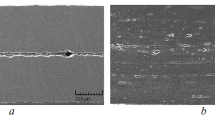

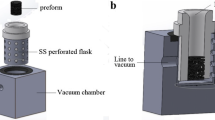

Aluminum metal matrix composites (AMMCs) are a new modern group of composite materials that are becoming more popular in industrial progress. As a solid welding method to fabricate metal matrix composites, accumulative press bonding (APB) is one of the most capable processes. One of the major disadvantages of the APB process is the weak bonding strength. This study utilizes tin (Sn) particles as filler metal to enhance the bonding strength of aluminum laminates. Thus, AA1060 bars with different content of Sn particles (interlayer filler material) were manufactured at various pressing temperatures and APB steps. The peeling test was used to evaluate the bonding strength. It was found that by increasing the number of APB steps, Sn content, and pressing temperature, better bonds of higher strength and quality were generated. The bonding strength was improved to 424 N for a sample fabricated with 15 wt.% of Sn particles at 300°C. Scanning electron microscopy (SEM) was used to examine the peeling surface of Al/Sn composite samples.

Similar content being viewed by others

References

M. Heydari Vini, M. Sedighi, and M. Mondali, “Mechanical properties, bond strength and microstructural evolution of AA1060/TiO2 composites fabricated by warm accumulative roll bonding (WARB),” J. Mater. Research., 108, No. 1, 53–59 (2017).

M. Sedighi, P. Farhadipour, and M. Heydari Vini, “Mechanical properties and microstructural evolution of bimetal 1050/Al2O3/5083 composites fabricated by warm accumulative roll bonding,” JOM, 68, No. 12, 3193–3200 (2016).

V. Vignesh Kumar and T.S. Senthil Kumar, “Studies on mechanical property and wear behavior of AA7075 hybrid composites prepared by a conventional casting method,” Proc. Inst. Mechan. Eng. Part E, 235, No. 6, 2180–2188 (2021).

R. Jamaati and M.R. Toroghinejad, “Manufacturing of high-strength aluminum/alumina composite by accumulative roll bonding,” Mater. Sci. Eng. A, 527, No. 16–17, 4146–4151 (2010).

M. Heydari Vini, M. Sedighi, and M. Mondali, “Mechanical properties and microstructural evolution of AA5083/Al2O3 composites fabricated by warm accumulative roll bonding,” ADMT J., 9, No. 4, 13–22 (2017).

Emmanuel P.R. Lima, Pedro C. de Lima, Paulo X.A. Filho, and Nélio S. Furtado, “Preparation and characterization of AA6061 aluminum alloy composite reinforced with different contents of blast-furnace slag by powder metallurgy,” MRS Adv., 4 (54), 2969–2976 (2019).

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, “Evaluation of mechanical properties of 1060-Al reinforced with WC particles less via warm accumulative roll bonding process,” Mater. Des., 43, 367–372 (2013).

M. Sedighi, M.H. Vini, and P. Farhadipour, “Effect of alumina content on the mechanical properties of AA5083/Al2O3 composites fabricated by warm accumulative roll bonding,” Powder Metall. Met. Ceram., 55(510), 413–418 (2016).

Emin Salur, Mustafa Acarer, and Ilyas Şavkliyildiz, “Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing,” Mater. Today Comm., 27, 102202 (2021).

M. Alizadeh, “Comparison of nanostructured Al/B4C composite produced by ARB and Al/B4C composite produced by RRB process,”Mater. Sci. Eng. A, 528, No. 2, 578–582 (2010).

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, “Effect of W particles on the properties of accumulatively roll-bonded Al/W composites,” Mater. Sci. Eng. A, 547, 120–124 (2012).

R. Ipek, “Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC),” J. Mater. Proc. Technol., 162–163, 71–75 (2005).

M. Alizadeh and M. Talebian, “Fabrication of Al/CuP composite by accumulative roll bonding process and investigation of mechanical properties,” Mater. Sci. Eng. A, 558, 331–337 (2012).

A. Korbel, M. Richert, and J. Richert, “The effects of very high cumulative deformation on structure and mechanical properties of aluminium,” in: Proc. Second RISO Int. Symp. Metall. Mater. Sci. (1981), p. 14–18.

C. Lu, K. Tieu, and D. Wexler, “Significant enhancement of bond strength in the accumulative roll bonding process using nano-sized SiO2 particlesles,” J. Mater. Proc. Technol., 209, No. 10, 4830–4834 (2009).

Mohd Bilal Naim Shaikh, Tariq Aziz, Sajjad Arif, Akhter H. Ansari, Panagiotis G. Karagiannidis, and Mohammad Uddin, “Effect of sintering techniques on microstructural, mechanical and tribological properties of Al–SiC composites,” Surf. Interf., 20, 100598 (2020).

S. Amirkhanlou, R. Jamaati, B. Niroumand, and M.R. Toroghinejad, “Using ARB process as a solution for dilemma of Si and SiC P distribution in cast Al–Si/SiC P composites,” J. Mater. Proc. Technol., 211, 1159–1165 (2011).

Guttikonda Manohar, K.M. Pandey, and S.R. Maity, “Effect of microwave sintering on the microstructure and mechanical properties of AA7075/B4C/ZrC hybrid nanocomposite fabricated by powder metallurgy techniques,” 47(23), 32610–32618 (2021).

Mohd Bilal Naim Shaikh, Sajjad Arif, and M. Arif Siddiqui, “Fabrication and characterization of aluminium hybrid composites reinforced with fly ash and silicon carbide through powder metallurgy,” Mater. Res. Express, 5, No. 4, 6506 (2018).

Afnan Haider Khan, Syed Ahmad Ali Shah, Farheen Umar, Uneeb Noor, Rizwan Mahmood Gul, Khaled Giasin, and Muhammad Aamir, “Investigating the microstructural and mechanical properties of, novel ternary reinforced AA7075 hybrid metal matrix composite,” Materials, 15 (15), 5303 (2022).

Mohd Bilal Naim Shaikh, Sajjad Arif, Tariq Aziz, Adnan Waseem, Mohd Ahmed Naim Shaikh, and Mohammed Ali, “Microstructural, mechanical, and tribological behavior of powder metallurgy processed SiC and RHA reinforced Al-based composites,” Surf. Interf., 15, 166–179 (2019).

M. Reihanian, E. Bagherpour, and M.H. Paydar, “Particle distribution in metal matrix composites fabricated by accumulative roll bonding,” Mater. Sci. Technol., 28, No. 1, 103–108 (2016).

M. Danaie, C. Mauer, D. Mitlin, and J. Huot, “Hydrogen storage in bulk Mg–Ti and Mg–stainless steel multilayer composites synthesized via accumulative roll-bonding (ARB),” Int. J. Hydrogen Energy, 36, No. 4, 3022–3036 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 62, Nos. 3–4 (550), pp. 115–123, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agrawal, O.P., Romero-Parra, R.M., Hussien, B.M. et al. Improvement of the Bond Strength in Al Laminates via APB Process Using Tin Particles. Powder Metall Met Ceram 62, 225–232 (2023). https://doi.org/10.1007/s11106-023-00387-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00387-0