Abstract

Background

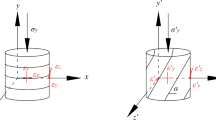

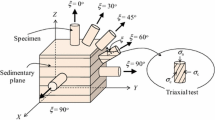

Measuring the physical properties of shale is critical for optimizing engineering activities such as geothermal energy generation and hydraulic fracturing. Shale is a transversely isotropic material. Furthermore, this material can also include micro and macro cracks at different locations and orientations that cause it to behave differently under tensile or compressive loading.

Objective

In this work, a combined experimental–numerical approach is proposed to evaluate the bi-modulus elastic properties of isotropic and transversely isotropic materials.

Methods

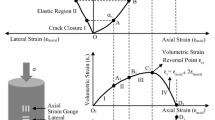

Full-field strain measurements for a circular disk under diametral compression are integrated with a regression analysis technique to evaluate the elastic properties of bi-modulus materials subjected to tensile and compressive loads using two loading configurations on the same specimen. Digital Image Correlation (DIC) is used to measure the full-field strains. Subsequently, in the case of an isotropic material, a linear least-squares approach is utilized to process the experimentally determined strains in conjunction with analytical expressions of the stress fields (in terms of far-field loading) to determine the elastic modulus E, the shear modulus G, and the Poisson’s ratio \(\nu\). In the case of a transversely isotopic material, such as shale, a finite element model is implemented to determine the stress fields (again in terms of far-field loading), which is followed by repeating the previous regression analysis in an iterative process to estimate the elastic parameters.

Results

The results show that the proposed technique successfully provides a complete set of elastic properties as a function of both the loading condition and the principal material directions. The technique is validated by measurements on a known isotropic material and then applied to determine the properties of shale.

Conclusion

The proposed approach is successfully used to calculate the bi-modulus elastic response of poly(methyl methacrylate) (PMMA) and shale. As expected, PMMA exhibits an isotropic response with no bi-modulus effect, however, shale exhibits both transverse isotropy and a bi-modulus effect. Therefore, this approach holds promise for investigating the elastic properties of materials like rocks and fiber-reinforced composite laminates as functions of the principal material directions and the loading conditions.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon request.

References

Zhou J, Tian S, Xian X, Zheng Y, Yang K, Liu J (2022) Comprehensive review of property alterations induced by CO\(_{2}\)-shale interaction: implications for CO\(_{2}\) sequestration in shale. Energ Fuel 36(15):8066–8080

Hu L (2022) A review of mechanical mechanism and prediction of natural fracture in shale. Arab J Geosci 15(6):474

Liu Y, Yang H, Zhang Q, Xiong D (2022) Properties of a shale bedding plane and its influence on the geometric parameters of fracture propagation in volume fracturing. Eng Fract Mech 266:108413

Mehana M, Santos JE, Neil C, Carey JW, Guthrie G, Hyman J, Kang Q, Karra S, Sweeney M, Xu H et al (2022) Shale fundamentals: experimental and modeling insights. Energy Rep 8:11192–11205

Gautam R, Wong RC (2006) Transversely isotropic stiffness parameters and their measurement in Colorado Shale. Can Geotech J 43(12):1290–1305

Hakala M, Kuula H, Hudson J (2007) Estimating the transversely isotropic elastic intact rock properties for in situ stress measurement data reduction: a case study of the Olkiluoto Mica Gneiss, Finland. Int J Rock Mech Min Sci 44(1):14–46

Ming F, Li D, Zhang M, Zhang Y (2017) A novel method for estimating the elastic modulus of frozen soil. Cold Reg Sci Technol 141:1–7

Patel S, Martin CD (2018) Evaluation of tensile Young’s modulus and Poisson’s ratio of a bi-modular rock from the displacement measurements in a Brazilian test. Rock Mech Rock Eng 51(2):361–373

Rybacki E, Reinicke A, Meier T, Makasi M, Dresen G (2015) What controls the mechanical properties of shale rocks?-part i: Strength and Young’s modulus. J Petrol Sci Eng 135:702–722

Li D, Wong LNY (2013) The Brazilian disc test for rock mechanics applications: review and new insights. Rock Mech Rock Eng 46:269–287

Khanlari G, Rafiei B, Abdilor Y (2015) Evaluation of strength anisotropy and failure modes of laminated sandstones. Arab J Geosci 8:3089–3102

Akazawa T (1943) New test method for evaluating internal stress due to compression of concrete (the splitting tension test)(part 1). J Jpn Soc Civ Eng 29:777–787

Carneiro F (1943) A new method to determine the tensile strength of concrete. In: Proceedings of the 5th meeting of the Brazilian Association for Technical Rules. pp 126–129

McLamore R, Gray KE (1967) The mechanical behavior of anisotropic sedimentary rocks. J Eng Ind 89:62–73

Barla G (1974) Rock anisotropy: theory and laboratory testing. In: Rock Mechanics. Springer, pp 131–169

Hondros G (1959) The evaluation of Poisson’s ratio and the modulus of materials of a low tensile resistance by the Brazilian (indirect tensile) test with particular reference to concrete. Aust J Appl Sci 10:243–264

Loureiro-Pinto J (1979) Determination of the elastic constants of anisotropic bodies by diametral compression tests. In: 4th ISRM Congress. OnePetro

Costin LS (1983) A microcrack model for the deformation and failure of brittle rock. J Geophys Res 88(B11):9485–9492

Muskhelishvili NI et al (1953) Some basic problems of the mathematical theory of elasticity, vol 15. Noordhoff Groningen

Amadei B, Rogers J, Goodman R (1983) Elastic constants and tensile strength of anisotropic rocks. In: 5th ISRM Congress. OnePetro

Ōkubo H (1952) The stress distribution in an aeolotropic circular disk compressed diametrically. J Math Phys 31(1–4):75–83

Lekhnitskii SG (1968) Anisotropic plates, tech. rep., Foreign Technology Div Wright-Patterson Afb Oh

Istvan J, Evans L, Weber J, Devine C (1997) Rock mechanics for gas storage in bedded salt caverns. Int J Rock Mech Min Sci 34(3–4):142-e1

ASTM-D3697-08 (2008) Standard test method for splitting tensile strength of intact rock core specimens. In: Annual book of ASTM standards. West Conshohocken PA: ASTM International., no. Reapproved, pp 1–3

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 15(3):99–103

Chen C-S, Pan E, Amadei B (1998) Determination of deformability and tensile strength of anisotropic rock using Brazilian tests. Int J Rock Mech Min Sci 35(1):43–61

ABAQUS (2017) Abaqus-CAE, Standard User’s Manual. Dassault Systèmes Simulia Corp., Version

Sutton MA, Orteu JJ, Schreier H (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer Science & Business Media

Ye J, Wu F, Zhang Y, Ji H (2012) Estimation of the bi-modulus of materials through deformation measurement in a Brazilian disk test. Int J Rock Mech Min Sci 52:122–131

Correlated Solutions. VIC–2D. Correlated Solutions Inc. VIC–2D software. http://www.correlatedsolutions.com. Accessed 1 Mar 2020

A. C496/C496M-17. Splitting tensile strength of cylindrical concrete specimens. ASTM International, no, pp 1–5. www.astm.org. Accessed 1 Mar 2020

Komurlu E, Kesimal A (2015) Evaluation of indirect tensile strength of rocks using different types of jaws. Rock Mech Rock Eng 48:1723–1730

Dally JW, Riley WF, Kobayashi A (1978) Experimental stress analysis. College House Enterprises Llc

Tu P, Liu X (2017) An error criterion in digital image correlation for unknown deformation fields and its application of parameters selection. Exp Mech 57:783–799

Chong KP, Smith JW, Borgman ES (1982) Tensile strengths of Colorado and Utah oil shales. J Energy 6(2):81–85

Jianhong Y, Wu F, Sun J (2009) Estimation of the tensile elastic modulus using Brazilian disc by applying diametrically opposed concentrated loads. Int J Rock Mech Min Sci 46(3):568–576

Wang QZ, Jia XM, Kou S, Zhang Z, Lindqvist P-A (2004) The flattened Brazilian disc specimen used for testing elastic modulus, tensile strength and fracture toughness of brittle rocks: analytical and numerical results. Int J Rock Mech Min Sci 41(2):245–253

Kourkoulis S, Markides CF, Chatzistergos P (2013) The standardized Brazilian disc test as a contact problem. Int J Rock Mech Min Sci 57:132–141

Saxena P, Shukla P (2022) A comparative analysis of the basic properties and applications of poly (vinylidene fluoride)(PVDF) and poly (methyl methacrylate)(PMMA). Polym Bull 79(8):5635–5665

Zafar MS (2020) Prosthodontic applications of polymethyl methacrylate (PMMA): an update. Polymers 12(10):2299

Acknowledgements

The authors would like to acknowledge Kyle R. Messer from Oklahoma State University for his assistance in experimental setup and specimen photography.

Funding

This material is based upon work supported by the Department of Energy under Award Number DE-FE0031777. This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

R.P. Singh and A. Thumbalam Guthai are members of SEM.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fahem, A.F., Thumbalam Guthai, A. & Singh, R.P. Full-Field Strain Measurement Integrated with Two Dimension Regression Analysis to Evaluate the Bi-Modulus Elastic Properties of Isotropic and Transversely Isotropic Materials. Exp Mech 64, 53–71 (2024). https://doi.org/10.1007/s11340-023-01007-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-01007-z