Abstract

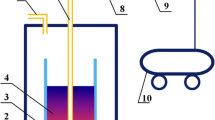

Compared with conventional pyrometallurgical recycling, hydrometallurgical recycling offers distinct advantages by mitigating emissions of waste gas and lead-containing dust; however, it also encounters challenges in effectively eliminating metal impurities from spent lead paste. This study presents a novel hydrometallurgical process for the recovery of spent lead paste, which entails the production of high-purity lead chloride through crystallization, coupled with the recovery of lead oxide via dechlorination, thereby realizing the preparation of high-purity recovered products. First, sulfated lead paste was leached using a sodium chloride solution. Lead could be completely leached when the solid–liquid ratio was 40 g·L−1, the concentration of sodium chloride solution was 250 g·L−1, the reaction temperature was 80 °C, and the leaching time was 20 min. Subsequently, the leachate was filtered and further treated through dilution with distilled water (at 1.6 times) at 0 °C, thereby yielding high-purity lead chloride through the crystallization process, wherein metal impurities were effectively prevented from precipitating out. Finally, the lead chloride product was dechlorinated using sodium hydroxide solution. The dechlorination conditions were as follows: the solid–liquid ratio was 136.09 g·L−1, the crystallization temperature was 0 °C, and the concentration of sodium hydroxide solution was 11.51 mol·L−1. α-PbO was obtained under these conditions. In this study, spent lead paste was recycled with the advantages of low energy consumption and no harmful gas emissions, thereby providing a new idea for recycling lead-containing waste.

Graphical Abstract

Similar content being viewed by others

References

May GJ, Davidson A, Monahov B (2018) Lead batteries for utility energy storage: a review. J Energy Storage 15:145–157. https://doi.org/10.1016/j.est.2017.11.008

Zou C, Zhang L, Hu X et al (2018) A review of fractional-order techniques applied to lithium-ion batteries, lead-acid batteries, and supercapacitors. J Power Sources 390:286–296. https://doi.org/10.1016/j.jpowsour.2018.04.033

He Y, Zheng Y, Wu Y et al (2019) Tracking flows of secondary vehicle batteries in China. Resour Conserv Recycl 142:34–36. https://doi.org/10.1016/j.resconrec.2018.11.016

Zhang W, Yang J, Wu X et al (2016) A critical review on secondary lead recycling technology and its prospect. Renew Sust Energ Rev 61:108–122. https://doi.org/10.1016/j.rser.2016.03.046

Rada S, Cuibus D, Vermesan H et al (2018) Structural and electrochemical properties of recycled active electrodes from spent lead acid battery and modified with different manganese dioxide contents. Electrochim Acta 268:332–339. https://doi.org/10.1016/j.electacta.2018.02.135

Li M, Yang J, Liang S et al (2019) Review on clean recovery of discarded/spent lead-acid battery and trends of recycled products. J Power Sources 436:226853. https://doi.org/10.1016/j.jpowsour.2019.226853

Li Y, Yang S, Taskinen P et al (2019) Novel recycling process for lead-acid battery paste without SO2 generation - Reaction mechanism and industrial pilot campaign. J Clean Prod 217:162–171. https://doi.org/10.1016/j.jclepro.2019.01.197

Xing P, Wang C, Wang L et al (2019) Hydrometallurgical recovery of lead from spent lead-acid battery paste via leaching and electrowinning in chloride solution. Hydrometallurgy 189:105134. https://doi.org/10.1016/j.hydromet.2019.105134

Huang K, Liu H, Dong H et al (2021) A novel approach to recover lead oxide from spent lead acid batteries by desulfurization and crystallization in sodium hydroxide solution after sulfation. Resour Conserv Recycl 167:105385. https://doi.org/10.1016/j.resconrec.2020.105385

Zhu X, Yang J, Gao L et al (2013) Preparation of lead carbonate from spent lead paste via chemical conversion. Hydrometallurgy 134–135:47–53. https://doi.org/10.1016/j.hydromet.2013.01.018

Zhu X, Zhang W, Zhang L et al (2019) A green recycling process of the spent lead paste from discarded lead–acid battery by a hydrometallurgical process. Waste Manage Res 37:508–515. https://doi.org/10.1177/0734242X19830175

Ye L, Duan L, Liu W et al (2020) Facile method for preparing a nano lead powder by vacuum decomposition from spent lead-acid battery paste: leaching and desulfuration in tartaric acid and sodium tartrate mixed lixivium. Hydrometallurgy 197:105450. https://doi.org/10.1016/j.hydromet.2020.105450

Zhu X, He X, Yang J et al (2013) Leaching of spent lead acid battery paste components by sodium citrate and acetic acid. J Hazard Mater 250–251:387–396. https://doi.org/10.1016/j.jhazmat.2013.02.018

Yu W, Yang J, Li M et al (2019) A facile lead acetate conversion process for synthesis of high-purity alpha-lead oxide derived from spent lead-acid batteries. J Chem Technol Biot 94:88–97. https://doi.org/10.1002/jctb.5748

Li M, Yang J, Liang S et al (2020) A closed-loop ammonium salt system for recovery of high-purity lead tetroxide product from spent lead-acid battery paste. J Clean Prod 250:119488. https://doi.org/10.1016/j.jclepro.2019.119488

Deng X, Liu W, Zhang D et al (2021) Hydrothermal desulfurization of spent lead paste based on comproportionation reaction. Sep Purif Technol 259:118115. https://doi.org/10.1016/j.seppur.2020.118115

Hu G, Zhang P, Yang J et al (2022) A closed-loop acetic acid system for recovery of PbO@C composite derived from spent lead-acid battery. Resour Conserv Recycl 184:106391. https://doi.org/10.1016/j.resconrec.2022.106391

Wu Y, Chen Z, Yu Q et al (2022) Preparation of high-purity lead carbonate and lead oxide from spent lead paste. J Clean Prod 372:133786. https://doi.org/10.1016/j.jclepro.2022.133786

Wang J, Yang J, Hou H et al (2021) A green strategy to synthesize two-dimensional lead halide perovskite via direct recovery of spent lead-acid battery. Resour Conserv Recycl 169:105463. https://doi.org/10.1016/j.resconrec.2021.105463

Pan J, Zhang X, Sun Y et al (2016) Preparation of high purity lead oxide from spent lead acid batteries via desulfurization and recrystallization in sodium hydroxide. Ind Eng Chem Res 55:2059–2068. https://doi.org/10.1021/acs.iecr.5b04221

Shu Y, Ma C, Zhu L, Chen H (2015) Leaching of lead slag component by sodium chloride and diluted nitric acid and synthesis of ultrafine lead oxide powders. J Power Sources 281:219–226. https://doi.org/10.1016/j.jpowsour.2015.01.181

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No.51464021).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Veena Sahajwalla.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Y., Wang, M., Yu, Q. et al. Preparation of High-Purity Lead Chloride and Lead Oxide from Spent Lead Paste by Crystallization. J. Sustain. Metall. 9, 1777–1789 (2023). https://doi.org/10.1007/s40831-023-00764-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00764-4