Abstract

Loess soils have always been among the most problematic soils, according to engineers. Due to the sensitivity and vulnerability of this soil type, researchers are constantly looking for different solutions to improve and stabilize this soil using different methods. In the present study, a mixture of lime and rice husk ash (LRHA) was used to modify the loess soil of the Golestan province, Iran. Lime and RHA were mixed in a ratio of 2:4 and with different contents of 2.5, 5, 7.5, 10 and 12.5% of the dry weight of the soil. To study the effect of curing on the strength properties, the samples were cured and tested for 7, 18 and 28 days. Atterberg limits, modified Proctor, unconfined compressive strength (UCS) and scanning electron microscope tests (SEM) were performed. It was found that increasing LRHA content increased the value of UCS at different curing times, such that UCS increased about five times by the addition of 5% LRHA to the loess at the end of 28 days. As the curing time increased, the optimum amount of the additive also decreased. The results showed that combining the soil with LRHA is an effective method for improving and stabilizing loess soil. According to the results of the study, the optimum value of 5% additive is economically and technically recommended.

Similar content being viewed by others

Introduction

Loess is one of the most extensive Quaternary deposits, covering more than 10% of the Earth’s surface [1] and encompassing a wide belt that includes the north and center of China, Russia, Siberia, all of Europe, Central and North America. It has also covered the surface of the earth in other regions such as South America, Australia, North Africa, Arab countries and Iran. 477000 hectares (about 20%) of Golestan province located in the north of Iran are covered by loess soil, which is known as collapsible soil [2]. Loess is mainly composed of clay particles, silty mineral particles and quartz particles and is characterized by high porosity, metastable microstructure and water sensitivity [3]. In unsaturated state, it has certain strength and stability due to the bonding between quartz particles inside the loess [4]. However, these bonds may dissolve after immersion in water or after a major load, which may lead to collapse and deformation of the structure [5]. Stabilization of various problematic soils by cementing agents to achieve excellent engineering properties is a common practice worldwide [6].

In recent decades, many studies have been conducted on the use of rice husk ash (RHA) as a stabilizing agent for soil improvement and materials. Although RHA can improve soil, the improvement effect is not significant, so the soil should be effectively improved by using else additive in combination with pozzolanic and cementitious materials [7,8,9,10,11,12,13,14,15,16,17,18,19,20]. Chemical stabilization with cement or lime is usually done in the presence of RHA to improve the performance of problematic and weak soils (in terms of strength and deformation) [21, 22]. RHA contains a lot of silica with a high specific surface, which is very suitable for activating the soil reaction with lime the use of RHA (as Agricultural waste material) and lime for soil stabilization can lead to low-cost construction and provide an environmentally friendly means of disposal. Increased use of such materials would reduce the use of cement and also provide savings in energy and greenhouse gas emissions. Glassey studied the geotechnical properties of Port Hill loess soil in New Zealand that was stabilized with lime. He reported that the optimum lime content is 7.5% to prevent loess erosion and performed various tests such as Atterberg limits, unconfined compressive strength, and pinhole [23]. Muntohar and Hantoro [24] investigated the effect of LRHA on the engineering properties of clay soils. The test results showed that LRHA reduced the swelling behavior of clay soils. The plasticity index (PI) of the soil was decreased from 41.25 to 0.96%, and when the soil was mixed with 6–12.5% additive, the California bearing capacity (CBR) values of the soil increased up to four times. Li et al. [25] used three different additive combinations, including lime- fly ash, lime- cement, and cement- fly ash, to improve the engineering properties of loess soils in Shuzhou, China, and reported that the combination of loess soil and lime fly ash more effectively improved the shear strength parameters of the soil and reduced the collapse potential.

Huangjing and Gasaluck [26] used cement-fly ash and cement- RHA combinations to stabilize loess soils for road construction and found that the appropriate and optimum ratio in both mixtures is the cement to ash ratio of 60: 40.

Liu et al. [27] used LRHA at a ratio of 1: 4 to stabilize expanded clay soils in China. They found that the addition of 20% additive significantly reduced the specific surface area of soil particles. In addition, increasing the loading value improved the resistance properties including unconfined compressive strength, internal friction angle, and cohesion values. They recommended an additive amount of 15% and a suitable water content for mixing that was 1.2 times the optimum water content. Pushpakumara et al. [28] used the combination of RHA (5, 10, 20 and 30%) and lime (10 and 20%) during a 28 days curing time to improve clay soil with high plasticity. Their results showed that 10% ash and 20% lime were the optimum amount of additives. From the extensive literature reviews, we conclude that LRHA reinforcement has been shown to be effective for treating clayey materials and improving mechanical behavior. However, these results cannot be directly applied to loess because there are differences in soil source, composition, structure, and environmental conditions that may affect the selection of engineering practices used and the resulting properties of the stabilized loess. Loess soil in Golestan province of Iran has been studied mainly in terms of geology, while few studies have been conducted on its geotechnical properties. Considering the extent of loess soil in Golestan province, further study of its geotechnical properties and finding solutions to manage the associated risks and improve this soil type is essential [29]. This study aims to investigate the effects of LRHA on the geotechnical parameters of the loess soil of Golestan province in the north of Iran. The soil studied is loess, which constitutes about 70% of the soil in Golestan province. This type of soil has a good resistance to natural water content, and the change of water content causes many problems during the implementation of engineering projects or afterwards. Therefore, there is a need for improvement techniques and stabilizers to modify the project site and reduce the erosion potential. Due to the good effects of chemical stabilization methods on reducing the risks of such soils, the addition of lime and rice husk ash has been used to stabilize and improve loess soils.

Materials and laboratory tests

Soil properties

The study area of this research is located in the north of Iran, in Golestan province (37° 42'N, 54° 52'E). Figure 1 shows the location of the soil sampling area. According to the Unified Classification System (UCS), the soil studied is silt (ML) with low PI. The geotechnical properties of the loess soil used are summarized in Table 1. Figure 2 shows the grain distribution curve of the soil. The loess soil used was found to be uniformly graded material with particles ranging from silt to clay size. According to the Unified Soil Classification System, the soil is classified as ML. The mineralogy of the soil by X-ray diffraction (XRD) and the results of XRF are shown in Fig. 3 and Table 2, respectively. From the XRD pattern analysis, the studied soil contains mainly minerals such as calcite and muscovite, and other minerals such as quartz and albite. The main mineral composition is shown on the XRD pattern in Fig. 3. The chemical constituents of loess are mainly silica, alumina and calcium oxide. The main composition of silica indicates that loess contains significantly large amounts of quartz.

Lime

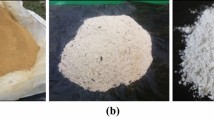

The lime used in this study is commercially available (Shahroud, Iran). The lime was sieved through sieve No. 200 before use. The results of X-ray fluorescence (XRF) examination of the lime sample used in this study are summarized in Table 3. The main constituent is CaO.

Rice husk ash

Rice husk is an agricultural by-product obtained from paddy fields. 1 ton of rice husk is obtained from every 4 tons of rice produced [30]. In the northern areas of Iran, large quantities of rice husks are produced annually, which are unsuitable as animal feed and are problematic to dispose of into the environment. Given the high content of available silica and the low cost and availability of RHA in Golestan province due to rice cultivation, it can be used in combination with lime to stabilize loess soils. In tropical countries where rice husk is widely used and considered as waste material, the use of RHA for the construction of roads, airports and other buildings is very effective in reducing construction and disposal costs and reducing environmental damage.

The rice husk used in this study came from fields in northern Iran that was burned outdoors and contained white ash with black grains. The results of XRF analysis of the sample RHA used in this study are summarized in Table 4. The amount of silica in this ash is 84.71%, indicating a high percentage of ash activity. The high percentage of siliceous material in rice husk ash indicates that it has potential pozzolonic properties and can be an excellent material for improving lime stabilization. To use RHA, it should be sieved through the No. 200 sieve.

Test procedure

First, as a preliminary study, the engineering properties of the sampled soil, such as particle size distribution, specific gravity, Atterberg limits, etc., were investigated based on the American Society for Testing and Materials (ASTM) standards. To modify and chemically improve the loess soil and to select the appropriate mixing ratio, lime and RHA were mixed with the natural soil in the ratios of 1: 1, 2: 3, 2: 4 and 2: 5 (2.5, 5, 7.5, 10 and 12.5% of the dry weight of the soil) and subjected to Atterberg limit test. As shown in Table 5, the value of the modified PI is lowest at a ratio of 2:4, so the 2:4 ratio was chosen in this study. Various tests were then performed with this ratio, such as modified Proctor (ASTM D1557), Atterberg.

limits (ASTM D4318), unconfined compressive strength (ASTM D2166). Figure 4 shows the SEM images with 2000 × magnification of loess soil, RHA and lime. It can be seen that there are a large number of pores in the loess. It shows a loose honeycomb structure. Surface structure and morphology of natural RHA are shown in Fig. 4b with SEM. The outer surface of RHA is somewhat thick and the inner surface is thin. There is a sandwich between the inner and outer surfaces. The interlayer is composed of criss-crossed plates and the arrangement direction is similar. The microstructure of lime in Fig. 3c shows that the particles are very fine and uniform.

Sampling

First, the natural soil was placed and dried in an oven at the approximate temperature of 105 ± 5 °C for 24 h. In the present study, the natural soil was passed through the sieve No. 4. Then, the samples of soil mixed with LRHA were prepared according to the weight percentages shown in Table 6. For preparing the samples first the dry soil was well mixed with lime and fly ash to obtain a homogeneous mixture. Then, water is added to the soil sample according to modified proctor test procedure at several stages and was remixed again. The mixing process continued till a visually uniform product was achieved. For each percentage of additive, three specimens were prepared. Care was taken to cure the specimens under stable temperature and moisture conditions. Curing times adopted were 7, 18, and 28 days, and at least three specimens of each category of samples were tested, and the average of the three results was reported.

Results and discussion

Modified proctor test

The results of the modified Proctor test for all samples examined in this study are summarized in Table 7. The optimum water content (OWC) value of the natural loess soil without additives is 12.2% and the Maximum dry density (MDD) value is 18.4 kN/m3. For all samples with adding LRHA, the values of OWC and MDD increased and decreased, respectively, so that for the soil mixed with 12.5% additive, during a curing time of 28 days, the values of OWC and MDD were 17.5% and 16.40 kN/m3, respectively. The observed changes are due to the partial replacement of LRHA by the soil [30,31,32,33]. Table 7 shows that the addition of LRHA decreases the MDD value of the samples, and more so the higher the LRHA value. This condition is caused by the low specific weight of LRHA relative to soil and the initial setting of the mixture due to the addition of additives and the lack of proper compaction. Over time, the MDD of the materials also decreases, which is due to the pozzolanic reaction between LRHA and soil and the formation of more cementitious material in the stabilized soil. When the amount of LRHA is increased, the OWC of the samples tends to increase. This is due to the pozzolanic reaction requiring additional water. Over time, it can be observed that the OWC of the samples decreases.

Atterberg limits

As a rapid and simple test, the Atterberg limits test is a suitable test for evaluating the performance of soils modified by stabilizing agents, which can provide a better understanding of the reaction mechanism, i.e., the performance and structure of the soils [34,35,36,37,38].

The values of LL, PL and PI for all samples during the 7, 18 and 28 days curing times are summarized in Table 8. The results of the tests performed on the samples showed that the addition of LRHA to the soil increased the LL from 22% for the natural soil to 33.4% for the soil with 12.5% additive. This mechanism is in agreement with the study results of Ma and Chen [38]. Metelkova et al. [39] also found that increasing the amount of lime in loess soil increased the LL of the soil, which was due to the reduction of soil pores and the coagulation and formation of cement between the grains.

As the curing time increased, the PL of the soil decreased, so that it is impossible to make a thread with a diameter of 3.2 mm and it cracks quickly under any water content and plasticity of the soil is reduced. For these samples, the PL and PI values are not reported.

Unconfined compressive strength

Figures 5, 6, and 7 shows the stress–strain curves of all specimens investigated in this study during the 7, 18 and 28 days curing times, respectively. The results and comparison of the figures show that the addition of LRHA to the soil significantly increases the unconfined compressive strength of the specimens at very low strains. It should be noted that the stabilized soil, when used in the roadbed or as a construction material, shows significant resistance when loaded at very low strains. This resistance is not observed in non-stabilized soil.

To better compare and understand the effects of curing time on the changes in unconfined compressive strength, Fig. 8 shows the trend of changes in the compressive strength of all specimens during the 7, 18 and 28 days curing times. It can be seen that as the amount of LRHA increases, the soil resistance first increases and then decreases for all curing times. At the 7 days curing time of the specimens, the pozzolanic reaction is not yet complete and the increase in resistance is due to ion exchange. For the samples with short curing times (7 and 18 days) and at 7.5% LRHA, the samples showed more resistance, but at the 28 days curing time, the sample with 5% LRHA showed the highest resistance. With the completion of pozzolanic reactions during the 28 days curing time, the soil resistance increases by 25, 112, and 111%, respectively, compared to the samples with 7.5, 10, and 12.5% additive. In fact, the effect of curing time on the strength of the specimens was much greater than the amount of additive. Similar results were reported by Zhang et al. [40]. This phenomenon may be caused by the presence of too much additive in the volume of the soil mass, resulting in a decrease in the dry density of the soil. Moreover, this phenomenon can be explained by the presence of additional alumina, which no longer participates in the pozzolanic reaction and causes a reduction in resistance. Over time, the LRHA begins to change the soil texture by absorbing the water content. As a result, the volume of soil particles increases slightly and their specific surface area decreases. This means that the soil mass requires fewer additives for stabilization.

Scanning electron microscope test

Chemical analysis

The microstructure of the soil represents its physical and mechanical properties. It determines the macroscopic bonding of the soil structure [20]. For scanning electron microscope (SEM), the samples were first dried, then covered with gold foil and cut with a laser cutter to minimize the distortion in the sample tissue. Figures 9 and 10 show the SEM images of specimens with 5, 7.5, 10 and 12.5% LRHA at 7 and 28 days of curing, respectively. From the micro chemical analysis, when water, lime and RHA are added to the soil, the water is decomposed into hydroxy (OH -) and hydrogen (H-) ions and then reacts with the calcium in the lime. Then, the active silica in RHA reacts with Ca (OH)2 and the calcium silicate hydrate gelling material (C-S-H) is formed [41]. These products fill the soil pores and the soil structure becomes denser. Comparison of Figs. 9 and 10 shows that when LRHA is added to the soil and the curing time is 28 days, the growth of C-S-H crystals between the pores increases and the soil cohesion increases compared to the samples treated for a curing time of 7 days. The test results from SEM show that the reduction of pores and the increase of soil cohesion lead to an increase in soil strength. In fact, during the 28 days curing time, the specimens have a denser and flocculated structure and exhibit higher unconfined compressive strength. This stabilization mechanism is consistent with the study results of Jiang et al. and Ghorbani et al. [20, 41]. The decrease in the strength of the specimens after increasing the amount of LRHA above the optimum value at 28 days curing time (the specimen with 5% additive) was due to the increase in the amount of LRHA required to participate in the chemical reactions, resulting in a decrease in soil dry density.

Changes in porosity and particles percentage

Samples with 5% to 12.5% stabilizer (LRHA) are further examined to investigate variations in microstructure. Images from SEM were analyzed using Microstructure Distance Measurement software (Nahamin Pardazan Asia Co., Iran) to determine the size distribution of particles and pores. This software automatically transfers an original digital image into a binary image. The quantitative analysis of soil microstructure using the SEM images in this study is summarized in Table 9. As shown in Table 9, the porosity (%) of the soil sample decreases as the amount of LRHA increases, while the particles (%) increase. For example, considering the sample with 7 days curing time, the porosity of the soil sample, which was 57.1% in the unstabilized condition, decreases to 35.09% in the sample with 7.5% LRHA. In addition, the particles of the soil sample increased from 42.9% in the unstabilized condition to 64.9% in the sample with 7.5% LRHA. As the curing time increases, the values of soil sample porosity (%) and particles (%) also change similarly, so that increasing the curing time causes a decrease in soil sample porosity (%) and an increase in particles (%).

Conclusions

In the present study, an attempt was made to investigate the geotechnical properties of the loess soil stabilized with LRHA. For this purpose, the loess soil samples stabilized with LRHA were prepared at different mixing proportions and curing times. Then, various tests were conducted, such as the modified Proctor, Atterberg limits, unconfined compressive strength, and SEM tests. The test results showed that the physical and mechanical properties of loess soil can be effectively and significantly improved by LRHA. The main conclusions are as follows:

-

1.

With the increase of LRHA content (%) in the soil, the OWC of the samples exhibits an increasing trend, which is due to the pozzolanic reaction in the coagulated soil structure that requires additional water.

-

2.

According to the compaction test results, it was found that the maximum value of MDD was obtained when 5% LRHA was used. Adding more than 5% LRHA to the soil decreased the MDD value. As the curing time increased, the MDD of the soil also decreased.

-

3.

By adding LRHA to the soil, the LL and PL values increased, but by adding more than 5% LRHA, the PI value decreased, and the soil changed from plastic to nonplastic state. Therefore, the maximum limit of 5% LRHA should be used for this type of soil.

-

4.

The addition of LRHA to the soil significantly increased the unconfined compressive strength of the specimens at very low strains.

-

5.

The addition of 5% LRHA during the 28 days curing time increased soil resistance by 25, 112, and 111%, respectively, compared to other samples (with 7.5, 10, and 12.5% additive). According to the results of this study, the optimum percentage of additive is 5% LRHA, which is economically and technically appropriate. This increases the resistance of the soil mixture by 480% compared to the sample without additive (natural soil sample).

-

6.

The analysis of the SEM test showed that the addition of LRHA to the soil fills the pores of the soil by forming C-S–H gel and the soil becomes denser. Thus, during the 28 days curing time, the growth of C-S–H crystals in the pores increased compared to the specimens with 7 days curing time, and due to the denser flocculated structure, the unconfined compressive strength also increased significantly.

-

7.

The analysis and processing of the images of the stabilized soil SEM showed a reasonable relationship with the results of the UCS, so that the increase in soil strength was related to the decrease in porosity (%) of the stabilized soil specimens.

Data Availability

All the analysis was carried out in accordance with the code of investigation and practice.

References

Smalley I, Marković SB, Svirčev Z (2011) Loess is [almost totally formed by] the accumulation of dust. Quat Int. https://doi.org/10.1016/j.quaint.2010.07.011

Khadjeh M, Ghauomian J, Faiznia S (2003) The study of lateral variation of grain size and mineralogy in order to determine prevailing winds direction in the formation of loess sediments of Golestan province. Desert Journal 2:293–306

Liu Z, Cai CS, Liu F, Fan F (2016) Feasibility study of loess stabilization with fly ash–based geopolymer. J Mater Civ Eng 28(5):04016003

Jefferson I, Rogers C, Evstatiev D, Karastanev D (2005) Treatment of metastable loess soils: Lessons from Eastern Europe. In Elsevier geo-engineering book series (Vol. 3, pp. 723–762). Elsevier

Xie WL, Li P, Zhang MS, Cheng TE, Wang Y (2018) Collapse behavior and microstructural evolution of loess soils from the Loess Plateau of China. J Mt Sci 15(8):1642–1657

Zhang CL, Jiang GL, Su LJ, Zhou GD (2017) Effect of cement on the stabilization of loess. J Mt Sci 14(11):2325–2336

Silitonga E, Levacher D, Mezazigh S (2010) Utilization of fly ash for stabilization of marine dredged sediments. Eur J Environ Civ Eng 14(2):253–265

Anwar Hossain KM (2011) Stabilized soils incorporating combinations of rice husk ash and cement kiln dust. J Mater Civ Eng 23(9):1320–1327

Ashango AA, Patra NR (2016) Behavior of expansive soil treated with steel slag, rice husk ash, and lime. J Mater Civ Eng 28(7):06016008

Bagheri Y, Ahmad F, Ismail MAM (2014) Strength and mechanical behavior of soil–cement–lime–rice husk ash (soil–CLR) mixture. Mater Struct 47:55–66

Basha EA, Hashim R, Mahmud HB, Muntohar AS (2005) Stabilization of residual soil with rice husk ash and cement. Constr Build Mater 19(6):448–453

Eberemu AO, Tukka DD, Osinubi KJ (2014) Potential use of rice husk ash in the stabilization and solidification of lateritic soil contaminated with tannery effluent. In Geo-Congress 2014: Geo-characterization and Modeling for Sustainability (pp. 2263–2272)

Jauberthie R, Rendell F, Tamba S, Cissé IK (2003) Properties of cement—rice husk mixture. Constr Build Mater 17(4):239–243

Sabat AK (2012) Effect of polypropylene fiber on engineering properties of rice husk ash–lime stabilized expansive soil. Electron J Geotech Eng 17:651–660

Sivapullaiah PV, Subba Rao KS, Gurumurthy JV (2004) Stabilisation of rice husk ash for use as cushion below foundations on expansive soils. Proc Inst Civil Eng Ground Improv 8(4):137–149

Yin CY, Mahmud HB, Shaaban MG (2006) Stabilization/solidification of lead-contaminated soil using cement and rice husk ash. J Hazard Mater 137(3):1758–1764

Nair DG, Jagadish KS, Fraaij A (2006) Reactive pozzolanas from rice husk ash: an alternative to cement for rural housing. Cem Concr Res 36(6):1062–1071

Nair DG, Fraaij A, Klaassen AA, Kentgens AP (2008) A structural investigation relating to the pozzolanic activity of rice husk ashes. Cem Concr Res 38(6):861–869

Kumar A, Gupta D (2016) Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext Geomembr 44(3):466–474

Jiang X, Huang Z, Ma F, Luo X (2019) Analysis of strength development and soil–water characteristics of rice husk ash–lime stabilized soft soil. Materials 12(23):3873

Hashemi MA, Massart TJ, François B (2018) Experimental characterisation of clay-sand mixtures treated with lime. Eur J Environ Civ Eng 22(8):962–977

Bourokba Mrabent SA, Hachichi A, Souli H, Taibi S, Fleureau JM (2017) Effect of lime on some physical parameters of a natural expansive clay from Algeria. Eur J Environ Civ Eng 21(1):108–125

Glassey PJ (1986) Geotechnical properties of lime stabilised loess. Canterbury, Port Hills

Muntohar AS, Hantoro G (2000) Influence of rice husk ash and lime on engineering properties of a clayey subgrade. Electron J Geotech Eng 5(2000):1–13

Li ZQ, Cui ZD, Wang YP, Wang LC, Zhong D (2011) Experimental study on the engineering characteristics of improved soil. Adv Mater Res 168:1426–1431

Huangjing S, Gasaluck W (2010) The stabilization of loess by chemical additives for road base. EJGE 15:1651–1668

Liu Y, Su Y, Namdar A, Zhou G, She Y, Yang Q (2019) Utilization of cementitious material from residual rice husk ash and lime in stabilization of expansive soil. Adv Civil Eng 2019:1

Pushpakumara BHJ, Mendis WSW (2022) Suitability of Rice Husk Ash (RHA) with lime as a soil stabilizer in geotechnical applications. Int J Geo Eng 13(1):4

Rezaei, H. (2013). An investigation of dynamic compaction and static loads on shear strength of loess's soils in golestan province. FerdowsiUniversity (Doctoral dissertation, Ph. D thesis, 150p (in persian).

Ali FH, Adnan A, Choy CK (1992) Use of rice husk ash to enhance lime treatment of soil. Can Geotech J 29(5):843–852

Alhassan M (2008) Potentials of rice Husk Ash for soil stabilization. Assumption University (AU). J Technol 11(4):246–250

Jha JN, Gill KS (2006) Effect of rice husk ash on lime stabilization of soil. Journal of the Institution of Engineers(India). Part CV Civil Eng Div 87:33–39

Locat J, Bérubé MA, Choquette M (1990) Laboratory investigations on the lime stabilization of sensitive clays: shear strength development. Can Geotech J 27(3):294–304

Bell FG (1996) Lime stabilization of clay minerals and soils. Eng Geol 42(4):223–237

Boardman DI, Glendinning S, Rogers CDF (2001) Development of stabilisation and solidification in lime–clay mixes. Geotechnique 51(6):533–543

Sariosseiri F, Muhunthan B (2009) Effect of cement treatment on geotechnical properties of some Washington State soils. Eng Geol 104(1–2):119–125

Pei X, Zhang F, Wu W, Liang S (2015) Physicochemical and index properties of loess stabilized with lime and fly ash piles. Appl Clay Sci 114:77–84

Ma Y, Chen W (2021) Study on the mechanism of stabilizing loess with lime: analysis of mineral and microstructure evolution. Adv Civil Eng 2021:1–11

Metelková Z, Boháč J, Přikryl R, Sedlářová I (2012) Maturation of loess treated with variable lime admixture: pore space textural evolution and related phase changes. Appl Clay Sci 61:37–43

Zhang F, Pei X, Yan X (2018) Physicochemical and mechanical properties of lime-treated loess. Geotech Geol Eng 36:685–696

Ghorbani A, Salimzadehshooiili M, Medzvieckas J, Kliukas R (2018) Strength characteristics of cement-rice husk ash stabilised sand-clay mixture reinforced with polypropylene fibers. Baltic J Road Bridge Eng 13(4):447–474

Author information

Authors and Affiliations

Contributions

MS designed the research. AZ performed the tests, analyzed the data and drafted the manuscript. MS and HR edited and improved the manuscript until all authors were satisfied with the final version. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that there are no competing interest regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zivari, A., Siavoshnia, M. & Rezaei, H. Effect of lime-rice husk ash on geotechnical properties of loess soil in Golestan province, Iran. Geo-Engineering 14, 20 (2023). https://doi.org/10.1186/s40703-023-00199-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-023-00199-6