Abstract

The main objective of food rheology is to identify food structure and texture by rheological measurements, thereby reducing the requirement for sensory analysis in evaluating food products. However, determining food texture and structure exclusively from rheological measurements can be challenging because of the complicated composition and structure of food, as well as the complexities of factoring in the changes that occur during food mastication. This article provides a comprehensive review of the current experimental, computational and machine learning techniques used in food rheology to probe the structure and texture of food products. The textural attributes and structural information that can be inferred from each measurement technique is discussed and recent studies that carried out the measurements are highlighted. Also presented in this review are the recent progress in the experimental techniques and challenges.

Graphical abstract

Similar content being viewed by others

References

Nnyigide OS (2019) A Study of Bovine Serum Albumin (BSA) Hydrogel with Various Chemical Denaturants by Rheological Measurements and Molecular Dynamics Simulation, Ph.D. Thesis. Pusan National University.

Borwankar RP (1992) Food texture and rheology: a tutorial review. J Food Eng 16:1–16. https://doi.org/10.1016/0260-8774(92)90016-Y

Melito HS, Daubert CR (2011) Rheological innovations for characterizing food material properties. Annu Rev Food Sci Technol 2:153–179. https://doi.org/10.1146/annurev-food-022510-133626

Tabilo-Munizaga G, Barbosa-Cánovas GV (2005) Rheology for the food industry. J Food Eng 67:147–156. https://doi.org/10.1016/j.jfoodeng.2004.05.062

Ipsen R (2008) Food rheology: A personal view of the past and future. Annu trans Nord Rheol Soc 16

Zhu Y, Gao H, Liu W, Zou L, McClements DJ (2020) A review of the rheological properties of dilute and concentrated food emulsions. J Texture Stud 51:45–55. https://doi.org/10.1111/jtxs.12444

Diamante L, Umemoto M (2015) Rheological properties of fruits and vegetables: a review. Int J Food Prop 18(6):1191–1210. https://doi.org/10.1080/10942912.2014.898653

Wang Y, Selomulya C (2022) Food rheology applications of large amplitude oscillation shear (LAOS). Trends Food Sci Technol 127:221–244. https://doi.org/10.1016/j.tifs.2022.05.018

Joyner HS (2021) Nonlinear (large-amplitude oscillatory shear) rheological properties and their impact on food processing and quality. Annu Rev Food Sci Technol 12:591–609. https://doi.org/10.1146/annurev-food-061220-100714

Nnyigide OS, Hyun K (2018) Effects of anionic and cationic surfactants on the rheological properties and kinetics of bovine serum albumin hydrogel. Rheol Acta 57:563–573. https://doi.org/10.1007/s00397-018-1100-1

Nnyigide OS, Hyun K (2020) The rheological properties and gelation kinetics of corn starch/bovine serum albumin blend. Korea Aust Rheol J 32:71–78. https://doi.org/10.1007/s13367-020-0008-3

Nnyigide OS, Hyun K (2018) Rheo-kinetics of bovine serum albumin in catanionic surfactant systems. Korean J Chem Eng 35:1969–1978. https://doi.org/10.1007/s11814-018-0128-3

Faber TJ, Van Breemen LCA, McKinley GH (2017) From firm to fluid—structure-texture relations of filled gels probed under large amplitude oscillatory shear. J Food Eng 210:1–18. https://doi.org/10.1016/j.jfoodeng.2017.03.028

Fancey KS (2005) A mechanical model for creep, recovery and stress relaxation in polymeric materials. J Mater Sci 40(18):4827–4831. https://doi.org/10.1007/s10853-005-2020-x

Freer EM, Yim KS, Fuller GG, Radke CJ (2004) Interfacial rheology of globular and flexible proteins at the hexadecane/water interface: comparison of shear and dilatation deformation. J Phys Chem B 108(12):3835–3844. https://doi.org/10.1021/jp037236k

Heyer P, Läuger J (2008) Interfacial Shear Rheology of Films Formed by Coffee. Annu trans Nord Rheol Soc 16.

Joyner HS (2018) Explaining food texture through rheology. Curr Opin Food Sci 21:7–14. https://doi.org/10.1016/j.cofs.2018.04.003

Hyun K, Wilhelm M, Klein CO, Cho KS, Nam JG, Ahn KH, Lee SJ, Ewoldt RH, McKinley GH (2011) A review of nonlinear oscillatory shear tests: analysis and application of large amplitude oscillatory shear (LAOS). Prog Polym Sci 36:1697–1753. https://doi.org/10.1016/j.progpolymsci.2011.02.002

Du J, Ohtani H, Owens CE, Zhang L, Ellwood K, McKinley GH (2021) An improved capillary breakup extensional rheometer to characterize weakly rate-thickening fluids: applications in synthetic automotive oils. J Nonnewton Fluid Mech 291:104496. https://doi.org/10.1016/j.jnnfm.2021.104496

Huang Q (2022) When polymer chains are highly aligned: a perspective on extensional rheology. Macromolecules 55(3):715–727. https://doi.org/10.1021/acs.macromol.1c02262

Lee CW, Rogers SA (2017) A sequence of physical processes quantified in LAOS by continuous local measures. Korea-Aust Rheol J 29(4):269–279. https://doi.org/10.1007/s13367-017-0027-x

Melito HS, Daubert CR, Foegeding EA (2013) Relating large amplitude oscillatory shear and food behavior: correlation of nonlinear viscoelastic, rheological, sensory and oral processing behavior of whey protein isolate/κ-carrageenan gels: relating LAOS and food behavior. J Food Process Eng 36(4):521–534. https://doi.org/10.1111/jfpe.12015

Yue Q, Li M, Liu C, Li L, Zheng X, Bian K (2020) Comparison of uniaxial/biaxial extensional rheological properties of mixed dough with traditional rheological test results: relationship with the quality of steamed bread. Int J Food Sci Technol 55(7):2751–2761. https://doi.org/10.1111/ijfs.14528

Del Nobile MA, Chillo S, Mentana A, Baiano A (2007) Use of the generalized maxwell model for describing the stress relaxation behavior of solid-like foods. J Food Eng 78(3):978–983. https://doi.org/10.1016/j.jfoodeng.2005.12.011

Vithanage CR, Grimson MJ, Smith BG, Wills PR (2011) Creep test observation of viscoelastic failure of edible fats. J Phys Conf Ser 286:012008. https://doi.org/10.1088/1742-6596/286/1/012008

Yu C, Gunasekaran S (2001) Correlation of dynamic and steady flow viscosities of food materials. Appl Rheol 11(3):134–140. https://doi.org/10.1515/arh-2001-0008

Song HY, Nnyigide OS, Salehiyan R, Hyun K (2016) Investigation of nonlinear rheological behavior of linear and 3-arm star 1,4-Cis-polyisoprene (PI) under medium amplitude oscillatory shear (MAOS) flow via FT-rheology. Polymer 104:268–278. https://doi.org/10.1016/j.polymer.2016.04.052

Hyun K, Kim SH, Ahn KH, Lee SJ (2002) Large amplitude oscillatory shear as a way to classify the complex fluids. J Nonnewton Fluid Mech 107(1):51–65. https://doi.org/10.1016/S0377-0257(02)00141-6

Song HY, Park SY, Kim S, Youn HJ, Hyun K (2022) Linear and nonlinear oscillatory rheology of chemically pretreated and non-pretreated cellulose nanofiber suspensions. Carbohydr Polym 275:118765. https://doi.org/10.1016/j.carbpol.2021.118765

Van Den Berg L, Jan Klok H, Van Vliet T, Van Der Linden E, Van Boekel MAJS, Van De Velde F (2008) Quantification of a 3D structural evolution of food composites under large deformations using microrheology. Food Hydrocoll 22(8):1574–1583. https://doi.org/10.1016/j.foodhyd.2007.11.002

Rogers SA (2017) In search of physical meaning: defining transient parameters for nonlinear viscoelasticity. Rheol Acta 56(5):501–525. https://doi.org/10.1007/s00397-017-1008-1

Wilhelm M (2002) Fourier-Transform Rheology. Macromol Mater Eng 287:83–105. https://doi.org/10.1002/1439-2054(20020201)287:2%3c83::AID-MAME83%3e3.0.CO;2-B

Kohyama K, Ishihara S, Nakauma M, Funami T (2021) Fracture phenomena of soft gellan gum gels during compression with artificial tongues. Food Hydrocoll 112:106283. https://doi.org/10.1016/j.foodhyd.2020.106283

Ishihara S, Isono M, Nakao S, Nakauma M, Funami T, Hori K, Ono T, Kohyama K, Nishinari K (2014) Instrumental uniaxial compression test of gellan gels of various mechanical properties using artificial tongue and its comparison with human oral strategy for the first size reduction. J Texture Stud 45:354–366. https://doi.org/10.1111/jtxs.12080

Zhou B, Tobin JT, Drusch S, Hogan SA (2021) Dynamic adsorption and interfacial rheology of whey protein isolate at oil-water interfaces: effects of protein concentration. PH and Heat Treatment Food Hydrocoll 116:106640. https://doi.org/10.1016/j.foodhyd.2021.106640

Moore PB, Langley K, Wilde PJ, Fillery-Travis A, Mela DJ (1998) Effect of emulsifier type on sensory properties of oil-in-water emulsions. J Sci Food Agric 76:469–476. https://doi.org/10.1002/(SICI)1097-0010(199803)76:3%3c469::AID-JSFA974%3e3.0.CO;2-Y

El Omari Y, Yousfi M, Duchet-Rumeau J, Maazouz A (2022) Recent advances in the interfacial shear and dilational rheology of polymer systems: from fundamentals to applications. Polymers 14(14):2844. https://doi.org/10.3390/polym14142844

Murray BS (2002) Interfacial rheology of food emulsifiers and proteins. Curr Opin Colloid Interface 7:426–431. https://doi.org/10.1016/S1359-0294(02)00077-8

Zhou Y, Mei Y, Luo T, Chen W, Zhong Q, Chen H, Chen W (2021) Study on the relationship between emulsion properties and interfacial rheology of sugar beet pectin modified by different enzymes. Molecules 26(9):2829. https://doi.org/10.3390/molecules26092829

Wang S, Zhou B, Yang X, Niu L, Li S (2022) Tannic acid enhanced the emulsion stability, rheology and interface characteristics of clanis bilineata tingtauica mell protein stabilised oil-in-water emulsion. Int J of Food Sci Tech 57(8):5228–5238. https://doi.org/10.1111/ijfs.15839

Wang S, Yang J, Shao G, Qu D, Zhao H, Yang L, Zhu L, He Y, Liu H, Zhu D (2020) Soy protein isolated-soy hull polysaccharides stabilized O/W emulsion: effect of polysaccharides concentration on the storage stability and interfacial rheological properties. Food Hydrocoll 101:105490. https://doi.org/10.1016/j.foodhyd.2019.105490

Yang J, Thielen I, Berton-Carabin CC, van der Linden E, Sagis LMC (2020) Nonlinear interfacial rheology and atomic force microscopy of air-water interfaces stabilized by whey protein beads and their constituents. Food Hydrocoll 101:105466. https://doi.org/10.1016/j.foodhyd.2019.105466

Geonzon LC, Kobayashi M, Tassieri M, Bacabac RG, Adachi Y, Matsukawa S (2023) Microrheological properties and local structure of ι-carrageenan gels probed by using optical tweezers. Food Hydrocoll 137:108325. https://doi.org/10.1016/j.foodhyd.2022.108325

Mettu S, Zhou M, Tardy BL, Ashokkumar M, Dagastine RR (2016) Temperature dependent mechanical properties of air, oil and water filled microcapsules studied by atomic force microscopy. Polymer 102:333–341. https://doi.org/10.1016/j.polymer.2016.02.046

Papagiannopoulos A, Sotiropoulos K, Pispas S (2016) Particle tracking microrheology of the power-law viscoelasticity of xanthan solutions. Food Hydrocoll 61:201–210. https://doi.org/10.1016/j.foodhyd.2016.05.020

Jin H, Chen J, Zhang J, Sheng L (2021) Impact of phosphates on heat-induced egg white gel properties: Texture, water state, micro-rheology and microstructure. Food Hydrocoll 110:106200. https://doi.org/10.1016/j.foodhyd.2020.106200

Bakhsh A, Elobeid T, Avci E, Demirci M, Taylan O, Ozmen D, Meral R, Yilmaz MT (2022) A tracer microrheology for determination of viscoelasticity of dilute ovalbumin colloids. Emerg Mater Res 11(1):98–104. https://doi.org/10.1680/jemmr.20.00282

Xu J, Boddu VM, Liu SX (2023) Microrheological investigation of low-viscosity barley β-glucan (LVBBG) solutions by diffusion wave spectroscopy (DWS). Am J Food Technol 18:8–15. https://doi.org/10.3923/ajft.2023.8.15

Yang N, Lv R, Jia J, Nishinari K, Fang Y (2017) Application of microrheology in food science. Annu Rev Food Sci Technol 8(1):493–521. https://doi.org/10.1146/annurev-food-030216-025859

Nath PC, Debnath S, Sridhar K, Inbaraj BS, Nayak PK, Sharma M (2022) A comprehensive review of food hydrogels: principles, formation mechanisms, microstructure, and its applications. Gels 9(1):1. https://doi.org/10.3390/gels9010001

Lodge JFM, Heyes DM (1999) Rheology of transient colloidal gels by brownian dynamics computer simulation. J Rheol 4(1):219–244. https://doi.org/10.1122/1.550984

Whittle M, Dickinso E (1997) Brownian Dynamics simulation of gelation in soft sphere systems with irreversible bond formation. Mol Phys 90(5):739–758. https://doi.org/10.1080/002689797172101

Carpen IC, Brady JF (2005) Microrheology of colloidal dispersions by brownian dynamics simulations. J Rheol 49(6):1483–1502. https://doi.org/10.1122/1.2085174

Santos PHS, Campanella OH, Carignano MA (2010) Brownian dynamics study of gel-forming colloidal particles. J Phys Chem B 114(41):13052–13058. https://doi.org/10.1021/jp105711y

Liu L, Zhang Y, Dao L, Huang X, Qiu R, Pang P, Wu S (2023) Efficient and accurate multi-scale simulation for viscosity mechanism of konjac glucomannan colloids. Int J Biol Macromol 236:123992. https://doi.org/10.1016/j.ijbiomac.2023.123992

Azevedo TN, Rizzi LG (2020) Microrheology of filament networks from brownian dynamics simulations. J Phys Conf Ser 1483(1):012001. https://doi.org/10.1088/1742-6596/1483/1/012001

Chen JY, Li Z, Szlufarska I, Klingenberg DJ (2021) Rheology and structure of suspensions of spherocylinders via brownian dynamics simulations. J Rheol 65(2):273–288. https://doi.org/10.1122/8.0000155

Park JD, Rogers SA (2020) Rheological manifestation of microstructural change of colloidal gel under oscillatory shear flow. Phys Fluids 32(6):063102. https://doi.org/10.1063/5.0006792

Sánchez-Diáz LE, Iwashita T, Egami T, Chen WR (2019) Connection between the anisotropic structure and nonlinear rheology of sheared colloidal suspensions investigated by brownian dynamics simulations. J Phys Commun 3(5):055018. https://doi.org/10.1088/2399-6528/ab1e79

Liu L, Zhou N, Yang Y, Huang X, Qiu R, Pang J, Wu S (2022) Rheological properties of konjac glucomannan composite colloids in strong shear flow affected by mesoscopic structures: Multi-scale simulation and experiment. Colloids Surf A Physicochem Eng Asp 652:129850. https://doi.org/10.1016/j.colsurfa.2022.129850

Nnyigide OS, Lee SG, Hyun K (2018) Exploring the differences and similarities between urea and thermally driven denaturation of bovine serum albumin: intermolecular forces and solvation preferences. J Mol Model 24:75. https://doi.org/10.1007/s00894-018-3622-y

Nnyigide OS, Hyun K (2021) Molecular dynamics studies of the protective and destructive effects of sodium dodecyl sulfate in thermal denaturation of hen egg-white lysozyme and bovine serum albumin. J Biomol Struct Dyn 39:1106–1120. https://doi.org/10.1080/07391102.2020.1726209

Nnyigide OS, Lee SG, Hyun K (2019) In Silico Characterization of the binding modes of surfactants with bovine serum albumin. Sci Rep 9:10643. https://doi.org/10.1038/s41598-019-47135-2

Nnyigide OS, Nnyigide TO, Lee SG, Hyun K (2022) Protein repair and analysis server: a web server to repair PDB structures, add missing heavy atoms and hydrogen atoms, and assign secondary structures by amide interactions. J Chem Inf Model 62:4232–4246. https://doi.org/10.1021/acs.jcim.2c00571

Ore Areche F, Flores DDC, Quispe-Solano MA, Nayik GA, Cruz-Porta EADL, Rodríguez AR, Roman AV, Chweya R (2023) Formulation, characterization, and determination of the rheological profile of loquat compote Mespilus Germánica L. through sustenance artificial intelligence. J Food Qual 2023:1–12. https://doi.org/10.1155/2023/3344539

Lee S, Kim SR, Lee HJ, Kim BS, Oh H, Lee JB, Park K, Yi YJ, Park CH, Park JD (2022) Predictive model for the spreadability of cosmetic formulations based on large amplitude oscillatory shear (LAOS) and machine learning. Phys Fluids 34(10):103109. https://doi.org/10.1063/5.0117989

Schmidt J, Marques MRG, Botti S, Marques MAL (2019) Recent advances and applications of machine learning in solid-state materials science. npj Comput Mater 5(1): 83. https://doi.org/10.1038/s41524-019-0221-0

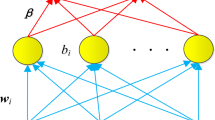

Guiné, RPF (2019) The use of artificial neural networks (ANN) in food process engineering. Int J Food Eng 5: 15–21. https://doi.org/10.18178/ijfe.5.1.15-21

Abang Zaidel DN, Chin NL, Yusof YA (2010) A Review on rheological properties and measurements of dough and gluten. J Appl Sci 10:2478–2490. https://doi.org/10.3923/jas.2010.2478.2490

Xia W, Siu WK, Sagis LMC (2021) Linear and non-linear rheology of heat-set soy protein gels: effects of selective proteolysis of β-conglycinin and glycinin. Food Hydrocoll 120:106962. https://doi.org/10.1016/j.foodhyd.2021.106962

Deblais A, Hollander ED, Boucon C, Blok AE, Veltkamp B, Voudouris P, Versluis P, Kim HJ, Mellema M, Stieger M, Bonn D, Velikov KP (2021) Predicting thickness perception of liquid food products from their non-newtonian rheology. Nat Commun 12(1):6328. https://doi.org/10.1038/s41467-021-26687-w

Agoda-Tandjawa G, Le Garnec C, Boulenguer P, Gilles M, Langendorff V (2017) Rheological behavior of starch/carrageenan/milk proteins mixed systems: role of each biopolymer type and chemical characteristics. Food Hydrocoll 73:300–312. https://doi.org/10.1016/j.foodhyd.2017.07.012

Contador L, Díaz M, Hernández E, Shinya P, Infante R (2017) The relationship between instrumental tests and sensory determinations of peach and nectarine texture. Eur J Hoticultural Sci 81:189 196.https://doi.org/10.17660/eJHS.2016/81.4.1

Nnyigide OS, Oh Y, Song HY, Park E, Choi SH, Hyun K (2017) Effect of urea on heat-induced gelation of bovine serum albumin (BSA) studied by rheology and small angle neutron scattering (SANS). Korea Aust Rheol J 29:101–113. https://doi.org/10.1007/s13367-017-0012-4

Kohyama K, Ishihara S, Nakauma M, Funami T (2019) Compression test of soft food gels using a soft machine with an artificial tongue. Foods 8(6):182. https://doi.org/10.3390/foods8060182

Ishihara S, Nakao S, Nakauma M, Funami T, Hori K, Ono T, Kohyama K, Nishinari K (2013) Compression test of food gels on artificial tongue and its comparison with human test. J Texture Stud 44(2):104–114. https://doi.org/10.1111/jtxs.12002

Melito HS, Daubert CR, Foegeding EA (2013) Relating Large Amplitude Oscillatory Shear and Food Behavior: Correlation of Nonlinear Viscoelastic, Rheological, Sensory and Oral Processing Behavior of Whey Protein Isolate/κ-Carrageenan Gels. J Food Process Eng 36: 521–534.https://doi.org/10.1111/jfpe.12015

Morell P, Hernando I, Llorca E, Fiszman S (2015) Yogurts with an increased protein content and physically modified starch: rheological, structural, oral digestion and sensory properties related to enhanced satiating capacity. Food Res Int 70:64–73. https://doi.org/10.1016/j.foodres.2015.01.024

Varela P, Pintor A, Fiszman S (2014) How hydrocolloids affect the temporal oral perception of ice cream. Food Hydrocoll 36:220–228. https://doi.org/10.1016/j.foodhyd.2013.10.005

Pereira EPR, Cavalcanti RN, Esmerino EA, Silva R, Guerreiro LRM, Cunha RL, Bolini HMA, Meireles MA, Faria JAF, Cruz AG (2016) Effect of incorporation of antioxidants on the chemical, rheological, and sensory properties of probiotic petit suisse cheese. J Dairy Sci 99:1762–1772. https://doi.org/10.3168/jds.2015-9701

Basu S, Shivhare US (2013) Rheological, textural, microstructural, and sensory properties of sorbitol-substituted mango jam. Food Bioprocess Technol 6:1401–1413. https://doi.org/10.1007/s11947-012-0795-8

Li Z, Yang Z, Zhang Y, Lu T, Zhang X, Qi Y, Wang P, Xu X (2021) Innovative characterization based on stress relaxation and creep to reveal the tenderizing effect of ultrasound on wooden breast. Foods 10(1):195. https://doi.org/10.3390/foods10010195

Jakubczyk E, Kamińska-Dwórznicka A, Kot A (2022) The rheological properties and texture of agar gels with canola oil—effect of mixing rate and addition of lecithin. Gels 8(11):738. https://doi.org/10.3390/gels8110738

Okonkwo VC, Kwofie EM, Mba OI, Ngadi MO (2021) Impact of thermos sonication on quality indices of starch-based sauces. Ultrason Sonochem 73:105473. https://doi.org/10.1016/j.ultsonch.2021.105473

Nnyigide OS, Hyun K (2020) The protection of bovine serum albumin against thermal denaturation and gelation by sodium dodecyl sulfate studied by rheology and molecular dynamics simulation. Food Hydrocoll 103:105656. https://doi.org/10.1016/j.foodhyd.2020.105656

Stading M (2021) Bolus rheology of texture-modified food: effect of degree of modification. J Texture Stud 52:540–551. https://doi.org/10.1111/jtxs.12598

Melito HS, Foegeding DCREA (2013) Relating LAOS and food behavior. J Food Process Eng 36:521–534. https://doi.org/10.1111/jfpe.12015

Jung H, Oyinloye TM, Yoon WB (2022) Evaluating the mechanical response of agarose-xanthan mixture gels using tensile testing, numerical simulation, and a large amplitude oscillatory shear (LAOS) approach. Foods 11(24):4042. https://doi.org/10.3390/foods11244042

Nnyigide OS, Nnyigide TO, Hyun K (2021) The degradation of xanthan gum in ionic and non-ionic denaturants studied by rheology and molecular dynamics simulation. Carbohydr Polym 251:117061. https://doi.org/10.1016/j.carbpol.2020.117061

Schreuders FKG, Schlangen M, Bodnár I, Erni P, Boom RM, Jan van der Goot A (2022) Structure formation and non-linear rheology of blends of plant proteins with pectin and cellulose. Food Hydrocoll 124:107327. https://doi.org/10.1016/j.foodhyd.2021.107327

Hyun K, Wilhelm M (2009) Establishing a new mechanical nonlinear coefficient Q from FT-rheology: first investigation of entangled linear and comb polymer model systems. Macromolecules 42(1):411–422. https://doi.org/10.1021/ma8017266

Pearson DS, Rochefort WE (1982) Behavior of concentrated polystyrene solutions in large-amplitude oscillating shear fields. J polym sci 20(1):83–98. https://doi.org/10.1002/pol.1982.180200107

Cho KS, Hyun K, Ahn KH, Lee SJ (2005) A geometrical interpretation of large amplitude oscillatory shear response. J Rheol 49(3):747–758. https://doi.org/10.1122/1.1895801

Ewoldt RH, Hosoi AE, McKinley GH (2008) New measures for characterizing nonlinear viscoelasticity in large amplitude oscillatory shear. J Rheol 52(6):1427–1458. https://doi.org/10.1122/1.2970095

Erturk MY, Rogers SA, Kokini J (2022) Comparison of sequence of physical processes (SPP) and fourier transform coupled with chebyshev polynomials (FTC) methods to interpret large amplitude oscillatory shear (LAOS) response of viscoelastic doughs and viscous pectin solution. Food Hydrocoll 128:107558. https://doi.org/10.1016/j.foodhyd.2022.107558

Jimenez LN, Martínez Narváez CDV, Sharma V (2020) Capillary breakup and extensional rheology response of food thickener cellulose gum (NaCMC) in salt-free and excess salt solutions. Phys Fluids 32(1):012113. https://doi.org/10.1063/1.5128254

Hadde EK, Cichero JAY, Zhao S, Chen W, Chen J (2019) The importance of extensional rheology in bolus control during swallowing. Sci Rep 9(1):16106. https://doi.org/10.1038/s41598-019-52269-4

Dinic J, Jimenez LN, Sharma V (2017) Pinch-off dynamics and dripping-onto-substrate (DoS) rheometry of complex fluids. Lab Chip 17(3):460–473. https://doi.org/10.1039/C6LC01155A

Renardy M (1995) A numerical study of the asymptotic evolution and breakup of Newtonian and viscoelastic jets. J Non-Newton Fluid Mech 59:267–282. https://doi.org/10.1016/0377-0257(95)01375-6

Marconati M, Ramaioli M (2020) The role of extensional rheology in the oral phase of swallowing: an in vitro study. Food Funct 11(5):4363–4375. https://doi.org/10.1039/C9FO02327E

Hadde EK, Nicholson TM, Cichero JAY (2020) Evaluation of thickened fluids used in dysphagia management using extensional rheology. Dysphagia 35:242–252. https://doi.org/10.1007/s00455-019-10012-1

Yue Q, Li M, Liu C, Li L, Zheng X, Bian K (2020) Extensional rheological properties in mixed and fermented/rested dough and relationships with steamed bread quality. J Cereal Sci 93:102968. https://doi.org/10.1016/j.jcs.2020.102968

Derkanosova NM, Stakhurlova AA, Vukic M, Vujadinovic D (2022) Rheological properties of composite mixtures from wheat and amaranth flour. IOP Conf Ser Earth Environ Sci 954(1):012079. https://doi.org/10.1088/1755-1315/954/1/012079

Ravera F, Loglio G, Kovalchuk VI (2010) Interfacial dilational rheology by oscillating bubble/drop methods. Curr Opin Colloid Interface 15(4):217–228. https://doi.org/10.1016/j.cocis.2010.04.001

Wijmans CM, Dickinson E (1998) Simulation of interfacial shear and dilatational rheology of an adsorbed protein monolayer modeled as a network of spherical particles. Langmuir 14(25):7278–7286. https://doi.org/10.1021/la980687p

Meleties M, Martineau RL, Gupta MK, Montclare JK (2022) Particle-based microrheology as a tool for characterizing protein-based materials. ACS Biomater Sci Eng 8(7):2747–2763. https://doi.org/10.1021/acsbiomaterials.2c00035

Nnyigide TO, Nnyigide OS, Hyun K (2023) Rheological and molecular dynamics simulation studies of the gelation of human serum albumin in anionic and cationic surfactants. Korean J Chem Eng. https://doi.org/10.1007/s11814-023-1513-0

Lee YJ, Jin H, Kim S, Myung JS, Ahn KH (2021) Brownian dynamics simulation on orthogonal superposition rheology: time-shear rate superposition of colloidal gel. J Rheol 65(3):337–354. https://doi.org/10.1122/8.0000161

Nnyigide OS, Hyun K (2016) Effect of urea and temperature on the molecular dynamics of bovine serum albumin in heavy and light water. J Chem Technol Metall 51:147–149

Nnyigide OS, Hyun K (2023) Charge-induced low-temperature gelation of mixed proteins and the effect of pH on the gelation: a spectroscopic, rheological and coarse-grained molecular dynamics study. Colloids Surf B 230:113527. https://doi.org/10.1016/j.colsurfb.2023.113527

Saeidirad MH, Rohani A, Zarifneshat S (2013) Predictions of viscoelastic behavior of pomegranate using artificial neural network and maxwell model. Comput Electron Agric 98:1–7. https://doi.org/10.1016/j.compag.2013.07.009

Torkashvand AM, Ahmadi A, Nikravesh NL (2017) Prediction of kiwifruit firmness using fruit mineral nutrient concentration by artificial neural network (ANN) and multiple linear regressions (MLR). J Integr Agric 16(7):1634–1644. https://doi.org/10.1016/S2095-3119(16)61546-0

Toker OS, Dogan M (2013) Effect of temperature and starch concentration on the creep/recovery behaviour of the grape molasses: modelling with ANN, ANFIS and response surface methodology. Eur Food Res Technol 236(6):1049–1061. https://doi.org/10.1007/s00217-013-1959-0

Al-Mahasneh M, Aljarrah M, Rababah T, Alu’datt M, (2016) Application of hybrid neural fuzzy system (ANFIS) in food processing and technology. Food Eng Rev 8(3):351–366. https://doi.org/10.1007/s12393-016-9141-7

Al-Mahasneh MA, Rababah TM, Ma’Abreh AS (2013) Evaluating the Combined Effect of Temperature, Shear Rate and Water Content on Wild-Flower Honey Viscosity Using Adaptive Neural Fuzzy Inference System and Artificial Neural Networks. J Food Process Eng 36(4): 510–520. https://doi.org/10.1111/jfpe.12014

Jeong S, Kim H, Lee S (2021) Rheology-based classification of foods for the elderly by machine learning analysis. Appl Sci 11(5):2262. https://doi.org/10.3390/app11052262

Funding

Funded by Pusan National University (2-Year Research Grant)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nnyigide, O.S., Hyun, K. A comprehensive review of food rheology: analysis of experimental, computational, and machine learning techniques. Korea-Aust. Rheol. J. 35, 279–306 (2023). https://doi.org/10.1007/s13367-023-00075-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-023-00075-w