Centre, Egypt. The microalga was cultivated on bold basal medium (BBM) supplemented with 70 g/L sea salts as previously mentioned [24]. Cultivation was performed in air-bubbled glass flasks (5 L) under continuous illumination (using white, fluorescent lights) for 28 days. Biomass was harvested (after different culture ages, i.e., 14, 21, and 28 days) via centrifugation at 6000 rpm for 10 min. The harvested biomass was washed with dH2O to remove residual salts and impurities from the culture and dried at 50 °C for 24 h.

Aqueous extracts of the microalga

Aqueous extraction of Dunaliella sp. was carried out according to Somasekharan et al. [25] and Saleh et al., [26] with a modification as follows: one gram of dried and ground microalgal biomass was suspended in a glass tube containing 20 mL of dH2O and extracted in a water bath sonicator at 50 °C for 30 min. Then, the cells and their solid residues were separated by centrifugation (2000 rpm for 10 min) and re-suspended in a suitable volume of dH2O for another sonication/extraction cycle, which was repeated four times at elevated temperatures, i.e., 60, 70, 75 and 80 °C. The aqueous fractions were collected after the five extraction cycles and centrifuged, and the final volume was adjusted to 100 mL.

Biosynthesis of Dunaliella-ZnO-NPs

The biosynthesis of Dunaliella-ZnO-NPs was performed using the aqueous cell extracts of Dunaliella sp. The impact of culture age on zinc biosynthesis was studied at three different culture ages, i.e., 2, 3 and 4 weeks of culture incubation. The microalgal extract was combined with an equivalent volume of 0.5% zinc acetate solution, and the mixture was shaken at 100 rpm for an overnight period in the dark at 28 °C. The precipitates were collected by centrifugation (10,000 rpm for 15 min), washed 3 times with deionized water and 2 times with absolute ethanol and then dried in an oven at 50 °C until a constant weight was obtained. The formation of ZnO-NPs was checked by scanning the obtained precipitates using a spectrophotometer. In addition, the optimum conditions were selected by measuring the absorbance values at 350 nm [27]. The dried and ground ZnO-NPs at the optimum condition were collected and subjected to further characterization.

Characterization of Dunaliella-ZnO-NPs for environmental-textile applications

The characteristics of produced Dunaliella-ZnO-NPs were assayed by high-resolution transmission electron microscopy (JEOL 2100, Japan) at the National Research Centre, Egypt to describe their size and shape [27]. To identify potential biomolecule associations for capping, reduction, and effective stabilization of the Dunaliella-ZnO-NPs, a Fourier Transforms Infrared spectroscopy (FTIR) study was performed. Using an FTIR spectrometer, the materials were scanned using infrared light in the range of 4000:400 cm−1 (Agilent system Cary 630 FTIR model, Santa Clara, USA). To determine whether functional groups were present in the sample, the resulting spectrum data were compared with the reference charts [28]. As noted by Djearamane et al. [29], an X-Ray Diffractometer (XRD-6000 series by Shimadzu equipment, Tokyo, Japan) was used to analyze the crystalline structure of the Dunaliella-ZnO-NPs. A scanning electron microscope (SEM) was used to reveal the surface morphology and provide details of high-resolution photographs of the sample. Moreover, an energy-dispersive X-ray analyzer was employed to give quantitative compositional data and elemental identification.

Cytotoxic evaluation of Dunaliella-ZnO-NPs on human normal fibroblast cell line (BJ1)

Cytotoxic activity test (in vitro bioassay on human normal cell lines) was conducted and determined by the Bioassay-Cell Culture Laboratory, National Research Centre (Cairo, Egypt). By converting yellow color of 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide (MTT) to purple formazan in a mitochondrial-dependent reaction, cell viability was determined [30, 31].

Preparation of activated fabric waste

PET/C blended fabric waste applied during the present work was in the form of woven fabric paste that was collected from textile factories (Misr Al-Amerya Co., Alex; Misr Al-Mahalla Co., Al-Mahalla El-Kobra and Misr ElBida Co., Kafer El-Dawar). The enzymatic treatment of PET/C fabric was performed using commercial acid cellulases (Cellusoft® L; Novo Nordisk A/S, Denmark) using a laboratory dyeing machine with high temperature/high pressure. In brief, the needed concentrations of cellulase enzyme (1% and 3%) and the fabric samples were mixed into stainless steel bowls with pH 4.5 adjusted by acetic acid, followed by rotating shaking at 45 °C into a closed bath of ethylene glycol. The ratio between fabrics and enzyme solutions (F:E) was 1:15. The temperature of the water bath was increased by 5 °C/min. After that (40 min), the pH was increased to 10 using Na2CO3 to terminate the enzymes, and the samples were removed from the bath, and rinsed with hot and cold distilled water sequentially. Then, the treated fabric samples were put onto stainless sheets in open air to dry. The weight loss of fabric enzyme-degradation (WL) was estimated from the weight loss of the fabric samples based on the following equation:

where W1 is the weight of the samples before enzymatic treatments and W2 is the weight of the sample after enzymatic treatments.

The carboxylic content was used to evaluate the enzymes working. Thus, it was applied to parent and activated fabric waste as mentioned in the previous process described by Yang and Tsai [32].

Modification of textile waste by attaching the Dunaliella-ZnO-NPs on its surface

The fabric samples (parent and activated PET/C blended textiles) were soaked in the Dunaliella-ZnO-NPs dispersion for 1 h. The samples were dried in the air at a temperature of around 28 °C (laboratory temperature) for 24 h and then cured for 15 min in an oven at 150 °C. The treated textiles were washed five times by the recommended American Association of Textile Chemists and Colorists (AATCC) test procedure, to assess the adherence of Dunaliella-ZnO-NPs to the polyester fabrics (61-1989) as mentioned in Fig. 1.

Antimicrobial properties evaluation of Dunaliella-ZnO-NPs and modified PET/C fabric wastes

The antimicrobial properties were examined against different environmental pathogens; Listeria monocytogenes ATCC (American Type Culture Collection)-35152, Staphylococcus aureus ATCC-47077, Salmonella typhi ATCC-15566, Escherichia coli ATCC-25922 and Candida albicans ATCC-10231 [33, 34]. The well diffusion agar method was applied to evaluate the antimicrobial activity of the prepared Dunaliella-ZnO-NPs as presented previously by Darwesh et al. [35]. Each sample was run in triplicate, and the results were presented as average values standard deviation (SD).

The antimicrobial properties of the modified PET/C (activated PET/C blended fabric waste and loaded with Dunaliella-ZnO-NPs) against unmodified PET/C fabric waste were evaluated using the disk diffusion technique. In this procedure, the antimicrobial efficacy was measured using the AATCC standard test technique by measuring the diameter of the growth inhibition zone surrounding the sample in millimeters [36].

Characterization of the modified PET/C fabric wastes by SEM–EDX (energy dispersive X-ray analyzer) and FTIR analyses

A JEOL-Model JSM T20 SEM was used to describe the surface structure and morphology of the fabric waste sample, either before or after modification, and to take photos of the fabric surfaces. Using the FTIR (model NEXUS 670, NICOLET, USA), it was possible to identify the chemical structure of the NPs and how they interacted chemically with the functional groups of the loaded fabric waste. The observations were made in the 4000–500 cm−1 spectral region. Using the reflection percentage measuring technique (R%), all samples were determined.

Determination of ultraviolet protection factor (UPF)

The amount of ultraviolet protection provided by the finished samples was evaluated by measuring Ultraviolet Radiation (UVR) transmission using UV-Shimadzu 3101-PC-Spectrophotometer. The UPF values were calculated according to the Australian/New Zealand Standard (AS/NZS-4399-1996) [37]. UPF values were calculated, and the protection category was classified as follows: (0–10) non-ratable, (15–20) good, (25–35) very good, and (40–50, >50) excellent protection categories [37].

Results and discussion

Microalgal-synthesis of Dunaliella-ZnO-NPs and characterization

The aqueous cell extract of the marine microalga Dunaliella sp. (cultivation on BBM supplemented with sea salts) was used for the biosynthesis of ZnO-NPs. The results showed that the amount of ZnNPs obtained from the biomass extract of 3-week-old microalgae was greater than that of 2- or 4-week-olds. This age was relatively important for producing bioactive substances that are used as reducing, capping, and protective agents. The cell-free aqueous extract of dry biomass was used as a biological reduction system to convert zinc ions to their nanoform. In addition, it was observed that the percentage of the total phenols, as reducing agents, in the obtained extract was relatively high (5.762 mg/g as gallic acid), indicating that the extraction procedures were efficient, and a significant portion of the cell contents was extracted. Our findings comply with some previous investigations reporting that microalgae, as photosynthesis microorganisms, play an important role as factories for producing bioactive substances as reducing agents [38] such as phenols, polysaccharides, flavonoids, and proteins, etc., which are beneficial in nanomaterials manufacturing [39]. The manufacturing process starts with overnight incubation of the cell-free aqueous extract with zinc acetate solution, which forms creamy-white precipitates. The formation of Dunaliella-ZnO-NPs was confirmed by the spectrophotometric scan of the mixture, and the results showed that the maximum achieved wavelength was 350 nm (Fig. 2).

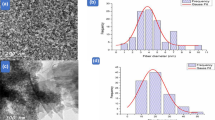

The biosynthesized Dunaliella-ZnO-NPs using the aqueous extract of the marine microalga, Dunaliella sp. were characterized using SEM–EDX, HRTEM, XRD, and FTIR techniques. SEM was used to study the morphology, size, and topography of the biosynthesized Dunaliella-ZnO-NPs (Fig. 3), and the electron microscopy picture confirmed the formation of nearly spherical Zn nanoparticles entrapped with O molecules (Fig. 3a). Moreover, the formed zinc nanoparticles were proven to be mainly ZnO-NPs after elemental analysis (EDX), which confirmed the SEM pictures, as illustrated in Fig. 3b. Dunaliella sp., as a photosynthetic-single cell-organism, produces phenolic and flavonoid compounds as reducing agents to reduce Zn ions to zero valent forms and then oxidize them to produce an oxide state of nanometal [40]. In addition, the SEM–EDX instrument was used to deliver a quick non-destructive determination of the elemental composition [41]. The related size and shape of the produced Dunaliella-ZnO-NPs, as presented in Fig. 3c, ranged between 10–20 nm with a spherical shape, as shown in the HRTEM picture. This means that the produced Dunaliella-ZnO was in nanoparticle form. This is in agreement with Rabecca and his coauthors [16].

FTIR was used to determine the possible biomolecules responsible for the reduction, capping, and effective stabilization of ZnO-NPs (Fig. 4a). FTIR spectrum of Dunaliella-ZnO-NPs prepared from the aqueous extract of Dunaliella sp. was obtained to provide insights into the presence of functional groups in the synthesized ZnO-NPs. In addition, FTIR analysis provides insight into different bio-compounds in microalgae extract that may act as reducing, stabilizing, and capping agents during the biosynthesis of such NPs. The FTIR spectrum of zinc oxide nanoparticles shows intense absorption peaks at 3413 (NH), in addition to 2925, 1633, 1415, 1392, 1099, 1041, 873, 769, and 603 cm−1, which reprsent zinc nanoparticles (Fig. 4a). As illustrated in this figure, several peaks were discovered in the spectral range of alkanes, alcohols, carboxylic acids and amids groups, as previously mentioned [42]. The dual role as a green reducing agent and also as a stabilizing agent is indicated by the FTIR of ZnO-NPs and the existing bands.

The crystalline structure of the produced ZnO-NPs was determined using XRD, as shown in Fig. 4b. The peaks at 2θ values can be associated with (100), (002), (101), (102), (110) (103), (200) and (004). These values correlate to the hexagonal zinc item phase of ZnO and are in good accord with previously reported data (JCPDS card No. 36-1451) [43]. No additional diffraction peaks were detected for the other phases indicating the phase purity of ZnO nanopowder (Fig. 4b).

Production of smart textile from PET/C wastes after activation by Dunaliella-ZnO-NPs

Textile fabric wastes are produced in large amounts daily. It is important to take benefits from such wastes to prevent the resulting pollution. Thus, the wastes of PET/C fabrics were collected from Misr Al-Amerya Co., Alex., Misr Al-Mahalla Co., Al-Mahalla El-Kobra and Misr ElBida Co. (Kafr El-Dawar, Egypt) to convert it to smart textiles. The fabric wastes were activated by cellulase enzyme to ensure the availability of the active groups that combine with the prepared Dunaliella-ZnO-NPs (Fig. 5). In this work, biological treatment of PET/C blended fabrics was performed using fungal cellulases (3%). As a result of the action of cellulase enzymes, partial degradation of cellulose fibers occurred, which resulted in the release of some soluble compounds, such as short-chain oligomers and glucose; accordingly, three percent of the fiber weight was lost due to the partial degradation process [44]. Moreover, the biotinylated tissues’ surface modification enhanced the carboxylic content and hence enhanced the ability of nanoparticles to be immobilized on their surfaces. According to the obtained results, the carboxylic content increased from 3.65 × 10−3 to 1.02 × 10−2 mmol/g fabric due to the enzymatic treatment. Thus, by increasing the number of carboxylic groups, which was confirmed by the EDX analysis, the amount of Dunaliella-ZnO-NPs loaded on the surface of activated textile waste increased.

The main objective of transferring selected nanoparticles and attaching them to textile materials is to add new desirable properties to improve the specifications of the final product. Loading nanomaterials onto the fabrics could be improved by increasing the number of active sites and functional groups on the surface of the fabric material itself. Surface characterization of the activated fabric waste in terms of shape, surface coating, and distribution of Dunaliella-ZnO-NPs was visualized by scanning electron microscopy (Fig. 6). SEM images of activated fabric waste either loaded or not with Dunaliella-ZnO-NPs were recorded in comparison with the parent untreated fiber (control). As shown in Fig. 6a, b, the parent and activated PET/C textiles mixed with cellulases have pristine and smooth surfaces. In addition, the textiles gained a smooth surface with better resilience and soft handling after partial hydrolysis by cellulases. In addition, the marked reduction in fabric weight and the removal of the hair from the cloth surface reduced the stiffness and thickness and provided a smooth surface. Dunaliella-ZnO-NPs treated textiles resulted in the development of certain deposits on the surface of activated fabrics (Fig. 6c). In addition, the size and construction of such deposits differ depending on the applied NPs.

SEM–EDX pictures of activated PET/C blended fabrics waste and the loaded with Dunaliella-ZnO-NPs (1000×) after five washing cycles according to AATCC test method (61-1989); a PET/C; b PET/C+E; c PET/C+E+ZnO; d EDX picture of PET/C+E+ZnO. NPs, Nanoparticles; AATCC, American Association of Textile Chemists and Colorists; PET/C, polyester/cotton; E, cellulases enzyme

EDX analysis supports the detection of Dunaliella-ZnO-NPs on the surface of waste PET/C mixed textiles. Figure 6d displays the EDX spectra of the textiles loaded with Dunaliella-ZnO-NPs following five washing cycles. It is significant to conclude that the composition of the deposited material mainly contains Zn and oxygen molecules based on the generated spectra. On the other hand, the results showed that even after five washing cycles (equal to about 25 home washings), metal oxide NPs were still attached to the fabrics’ waste surfaces. EDX measurements also revealed a higher NP content on activated fabrics by cellulases (NP mass percent of ZnO-NPs was 9.53%). This indicates that the activated fabric waste sufficiently adhered to the Dunaliella-ZnO-NPs. The chemical composition of the textile surfaces was significantly altered by enzymatic activity.

To study the changes in the bio-molecular composition of the produced textile, the formation of the molecule’s covalent bonds was studied by FTIR spectrum (Fig. 7). The obtained graph from this analysis showed that the parent fabric involved absorptions at 1649–1712, 2317, 3388 and 3408 cm−1, which are typical of those of C=O, CH and OH stretching [45]. The FTIR spectrum of activated PET/C blended fabric waste after enzyme activation and loading of Dunaliella-ZnO-NPs showed that new characteristic peaks appeared at around 665 cm−1 and 540 cm−1. Zn–O bonds were represented by these peaks as reported by Hong et al. [46] and Mawed et al. [47]. The results achieved during the current study explained that NPs from dispersion solutions could only be fixed on active surfaces.

The cytotoxicity of the prepared nanomaterials is a very important concern, especially with those materials applied with direct human contact. From these materials, such nanomaterials have been applied in textiles to develop their biological properties. Thus, the current work aimed to evaluate the cytotoxicity of the prepared Dunaliella-ZnO-NPs. The results of cytotoxicity experiment showed that the prepared Dunaliella-ZnO-NPs did not have any toxicity against the human normal fibroblast cell line (BJ1). Thus, it safe to use these materials in human-related applications.

Application of cotton fabric wastes after modification by Dunaliella-ZnO-NPs as antimicrobial and ultraviolet protection fabrics

The action against pathogenic microbes of PET/C blended fabric waste activated by cellulases enzymes and loaded with Dunaliella-ZnO-NPs was investigated. The targeted microorganisms were Listeria monocytogenes, Staphylococcus aureus, Salmonella typhi, Escherichia coli, and non-filamentous fungi Candida albicans. Generally, the produced Dunaliella-ZnO-NPs showed antimicrobial activity against all tested pathogens (Table 1) in the range of 25–28 mm. The activity was expressed by estimating the clear zone (inhibition zone) around the well loaded with the bioactive extract. The antimicrobial properties of PET/C blended fabrics loaded with Dunaliella-ZnO-NPs after activation by cellulases are illustrated in Table 1. It is seen from these data that all fabrics after 5 washing cycles showed high antimicrobial activity against the previously mentioned pathogenic microorganisms. The inhibition zones for the fabric samples before adding Dunaliella-ZnO-NPs were lost. On the contrary, after the addition of Dunaliella-ZnO-NPs, all tested fabric samples had significant activity to inhibit the growth of the tested pathogenic microbes. The role of PET/C blended fabrics waste activation by cellulase enzymes before loading Dunaliella-ZnO-NPs on the antimicrobial property appears to be more noteworthy as the samples were washed continually in a launder-Ometer. This demonstrates the possibility of applying biosynthesis technology for preparing NPs and their application as a finishing agent with PET/C blended fabrics waste [48]. The antibacterial activity of ZnO-NPs was attributed to reactive oxygen species generation on the surface of this oxide. In addition, this agent binds to the surface of microbes and enters the pathogens to damage the nucleic materials.

To study the ultraviolet protection (UVP) properties of PET/C blended textile waste treated with cellulases reaction either before or after loading Dunaliella-ZnO-NPs, UPF values were examined and the rate of UVP was measured and expressed (Table 2). According to the UVP results, the UPF factors for parent PET/C blended textiles were equivalent to 9.6. However, after five washing cycles, activation with cellulases followed by the deposition of Dunaliella-ZnO-NPs, the UPF factor showed a significant increase to a level equal to an almost 50-fold increase in the UPF rating, which indicates outstanding UVP. These results imply excellent laundering durability of fabrics activated with enzymes and loaded with Dunaliella-ZnO-NPs. Even after five washing cycles, the UVP effectiveness of these materials is higher, demonstrating outstanding laundry durability. This also proves the feasibility of applying biosynthesis technology for preparing NPs suitable to enhance the properties of textile materials. Similar results were reported by Ran and his coauthors [49], who recorded that the UVF reached 157.8 even after five washing cycles of textile material loaded with chemically synthesized ZnO nanoparticles. Likewise, our obtained results may be due to the biomolecules attached to Dunaliella-ZnO-NPs as enhancing agents. Because ZnO ultrafine nanoparticles are well-documented UV blocking materials, they can be widely used in smart textiles to enhance their properties.

Conclusions

The aqueous extract of the marine microalga Dunaliella sp. has been shown to have the ability to biologically reduce zinc ions and convert them into their nanoform. The partial hydrolysis due to enzymatic treatments of PET/C fabric waste with cellulases causes an increase in free hydroxyl and carboxyl groups. This bio-treatment leads to a change in the surface properties of the treated fabric, hence enhanced the immobilization of Dunaliella-ZnO-NPs on their surface, giving them photoprotective and antimicrobial properties.

References

Wang, S., and Salmon, S. 2022. Progress toward circularity of polyester and cotton textiles. Sustainable Chemistry 3: 376–403. https://doi.org/10.3390/suschem3030024.

Shukla, S.R., Harad, A.M., and Jawale, L.S. 2008. Recycling of waste PET into useful textile auxiliaries. Waste Management 28: 51–56. https://doi.org/10.1016/j.wasman.2006.11.002.

Suhaimi, N.S., Muhamad, F., and Abd Razak, N.A. 2022. Recycling of polyethylene terephthalate wastes: A review of technologies, routes, and applications. Polymer Engineering and Science 62: 2355–2375. https://doi.org/10.1002/pen.26017.

Guo, Z., Eriksson, M., de la Motte, H., et al. 2021. Circular recycling of polyester textile waste using a sustainable catalyst. Journal of Cleaner Production 283: 1245792. https://doi.org/10.1016/j.jclepro.2020.124579.

Palakurthi, M. 2016. Development of composites from waste PET—cotton textiles. MSc. Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, p. 56.

Patel, V., Berthold, D., Puranik, P., et al. 2015. Screening of cyanobacteria and microalgae for their ability to synthesize silver nanoparticles with antibacterial activity. Biotechnology Reports 5: 112–119. https://doi.org/10.1016/j.btre.2014.12.001.

Annamalai, J., and Nallamuthu, T. 2016. Green synthesis of silver nanoparticles: Characterization and determination of antibacterial potency. Applied Nanoscience 6 (2): 259–265. https://doi.org/10.1007/s13204-015-0426-6.

Darwesh, O.M., Matter, I.A., Eida, M.F., et al. 2019. Influence of nitrogen source and growth phase on extracellular biosynthesis of silver nanoparticles using cultural filtrates of Scenedesmus obliquus. Applied Sciences 9 (7): 1465. https://doi.org/10.3390/app9071465.

Siddiqi, K.S., and Husen, A. 2016. Fabrication of metal and metal oxide nanoparticles by algae and their toxic effects. Nanoscale Research Letters 11: 363. https://doi.org/10.1186/s11671-016-1580-9.

Priyadarshini, E., Priyadarshini, S.S., and Pradhan, N. 2019. Heavy metal resistance in algae and its application for metal nanoparticle synthesis. Applied Microbiology and Biotechnology 103: 3297–3316. https://doi.org/10.1007/s00253-019-09685-3.

Darwesh, O.M., Li, H., and Matter, I.A. 2023. Nano-bioremediation of textile industry wastewater using immobilized CuO-NPs myco-synthesized by a novel Cu-resistant Fusarium oxysporum OSF18. Environmental Science and Pollution Research 30: 16694–16706. https://doi.org/10.1007/s11356-022-23360-7.

El-Naggar, N.E., Abdelwahed, N.A.M., and Darwesh, O.M. 2014. Fabrication of biogenic antimicrobial silver nanoparticles by Streptomyces aegyptia NEAE 102 as eco-friendly nanofactory. Journal of Microbiology and Biotechnology 24: 453–464. https://doi.org/10.4014/jmb.1310.10095.

Satapathy, S., Shukla, S.P., Sandeep, K.P., et al. 2015. Evaluation of the performance of an algal bioreactor for silver nanoparticle production. Journal of Applied Phycology 27: 285–291. https://doi.org/10.1007/s10811-014-0311-9.

Matter, I.A., Darwesh, O.M., and Eida, M.F. 2018. Harvesting of microalgae Scenedesmus obliquus using chitosan-alginate dual flocculation system. Bioscience Research 15 (1): 540–548.

Matter, I.A., Darwesh, O.M., and El-Baz, F.K. 2016. Using the natural polymer chitosan in harvesting Scenedesmus species under different concentrations and cultural pH values. International Journal of Pharma and Bio Sciences 7 (4): b254–b260.

Rabecca, R., Doss, A., Mary Kensa, V., et al. 2022. Facile synthesis of zinc oxide nanoparticle using algal extract and their antibacterial potential. Biomass Conversion and Biorefinery https://doi.org/10.1007/s13399-022-03275-6.

Vincy, W., Mahathalana, T.J., Sukumaran, S., et al. 2017. Algae as a source for synthesis of nanoparticles—a review. International Journal of Latest Trends in Engineering and Technology 5: 005–009.

Guebitz, G.M., and Cavaco-Paulo, A. 2008. Enzymes go big: Surface hydrolysis and functionalization of synthetic polymers. Trends Biotechnology 26: 32–38. https://doi.org/10.1016/j.tibtech.2007.10.003.

Silva, C., Matama, T., and Cavaco-Paulo, A. 2010. Biotransformation of synthetic fibers. In Encyclopedia of industrial biotechnology: bioprocess, bio-separation, and cell technology, ed. M.G. Flickinger. New York: Wiley.

Sarkar, A.K., and Etters, J.N. 2004. Enzymatic hydrolysis of cotton fibers: Modeling using an empirical equation. The Journal of Cotton Science 8: 254–260.

Darwesh, O.M., Ali, S.S., Matter, I.A., et al. 2020. Enzymes immobilization onto magnetic nanoparticles to improve industrial and environmental applications. Methods in Enzymology 630: 481–502. https://doi.org/10.1016/bs.mie.2019.11.006.

Malik, W.A., and Javed, S. 2021. Biochemical characterization of cellulase from Bacillus subtilis strain and its effect on digestibility and structural modifications of lignocellulose rich biomass. Frontiers in Bioengineering and Biotechnology 9: 800265. https://doi.org/10.3389/fbioe.2021.800265.

Al-Balakocy, N.G., El-Badry, K.H., and Hassan, T.M. 2013. Multi-finishing of polyester and polyester cotton blend fabrics activated by enzymatic treatment and loaded with zinc oxide NPs. Journal of Applied Sciences Research 9 (4): 2767–2776.

Barsanti, L., and Gualtieri, P. 2014. Algae: Anatomy, biochemistry, and biotechnology, 2nd ed. Boca Raton: CRC Press, Taylor & Francis Group, LLC.

Somasekharan, S.P., El-Naggar, A., Sorensen, P.H., et al. 2016. An aqueous extract of marine microalgae exhibits antimetastatic activity through preferential killing of suspended cancer cells and anticolony forming activity. Evidence-Based Complementary and Alternative Medicine 2016: 9730654. https://doi.org/10.1155/2016/9730654.

Saleh, H.A., Matter, I.A., Abdel-Wareth, M.T.A., et al. 2022. Molluscicidal, histopathological and genotoxic effects of Scenedesmus obliquus and Spirulina platensis extracts and their biosynthesized zinc oxide nanoparticles on Biomphalaria alexandrina snails. Aquaculture Research 53: 3680–3695. https://doi.org/10.1111/are.15872.

Sajjad, A., Bhatti, S.H., Ali, Z., et al. 2021. Photoinduced fabrication of zinc oxide nanoparticles: Transformation of morphological and biological response on light irradiance. ACS Omega 6 (17): 11783–11793. https://doi.org/10.1021/acsomega.1c01512.

El-Shanshoury, A.R., Darwesh, O.M., Sabae, S.Z., et al. 2020. Bio-manufacturing of selenium nanoparticles by Bacillus subtilis isolated from Qarun Lake and evaluation their activity for water remediation. Biointerface Research in Applied Chemistry 10 (4): 5834–5842. https://doi.org/10.33263/BRIAC104.834842.

Djearamane, S., Lim, Y.M., Wong, L.S., et al. 2019. Cellular accumulation and cytotoxic effects of zinc oxide nanoparticles in microalga Haematococcus pluvialis. PeerJ 7: e7582. https://doi.org/10.7717/peerj.7582.

Mosmann, T. 1983. Rapid colorimetric assays for cellular growth and survival: Application to proliferation and cytotoxicity assays. Journal of Immunological Methods 65: 55–63.

Thabrew, M.I., Hughes, R.D., and McFarlane, I.G. 1997. Screening of hepatoprotective plant components using a HepG2 cell cytotoxicity assay. Journal of Pharmacy and Pharmacology 49: 1132–1135. https://doi.org/10.1111/j.2042-7158.1997.tb06055.x.

Yang, M.-C., and Tsai, H.-Y. 1997. Ethylene glycol and glycerin as the solvent for alkaline treatment of poly(ethylene terephthalate) fabrics. Textile Research Journal 67 (10): 760–766. https://doi.org/10.1177/004051759706701009.

Mourad, R., Helaly, F., Darwesh, O.M., et al. 2019. Antimicrobial and physicomechanical natures of silver nanoparticles incorporated into silicone-hydrogel films. Contact Lens and Anterior Eye 42: 325–333. https://doi.org/10.1016/j.clae.2019.02.007.

Mourad, R.M., Darwesh, O.M., and Abdel-Hakim, A. 2020. Enhancing physico-mechanical and antibacterial properties of natural rubber using synthesized Ag–SiO2 nanoparticles. International Journal of Biological Macromolecules 164: 3243–3249. https://doi.org/10.1016/j.ijbiomac.2020.08.063.

Darwesh, O.M., Barakat, K.M., Mattar, M.Z., et al. 2019. Production of antimicrobial blue green pigment Pyocyanin by marine Pseudomonas aeruginosa. Biointerface Research in Applied Chemistry 9 (5): 4334–4339. https://doi.org/10.33263/BRIAC95.334339.

Pinho, E., Magalhães, L., Henriques, M., et al. 2011. Antimicrobial activity assessment of textiles: Standard methods comparison. Annals of Microbiology 61: 493–498. https://doi.org/10.1007/s13213-010-0163-8.

Gambichler, T., Avermaete, A., Bader, A., et al. 2001. Ultraviolet protection by summer textiles. Ultraviolet transmission verified by the determination of the minimal erythematic dose with solar-simulated radiation. British Journal of Dermatology 144: 484–489. https://doi.org/10.1046/j.1365-2133.2001.04072.x.

Martínez-Ruiz, M., Martínez-González, C.A., Kim, D.-H., et al. 2022. Microalgae bioactive compounds to topical applications products—a review. Molecules 27: 3512. https://doi.org/10.3390/molecules27113512.

Karuvantevida, N., Razia, M., Bhuvaneshwar, R., et al. 2022. Bioactive flavonoid used as a stabilizing agent of mono and bimetallic nanomaterials for multifunctional activities. Journal of Pure and Applied Microbiology 16 (3): 1652–1662. https://doi.org/10.22207/JPAM.16.3.03.

Senousy, H.H., El-Sheekh, M.M., Saber, A.A., et al. 2022. Biochemical analyses of ten cyanobacterial and microalgal strains isolated from Egyptian habitats, and screening for their potential against some selected phytopathogenic fungal strains. Agronomy 12: 1340. https://doi.org/10.3390/agronomy12061340.

Scimeca, M., Bischetti, S., Lamsira, H.K., et al. 2018. Energy dispersive X-ray (EDX) microanalysis: A powerful tool in biomedical research and diagnosis. European Journal of Histochemistry 62: 2841. https://doi.org/10.4081/ejh.2018.2841.

Bachheti, R.K., Fikadu, A., Bachheti, A., et al. 2020. Biogenic fabrication of nanomaterials from flower-based chemical compounds, characterization and their various applications: A review. Saudi Journal of Biological Sciences 27: 2551–2562. https://doi.org/10.1016/j.sjbs.2020.05.012.

Yahyaoui, A., Djebar, M.R., Khene, L., et al. 2017. Assessment of exposure wheat Triticum aestivum L. to zinc oxide nanoparticles (ZnO): evaluation of oxidative damage. Studia Universitatis" Vasile Goldis" Arad. Seria Stiintele Vietii (Life Sciences Series) 27 (4): 271–280.

Sohail, M., Barzkar, N., Michaud, P., et al. 2022. Cellulolytic and xylanolytic enzymes from yeasts: Properties and industrial applications. Molecules 27 (12): 3783. https://doi.org/10.3390/molecules27123783.

Ibrahim, N.A., El-zairy, M.R., Allam, E. and Hassan, T.M. 1999. Dyeability of bio-finished cellulosic fabrics. Colourage Annual 46: 47–54.

Hong, R.Y., Li, J.H., Chen, L.L., et al. 2009. Synthesis surface modification and photocatalytic property of ZnO nanoparticles. Powder Technology 189 (3): 426–432. https://doi.org/10.1016/j.powtec.2008.07.004.

Mawed, S.A., Centoducati, G., Farag, M.R., et al. 2022. Dunaliella salina microalga restores the metabolic equilibrium and ameliorates the hepatic inflammatory response induced by zinc oxide nanoparticles (ZnO-NPs) in male zebrafish. Biology 11: 1447. https://doi.org/10.3390/biology11101447.

Darwesh, O.M., and Elshahawy, I.E. 2021. Silver nanoparticles inactivate sclerotial formation in controlling white rot disease in onion and garlic caused by the soil borne fungus Stromatinia cepivora. European Journal of Plant Pathology https://doi.org/10.1007/s10658-021-02296-7.

Ran, J., He, M., Li, W., et al. 2018. Growing ZnO nanoparticles on polydopamine-templated cotton fabrics for durable antimicrobial activity and UV protection. Polymers 10: 495. https://doi.org/10.3390/polym10050495.

Acknowledgements

This work was supported by the program of the science, technology and innovation funding authority (STDF), Egypt under Grant No. 43447.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Darwesh, O.M., Al-Balakocy, N.G., Ghanem, A. et al. Application of microalgal-ZnO-NPs for reusing polyester/cotton blended fabric wastes after modification by cellulases enzymes. Waste Dispos. Sustain. Energy 5, 471–482 (2023). https://doi.org/10.1007/s42768-023-00170-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-023-00170-2